Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Building Construction Project 1

Caricato da

Cynthia LeeCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Building Construction Project 1

Caricato da

Cynthia LeeCopyright:

Formati disponibili

CYNTHIA LEE SIAW WUN 0306112

DEIDRE ZHANG SHU-WEI 0304619

GAN SUE JING 0307957

LEE JIA XIN 0308389

WONG YOKE LIN 0308254

BSc (HONS) ARCHITECTURE

BUILDING CONSTRUCTION 2

[ARC 2513]

PROJECT 1

UNDERSTANDING FORCES IN SKELETAL

STRUCTURE

CONTENT PAGE

EXPLORING PROCESS 1

LOAD TEST 1 2

LOAD TEST 2 3

FINAL LOAD TEST 4

load distribution 5

orthographic drawings 6

design improvement 7

conclusion 8

references 9

l

A bracings, also known as chevron brace

Chevron bracings require a high level of accuracy and consistency in construc-

tion, and also the transfer point of the load on the bracing is very concentrated.

Thus, we cannot full the requirement due to the inconsistency in tying and

joining of the popsicle sticks, causing a high possibility for the tower to break at a

light weight.

EXPLORING PROCESS

BRACING

JOINING

For the rst experimentation, popsicle sticks were tied together and small slits were cut to better hold

the thread. Later on, it was discovered that this method was ineffective as the structure had no proper

intersections at the joints and was not secure enough.

For the second experimentation, interlocking joints were used. This new structure was more stable

than the rst as there were proper holds to support loads as well as keep the model together.

For the nal experimentation, popsicle sticks were cut and holes were drilled for further reinforcement

of joints. The cut popsicle sticks were layered and joined to serve as columns. The interlocking pop-

sicle sticks served as frames. Bracings were added as well. Toothpicks were used as a joint system.

For the nal reinforcement measure, the joints were bound by thread.

X bracings, combining with channel bracing

With this kind of bracing, our rst testing model did not last a lot of weight load.

One of the reasons is due to the horizontal force leading to topple of the tower.

Other than that, joining point of columns, beams and bracings were not tied

together thus the components of the tower scattered in a short period of time.

X bracings

With X bracings all around the tower, the second testing model withstood more load,

up to 85kgs. With x bracings all around with thread bringing the joints together, it was

denitely mode rigid. The second testing model toppled due to failure of load transfer

directly from column to column.

2

LOAD TEST 1

For the rst trial load test, the model withstood 20kg at the height of only 20cm.

The reason why the mockup model did not reach the height requirement was

because we wanted to test the strength of the skeletal structure and the joining

systems. The model collapsed due to the inappropriateness of bracing. The

model was only supported by pinning and interlocking systems with no rein-

forcements of tying with thread.

Height: 20cm

Mass: 45g

Number of sticks: 52

Maximum load: 20kg

Efciency: 8.89

progress

2.5KG 10.0KG 14.0KG 20.0KG

LOAD TEST 2

progress

For the second load test, the model withstood 85kg at the height of 20cm as

well. The model collapsed because the columns did not connect with one an-

other therefore load does not directly transfer to the ground, separating at the

point where both meet.

Height: 20cm

Mass: 70g

Number of sticks: 56

Maximum load: 85kg

Efciency: 24.2857

20.0KG 55.0KG 70.0KG 85.0KG

=

FINAL LOAD TEST

Final load test The nal model withstood 125kg. It collapsed due to one weak point

of the columns where the layering was not strong enough and lacked reinforce-

ment. The second reason is because the loads were slightly shifted as they were

being stacked on the model. It is believed that the models load-bearing ability was

not tested to its full potential.

Height: 30.2cm

Mass: 120g

Number of sticks: 92

Maximum load: 125kg

Efciency: 31.46

progress

20.0KG 65.0KG 95.0KG 125.0KG

5

Once the load is applied on top of the structure, it is evenly distributed onto the top surface.

The load is directly transferred down to the columns. The load is also transferred to the brac-

ings which connect the columns and the girders together.

