Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

THERMOMETER CALIBRATION USING CONTROLLED TEMPERATURE Baths Cal926 PDF

Caricato da

Gustavo SánchezDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

THERMOMETER CALIBRATION USING CONTROLLED TEMPERATURE Baths Cal926 PDF

Caricato da

Gustavo SánchezCopyright:

Formati disponibili

THERMOMETER CALIBRATION USING CONTROLLED TEMPERATURE

BATHS

TXDOT DESIGNATION: TEX-926-K

CONSTRUCTION DIVISION 1 7 EFFECTIVE DATE: AUGUST 1999

Test Procedure for

THERMOMETER CALI BRATI ON USI NG

CONTROLLED TEMPERATURE BATHS

TxDOT Designation: Tex-926-K

Effective Date: August 1999

1. SCOPE

1.1 Calibrate thermometers by comparison with standard thermometers while immersed in

stirred water or oil baths. Alternately, calibrate specific points by placing in a reference

temperature bath such as a mixture of crushed ice and water. Make comparisons at

various temperatures and record the errors. Then use correction factors when reading the

thermometer.

Note 1Few thermometers are absolutely accurate. The value of errors may vary over

the range of the thermometer.

Note 2This procedure may use hot liquids and equipment that will cause burns if

improperly handled. Hot oils also emit harmful vapors, so only use with proper

ventilation. Most liquid-in-glass thermometers contain mercury. Mercury fumes may be

hazardous if the thermometer is broken. This procedure does not address the safety

problems of working with these materials. It is the responsibility of all persons

performing these tests to use appropriate procedures and safety equipment.

1.2 The values given in parentheses (if provided) are not standard and may not be exact

mathematical conversions. Use each system of units separately. Combining values from

the two systems may result in nonconformance with the standard.

2. DEFINITIONS

2.1 BulbA bulb is the reservoir of fluid at the lower end of a liquid-in-glass thermometer.

2.2 CalibrationCalibration is the determination of errors or differences from the true value.

2.3 Electronic ThermometerAn electronic thermometer is an electrical device that

measures the change in some property of a sensor to determine the temperature. Three

common sensors are Resistance Temperature Detector (RTD), Thermistor, and

Thermocouple.

2.3.1 Resistance Temperature Detector (RTD)A resistance temperature detector is the

electrical resistance of a metallic sensor varies with its temperature. The sensor is usually

nickel or platinum. This resistance change is predictable and is stable with time and use.

Texas

Department

of Transportation

THERMOMETER CALIBRATION USING CONTROLLED TEMPERATURE

BATHS

TXDOT DESIGNATION: TEX-926-K

CONSTRUCTION DIVISION 2 7 EFFECTIVE DATE: AUGUST 1999

2.3.2 ThermistorThermistor is the electrical resistance of the sensor varies with its

temperature. The sensor is usually a composite material containing metallic oxides. The

resistance change is not generally as stable with time as the RTD sensors.

2.3.3 ThermocoupleThermocouple is made by twisting or welding two wires of different

metals together. When used correctly, a voltage is generated that varies with the

temperature. The voltage change is not linear with temperature but is predictable and

stable. There are many different "standard" types of thermocouples.

2.4 Ice PointIce point is the temperature where the solid and liquid phases of water can co-

exist.

2.5 Liquid-in-Glass ThermometerLiquid-in-glass thermometer is a thermometer that

indicates temperature by how far a liquid contained in a glass bulb has expanded and

traveled into a connecting capillary tube. Mercury or colored alcohols are usually used.

The capillary tube above the liquid column usually contains a gas such as dry nitrogen.

There are three common designs: Complete Immersion, Partial Immersion, and Total

Immersion thermometers.

2.5.1 Complete Immersion ThermometerA Complete Immersion thermometer is designed to

read correctly when the entire thermometer is exposed to the same temperature.

Thermometers inside ovens are being used as complete immersion thermometers.

2.5.2 Partial Immersion ThermometerPartial Immersion thermometers are designed to

indicate correctly when immersed to a specified depth. These are marked with a line to

show the immersion depth. They may have errors dependent upon the cooling of the glass

stem above this mark.

2.5.3 Total Immersion ThermometerTotal Immersion thermometers indicate correctly when

immersed so that only 6 to 12 mm (0.24 to 0.48 in.) of the liquid column is not immersed.

