Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

A Life Cycle Evaluation of Wood Pellet Gasification For District Heating

Caricato da

joasobralTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

A Life Cycle Evaluation of Wood Pellet Gasification For District Heating

Caricato da

joasobralCopyright:

Formati disponibili

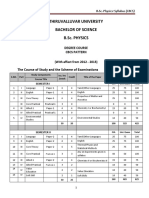

A life cycle evaluation of wood pellet gasication for district heating

in British Columbia

Ann Pa

a

, Xiaotao T. Bi

a,

, Shahab Sokhansanj

a,b

a

Clean Energy Research Centre for University of British Columbia, 2360 East Mall Vancouver, BC, Canada, V6T 1Z3

b

Environmental Sciences Division, Oak Ridge National Laboratory, Oak Ridge, TN 37831, USA

a r t i c l e i n f o

Article history:

Received 23 November 2010

Received in revised form 28 January 2011

Accepted 1 February 2011

Available online 5 February 2011

Keywords:

Life cycle analysis (LCA)

Wood pellets

British Columbia

District heating

Gasication

a b s t r a c t

The replacement of natural gas combustion for district heating by wood waste and wood pellets gasi-

cation systems with or without emission control has been investigated by a streamlined LCA. While stack

emissions from controlled gasication systems are lower than the applicable regulations, compared to

the current base case, 12% and 133% increases are expected in the overall human health impacts for wood

pellets and wood waste, respectively. With controlled gasication, external costs and GHG emission can

be reduced by 35% and 82% on average, respectively. Between wood pellets and wood waste, wood pellets

appear to be the better choice as it requires less primary energy and has a much lower impact on the local

air quality.

2011 Elsevier Ltd. All rights reserved.

1. Introduction

As climate change due to greenhouse gas (GHG) emissions is

gaining recognitions, various methods of climate change adapta-

tion and GHG emission mitigation have been proposed, discussed

and explored. Replacing a fraction of the current fossil fuel by

alternative energy sources such as bioenergy is one of the many

approaches recommended by policy makers. For instance, ethanol

blending requirement in transport fuel in the United States

reaches 1.14 EJ in 2010 and will increase to 3.18 EJ by 2022 while

the European Union target for renewable energy in the transport

sector in 2020 is set to 10%, or 1.29 EJ of biofuel (IEA and OECD,

2009; European Commission, 2007). Other than in the transport

sector, there are numerous studies that emphasize the potentials

of renewable energy, or more specically bioenergy, in district or

residential heating and in combined heat and power systems

(CHP) (Difs et al., 2010; Bjrklund et al., 2001). The importance

of policy developments to promote the use of bioenergy in these

sectors is also discussed (Kopetz, 2007; Rickerson et al., 2009).

However, the use of biomass for district heating has been quite

controversial due to concerns with possible increase in health im-

pact (Ries et al., 2009). This concern is especially true when the

fossil fuel to be replaced is natural gas and when the community

is densely populated. There are currently a few major district

heating systems in Vancouver. These include one located in the

stadium and entertainment district in the core of downtown

(Davis, 2004) and three in Vancouvers largest hospital sites (Roger

Bayley Inc., 2009; Ministry of Energy of British Columbia, 2010).

The most recent establishment is the Southeast False Creek Neigh-

bourhood Energy Utility (NEU) which provides hot water and heat

for all new buildings in the area, including the Olympic Village that

was built to accommodate Olympic athletes participating in the

2010 Winter Olympic (City of Vancouver, 2010). The downtown

system operates on natural gas while the NEU operates on a

base-load system utilizing sewer heat recovery pump along with

a natural gas peaking/back-up boiler. There was a debate at the

beginning on the energy source to be chosen for the base-load sys-

tem and the two contenders were biomass and sewer heat (Roger

Bayley Inc., 2009). In the end sewer heat recovery heat pump sys-

tem was selected because of the public concerns on local air qual-

ity and trafc inconvenience that may arise from biomass

utilization.

Another district heating system in Vancouver is at the Univer-

sity of British Columbia (UBC), where more than 99% of the heat

is generated from natural gas and the rest from fuel oil during peak

season. With UBCs ambitious plan of reducing GHG to 33%, 67%

and 100% below the 2007 level by 2015, 2020 and 2050, respec-

tively, the University has devised a detailed plan of action. Replac-

ing natural gas with renewable energy is an important part of the

actions to be taken (University of British Columbia, 2010a). In fact,

$26 million CAD has been allocated for the establishment of a bio-

mass gasication cogeneration system on campus for research and

0960-8524/$ - see front matter 2011 Elsevier Ltd. All rights reserved.

doi:10.1016/j.biortech.2011.02.009

Corresponding author. Tel.: +1 604 822 4408; fax: +1 604 822 6003.

E-mail address: xbi@chbe.ubc.ca (X.T. Bi).

Bioresource Technology 102 (2011) 61676177

Contents lists available at ScienceDirect

Bioresource Technology

j our nal homepage: www. el sevi er . com/ l ocat e/ bi or t ech

demonstration purposes (University of British Columbia, 2010b).

Given UBCs strong motive to become green and the large amount

of GHG emissions from the boiler house, it is interesting to inves-

tigate the complete replacement of fossil fuels in its boiler house

with bio-based fuels. Wood pellets, made of sawmill residue, burn

cleaner than biomass residue and are produced in large quantity in

BC are thus considered as a potential candidate. In 2008, 9 out of 30

pellet plants in operations in Canada are located in BC and about 35

Canadian pellet mills are in the planning stage with 13 of them to

be located in BC (Melin, 2008, unpublished data). Overall, about

90% of the pellets produced in Canada were exported and 78% of

these pellets were shipped to Europe (Melin, 2008, unpublished

data; Spelter and Toth, 2009). Finding domestic applications for

these pellets would result in less transportation-related GHG emis-

sions. The technology to be evaluated is gasication as it is cleaner

than direct combustion.

The replacement of UBCs current natural gas boiler house

with a wood pellet gasication system is evaluated by a stream-

lined life cycle analysis (LCA). LCA is a powerful tool for scenario

comparisons as the incremental variation between each scenario

would provide valuable insights for decision making. Up to date,

LCA has been used to examine the benets and impacts of various

new projects such as the wastewater treatment and reuse system

in China (Zhang et al., 2010). As there have been many concerns

on the true impacts and degree of sustainability of biomass en-

ergy systems, LCA has been used extensively in recent years to

evaluate a wide range of bioenergy systems and, sometimes for

comparison purposes, fossil fuel energy systems. Some examples

include the study on lignocellulosic ethanol production (Spatari

et al., 2010; Gonzlez-Garca et al., 2010), biofuel production from

microalgae (Campbell et al., 2011; Collet et al., 2011) and biomass

district heating systems (Eriksson et al., 2007). Eriksson et al.

(2007) conducted a LCA study of district heating and CHP system

in Sweden using three different fuels: waste incineration, biomass

combustion and natural gas combustion. Another study at-

tempted to use LCA to investigate which of natural gas combus-

tion, wood pellet combustion, sewer heat recovery and

geothermal recovery would be the best choice for a district heat-

ing system in Vancouver, BC, Canada (Ghafghazi et al., in press).

The study reveals that none of the energy sources has absolute

advantages over the others in all the impact categories considered

although by using renewable energy at least 200 kg of CO

2

-eqv

can be avoided per MWh of heat produced. Furthermore, the per-

formance of each type of energy source depends on many factors

such as electricity mix and types of energy utilized for producing

pellets.

