Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Forming machine 250 shapes premium-quality products

Caricato da

agung24864Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Forming machine 250 shapes premium-quality products

Caricato da

agung24864Copyright:

Formati disponibili

www.vemag.

de

Flexible deployment

The forming machine is controlled

via the portioning computer of the

vacuum ller. The operator can vary

the size of the product by making

weight corrections on the portioning

computer. Forming nozzles which

are simply pushed on allow a wide

variety of shapes of product (e.g.

round, cylindrical, disc-shaped or even

individual shapes) to be made.

Potential uses

The forming machine can be operated

with the following llers:

ROBOT 500

ROBOT HP-series

All the benets at a glance

Suitable for a variety of products:

- rissoles

- burgers

- spiced mince ngers

- ribs

- nuggets

Shape of product simple to

change with push-on forming

nozzles

Product size easy to adapt by

making weight corrections on the

portioning computer

High product quality with good

texture and natural bite

Grinding and separating during

processing means a high level

of product safety

Minimal rework = high degree of

utilization of the raw material in

use

Minimal cleaning effort = lower

costs

The forming machine shapes products

from meat and vegetable mixes which

hold their shape.

Use

The forming machine is connected

directly to a VEMAG ller. A grinder

in between ensures a nal cut

immediately before the product is

shaped and isolated. A attening belt

gives the products the desired nal

height as they run on a conveyor belt.

The isolated products are then passed

on for further processing.

Premium-quality products

Products made with the forming

machine are characterized by a good

texture and natural bite. As the forming

machine pumps the raw material

extremely gently, meat bres are not

crushed or destroyed in contrast to

conventional manufacturing methods.

The meat bres in the nished product

retain their natural alignment so that

the end-product has the bite of a hand-

made speciality.

Integrating a grinder with an optional

automatic separation valve also ensures

that hard product constituents like

particles of bone, sinew or foreign

bodies are reliably removed from the

product.

Precisely formed products.

Do you make products from meat or vegetable mixtures

which can be formed like rissoles, beefburgers or spiced

mince ngers, for example?

Trust VEMAGs forming machine 250 and enjoy the

benets of a exible production line. Forget the limits of

conventional production processes and vary the shape and

size of your product using quick-change forming nozzles or

settings on the portioning computer of the vacuum ller.

Benet from minimal rework and a high degree of

utilization of the raw material in use.

Forming machine 250

Forming machine 250

Device for producing formed products

980

1

0

7

0 1

4

8

8

1

0

0

0

-

1

1

5

0

Technical data

V

E

M

A

G

2

0

1

0

W

e

r

e

s

e

r

v

e

t

h

e

r

i

g

h

t

t

o

m

a

k

e

t

e

c

h

n

i

c

a

l

m

o

d

i

c

a

t

i

o

n

s

2

5

0

.

2

.

E

N

0

3

/

0

7

Presented by:

VEMAG Maschinenbau GmbH

P.O. Box 1620, D-27266 Verden

Phone +49 42 31 - 77 70, Fax +49 42 31 - 77 72 41

http://www.vemag.de, e-mail@vemag.de

Types of product:

Product thickness:

Product weight:

Portioning rate:

rissoles, burgers, spiced mince ngers, ribs, nuggets

10 - 15 mm (rissoles)

15 - 25 mm (burgers)

20 - 30 mm (spiced mince ngers)

> 10 mm (ribs)

10 - 15 mm (nuggets)

60 - 125 g (rissoles)

60 - 125 g (burgers)

15 - 50 g (spiced mince ngers)

100 g (ribs)

10 - 30 g (nuggets)

up to 300 portions/min.

approx. 1260

approx. 4396

Potrebbero piacerti anche

- Aerial Robot Swarms: A ReviewDocumento9 pagineAerial Robot Swarms: A ReviewIAES International Journal of Robotics and AutomationNessuna valutazione finora

- Палетувальна XT 4505 Manual 1Documento33 pagineПалетувальна XT 4505 Manual 1Viktor YavtushenkoNessuna valutazione finora