2.6 Standard ThermometerA standard thermometer is a thermometer whose errors are

known. The calibration must be documented and traceable to National Institute of

Standards and Technology standards.

2.7 StemA stem is the part of a liquid-in-glass thermometer containing the capillary tube,

various expansion chambers, and markings.

2.8 VerificationVerification is to confirm, by either testing or comparison with a

recognized standard, that specific requirements are being met.

3. REFERENCES

3.1 ASTM E 77.

3.2 ASTM E 563.

3.3 ASTM E 1.

THERMOMETER CALIBRATION USING CONTROLLED TEMPERATURE

BATHS

TXDOT DESIGNATION: TEX-926-K

CONSTRUCTION DIVISION 3 7 EFFECTIVE DATE: AUGUST 1999

4. APPARATUS

4.1 Magnifying lens, of at least two-power.

4.2 Standard thermometers.

5. CHOOSING CALIBRATION POINTS

5.1 Calibrate ASTM specification thermometers at the temperatures given in ASTM E 1,

Table 3. Calibrate wide range thermometers, such as electronic or general-purpose liquid-

in-glass thermometers, at no less than five points within their range. Use at least one

reference temperature bath point to verify any temperatures covered by a thermometer.

EXAMPLE: One useful reference temperature is the ice point of water0C or 32F.

5.2 Calibrate specialized thermometers at the operating temperature and any specified

reference temperatures.

6. PROCEDURE

6.1 Determine the accuracy required, the identification number, the immersion depth, and the

calibration points to be used. For liquid-in-glass thermometers, verify the condition of the

liquid column (See Section 9).

6.2 Calibration should be by comparison with standard thermometers in stirred, controlled-

temperature baths (See Section 10).

6.3 Use a reference-temperature bath such as an ice-point bath for direct calibration at

specific temperatures (See Section 11).

6.4 Suspend liquid-in-glass thermometers to the proper depth in the bath by the stem above

the liquid column. Support electronic sensors by the sheath or wire leads. Immerse

sheathed sensors to just short of the leads. Locate each so that they do not touch each

other or the bath walls.

6.5 Start with the calibration bath at the lowest temperature to be used. Allow the

temperature to stabilize. Consider the temperature stable when two or more consecutive

readings of the standard thermometer are equal. Take the readings at least 30 seconds

apart.

6.6 Once reaching the correct temperature, reset each thermometer or sensor to the correct

immersion depth and again allow stabilization.

6.7 Read the liquid-in-glass thermometers using a magnifying lens with the lens and the

user's eye at the level of the liquid column.

6.8 Read the standard thermometer, each thermometer being checked, and the standard again.

If the two readings of the standard do not agree within the required accuracy, the bath is

THERMOMETER CALIBRATION USING CONTROLLED TEMPERATURE

BATHS

TXDOT DESIGNATION: TEX-926-K

CONSTRUCTION DIVISION 4 7 EFFECTIVE DATE: AUGUST 1999

not stable. Repeat until the readings match, and then record the temperature of each

thermometer.

6.9 To determine the true temperature, apply the correction factor for each point of the

standard to its indicated reading. Record the true temperatures.

6.10 Find the error at each point by subtracting true temperature from the indicated

temperature. Record the errors.

6.11 Record the correction factor for each calibration temperature. The correction factor has

the same numerical value as the error but with the opposite sign.

6.11.1 EXAMPLE: If the true temperature is 100.0 and the indicated temperature is 100.8, the

thermometer reads high and the error is + 0.8. The correction factor to apply at that point

is 0.8.

6.12 Set the bath to the next calibration temperature and repeat the above steps.

Note 3When using reference-temperature baths, follow the procedure in Section 11.

7. MERCURY-IN-GLASS THERMOMETERS, ICE POINT CORRECTIONS

7.1 The bulb of mercury-in-glass thermometers may slightly change dimensions during use.

By comparison, the stem will remain stable. Bulb dimensional changes affect all

temperature readings equally. For those thermometers with an ice-point marking, perform

periodic verification in an ice-point reference-temperature bath at intervals to determine

such changes.