For this study, an in-house life cycle inventory (LCI) database of

BC pellets (Pa et al., 2009) is utilized to evaluate a total of ve sce-

narios for district heating at UBC. The base scenario is the current

installation and the others are wood waste gasication, wood pel-

let gasication and each of the two gasication operations with

emission controls. The wood waste gasication scenario utilizes

emission factors from the industry for wood waste gasication

while the pellet scenario uses estimated wood pellet gasication

emission factors based on literature values and wood waste gasi-

cation emission factors from industry. For the scenarios with emis-

sion controls, an electrostatic precipitator (ESP) for dust control

and a selective catalytic reduction (SCR) unit for NO

X

control are

included. The overall impacts on human health, ecosystem quality

and primary energy consumption in addition to GHG reduction

resulting from using wood waste and wood pellets are compared

to demonstrate the pros and cons of wood waste and wood pellet

utilization when replacing natural gas. The externality analysis

based on variations in emission proles in different scenarios is

also performed to quantify the economical benets for each

option.

2. Method and calculation

2.1. In-house BC pellet LCI Database

The functional unit for the in-house BC pellet LCI database is

one tonne (t) of wood pellets. Allocations are mass-based. The

streamlined life cycle consists of harvesting, transportation of har-

vested material to sawmill, sawmill processing, transportation of

sawmill by-products such as planer shavings and sawdust to pellet

mill, pellet mill operations, pellet transportation in bulk via heavy

duty trucks (HDV, class 8, which has a gross vehicle weight rating

of above 15 t) and train to port in North Vancouver. For this study,

the transportation of pellets from port in North Vancouver to UBC

campus and the pellet usage in the UBC gasication/combustion

boiler are also included. The 20.2 km transportation from port in

North Vancouver to UBC is by HDV. Emissions from infrastructures

and land use changes are not included in the database in view that

pellets in BC are made from sawmill residue and forest residue.

The pollutants investigated are CO

2

, CH

4

, N

2

O, CO, non-methane

volatile organic compound (NMVOC), NO

X

, SO

X

and particulate

matters (PM). Other pollutants in trace amounts, although avail-

able in some databases, are not included in this study for consis-

tency reasons. CO

2

is categorized as either fossil or biogenic.

However, CH

4

and CO are separated into biogenic or generic where

generic may contain a small amount of biogenic emissions as not

all emission data used segregated fossil and biogenic emissions

of CH

4

and CO. Note that all indirect emissions are also included

in the analysis. For instances, emissions produced during produc-

tion and transportation of fuels are all accounted for in the

database.

Energy consumption data during harvesting and sawmill oper-

ations are obtained from Sambos (2002) and Nyboers (2008)

work, respectively. Information gathered from a few member com-

panies of Wood Pellet Association of Canada provided energy con-

sumption data for pellet mill and port operations. The different

types of energy considered are electricity, natural gas, heavy fuel

oil (HFO), middle distillates (diesel), propane, steam, wood waste

and gasoline. The primary energy consumptions are included in

this database and the electricity mix used is specic to BC. Details

regarding various transportation segments are also obtained from

the surveys.

The pellet LCI database was presented in the 8th World Con-

gress of Chemical Engineering in Montral (Pa et al., 2009) and will

be released in a follow-up publication with more details. The

methodology used to establish this database is used to construct

all the scenarios in this study.

2.2. UBC district heating system

For this study, a total of ve scenarios will be investigated. The

base case is the current operation and the four woody biomass gas-

ication systems are wood waste, wood pellets and each of these

two systems equipped with ESPs with 99% PM removal efciency

and SCR with 80% NO

X

removal efciency.

The values presented in this work are either per MJ of fuel input

or per year of operation. The annual operation is based on the

amount of heat that is currently generated in the base scenario

on a yearly basis, which is 974 TJ. This is chosen as the functional

unit because the amount of heat to be produced in a year is iden-

tical for all scenarios thus allowing for scenario comparison, which

is also equivalent to the functional unit of per unit of energy

produced.

2.2.1. Base scenario

The current facility conguration consists of boilers where the

fuels (natural gas and fuel oil) are fed into. The fuels are combusted

6168 A. Pa et al. / Bioresource Technology 102 (2011) 61676177

to heat up the entering water stream to produce steam at 165 psig

(1138 kPa) that is then distributed around the campus. The ue gas

from the boilers is directed to an economizer to preheat the water

entering the boiler before the ue gas exits the facility. For the base

case, the stages in the LCA of both natural gas and oil include pro-

duction of fuels, their transportation or transmission to UBC, and

emissions during the end usage at the current facility. The emis-

sion factors for natural gas and fuel oil production and transmis-

sion are obtained from GHGenius v3.17 (Delucchi and Levelton,

2010) and are referred to as upstream emission factors. In GHGe-

nius, CH

4

and CO emissions from both fossil and biomass origins

are not segregated and are both reported simply as CH

4

and CO.

By default, GHGenius does not display biogenic emissions of CO

2

but this can be altered so biogenic CO

2

emission values can be ex-

tracted. The combustion emission factors for the current installa-

tion are from the Combustion Test Report provided by UBC boiler

house (Northwest Instrument Systems Inc., 2009), EMEP CORINAIR

Emission Inventory Guidebook (European Environment Agency,

2007) and US EPA AP-42 documents (US Environmental Protection

Agency, 1995). For the Combustion Test Report, the boiler was red

with different fuels and at different capacities. The emissions were

higher if the equipment was operated at a lower capacity. For the

purpose of this study, the emission factors at 50% capacity are se-

lected. The emissions were reported as concentrations (in ppmv) of

the ue gas so material balance is carried out to determine the ue

gas ow rate. For natural gas ring, SO

X

emission is assumed to be

0 as sulfur content in the BC natural gas is negligible. Table 1 lists

the total emission factors of the UBC boiler running on natural gas

and fuel oil with the sources of emission factors specied. The cur-

rent amount of steam production is further explained in detail in

the following section for easy comparison with the woody biomass

scenarios.

2.2.2. Woody biomass gasication scenarios

The system boundary and stages for the wood pellet scenario

have already been described earlier in the In-house BC pellet LCI

Database section. The life cycle stages for the wood waste gasi-

cation scenarios include the production of two types of wood res-

idues and their transportation, and the nal usage at UBC. The two

types of wood residues are forest harvesting residues and sawmill

residues.

The forest residue production started from harvesting operation

with data taken from Sambo (2002). The forest residue is chopped

in the forest using mobile chopper and the emissions related to this

process are from US-EI (Swiss Centre for Life Cycle Inventories

et al., 2008). The chopped residue is then transported to railhead

via HDV over a distance of 150 km. From the railhead to the North

Vancouver shipping port, the train would travel 350 km. From the

shipping port, the forest residue would be delivered to UBC district

heating facility via HDV over a distance of 20.2 km.

For the sawmill and planer mill residue, the harvesting of wood

for the forest and sawmill operations are all included and emission

data are based on literature used for the pellet LCI but converted

accordingly so that the functional units are per tonne of wood res-

idue with 51% moisture content, dry basis. The sawmill residue

would be transported to the railhead via HDV over a distance of

25 km. The residue then travel by train for 350 km before arriving

the North Vancouver port. The residue is then delivered to UBC via

HDV over a distance of 20.2 km. The distances used in the calcula-

tions are estimated based on harvest eld and sawmill locations in

BC, Canada (Natural Resources of Canada, 2003a,b) and opinions

from the local industry (Melin, 2010, personal communication).