- Maintenance Manual: MANUAL NUMBER 006-15545-0002 REVISION 2, December, 1999Documento181 pagineMaintenance Manual: MANUAL NUMBER 006-15545-0002 REVISION 2, December, 1999AndrewNessuna valutazione finora

- Manual of AD-WTS1206Documento20 pagineManual of AD-WTS1206Vũ Thế AnhNessuna valutazione finora

- Brochure Crane SmartDocumento8 pagineBrochure Crane SmartMichael LazarusNessuna valutazione finora

- RF DC Bias TeeDocumento15 pagineRF DC Bias TeechrisjennNessuna valutazione finora

- Star Evo en PDFDocumento93 pagineStar Evo en PDFferprissNessuna valutazione finora

- Cameron Orb Valve 01Documento28 pagineCameron Orb Valve 01Luis Pol SistiNessuna valutazione finora

- CAH Small Frame Air Hoist Manual 11720901Documento30 pagineCAH Small Frame Air Hoist Manual 11720901cj7man80Nessuna valutazione finora

- Hi-Vac (800 Series) Operations ManualDocumento57 pagineHi-Vac (800 Series) Operations ManualMatias Contreras KöbrichNessuna valutazione finora

- Manual ZIS SeriesDocumento113 pagineManual ZIS SeriesDennis Alexander Oseguera OsegueraNessuna valutazione finora

- 750-225 CBR 11 2015Documento156 pagine750-225 CBR 11 2015AmiyaNessuna valutazione finora

- Manual Masterplat - Plus - FRD - SeriesDocumento123 pagineManual Masterplat - Plus - FRD - SeriesAdan Hernández VicenciosNessuna valutazione finora

- Technical Guide CHVX GBDocumento36 pagineTechnical Guide CHVX GBJett AglipayNessuna valutazione finora

- WEN 4214 12-Inch Variable Speed Drill Press ManualDocumento24 pagineWEN 4214 12-Inch Variable Speed Drill Press ManualcaseykretschmanNessuna valutazione finora

- Vacuum Box Leak TestingDocumento6 pagineVacuum Box Leak TestingSivaraman SelvarajNessuna valutazione finora

- Decantador Intermedio IsDocumento38 pagineDecantador Intermedio IsAlessacolNessuna valutazione finora

- Instrucciones de Operacion BirielDocumento88 pagineInstrucciones de Operacion BirielCristhian RamirezNessuna valutazione finora

- 2.tekla Structures 2016i Administrator's Release NotesDocumento48 pagine2.tekla Structures 2016i Administrator's Release NotesomerumeromerNessuna valutazione finora

- Smoothies & Beyond: Recipes and Ideas for Using Your Pro-Blender for Any Meal of the Day from Batters to Soups to DessertsDa EverandSmoothies & Beyond: Recipes and Ideas for Using Your Pro-Blender for Any Meal of the Day from Batters to Soups to DessertsValutazione: 5 su 5 stelle5/5 (1)

- Instruction and Spare Part Manual: Type: Evolution Model: 1R.9.36.126 - Neck Handling YEAR: 2013 Ref.: BielorussiaDocumento524 pagineInstruction and Spare Part Manual: Type: Evolution Model: 1R.9.36.126 - Neck Handling YEAR: 2013 Ref.: BielorussiaVasiliyNessuna valutazione finora

- Vacuum Forming GuideDocumento29 pagineVacuum Forming GuideAnanda B UNessuna valutazione finora

- Variable Speed Electric Chain Hoist: Operating, Maintenance & Parts ManualDocumento68 pagineVariable Speed Electric Chain Hoist: Operating, Maintenance & Parts ManualScottNessuna valutazione finora

- O'Brien Met-Track Workstation Bridge CranesDocumento16 pagineO'Brien Met-Track Workstation Bridge Cranesdf_campos3353Nessuna valutazione finora