7.2 Procedure:

7.2.1 Prepare and use an ice-point bath as instructed in Section 11.

7.2.2 Record the indicated temperature.

7.2.3 The thermometer error is equal to the indicated temperature minus the reference-

temperature bath temperature (0C or 32F).

7.2.4 A correction factor is equal to the value of the error but with reversed sign. Add the

change in this factor to all previously determined correction factors. Observe all plus (+)

and minus (-) signs.

EXAMPLE: A thermometers correction factor is + 0.15 at 0. That is, the thermometer

reads low and 0.15 must be added to all readings near 0 as a correction factor. Assume

that the thermometer had an old correction factor of + 0.20. The change is minus 0.05.

Apply this change to all the old corrections factors. That is, if the last correction factor at

100 was -0.06, it is now -0.11.

Note 4Verify restricted range and high temperature calibrated liquid-in-glass

thermometers periodically. Use an ice-point reference-temperature bath if marked on the

stem. Verify electronic thermometers throughout their calibration range.

THERMOMETER CALIBRATION USING CONTROLLED TEMPERATURE

BATHS

TXDOT DESIGNATION: TEX-926-K

CONSTRUCTION DIVISION 5 7 EFFECTIVE DATE: AUGUST 1999

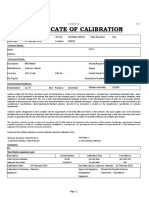

8. CALIBRATION DOCUMENTATION

8.1 Prepare a certification document that contains:

make, type or model, and serial number of the thermometer

sensor type for electronic thermometers

temperature range calibrated

correction factor for each true calibration temperature

standard(s) used

where the calibration was performed

date of the calibration

technician's name

a copy of the procedure used.

Note 5In general, it is not practical to apply a label to liquid-in-glass thermometers. If

there is no serial number on the thermometer, it may be possible to assign identification

and mark the stem with a permanent marker pen or to attach a tag to the thermometer. If

this is not possible, the laboratory should develop a written in-house procedure for

ensuring identification of the calibrated thermometer and linkage to the certification.

9. VISUAL EXAMINATION OF LIQUID-IN-GLASS THERMOMETERS

9.1 A liquid-in-glass thermometer must have an unbroken liquid column or it will give an

incorrect indication.

9.2 Before calibration or use, always examine the column to determine its condition. Use a

magnifying lens of at least two-power for this examination.

9.3 Examine the entire length of the capillary tube to verify that there are no gaps in the

liquid column or filled chamber.

9.4 Examine all empty chambers to verify that no liquid remains in them.

Note 6Either improper use or dropping can cause a break in the liquid column or

mercury left in a chamber. When using multiple chamber liquid-in-glass thermometers,

use in a vertical position.

9.5 There are two common ways to rejoin the liquid column. Perform both carefully to

prevent personal injury or breaking the thermometer.

9.5.1 Preferred MethodAttempt to force the liquid together by tightly holding the

thermometer while slinging it in a circle and jerking it to a stop.

9.5.2 Second MethodHeat the bulb slowly in a controlled temperature bath to force the

bubble into a chamber and then tap the thermometer to force the liquid to rejoin.

THERMOMETER CALIBRATION USING CONTROLLED TEMPERATURE

BATHS

TXDOT DESIGNATION: TEX-926-K

CONSTRUCTION DIVISION 6 7 EFFECTIVE DATE: AUGUST 1999

Note 7Never use an open flame, as the thermometer will almost always break. When

heating, the technician must use safety equipment including gloves and face protection.

10. CONTROLLED-TEMPERATURE BATHS

10.1 Make calibrations by comparison in a stirred, controlled-temperature bath. The bath

should keep temperature variances within the bath at a minimum. These baths may use

water, oil, or specialized heat transfer fluids.

10.2 If a specialized bath is not available, improvise one with a beaker on a hot plate

containing a built in magnetic stirrer. The user must be very careful to ensure that the

temperature is stable each time reading the thermometers. The thermometers must be

close (but not touching each other) in order to read the same. Each thermometer must also

be held in the liquid at the correct immersion depth. With practice and patience, it is

possible to manually regulate this combination well enough to hold an accuracy of about

0.2C (0.4F) for about a minute. This will be sufficient for many purposes.