The nal wood waste to be gasied is assumed to have a mois-

ture content of 60%, dry basis, as that is maximum moisture con-

tent allowed for smooth operation of the gasier. Due to this

limitation, some natural drying/aging is assumed to happen at

UBC and the moisture content difference between the fuel deliv-

ered and the fuel fed into the system is taken into account.

The proposed biomass utilization system for woody biomass

gasication is a retrotted air gasication system because gasica-

tion generally produces lower PM, CO, VOC (volatile organics) and

NO

X

emissions compared to direct combustion (European Environ-

ment Agency, 2007; Sparica, 2009, personal communication). The

syngas produced is combusted in the existing natural gas combus-

tor to heat up water in the boiler to generate steam. The ue gas

can be treated with an ESP to remove PM and/or a SCR unit to re-

move NO

X

if required.

The thermal efciency of this system depends on the moisture

content of the biomass fuel. Typical thermal efciency for biomass

fuel with approximately 60% moisture content (dry basis) is 62%

(Sparica, 2009, personal communication) and this is the thermal

efciency assumed for the wood waste scenarios. For biomass with

10% moisture content, the thermal efciency is 78% (Sparica, 2009,

personal communication). This number is used for wood pellet sce-

narios despite the moisture content of BC wood pellets is actually

around 6%. Combining thermal efciency and the amount of steam

produced in 2008, it is deduced that 126,015 t of wood waste, with

a gross caloric energy content at 12.50 MJ/kg (Forest Product

Table 1

Estimated total emission factors for UBC boiler house and their sources.

Fuel oil-ring boiler Natural gas-ring boiler

Total emission

factor (g/GJ of

fuel used)

Source of emission factor Total emission

factor (g/GJ of

fuel used)

Source of emission factor

Upstream Combustion Upstream Combustion

CO

2

, fossil 88,593 Delucchi and

Levelton (2010)

European Environment

Agency (2007)

53,393 Delucchi and

Levelton (2010)

Northwest Instrument Systems

Inc. (2009)

CO

2

, biogenic 475 0 79.9 0

CH

4

120 European Environment

Agency (2007)

72.3 European Environment

Agency (2007) N

2

O 7.97 1.67

CO 26.1 US Environmental Protection

Agency (1995)

9.14 Northwest Instrument Systems

Inc. (2009)

NMVOC

a

22.8 European Environment

Agency (2007)

5.05 European Environment

Agency (2007)

NO

X

89.8 Northwest Instrument Systems

Inc. (2009)

36.1 Northwest Instrument Systems

Inc. (2009)

SO

X

245 Mass balance based on input S

content from Podolski et al. (2008)

6.09 Mass balance based on input S

content

PM 5.73 European Environment Agency (2007) 0.49 European Environment

Agency (2007)

a

Non-methane volatile organic compounds.

A. Pa et al. / Bioresource Technology 102 (2011) 61676177 6169

Laboratory, 2004), is required annually to produce the same

amount of steam as the base case. For the wood pellet scenarios,

64,257 t of wood pellets, with a gross caloric energy content at

19.4 GJ/t (Accredited Laboratory, 2007), is required. Just for com-

parison, in 2008 the boiler house consumed 1034 TJ of natural

gas and 7.84 TJ of fuel oil to generate 350 kt of steam at 165 psig

(1138 kPa), translating to 974 TJ of heat produced (UBC Utilities,

2009). These numbers correspond to a 93% overall thermal

efciency.

2.2.1.2. Woody biomass gasication emission factors. For the wood

waste scenarios, the gasication emission factors utilized were

based on wood waste gasication in a commercial xed bed gas-

ier. The biogenic CO

2

emission is calculated based on the carbon

content of wood. It was assumed that the carbon content in dry

wood is 50% and the moisture content of wood waste, a mixture

of forest residue and sawmill and planner mill residue, is 60%,

dry basis, which is the maximum moisture allowed for the gasier.

At 60% moisture content, the mixed waste would give off 0.092 kg

of biogenic CO

2

emission per MJ of pellets gasied. The CH

4

, N

2

O

and SO

X

emission factors are not available so they are estimated

by the emissions of wood waste combustion in boiler from US

AP42 document (US Environmental Protection Agency, 1995). The

annual emissions are obtained by multiplying the emission factors

by the annual fuel consumption.

It is speculated that wood pellet gasication emission factors

may vary quite substantially given that the combustion emission

for wood waste and wood pellets do vary considerably as shown

in the literature or published database (Swiss Centre for Life Cycle

Inventories, 2008; Johansson et al., 2004; Wierzbicka et al., 2005;

Lillieblad et al., 2004). In attempt to better represent wood pellet

gasication emissions in the wood pellet scenarios, which are not

available in the literature, the emission factors are estimated using

two types of ratios. The rst ratio is the ratio between wood and

pellet combustion emission factors from literature and database.

This rst ratio together with the wood gasication emission factors

from the industry can yield a set of estimated emission factors for

the wood pellet gasication system. The second ratio is the ratio

between published wood combustion emissions and the wood gas-

ication emission from the industry. This ratio can then be applied

to pellet combustion emission factors from literature and database,

resulting in another set of estimated emission factors for pellet

gasication, provided that the values of pellet and wood combus-

tion emissions are different from those used to calculate the rst

ratio, as that would yield two identical sets of wood pellet gasica-

tion emission factors.

In order to carry out this approximation process based on ratios,

it is crucial to compare data with similar set-up in terms of emis-

sion controls, system type and type of biomass used. Different

emission data are matched based on considerations mentioned

and whenever possible, data from the same article or database

are compared. For the calculation of the rst type of ratio, no unit

conversion is required as the units used are usually consistent

within a single source. However, when calculating the second type

of ratios, unit conversions need to be performed as industrial emis-

sion data for wood gasication are provided in mass of pollutant

per energy unit of wood utilized while most literature report their

data in mass of pollutant per volume of ue gas with the O

2

% or

CO

2

% of ue gases provided along with the specication on dry

or wet gas basis. Conversions of units are performed as described

in The Handbook of Biomass Combustion and Co-ring (van Loo

and Koppejan, 2007). Since gasication emission factors from the

industry do not include CH

4

and N

2

O, their ratios are not calculated

and pellet combustion emission factors from the US-EI database

are used in the estimated pellet gasication emission data. Table 2

lists all the emission factors used in the calculation of the ratios. T

a

b

l

e

2

L

i

s

t

o

f

p

e

l

l

e

t

a

n

d

w

o

o

d

c

o

m

b

u

s

t

i

o

n

e

m

i

s

s

i

o

n

f

a

c

t

o

r

s

f

r

o

m

l

i

t

e

r

a

t

u

r

e

i

n

k

g

o

f

p

o

l

l

u

t

a

n

t

e

m

i

t

t

e

d

p

e

r

M

J

o

f

f

u

e

l

u

t

i

l

i

z

e

d

.

S

o

u

r

c

e

W

i

e

r

z

b

i

c

k

a

e

t

a

l

.

(

2

0

0

5

)

P

a

g

e

l

s

e

t

a

l

.

(

2

0

0

3

)

J

o

h

a

n

s

s

o

n

e

t

a

l

.