- INNOPACK KISTERS SP B SHRINK PACKER BASIC PACKAGINGDocumento2 pagineINNOPACK KISTERS SP B SHRINK PACKER BASIC PACKAGINGDrdbuoiu Poiñhb Monihugy100% (2)

- Ecofard 700 Aa MB PDFDocumento25 pagineEcofard 700 Aa MB PDFMichael George100% (1)

- Service Manual - Model Pp1808-28Documento56 pagineService Manual - Model Pp1808-28rasim_m1146Nessuna valutazione finora

- Manual Motores ICME Manual 07.2018Documento7 pagineManual Motores ICME Manual 07.2018Wanderson FIALHONessuna valutazione finora

- Neptune 7000Z IOM EnglishDocumento44 pagineNeptune 7000Z IOM Englisharisqi wahyuNessuna valutazione finora

- Blowing Wheel, Infeed/Discharge Starwheel: Contiform MaintenanceDocumento22 pagineBlowing Wheel, Infeed/Discharge Starwheel: Contiform Maintenancedavidwang8512Nessuna valutazione finora

- 2500-600 Down Feed Slitter Rewinder User ManualDocumento6 pagine2500-600 Down Feed Slitter Rewinder User ManualA.Magied MahmoudNessuna valutazione finora

- Krones AirCo The Air Conveyor For PET BottlesDocumento10 pagineKrones AirCo The Air Conveyor For PET BottlesfadyNessuna valutazione finora

- A New Dimension in Logistics in The Paper Industry: 24/7 Production and Logistics OperationDocumento8 pagineA New Dimension in Logistics in The Paper Industry: 24/7 Production and Logistics OperationChester SmithNessuna valutazione finora

- Hammer Mill Vertica PDFDocumento6 pagineHammer Mill Vertica PDFAditya Whisnu HeryudhantoNessuna valutazione finora

- Concept C-Series: Adhesive Melters The EconomicalsDocumento4 pagineConcept C-Series: Adhesive Melters The EconomicalsAhmed Awasha100% (1)

- Manual de Operacion OGB-3 英文说明书Documento68 pagineManual de Operacion OGB-3 英文说明书Gabriel Cab PaatNessuna valutazione finora

- 5266 Controls: Safety Exhaust (Dump)Documento12 pagine5266 Controls: Safety Exhaust (Dump)Julio Vazquez MorenoNessuna valutazione finora

- Hydraulic Lift Design RubricDocumento1 paginaHydraulic Lift Design Rubricapi-318809591Nessuna valutazione finora

- Cy 600 800gii PDFDocumento92 pagineCy 600 800gii PDFArmando Rivera100% (1)

- KBK BRDocumento36 pagineKBK BRJean-Pascal RossNessuna valutazione finora

- Manual Furadeira Radial Rd3050x16Documento56 pagineManual Furadeira Radial Rd3050x16rbocca123Nessuna valutazione finora

- CPV Process Valve ActuatorDocumento12 pagineCPV Process Valve ActuatormarklaforestNessuna valutazione finora

- En LASKADocumento13 pagineEn LASKASergiu Ionut LazarNessuna valutazione finora

- Cleaver Brooks - Cb-Le AnDocumento66 pagineCleaver Brooks - Cb-Le AnHarold Gutierrez LingánNessuna valutazione finora

- LASKA Industrial GrinderDocumento13 pagineLASKA Industrial GrinderLuthfi KhairuNessuna valutazione finora

- Husky H-Line Levelling & ParallelismDocumento22 pagineHusky H-Line Levelling & Parallelismgfplms50% (2)

- eSW-1200 eSW-1200s: Mechanical Edition For RobotDocumento44 pagineeSW-1200 eSW-1200s: Mechanical Edition For Robothung nguyenNessuna valutazione finora

- Angle Valve and Tap Assembly and Leak Test MachineDocumento7 pagineAngle Valve and Tap Assembly and Leak Test MachineJimmy KingNessuna valutazione finora

- Maintenance DCM SLITTING MACHINEDocumento4 pagineMaintenance DCM SLITTING MACHINEDeniMestiWidianto100% (1)