10.3 Use water baths from the ice point to the boiling point.

10.4 Only use oil baths above the boiling point of water. Determine the flash point of the oil

used and always stay well below this point. Special oils for very high temperatures are

available but expensive. Always use oil baths in a venting hood to avoid breathing fumes

and collecting flammable vapors.

10.5 Use an ice-point bath or distilled water boiling point bath as reference-temperatures. If

possible, use a calibrated thermometer to verify that these baths are properly prepared.

The temperature of these will change due to the mineral content of the water and the

altitude of the workplace.

11. PREPARING AND USING ICE POINT BATHS

11.1 Use a properly prepared ice-point bath for thermometer calibration. Poor preparation and

use of the bath will result in errors. With care, one can use common laboratory beakers

and stirring equipment to produce an ice-point bath that is within 0.01C (0.02F) of

the true ice point.

11.2 Cool and maintain the water to the ice-point temperature by using slush made of ice

shavings or crushed ice particles. Constantly stir the ice and water slush to keep it

distributed uniformly. The slush must contain only enough water to wet the ice particles

and allow the mixture to be slightly fluid. You must periodically remove water and add

ice as the bath is used. For best accuracy, use distilled water and clean, clear ice.

11.3 Do not allow clumps of ice or water pockets to form. When ice particles clump together,

the water between them freezes, and the temperature drops. If a pocket of water forms,

the temperature in it will rise. A water and ice cube mixture will not cool the water

between the cubes sufficiently.

THERMOMETER CALIBRATION USING CONTROLLED TEMPERATURE

BATHS

TXDOT DESIGNATION: TEX-926-K

CONSTRUCTION DIVISION 7 7 EFFECTIVE DATE: AUGUST 1999

11.4 Do not allow a thermometer or temperature sensor in the ice-point bath to touch any part

of the bath or any other thermometer or sensor. At least 25 mm (1 in.) of slush should

always be below the lowest point of any thermometer.

11.5 Suspend each thermometer from above and hold at the proper immersion depth. It will be

easier to read the liquid column of a glass thermometer if the container is almost full.

11.6 Constantly stir the bath to distribute the ice particles and water uniformly.

11.7 Allow the thermometer or sensor to stabilize at the temperature of the bath.

11.8 Read the thermometer, wait for about a minute, and read again. Record only those

readings where the indicated temperature is repeated within the desired accuracy.

Note 8You may stop stirring momentarily while reading a glass thermometer.

11.9 Record the indicated value.

11.10 Find the error by subtracting the ice point (i.e., 0C [32F]) from the indicated value. The

correction factor has the same numerical value as the error but with opposite sign.

EXAMPLE: The true temperature is 0 and the indicated temperature is -0.40; the

thermometer reads low with an error of -0.40, so the correction factor to apply at that

point is + 0.40.

Potrebbero piacerti anche

- E644 1285343-1Documento21 pagineE644 1285343-1jmrozo350% (2)

- NBS13Documento196 pagineNBS13Gustavo SánchezNessuna valutazione finora

- Calibrating Thermometers Lab ReportDocumento15 pagineCalibrating Thermometers Lab ReportJeshua LloreraNessuna valutazione finora

- BS en 60584-1-1996Documento121 pagineBS en 60584-1-1996Gustavo Sánchez100% (1)

- Fluk Ammeter CalibrationDocumento250 pagineFluk Ammeter CalibrationASHUTOSH BHATTNessuna valutazione finora

- Calibration of ThermocoupleDocumento22 pagineCalibration of ThermocoupleMuhammad Fahad100% (1)

- SOP For Calibration of Temperature GaugesDocumento3 pagineSOP For Calibration of Temperature Gaugesget_engineer0550% (2)

- Dial Indicator Calibration Procedure TS-0051Documento3 pagineDial Indicator Calibration Procedure TS-0051alexrferreiraNessuna valutazione finora

- Difference Between Calibration, Testing and Validation: Accuracy, Precision, Resolution & SensitivityDocumento27 pagineDifference Between Calibration, Testing and Validation: Accuracy, Precision, Resolution & SensitivityAmit NainNessuna valutazione finora

- ASTM E2593. Platinum Resistance ThermometersDocumento14 pagineASTM E2593. Platinum Resistance ThermometersPrincess NobleNessuna valutazione finora