(

2

0

0

4

)

U

S

E

n

v

i

r

o

n

m

e

n

t

a

l

P

r

o

t

e

c

t

i

o

n

A

g

e

n

c

y

(

1

9

9

5

)

S

w

i

s

s

C

e

n

t

r

e

f

o

r

L

i

f

e

C

y

c

l

e

I

n

v

e

n

t

o

r

i

e

s

e

t

a

l

.

(

2

0

0

8

)

L

i

l

l

i

e

b

l

a

d

e

t

a

l

.

(

2

0

0

4

)

F

u

e

l

F

o

r

e

s

t

r

e

s

i

d

u

e

P

e

l

l

e

t

F

o

r

e

s

t

r

e

s

i

d

u

e

M

i

x

e

d

w

o

o

d

P

e

l

l

e

t

W

e

t

w

o

o

d

M

i

x

e

d

w

o

o

d

c

h

i

p

f

r

o

m

f

o

r

e

s

t

P

e

l

l

e

t

S

h

a

v

i

n

g

c

h

i

p

s

,

a

n

d

s

a

w

d

u

s

t

P

e

l

l

e

t

L

o

a

d

M

e

d

i

u

m

H

i

g

h

M

e

d

i

u

m

8

0

%

6

0

%

4

5

%

L

o

w

L

o

w

E

m

i

s

s

i

o

n

c

o

n

t

r

o

l

M

u

l

t

i

c

y

c

l

o

n

e

M

u

l

t

i

c

y

c

l

o

n

e

N

o

n

e

M

u

l

t

i

c

y

c

l

o

n

e

M

u

l

t

i

c

y

c

l

o

n

e

T

y

p

e

o

f

e

q

u

i

p

m

e

n

t

1

.

5

M

W

,

m

o

v

i

n

g

g

r

a

t

e

1

M

W

,

m

o

v

i

n

g

g

r

a

t

e

E

m

i

s

s

i

o

n

m

e

d

i

a

n

f

o

r

p

e

l

l

e

t

b

o

i

l

e

r

E

m

i

s

s

i

o

n

m

e

d

i

a

n

f

o

r

p

e

l

l

e

t

b

o

i

l

e

r

F

u

r

n

a

c

e

,

5

0

k

W

1

.

5

M

W

,

m

o

v

i

n

g

g

r

a

t

e

B

i

o

g

e

n

i

c

C

O

2

9

.

1

7

E

0

2

9

.

1

7

E

0

2

1

.

0

3

E

0

1

9

.

6

5

E

0

2

8

.

9

3

E

0

2

7

.

8

5

E

0

2

B

i

o

g

e

n

i

c

C

H

4

4

.

3

5

E

0

5

1

.

7

7

E

0

6

9

.

0

3

E

0

6

9

.

0

3

E

0

6

7

.

0

0

E

0

7

3

.

0

0

E

0

7

N

2

O

5

.

5

9

E

0

6

5

.

5

9

E

0

6

3

.

0

0

E

0

6

2

.

5

0

E

0

6

B

i

o

g

e

n

i

c

C

O

4

.

1

0

E

0

3

3

.

2

0

E

0

4

2

.

5

8

E

0

4

2

.

5

8

E

0

4

1

.

1

8

E

0

4

6

.

5

0

E

0

5

4

.

0

0

E

0

4

3

.

4

4

E

0

5

N

M

V

O

C

2

.

8

5

E

0

5

2

.

5

0

E

0

6

7

.

3

1

E

0

6

7

.

3

1

E

0

6

9

.

0

0

E

0

7

1

.

5

0

E

0

6

N

O

X

7

.

2

0

E

0

5

6

.

7

0

E

0

5

9

.

4

6

E

0

5

9

.

4

6

E

0

5

1

.

1

0

E

0

4

7

.

4

0

E

0

5

3

.

3

1

E

0

5

4

.

6

7

E

0

5

S

O

X

1

.

0

7

E

0

5

1

.

0

7

E

0

5

2

.

5

0

E

0

6

2

.

5

0

E

0

6

P

M

2

.

5

3

.

4

0

E

0

5

2

.

0

0

E

0

5

P

M

4

.

4

6

E

0

5

6

.

8

8

E

0

5

1

.

8

7

E

0

5

8

.

1

0

E

0

5

5

.

5

9

E

0

5

4

.

5

4

E

0

5

8

.

8

0

E

0

5

1

.

9

0

E

0

5

1

.

4

2

E

0

4

9

.

4

6

E

0

5

4

.

3

0

E

0

5

2

.

3

7

E

0

5

2

.

1

6

E

0

5

2

.

1

6

E

0

5

6170 A. Pa et al. / Bioresource Technology 102 (2011) 61676177

Table 3 summarizes the two set of emission factors obtained

from the two types of ratios and their average values. The average

estimated pellet gasication emission factors are used for the cal-

culation in uncontrolled pellet scenario in this study. Note that SO

X

is manually set to zero since SO

X

emission depends mostly on the

sulfur content of the fuel and wood pellet contains negligible sulfur

at less than 0.01%, dry basis (Johansson et al., 2004).

2.2.1.3. Emission controlled woody biomass gasication scenarios.

Table 3 also includes the current air emission limits, in kg per MJ

of fuel consumed, for biomass boilers and heaters in Metro Van-

couver (Metro Vancouver, 2008) and the wood waste gasication

emission factors used in this study. It is apparent that emission

control units need to be in place in order to stay below the local

air emission limit. The numbers show that NO

X

and PM need to

be reduced by 37% and 66%, respectively for wood pellet and 44%

and 87% for wood waste gasication. Both can be easily achieved

by technologies such as SCR for NO

X

reduction and ESP for PM re-

moval as the typical removal efciencies for these units are

approximately 80% and 99%, respectively (Forzatti, 2001; De

Nevers, 2000). These efciencies are applied for the controlled

woody biomass gasication emission scenarios.

2.3. Life cycle impact assessments of the scenarios

Biogenic CO, CO

2

and CH

4

have the same impacts as non-bio-

genic emissions in terms of human and ecosystem quality as the

chemical structure does not depend on the origin of emissions.

However, in terms of climate change impact, biogenic CO, CO

2

and CH

4

are considered to have less impact than their fossil-origin

counterparts as biogenic carbon emissions are considered to be

carbonneutral and do not result in net-increase in the carbon con-

tent of the atmosphere. By denition PM is for all particulate mat-

ters while PM

2.5

refers to those less than 2.5 lm and PM

10

are

those less than 10 lm. PM

2.5

are the ones with signicant health

impacts (Humbert et al., 2005). The impact factors for PM are esti-

mated based on an average PM

2.5

to PM ratio in ambient air of 0.33

(Humbert et al., 2005; Dockery and Pope, 1994). Throughout this

study, care was taken to avoid double accounting. When only PM

emission factors are available, such as from GHGenius database

(Delucchi and Levelton, 2010), they are used and the impacts are

calculated using PM impact factors. When both PM and PM

2.5

emission factors are available, only the PM

2.5

emission factors

and thus impacts are utilized. In the result section, sometimes both

PM and PM

2.5

are listed, but it is important to acknowledge that for

each process, only one of the PM or PM

2.5

emission factors, and

thus their respective impact factors, is used, not both.