- Siwertell Ship Unloaders - Original - 33001 PDFDocumento6 pagineSiwertell Ship Unloaders - Original - 33001 PDFHarish KumarNessuna valutazione finora

- High-Performance Stretch Blow Molder: 1 - Innopet® Blomax Serie IvDocumento2 pagineHigh-Performance Stretch Blow Molder: 1 - Innopet® Blomax Serie IvSundar MoorthiNessuna valutazione finora

- For Position Control Applications: Your Ultimate Solution PartnerDocumento40 pagineFor Position Control Applications: Your Ultimate Solution PartnerAbhay AbhyankarNessuna valutazione finora

- EI 65 Install 8Documento17 pagineEI 65 Install 8Alex Bravo100% (1)

- Almig HL Range Operating ManualDocumento16 pagineAlmig HL Range Operating ManualAndy MitchellNessuna valutazione finora

- Apollo 10 TDocumento60 pagineApollo 10 TXavyer MoralesNessuna valutazione finora

- Ica 4 P301000-29-03-2017 enDocumento156 pagineIca 4 P301000-29-03-2017 enDiaconu MihaytzaNessuna valutazione finora

- MBL Volkmann Che Mag IsDocumento47 pagineMBL Volkmann Che Mag IsarizakarolNessuna valutazione finora

- Evisceration UKDocumento16 pagineEvisceration UKHelton OliveiraNessuna valutazione finora

- eSV + REFLEX CatalogueDocumento37 pagineeSV + REFLEX CatalogueFARAZamuNessuna valutazione finora

- LMI-IOM-3390089000-02.10 - SG-User-Manual PETARYDocumento56 pagineLMI-IOM-3390089000-02.10 - SG-User-Manual PETARYWilliam Melo100% (1)

- Netpack NP 350: Vertical Form, Fill and Seal MachineDocumento2 pagineNetpack NP 350: Vertical Form, Fill and Seal MachineJuan OrtegaNessuna valutazione finora

- LS ManualDocumento28 pagineLS ManualMd Sh100% (1)

- Sandwiching Performance, Like No OtherDocumento8 pagineSandwiching Performance, Like No OtherNeuro ToxinNessuna valutazione finora

- Vemag 500 Bakery BrochureDocumento4 pagineVemag 500 Bakery BrochureMilanVukicNessuna valutazione finora

- AKUATIK - Reducing Ammonia in Shrimp FarmsDocumento6 pagineAKUATIK - Reducing Ammonia in Shrimp Farmsagung24864Nessuna valutazione finora

- Pengaruh Penambahan Udang Putih (Penaeus Vannamei) TerhadapDocumento5 paginePengaruh Penambahan Udang Putih (Penaeus Vannamei) Terhadapagung24864Nessuna valutazione finora

- Studi Sebaran Sedimen Berdasarkan Ukuran Butir Di Perairan Kuala GigiengDocumento6 pagineStudi Sebaran Sedimen Berdasarkan Ukuran Butir Di Perairan Kuala Gigiengamelia ester sembiringNessuna valutazione finora

- BioremediationDocumento21 pagineBioremediationagung24864Nessuna valutazione finora

- Pelestarian Hutan MangroveDocumento7 paginePelestarian Hutan Mangroveagung24864Nessuna valutazione finora

- Eksplorasi Dan KonservasiDocumento6 pagineEksplorasi Dan Konservasiagung24864Nessuna valutazione finora

- Makalah Seminar Abon IkanDocumento10 pagineMakalah Seminar Abon Ikanagung24864Nessuna valutazione finora

- Bioactive Compounds From Zoanthids (Cnidaria - Anthozoa) - A Brief Review With Emphasis On AlkaloidsDocumento6 pagineBioactive Compounds From Zoanthids (Cnidaria - Anthozoa) - A Brief Review With Emphasis On Alkaloidsagung24864Nessuna valutazione finora

- Sea Cucumber ExtractDocumento8 pagineSea Cucumber Extractagung24864Nessuna valutazione finora