- Calibration, American Laboratory: FlijkeDocumento3 pagineCalibration, American Laboratory: FlijkeAMINE MEDDAHINessuna valutazione finora

- (PDF) ASTM E2847.21990 - CompressDocumento17 pagine(PDF) ASTM E2847.21990 - Compressjulian moraNessuna valutazione finora

- Method Statement For Conductivity MeterDocumento2 pagineMethod Statement For Conductivity MeterMuhamed RasheedNessuna valutazione finora

- EURAMET Cg-7 V 1.0 Calibration of Oscilloscopes 01Documento45 pagineEURAMET Cg-7 V 1.0 Calibration of Oscilloscopes 01libijahansNessuna valutazione finora

- Thermometer CalibrationDocumento8 pagineThermometer CalibrationGeroldo 'Rollie' L. Querijero100% (1)

- Lab3 Temperature and Calibration - FINALrrDocumento6 pagineLab3 Temperature and Calibration - FINALrrDerrick SheeNessuna valutazione finora

- Air Resistance of Paper (Gurley Method) t460Documento19 pagineAir Resistance of Paper (Gurley Method) t460Gustavo Sánchez100% (1)

- EURAMET CG 17.01 Electromechanical ManometersDocumento36 pagineEURAMET CG 17.01 Electromechanical Manometersyohagg100% (1)

- ThermometerCalibrationMethods PDFDocumento5 pagineThermometerCalibrationMethods PDFDragoonbk89Nessuna valutazione finora

- German Calibration Service: DKD-R 5-4 Temperature Block CalibratorsDocumento11 pagineGerman Calibration Service: DKD-R 5-4 Temperature Block Calibratorssmartbell100% (3)

- NIMT-CNL-SP No. 601 Standard Procedure for Calibration of Pressure Measuring Instruments Hydraulic TypeDocumento18 pagineNIMT-CNL-SP No. 601 Standard Procedure for Calibration of Pressure Measuring Instruments Hydraulic Typeamelchan_tiqueNessuna valutazione finora

- Method Statement For PH MeterDocumento2 pagineMethod Statement For PH MeterMuhamed RasheedNessuna valutazione finora

- Calibrate Stopwatches Using Talking ClockDocumento2 pagineCalibrate Stopwatches Using Talking Clockloukas_pNessuna valutazione finora

- U 929 RPM MeterDocumento7 pagineU 929 RPM MeterAmit KumarNessuna valutazione finora

- Stop Watch-ID-23 - 24 To 25Documento2 pagineStop Watch-ID-23 - 24 To 25monwar hosenNessuna valutazione finora

- Calibrate Metal Tapes Using Standard Tape MethodDocumento12 pagineCalibrate Metal Tapes Using Standard Tape Methodhaharamesh100% (1)

- U 5753 Centrifuge 17300Documento1 paginaU 5753 Centrifuge 17300NENO BHUBANESWAR100% (1)

- EPA Thermometer Calibration ProceduresDocumento7 pagineEPA Thermometer Calibration ProceduresGilberto Andrés Jurado100% (1)

- Calibration of AnemometerDocumento4 pagineCalibration of AnemometerAhmet ŞenNessuna valutazione finora

- ABB Motors and Technical Data Sheet - DOL Generators: No. Data Unit RemarksDocumento1 paginaABB Motors and Technical Data Sheet - DOL Generators: No. Data Unit Remarksarash esmaeiliNessuna valutazione finora

- Calibration Report for Digital ThermometerDocumento4 pagineCalibration Report for Digital ThermometerSherwin John NavarroNessuna valutazione finora

- Astm G 138 2006 PDFDocumento8 pagineAstm G 138 2006 PDFJORGE ARTURO TORIBIO HUERTANessuna valutazione finora

- Standard Densitometer Calibration ProcedureDocumento4 pagineStandard Densitometer Calibration ProcedureAjlan Khan100% (2)

- Analytical Balance SOPDocumento2 pagineAnalytical Balance SOPdivine productionNessuna valutazione finora

- Calibrating Piston PippetesDocumento7 pagineCalibrating Piston PippetesluigimasterNessuna valutazione finora

- 02-Calibration & Control of Measuring & Monitoring DevicesDocumento1 pagina02-Calibration & Control of Measuring & Monitoring DeviceskitekNessuna valutazione finora