The emission factors and energy consumption data are im-

ported into a commercial LCA software, SimaPro, to allow for the

use of various life cycle impact assessment (LCIA) methods. IM-

PACT 2002+ (Jolliet et al., 2003) is selected for impact assessment

in this case study. IMPACT 2002+ includes both midpoint and

end point impacts by linking all life cycle inventory data via 15

midpoint categories to four damage, or end point, categories, as

illustrated in Fig. 1. The dashed lines indicate that the conversion

into damage categories has not yet been properly established.

The units used for each impact category, such as DALY and

PDF m

2

yr, are dened in Fig. 1.

The most current version of IMPACT 2002+ at time of analysis

(v2.06) is adapted for analysis with two extra categories added to

keep track of the primary energy consumption and external costs

throughout the entire life cycle. These two new end point catego-

ries are also presented in Fig. 1. The impacts of biogenic CH

4

and

CO are added under the categories of respiratory organic and inor-

ganic, respectively, using the impact values of their fossil fuel ori-

gin counterparts. Six endpoint categories, human health,

ecosystem quality, climate change, primary energy consumption,

external cost and resources can be obtained. Only the rst ve will

be evaluated in this study. It is important to keep in mind that IM-

PACT 2002+ was developed in Europe so the values of parameters

used for the compilation of human toxicity are at a continental le-

vel for Western Europe. Due to this reason, the nal values to be

presented here only serve as indicators for scenario comparisons

as the absolute values may not be so meaningful due to geograph-

ical and geological differences in Western Canada and Western

Europe.

External cost, also known as externality, is the unaccounted and

uncompensated impact on a group arising from the social or eco-

nomic activities of other groups (European Commission, 2003).

Table 3

Estimated wood pellet gasication emission factors and air emission limits for biomass boilers in Vancouver, Canada.

Pollutant Wood waste

gasication emission

factors (kg/MJ)

Estimated pellet gasication

emission factors based on

ratio 1 (kg/MJ)

Estimated pellet gasication

emission factors based on

ratio 2 (kg/MJ)

Average estimated pellet

gasication emission

factors (kg/MJ)

Vancouver air emission

limit for biomass boilers

(kg/MJ)

Biogenic CO

2

9.17E02 8.50E02 8.22E02 8.36E02

Biogenic CH

4

9.03E06 3.00E07 3.00E07 3.00E07

N

2

O 5.59E06 2.50E06 2.50E06 2.50E06

Biogenic CO 1.46E05 1.26E06 1.14E06 1.20E06 1.59E04

NMVOC 4.30E06 3.77E07 3.02E07 3.39E07

NO

X

7.31E05 6.80E05 6.33E05 6.56E05 4.10E05

PM 4.00E05 1.92E05 1.14E05 1.53E05 5.13E06

Fig. 1. Overall scheme of the IMPACT 2002+ framework, linking LCI results via the

midpoint categories to damage categories with modications implemented for this

study (based on Jolliet et al., 2003).

A. Pa et al. / Bioresource Technology 102 (2011) 61676177 6171

Therefore, externality reects the impact on environment and hu-

man health. Table 4 lists three sets of reported external costs for air

pollutants investigated in this study. The costs for biogenic CO

2

,

CH

4

and CO are estimated using the impact factors for different

pollutants in IMPACT 2002+. The global warming factors listed in

IMPACT 2002+ are mostly based on IPCC 2001s 500-year time

horizon values. Since CO

2

only has an effect on climate change

and biogenic CO

2

has no impact, biogenic CO

2

has been assigned

a zero external cost. It is noted that the average external cost for

CH

4

in the literature is close to $0.23, which is equal to the cost

of CO

2

multiplied by the impact factor of CH

4

, a value of seven.

The same observation is made for N

2

O where the calculated value

based on its impact factor of 156 is $5.15. Based on these observa-

tions, the external cost of biogenic CH

4

is estimated by multiplying

its impact factor of 4.25 by the cost of CO

2

to yield $0.14. This is

plausible as CH

4

only has effects on global warming according to

IMPACT 2002+. For biogenic CO, it also has impact on human

health, which is the total cost of CO minus the cost of climate

change. With the cost of climate change for CO being estimated

as the cost of CO

2

multiplied by the climate change impact factor

for CO in IMPACT 2002+, which is 1.57, the health cost for CO is

found to be $0.67, which applies to CO from all sources. Since

the climate change impact factor of biogenic CO is 0, the total cost

of biogenic CO is equal to the health cost of CO. The emission

reduction achieved from replacing natural gas and fuel oil with

wood pellets can then be combined with external cost for each pol-

lutant in Table 4 to derive the reduction in external costs.

Since health impact depends heavily on the emission location

and its proximity to population, the health impact associated with

end usage alone for all ve scenarios are compared as the point of

usage is at UBC campus, where the risk of exposure to pollutant is

much higher compared to pellet mills in suburban areas. The end

stage health impacts for all scenarios are normalized by the value

of the base scenario as it is the relative, not the absolute, values of

the health impact that are relevant for this comparison.

3. Results and discussion

Using values presented in Table 1, the current annual emissions

from UBC boiler house are calculated and presented in Table 5,

together with the emissions from all the biomass gasication sce-

narios. The emission factor for PM instead of PM

2.5

is provided for

all processes in the life cycle except for steam generation, where

the PM

2.5

emission factor is provided instead of PM. Due to this

reason, there are both PM and PM

2.5

emissions reported in Table 5

but there is no overlapping between them as the emission factor

for PM during steam generation was not used in the calculation.

From Table 5 it is apparent that the estimated biogenic CO,

NMVOC, NO

X

and PM emissions for pellet gasication are lower

than wood waste gasication, as observed in pellet and wood

waste combustion. It appears that the most obvious advantage of

switching to woody biomass gasication is the drastic reduction

of CO

2

emissions of fossil fuel origin. However, this is coupled with

a substantial increase in biogenic CO

2

emission, particularly due to

lower thermal efciency for the biomass gasication system and

the high carbon intensity of biomass energy. Another emission

reduction lies in generic CH

4

. Even though there is a slight increase

of biogenic CH

4

emission, there is a net CH

4

reduction of 64% and

77% when accounting CH

4

from all origins for wood waste and pel-

let gasication, respectively. The high CH

4

emission from the cur-

rent scenario arises from the upstream processing of natural gas

as well as the leakage and loss during pipeline transmission. This

observation is more noticeable in Fig. 2 where the stage-wise dis-

tribution of each pollutant for the current scenario is illustrated. It

is evident from the same gure that natural gas burns very cleanly

with most of the emissions from upstream, with the exception of

fossil CO

2

, N

2

O and NMVOC. Despite that natural gas combustion

and upstream operations seem to be contributing the most to the

emissions and environmental impacts, it is important to note that

more than 99% of the energy input was from natural gas thus Fig. 2

does not suggest that fuel oil burning is cleaner than natural gas.

However, it is noted that there is a signicant SO

X

emission from

oil combustion despite that only less than 1% of the energy input

was from fuel oil.

Other than generic CH

4

emission and CO

2

emission of fossil ori-

gins, all other emissions would increase when the boiler is

switched from natural gas to woody biomass gasication. The most

signicant increase, other than in biogenic CO

2

, is in PM emissions,

reaching approximately 130- and 77-folds for wood waste and

wood pellets, respectively. Even with an ESP unit, the increase

Table 4

Summary of external costs from literature and the external costs used in this study.