- Fishery BulletinDocumento7 pagineFishery Bulletinagung24864Nessuna valutazione finora

- Toy Shell AssignmentDocumento5 pagineToy Shell AssignmentPrafulla SaxenaNessuna valutazione finora

- Tieng Anh 10 Friends Global - Unit 8 - Test 2Documento8 pagineTieng Anh 10 Friends Global - Unit 8 - Test 2haminhpham1708Nessuna valutazione finora

- Model Cards For Model ReportingDocumento10 pagineModel Cards For Model Reportingoscar Julian Perdomo CharryNessuna valutazione finora

- Test Script 459680Documento9 pagineTest Script 459680Naresh KumarNessuna valutazione finora

- Harsh Environment UPS Features for Critical Industrial ApplicationsDocumento2 pagineHarsh Environment UPS Features for Critical Industrial Applicationsandy175Nessuna valutazione finora

- Visi Misi Ketos 20Documento11 pagineVisi Misi Ketos 20haidar alyNessuna valutazione finora

- KC130GT 1Documento2 pagineKC130GT 1aleenizzyNessuna valutazione finora

- Contactless Linear Position TransducerDocumento5 pagineContactless Linear Position TransducerRONALDECCONANessuna valutazione finora

- Churn Consultancy For V Case SharingDocumento13 pagineChurn Consultancy For V Case SharingObeid AllahNessuna valutazione finora

- Click To Edit Master Title Style Crawl, Walk, RunDocumento43 pagineClick To Edit Master Title Style Crawl, Walk, RunFlavio XongasNessuna valutazione finora

- Function X - A Universal Decentralized InternetDocumento24 pagineFunction X - A Universal Decentralized InternetrahmahNessuna valutazione finora

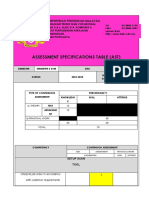

- Assessment Specifications Table (Ast) : Kementerian Pendidikan MalaysiaDocumento6 pagineAssessment Specifications Table (Ast) : Kementerian Pendidikan MalaysiaMohd raziffNessuna valutazione finora

- Online Dispute Resolution For Smart ContractsDocumento24 pagineOnline Dispute Resolution For Smart ContractsRidhima SharmaNessuna valutazione finora

- Nemo Windcatcher: Industry-Leading Drive Test Data Post-Processing and AnalysisDocumento2 pagineNemo Windcatcher: Industry-Leading Drive Test Data Post-Processing and AnalysistreejumboNessuna valutazione finora

- CEA201 CH11-DigitalLogicDocumento24 pagineCEA201 CH11-DigitalLogicTTNessuna valutazione finora

- Shopping CartDocumento40 pagineShopping CartveerusadarNessuna valutazione finora

- AI QuestionsDocumento2 pagineAI QuestionsNarender SinghNessuna valutazione finora

- LearnTube Project ReportDocumento14 pagineLearnTube Project ReportManogya Pratap SinghNessuna valutazione finora

- FSP150-50LE Is An Industrial Level of Switching Power Supply - SpecificationDocumento1 paginaFSP150-50LE Is An Industrial Level of Switching Power Supply - SpecificationJohn HallowsNessuna valutazione finora

- Mary PowellDocumento53 pagineMary PowellAnonymous HZgwzwNessuna valutazione finora

- Communication Signal Processing I Mini-ExamDocumento1 paginaCommunication Signal Processing I Mini-ExamSadiqur Rahaman SumonNessuna valutazione finora

- ABB Price Book 714Documento1 paginaABB Price Book 714EliasNessuna valutazione finora

- Company Profile PT Karta Bhumi Nusantara - 2023Documento22 pagineCompany Profile PT Karta Bhumi Nusantara - 2023Syarifuddin IshakNessuna valutazione finora

- TranslatorsDocumento3 pagineTranslatorsijas100% (1)

- Gravity WorkoutDocumento4 pagineGravity WorkoutMIIBNessuna valutazione finora