- Temperature HandbookDocumento136 pagineTemperature HandbookGustavo SánchezNessuna valutazione finora

- Insulation Tester 1 CI 02 I2Documento13 pagineInsulation Tester 1 CI 02 I2ebbasinghNessuna valutazione finora

- CP No.401-IPRT CalibrationDocumento20 pagineCP No.401-IPRT Calibrationsirsa11Nessuna valutazione finora

- Cal Cert FormatDocumento6 pagineCal Cert FormatINSTRUCAL CALIBRATION SERVICESNessuna valutazione finora

- Calibrate BTU Meter CertificateDocumento1 paginaCalibrate BTU Meter CertificateEby JoyNessuna valutazione finora

- Gravity-Convection and Forced-Circulation Water Baths: Standard Specification ForDocumento2 pagineGravity-Convection and Forced-Circulation Water Baths: Standard Specification ForAhmed Alzubaidi0% (1)

- ISO 7027 Turbidity TechniqueDocumento2 pagineISO 7027 Turbidity TechniqueGustavo Sánchez0% (1)

- Temperature Measurement and CalibrationDocumento7 pagineTemperature Measurement and CalibrationMorosanu Andreea-DianaNessuna valutazione finora

- Stability and UniformityDocumento6 pagineStability and UniformitymegacobNessuna valutazione finora

- Mitutoyo Bore Gauge PDFDocumento12 pagineMitutoyo Bore Gauge PDFAnonymous 8rb48tZSNessuna valutazione finora

- 29-Stop Watch Calibration CartificateDocumento1 pagina29-Stop Watch Calibration CartificateCustomer SupportNessuna valutazione finora

- Determination of Color by SpectrocolorimeterDocumento11 pagineDetermination of Color by Spectrocolorimeternvithyarajan6872Nessuna valutazione finora

- Calibration Certificate for Digital Pressure GaugeDocumento2 pagineCalibration Certificate for Digital Pressure GaugeUmang SOdhiNessuna valutazione finora

- Calibrating Balances MLS Technical Guide 25Documento9 pagineCalibrating Balances MLS Technical Guide 25iptNessuna valutazione finora

- DKD Guidance - Calibration of Liquid WaterDocumento14 pagineDKD Guidance - Calibration of Liquid WatergustavoesanchezNessuna valutazione finora

- DKD R 6 2 t5 e PDFDocumento9 pagineDKD R 6 2 t5 e PDFDragan IlicNessuna valutazione finora

- Vaisala Humidity Conversion Formulas-EnDocumento17 pagineVaisala Humidity Conversion Formulas-Endpee27619438Nessuna valutazione finora

- Calibrating ultrasonic flowmeters independently of pipesDocumento18 pagineCalibrating ultrasonic flowmeters independently of pipesMARIANNessuna valutazione finora

- HumedadDocumento49 pagineHumedadCarlos Jose Sibaja CardozoNessuna valutazione finora

- Master sensor calibration certificateDocumento2 pagineMaster sensor calibration certificatemaniNessuna valutazione finora

- Uncertainty in Thermometer CalibrationDocumento6 pagineUncertainty in Thermometer CalibrationJoel Villasanta DeocaresNessuna valutazione finora

- PH Electrodes 2724 To 2726 From GF SignetDocumento6 paginePH Electrodes 2724 To 2726 From GF Signetguita riefNessuna valutazione finora

- Astm E145 1994 OVENDocumento4 pagineAstm E145 1994 OVENNinit MiyuNessuna valutazione finora

- KippZonen ISO9847 Calibration StatementDocumento1 paginaKippZonen ISO9847 Calibration Statementmoro1381Nessuna valutazione finora

- Thermomeer PDFDocumento7 pagineThermomeer PDFbharatheeeyuduNessuna valutazione finora

- Thermo CalibrationDocumento10 pagineThermo CalibrationAngelo De AsisNessuna valutazione finora

- Calibrate Liquid-in-Glass ThermometersDocumento10 pagineCalibrate Liquid-in-Glass Thermometersjuncar25100% (1)

- Somali National University: Mechanical Measurement (MM 3609)Documento28 pagineSomali National University: Mechanical Measurement (MM 3609)Omari AdamNessuna valutazione finora