Bi and Wang (2006) Average values from various

states in the US

a

Golay (2005)

Dones et al. (2005) Values used in this analysis Calculation and remarks

CAD $/kg CAD $/kg CAD $/kg CAD $/kg

CO

2

, fossil 0.04 0.03 0.03 0.03 Average of all values

CO

2

, biogenic 0 Estimated using impact factors in

IMPACT 2002+ method

CH

4

1.05

b

0.25 NA 0.25 State average value is used as it is

not just estimation based on GWP

CH

4

, biogenic 0.14 Estimated using impact factors in

IMPACT 2002 + method

N

2

O 12.52

b

4.73 NA 4.73 State average value is used as it is

not just estimation based on GWP

CO 0.41 1.02 NA 0.72 Average of all values

CO, biogenic 0.67 Estimated using impact factors in

IMPACT 2002 + method

NMVOC NA NA 1.78 1.78

VOC NA 3.76 NA 3.76

NO

X

5.23 6.41 4.59 5.41 Average of all values

SO

X

5.46 2.30 4.64 4.14 Average of all values

PM 14.70 3.14 18.52

c

12.12 Average of all values

PM

2.5

NA NA 30.87 30.87

a

Based on values from New York State Public Service Commission, Department of Public Utilities of Massachusetts, Public Service Commission of Nevada and

California Public Utilities Commission and presented in Golays lecture slides (Golay, 2005).

b

Estimated by source based on CO

2

cost multiplied by specic pollutants 100 years time horizon GWP (global warming potential) value from the 2007 IPCC report.

c

Estimated by source based on typical PM

2.5

/PM ratio.

6172 A. Pa et al. / Bioresource Technology 102 (2011) 61676177

would still be approximately 17- and 43-folds for wood waste and

pellet, respectively. ESP appears to be less effective for the pellet

scenario because a large portion of PM emission is released from

the upstream fuel preparation process, which is not controlled by

the ESP installed for the gasication plant. For wood pellet sce-

nario, approximately 31% of the total PM emission is from pellet

mill where wood residue is burned for biomass drying. Thus,

removing PM from gasication process alone would achieve a less

signicant PM reduction over the entire life cycle. However, it is

important to point out that the zero emission of PM

2.5

under cur-

rent natural gas operation results from the fact that all emission

factors related to base scenario are only for PM but not for PM

2.5

specically. With emission controls in place, the increase in other

pollutant emissions ranges from 215% (for NMOVC) to 448% (for

N

2

O) for wood waste and 42% (for SO

X

) to 393% (for all CO), for

wood pellets.

In Fig. 3, the stage-wise contributions to the total emissions are

illustrated for wood waste gasication (Fig. 3a), wood pellet gasi-

cation (Fig. 3b), wood waste gasication with emission controls

(Fig. 3c) and wood pellet gasication with emission controls

(Fig. 3d), respectively. Fig. 3 reveals that the top contributor to bio-

genic CO

2

and N

2

O emissions is the gasication stage for all woody

biomass gasication scenarios. For the uncontrolled wood waste

scenario, more than 80% of the generic CO and approximately

50% of the NMVOC emissions are emitted during the harvesting

stage. The gasication stage is the main contributor to the remain-

ing pollutants except for fossil-origin CO

2

and generic CH

4

as more

than 40% of each of these pollutants are emitted during harvesting.

For wood waste gasication with emission control units, the har-

vesting stage also becomes the main contributing stage for NO

X

and PM emissions throughout the life cycle and remains to be

the main contributor for fossil-origin CO

2

and generic CH

4

.

For both uncontrolled and controlled wood pellet scenarios, the

harvesting stage is the main contributor to fossil-origin CO

2

, gener-

ic CO, NMVOC, and SO

X

while pellet mill is where the majority of

biogenic CH

4

and CO is emitted due to the burning of wood residue

within the mill. In the uncontrolled pellet scenario, 42% of the NO

X

emission in the life cycle is emitted in the harvesting stage and 40%

from gasication. Moreover, gasication is responsible for 44% of

the life cycle PM emission. However, with emission control, gasi-

cation stages contribution to PM and NO

X

are reduced to 0.8% and

12%, respectively, with pellet mill becoming the new hot-spot for

PM emission. Note that the PM categories in both Figs. 2 and 3 refer

to All PM in Table 5.

The external costs from each scenario are also presented in Ta-

ble 5. By switching to wood waste gasication, there is actually an

increase of $450,000 CAD in external costs while wood pellet gas-

ication would result in an $87,000 CAD saving. It was stated ear-

lier that in order to satisfy the air emission limits in Vancouver for

biomass boiler the NO

X

and PM emissions need to be reduced. With

the installation of SCR and ESP units, these two pollutants can be

reduced by 80% and 99% thus achieving emissions much lower

than what is required. With the emission control units, the exter-

nal costs can be reduced by 38% and 31% from the base case for

wood waste and wood pellets, respectively. Note that no spatial

variation of the external cost has been considered in the current

analysis in which the emissions released in densely populated ur-

ban area and less populated remote area are given the same exter-

nal cost for each gas pollutant.

Since emissions are increased for all major pollutants when the

boiler house is switched from natural gas to wood pellet gasica-

tion, it is hard to comprehend the relative overall impacts from

each scenario based on emission inventories only. Fig. 4 compares

each of the ve scenarios impacts on human health, ecosystem

quality and climate change, as well as a breakdown of these

T

a

b

l

e

5

A

n

n

u

a

l

a

i

r

e

m

i

s

s

i

o

n

s

f

r

o

m

c

u

r

r

e

n

t

a

n

d

w

o

o

d

p

e

l

l

e

t

s

c

e

n

a

r

i

o

s

.

U

n

c

o

n

t

r

o

l

l

e

d

w

o

o

d

y

b

i

o

m

a

s

s

g

a

s

i

c

a

t

i

o

n

C

o

n

t

r

o

l

l

e

d

w

o

o

d

y

b

i

o

m

a

s

s

g

a

s

i

c

a

t

i

o

n

a

E

m

i

s

s

i

o

n

s

f

o

r

b

a

s

e

S

c

e

n

a

r

i

o

(

t

/

y

r

)

E

m

i

s

s

i

o

n

s

f

o

r

w

o

o

d

w

a

s

t

e

(

t

/

y

r

)

R

e

d

u

c

t

i

o

n

i

n

e

x

t

e

r

n

a

l

c

o

s

t

(

$

1

0

0

0

C

A

D

)

E

m

i

s

s

i

o

n

s

f

o

r

w

o

o

d

p

e

l

l

e

t

(

t

/

y

r

)

R

e

d

u

c

t

i

o

n

i

n

e

x

t

e

r

n

a

l

c

o

s

t

(

$

1

0

0

0

C

A

D

)

E

m

i

s

s

i

o

n

s

f

o

r

w

o

o

d

w

a

s

t

e

(

t

/

y

r

)

R

e

d

u

c

t

i

o

n

i

n

e

x

t

e

r

n

a

l

c

o

s

t

(

$

1

0

0

0

C

A

D

)

E

m

i

s

s

i

o

n

s

f

o

r

w

o

o

d

p

e

l

l

e

t

s

(

t

/

y

r

)

R

e

d

u

c

t

i

o

n

i

n

e

x

t

e

r

n

a

l

c

o

s

t

(

$

1

0

0

0

C

A

D

)

A

l

l

C

O

2

5

5

,

9

9

7

1

5

4

,

2

0

5

1

,

5

0

6

1

2

1

,

5

5

2

1

,

5

5

2

1

5

4

,

2

0

5

1

,

5

0

6

1

2

1

,

5

5

2

1

,

5

5

2

C

O

2

,

f

o

s

s

i

l

5

5

,

9

1

1

8

,

6

2

9

1

,

5

0

6

8

,

8

7

7

1

,

5

5

2

8

,

6

2

9

1

,

5

0

6

8

,

8

7

7

1

,

5

5

2

C

O

2

,

b

i

o

g

e

n

i

c

8

6

.