- Experiment 1: TheoryDocumento7 pagineExperiment 1: TheoryFatimah Nik MazlanNessuna valutazione finora

- 1a: Measurement of Ice Mixture and Boiling WaterDocumento6 pagine1a: Measurement of Ice Mixture and Boiling WaterSalina ShaffieNessuna valutazione finora

- Turbidity Calibration of OBS - SensorsDocumento5 pagineTurbidity Calibration of OBS - SensorsGustavo SánchezNessuna valutazione finora

- Anccscetisomer 0611 PDFDocumento2 pagineAnccscetisomer 0611 PDFGustavo SánchezNessuna valutazione finora

- Temperature Handbook 1 To 4Documento31 pagineTemperature Handbook 1 To 4Ravi Kiran100% (1)

- Review of Temperature MeasurementDocumento20 pagineReview of Temperature MeasurementxeonixblueNessuna valutazione finora

- Realizing ITS-90 temperature calibrationDocumento48 pagineRealizing ITS-90 temperature calibrationGustavo SánchezNessuna valutazione finora

- The Nist Industrial Thermometer Calibration LaboratoryDocumento6 pagineThe Nist Industrial Thermometer Calibration LaboratoryGustavo SánchezNessuna valutazione finora

- Sp250-1 Spectral IrradianceDocumento69 pagineSp250-1 Spectral IrradianceGustavo SánchezNessuna valutazione finora

- Sp250-1 Spectral IrradianceDocumento69 pagineSp250-1 Spectral IrradianceGustavo SánchezNessuna valutazione finora

- Guía para El Uso de Fotografías en CB Report CTL-OP 107-Ed.1Documento3 pagineGuía para El Uso de Fotografías en CB Report CTL-OP 107-Ed.1Gustavo SánchezNessuna valutazione finora

- The Thermo Electric Temperature Measurement Designer's GuideDocumento310 pagineThe Thermo Electric Temperature Measurement Designer's GuideGustavo SánchezNessuna valutazione finora

- Booklet No. 13 - The Use of Indicator OrganismsDocumento48 pagineBooklet No. 13 - The Use of Indicator OrganismsGustavo SánchezNessuna valutazione finora

- Finnigan LCQ - Training ManualDocumento19 pagineFinnigan LCQ - Training ManualGustavo SánchezNessuna valutazione finora

- 1KW 30011 0 NanotechHandbookDocumento142 pagine1KW 30011 0 NanotechHandbookgfasfwgfedsNessuna valutazione finora

- 01 EURAMET Cg-8 V 2.1 Calibration of ThermocouplesDocumento19 pagine01 EURAMET Cg-8 V 2.1 Calibration of ThermocouplesGustavo Sánchez0% (1)

- SOP For GLNPO TurbidityDocumento8 pagineSOP For GLNPO TurbidityGustavo SánchezNessuna valutazione finora

- Turbidity ScienceDocumento26 pagineTurbidity ScienceGustavo SánchezNessuna valutazione finora

- Chemistry of FructoseDocumento12 pagineChemistry of FructoseGustavo SánchezNessuna valutazione finora

- QTOF ManualDocumento21 pagineQTOF ManualGustavo SánchezNessuna valutazione finora

- Simplified Testing For Lead & Copper in Drinking WaterDocumento12 pagineSimplified Testing For Lead & Copper in Drinking WaterfranciscoNessuna valutazione finora

- Calibration of ChronometersDocumento13 pagineCalibration of ChronometersGustavo SánchezNessuna valutazione finora

- Calibration of ChronometersDocumento13 pagineCalibration of ChronometersGustavo SánchezNessuna valutazione finora

- Calibration of ChronometersDocumento13 pagineCalibration of ChronometersGustavo SánchezNessuna valutazione finora

- Brookfield Rheometer ManualDocumento83 pagineBrookfield Rheometer ManualtehhimsterNessuna valutazione finora

- Programming Data For Spectrophotometer and Spectroquant Test Kits Measured With A Reference SpectrophotometerDocumento17 pagineProgramming Data For Spectrophotometer and Spectroquant Test Kits Measured With A Reference SpectrophotometerGustavo SánchezNessuna valutazione finora