3

0

1

4

5

,

5

7

5

0

.

0

0

1

1

2

,

6

7

6

0

.

0

0

1

4

5

,

5

7

5

0

.

0

0

1

1

2

,

6

7

6

0

.

0

0

A

l

l

C

H

4

7

5

.

7

0

2

7

.

1

8

1

3

.

8

3

1

7

.

5

2

1

4

.

7

9

2

7

.

1

8

1

3

.

8

3

1

7

.

5

2

1

4

.

7

9

C

H

4

7

5

.

7

0

1

2

.

8

5

1

5

.

8

4

1

6

.

3

6

1

4

.

9

6

1

2

.

8

5

1

5

.

8

4

1

6

.

3

6

1

4

.

9

6

C

H

4

b

,

b

i

o

g

e

n

i

c

0

.

0

0

1

4

.

3

3

2

.

0

1

1

.

1

7

0

.

1

6

1

4

.

3

3

2

.

0

1

1

.

1

7

0

.

1

6

N

2

O

1

.

7

9

9

.

8

1

3

7

.

8

9

4

.

6

3

1

3

.

4

0

9

.

8

1

3

7

.

8

9

4

.

6

3

1

3

.

4

0

A

l

l

C

O

9

.

6

5

4

7

.

7

3

2

5

.

9

7

4

7

.

6

0

2

5

.

9

8

4

7

.

7

3

2

5

.

9

7

4

7

.

6

0

2

5

.

9

8

C

O

b

9

.

6

5

2

1

.

6

2

8

.

5

9

2

3

.

4

3

9

.

8

9

2

1

.

6

2

8

.

5

9

2

3

.

4

3

9

.

8

9

C

O

,

b

i

o

g

e

n

i

c

0

.

0

0

2

6

.

1

0

1

7

.

3

8

2

4

.

1

7

1

6

.

1

0

2

6

.

1

0

1

7

.

3

8

2

4

.

1

7

1

6

.

1

0

N

M

V

O

C

5

.

4

0

1

7

.

0

1

2

0

.

6

2

1

1

.

7

9

1

1

.

3

4

1

7

.

0

1

2

0

.

6

2

1

1

.

7

9

1

1

.

3

4

N

O

X

3

8

.

0

4

2

1

9

9

8

0

2

0

3

8

9

3

1

2

7

.

0

0

4

8

1

1

3

7

.

5

6

5

3

9

S

O

X

8

.

2

2

1

2

7

.

0

0

7

7

.

8

1

1

1

.

6

4

1

4

.

1

1

2

7

.

0

4

7

7

.

8

1

1

1

.

6

4

1

4

.

1

1

A

l

l

P

M

0

.

5

6

7

2

.

5

5

8

8

2

4

3

.

5

5

5

2

2

1

0

.

1

8

1

2

6

2

4

.

6

3

2

9

2

P

M

0

.

5

6

7

2

.

0

6

8

6

7

4

3

.

5

2

5

2

1

9

.

6

9

1

1

1

2

4

.

5

9

2

9

1

P

M

2

.

5

c

0

.

0

0

0

.

4

9

1

5

.

2

0

0

.

0

3

1

.

0

1

0

.

4

9

1

5

.

2

0

0

.

0

3

1

.

0

1

T

o

t

a

l

c

h

a

n

g

e

s

i

n

e

x

t

e

r

n

a

l

c

o

s

t

4

5

0

8

7

8

0

4

6

7

1

a

s

e

l

e

c

t

i

v

e

c

a

t

a

l

y

t

i

c

r

e

d

u

c

t

i

o

n

(

S

C

R

)

h

a

s

a

r

e

m

o

v

a

l

e

f

c

i

e

n

c

y

o

f

8

0

%

w

h

i

l

e

e

l

e

c

t

r

o

s

t

a

t

i

c

p

r

e

c

i

p

i

t

a

t

o

r

h

a

s

a

P

M

r

e

m

o

v

a

l

e

f

c

i

e

n

c

y

o

f

9

9

%

.

b

m

a

y

i

n

c

l

u

d

e

s

o

m

e

b

i

o

g

e

n

i

c

e

m

i

s

s

i

o

n

s

a

s

w

e

l

l

.

c

f

r

o

m

s

t

e

a

m

g

e

n

e

r

a

t

i

o

n

o

n

l

y

a

s

n

o

P

M

e

m

i

s

s

i

o

n

f

a

c

t

o

r

w

a

s

a

v

a

i

l

a

b

l

e

f

o

r

t

h

i

s

p

r

o

c

e

s

s

.

A. Pa et al. / Bioresource Technology 102 (2011) 61676177 6173

impacts into different stages to signal out hot-spots throughout

their life cycles.

By switching to woody biomass, both impacts on human health

and ecosystemquality increase signicantly. For human health, the

current impact is 4 DALY and it would increase by 6.2- and 8.6-

folds for wood pellets and wood waste, respectively. Even with

emission control units, the increase would still be 3.3-folds on

average for both woody biomass fuels. Since the parameters used

in the impact assessment method are based on Western Europe,

care should be exercised in the interpretation of human health

impact.

The current impact on ecosystem quality is 2.26E5 PDF m

2

yr

and it would increase by around 4.7 and 4.2 times when switched

from natural gas to wood waste and wood pellet gasication sys-

tems, respectively. With SCR and ESP, the increase can be lowered

to an average of 2.4-folds for both fuel types.

From Fig. 4 it becomes apparent that the harvesting of woody

material and the gasication stage contribute greatly to human

Fig. 2. Stage-wise emission distribution for current natural gas boiler scenario.

Fig. 3. Stage-wise emission distribution for (a) wood waste gasication, (b) wood pellet gasication, (c) wood waste gasication with SCR and ESP units with 80% NO

X

and

99% PM removal efciency, respectively, and (d) wood pellet gasication with identical emission control units.

6174 A. Pa et al. / Bioresource Technology 102 (2011) 61676177

health impact. It is evident that by adding emission control units,

the pellet scenarios human health impact for the entire life cycle

can be further reduced by 35% while the health impact associated

with gasication alone can be further reduced by 87%. However,

since wood waste requires little upstream processing, the addition

of emission control can effectively reduce the overall health impact

by 59% and the reduction in gasication stage alone would be 88%.

For the effect on ecosystem quality, the main contributions are

from the harvesting and gasication stages as well. With emission

control, gasication only contributes 20% and 12% to the entire life

cycles impact on ecosystem quality for wood waste and pellet,

respectively. Moreover, with emission controls the ecosystem

quality impact for the entire pellet gasication life cycle can be fur-

ther lowered by 32% while impacts associated with gasication

alone can be reduced by 80% when compared to uncontrolled pel-

let scenario.

Lastly, Fig. 4 conrms that the key advantage associated with

switching to woody biomass is the reduction in GHG emissions.

Fig. 4c clearly illustrates that impact on climate change can be re-

duced by 82% and 83% from the current 56.7 kt of CO

2

-equvalent

per year when wood waste and wood pellets are used, respectively.