- 8712 enDocumento2 pagine8712 enalpegambarliNessuna valutazione finora

- Volume 3 of 3 - Package-2Documento56 pagineVolume 3 of 3 - Package-2Pranoy BaruaNessuna valutazione finora

- Unit Conversion WorksheetDocumento2 pagineUnit Conversion WorksheetThea Sophia BuenoNessuna valutazione finora

- Assessment 9.1Documento1 paginaAssessment 9.1Kwen Ann OrtigzNessuna valutazione finora

- Conservation of MomentumDocumento8 pagineConservation of MomentumMat HafizNessuna valutazione finora

- Thessaloniki EstablishmentDocumento220 pagineThessaloniki Establishmentzedbolete6704Nessuna valutazione finora

- Physics2011 PDFDocumento16 paginePhysics2011 PDFceraNessuna valutazione finora

- Radiopharmaceutical Production: Cyclotron BasicsDocumento55 pagineRadiopharmaceutical Production: Cyclotron BasicsNURILNessuna valutazione finora

- Differentiation WorksheetDocumento2 pagineDifferentiation WorksheetSarahNessuna valutazione finora

- SEO-Optimized Title for Electrical Components DocumentDocumento3 pagineSEO-Optimized Title for Electrical Components DocumentJohan ChaconNessuna valutazione finora

- Motor and Generator Narrative Report - Group4 PDFDocumento18 pagineMotor and Generator Narrative Report - Group4 PDFJohn Lloyd ComiaNessuna valutazione finora

- All Questions of GT QuizzesDocumento10 pagineAll Questions of GT QuizzesnaumanNessuna valutazione finora

- MGVCL Internship 2Documento15 pagineMGVCL Internship 2Mihir Rana100% (2)

- 300kw Hybrid Solar System From BLUESUN Vicky20240116Documento1 pagina300kw Hybrid Solar System From BLUESUN Vicky20240116ghulam.abbasnoulNessuna valutazione finora

- 10th Class PhysicsDocumento2 pagine10th Class Physicsricha sonyNessuna valutazione finora

- Magnetostriction MichelsonDocumento6 pagineMagnetostriction MichelsonOktafiani Nurita SariNessuna valutazione finora

- Verifying Kirchhoff's Laws in DC CircuitsDocumento3 pagineVerifying Kirchhoff's Laws in DC CircuitsJaber Al Nahian70% (23)

- 5-KW Solar System QuotationDocumento1 pagina5-KW Solar System QuotationKidzee KidzeeNessuna valutazione finora

- Unr 3.3-8 D5Documento4 pagineUnr 3.3-8 D5Cheng Yi TsaiNessuna valutazione finora

- Manual Temporizador TH3M PDFDocumento10 pagineManual Temporizador TH3M PDFMauricio Barraza FigueroaNessuna valutazione finora

- 2011 GR 12 Phy Electrostatics-1Documento2 pagine2011 GR 12 Phy Electrostatics-1Tania LizNessuna valutazione finora

- Wind Tunnel Measurements of Cavity Pressure Dynamics in Low Rise Flexible Roof building-WEIADocumento22 pagineWind Tunnel Measurements of Cavity Pressure Dynamics in Low Rise Flexible Roof building-WEIAkostas formulagrNessuna valutazione finora

- PSO Based Technique For Loss MinimizatioDocumento6 paginePSO Based Technique For Loss MinimizatioVenkatesh PeruthambiNessuna valutazione finora

- Low Voltage Control CircuitsDocumento17 pagineLow Voltage Control CircuitsmersiumNessuna valutazione finora

- Air Filtration Technical ReferenceDocumento15 pagineAir Filtration Technical ReferenceMuhammad SaadNessuna valutazione finora

- VCRS RacDocumento15 pagineVCRS RacmonilNessuna valutazione finora

- 066 Alhqlcrloos 471 K 9 AgaytzqyyDocumento3 pagine066 Alhqlcrloos 471 K 9 AgaytzqyyledNessuna valutazione finora

- Reaffirmed 2019Documento8 pagineReaffirmed 2019Ashish DubeyNessuna valutazione finora

- Surge Arrester - Wikipedia, The Free EncyclopediaDocumento2 pagineSurge Arrester - Wikipedia, The Free EncyclopediaMuhammad Nico PermanaNessuna valutazione finora