Another scenario performance indicator is primary energy con-

sumption. To generate 974 TJ of usable heat annually, the current

natural gas scenario consumes 1284 TJ of primary energy and this

number is slightly higher for the pellet scenarios at 1516 and 1725

TJ for wood waste scenarios. Primary energy takes into account the

energy resource required to produce fuels, power or products.

These include the heating value of raw materials such as harvested

wood and crude oil, energy required to produce fuels such as die-

sel, and energy required to convert different fuels, such as natural

gas or diesel, to electricity.

It is important to acknowledge that human health impact is

more of local concern as compared to the global climate change im-

pact. As the UBC district heating systemis located in a densely pop-

ulated area, the stack emissions from the boiler house will have the

most signicant impact on human health. The end usage contribu-

tions to human health impact for all ve scenarios are normalized

by the base case value and are compared in Fig. 5. It is apparent that

the human health impact directly linked to the end usage increases

substantially when switched from natural gas to woody biomass as

it would be augmented by 18- and 7.7- folds for uncontrolled wood

waste and pellet gasication, respectively. This value is lowered to a

133% increase for controlled wood waste scenario and a mere 12%

increase for controlled wood pellet scenario. As a result, it is

strongly recommended that both the PM and NO

X

emission control

units be installed in biomass combustion/gasication district heat-

ing systems to prevent the deterioration of local air quality and

drastic increase in local health impact, in addition to meeting the

local emission standards. It should be noted that adopting wood

pellet gasication may have other impacts on the community that

are not accounted for in this study, such as the noise and inconve-

nience associated with pellet delivery trafcs.

In this study, the gasication plant produces only heat so the

LCA study of a CHP plant in place of the existing boiler house might

yield different results. As UBC also aims to become a net energy

exporter by 2050, the CHP option is readily pursued as UBC has

Fig. 4. Stage-wise impact analysis in terms of (a) human health, (b) ecosystem quality, and (c) climate change for current and woody biomass gasication with and without

emission control units.

A. Pa et al. / Bioresource Technology 102 (2011) 61676177 6175

already decided to establish a CHP demonstration unit on campus

using a system developed by Nexterra and GE to provide green

heat and electricity while serving as a research facility.

4. Conclusions

Replacing fossil fuels with biomass may not always be desirable

and the decision would depend heavily on the priorities of the spe-

cic project. Natural gas combustion outperforms emission-con-

trolled woody biomass gasication scenarios in primary energy

consumption and all impact categories considered other than cli-

mate change while all woody biomass gasication scenarios yield

signicant reduction on GHG and external costs. Pellet gasication

is superior to wood waste as it has lower primary energy consump-

tion and the health impact associated with stack emission for the

controlled waste wood gasication is 133% higher than the base

scenario, compared to 12% for pellets.

Acknowledgements

The authors would like to thank UBC Sustainability ofce, UBC

Utility, and Dr. Anthony Lau for providing the air emission data

for the existing natural gas district heating facility. The authors

are also grateful to the nancial support from Agriculture Canadas

ABIN program and the UBC Graduate Fellowship (UGF) program.

References

Bi, H.T., Wang, D., 2006. An evaluation of the AirCare program based on cost-benet

and cost-effectiveness analyses. Bull Sci Technol Soc. 26, 472478.

Bjrklund, A., Niklasson, T., Wahln, M., 2001. Biomass in Sweden: Biomass-red

CHP plant in Eskilstuna. Refocus. 2, 1418.

Campbell, P.K., Beer, T., Batten, D., 2011. Life cycle assessment of biodiesel

production from microalgae in ponds. Bioresour.Technol. 102, 5056.

Collet, P., Hlias, A., Lardon, L., Ras, M., Goy, R., Steyer, J., 2011. Life-cycle assessment

of microalgae culture coupled to biogas production. Bioresour.Technol. 102,

207214.

De Nevers, N., 2000. Air Pollution Control Engineering. 2nd ed. McGraw-Hill, Boston.

Difs, K., Wetterlund, E., Trygg, L., Sderstrm, M., 2010. Biomass gasication

opportunities in a district heating system. Biomass Bioenergy 34, 637651.

Dockery, D.W., Pope, C.A., 1994. Acute respiratory effects of particulate air pollution.

Annu.Rev.Public Health. 15, 107132.

Eriksson, O., Finnveden, G., Ekvall, T., Bjrklund, A., 2007. Life cycle assessment of

fuels for district heating: A comparison of waste incineration, biomass- and

natural gas combustion. Energy Policy. 35, 13461362.

Forzatti, P., 2001. Present status and perspectives in de-NO

X

SCR catalysis. Applied

Catalysis A: General. 222, 221236.

Ghafghazi, S., Sowlati, T., Sokhansanj, S., Bi, X., Melin, S. (in press). Life cycle

assessment of base-load heat sources for district heating system options. Int. J.

Life Cycle Assess.

Gonzlez-Garca, S., Moreira, M.T., Feijoo, G., 2010. Comparative environmental

performance of lignocellulosic ethanol from different feedstocks. Renewable

and Sustainable Energy Reviews. 14, 20772085.

Johansson, L.S., Leckner, B., Gustavsson, L., Cooper, D., Tullin, C., Potter, A., 2004.

Emission characteristics of modern and old-type residential boilers red with

wood logs and wood pellets. Atmos. Environ. 38, 13.

Jolliet, O., Margni, M., Charles, R., Humbert, S., Payet, J., Rebitzer, G., Rosenbaum, R.,

2003. IMPACT 2002+: A new life cycle impact assessment methodology. Int. J.

Life Cycle Assess. 8, 324330.

Kopetz, H., 2007. Biomassa burning issue: Policies needed to spark the biomass

heating market. Refocus. 8 (5254), 5658.

Lillieblad, L., Szpila, A., Strand, M., Pagels, J., Rupar-Gadd, K., Gudmundsson, A.,

Swietlicki, E., Bohgard, M., Sanati, M., 2004. Boiler operation inuence on the

emissions of submicrometer-sized particles and polycyclic aromatic

hydrocarbons from biomass-red grate boilers. Energy Fuels. 18, 410

417.

Pagels, J., Strand, M., Rissler, J., Szpila, A., Gudmundsson, A., Bohgard, M., Lilliebald,

L., Sanati, M., Swietlicki, E., 2003. Characteristics of aerosol particles formed

during grate combustion of moist forest residue. J.Aerosol Sci. 34, 1043

1059.

Rickerson, W., Halfpenny, T., Cohan, S., 2009. The emergence of renewable heating

and cooling policy in the United States. Policy and Society. 27, 365377.

Ries, F.J., Marshall, J.D., Brauer, M., 2009. Wood energy: The dangers of combustion.

Science. 324, 1390-a.

Sambo, S.M., 2002. Fuel consumption for ground-based harvesting systems in

western Canada. Advantage. 3, 112.

Spatari, S., Bagley, D.M., MacLean, H.L., 2010. Life cycle evaluation of emerging

lignocellulosic ethanol conversion technologies. Bioresour.Technol. 101, 654

667.

Wierzbicka, A., Lillieblad, L., Pagels, J., Strand, M., Gudmundsson, A., Gharibi, A.,

Swietlicki, E., Sanati, M., Bohgard, M., 2005. Particle emissions from district

heating units operating on three commonly used biofuels. Atmos.Environ. 39,

139150.