Bracings are a form of reinforcement applied in the construction technique. Cross bracing

allows diagonal supports to intersect to resist tension and compression forces. When cross

bracing is used, lateral force from one direction induces tension in one brace while the other

brace is in tension when the force is reversed.

Therefore, if two diagonals are used in the form of cross-bracing, they only need to resist ten-

sion. When one brace is in tension, compression will be applied to the other. However, the

slender compressive brace immediately sheds this compression by buckling out of plane to

avoid the force. Thus, the other brace then has to take 100% of the lateral force in tension.

Therefore, the compressive brace may be ignored.

The diagonal supports also intersect with the girders, which serve as the horizontal support,

connecting all the layers of the whole structure together with the columns. Thus, the force is

transferred diagonally down the structure through the bracings and to the girders, then to the

columns and down to the ground.

LOAD

LOAD TRANSFER

LOAD DISTRIBUTION

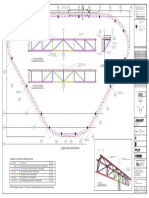

orthographic drawings

PLAN

LEFT ELEVATION RIGHT ELEVATION FRONT ELEVATION REAR ELEVATION

7

design improvement

After nal load test, we tried to gure out ways to improve the

model design. Firstly, the problem with the model is that the

columns did not erect 90* vertically. When constructing model,

bracings and horizontal members were secured together rst,

then adjusting the columns in accordingly. This caused the col-

umns to conform to the order of the bracings and vertical struc-

ture, causing it to twist slightly. Thus, the whole structure of the

tower was slightly imbalanced and twisted; load could not be

transferred directly to the ground. To solve this problem, col-

umns have to be erected rst, and then bracings and horizontal

members should be xed accordingly after.

Other than that, X bracings are only added at the rst, third and

fth layer of the tower. In addition to the slightly twisted columns,

bracings were not sufcient, causing it to twist further and col-

lapse. X bracings perhaps should be applied to every layer of the

tower.

Columns were constructing by combining three layers of pop-

sicle sticks together. They were sandwiched together and are

joined with toothpicks in a sequence. At a point of the columns,

it has only one popsicle stick that is transferring the load. Thus

it became a weak point to the column structure. During the -

nal load test, the main reason the tower collapse was due to

breakage of columns. To solve the problem, columns should be

stacked in a way that none of the point of the column has only

one layer of popsicle stick transferring the load.

8

This project was a test of critical and logical thinking whilst bearing in

mind the creative aspect as the project required not only functionality

but aesthetic value as well.

Throughout the model making process, we researched skeletal struc-

tures and studied the relationship between forms and load-bearing

capacities. Through such research and studies, we were able to apply

construction methods and mechanisms in design and understand the

implications of such methods to the structure.

After conducting several experiments and analysis of causes of fail-

ures, we were able to identify the methods to achieve higher capabili-

ties of strength, stiffness and stability in the structure. We also studied

how load is transferred down the structure as well as how forces and

stresses affect the structure. We identied the weak points and aws

in our design and construction methods and modied the structure

until a strong enough skeletal structure was achieved.

This assignment has taught us plenty and allowed us to gain a better

understanding of skeletal construction methods and their importance

in construction and/or design.

conclusion

9

Ching, Francis D.K. 2008. Building Construction Illustrate. 4th Edition. New Jersey. John

Wiley & Soons, Inc.

Bsci Capstone. 2014. Auburn, Alabama. Lateral Stability of Structures. Retrieved from

https://fp.auburn.edu/heinmic/StructuralStability/bracing.htm

references

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- GRC BrochureDocumento62 pagineGRC BrochurefazyroshanNessuna valutazione finora

- Interior Design StylesDocumento16 pagineInterior Design StylesCric Sports BDNessuna valutazione finora

- Macsteel Trading Structural Steel CatalogueDocumento36 pagineMacsteel Trading Structural Steel CatalogueAndrew Mwamba80% (5)

- Building Construction Project 2 ReportDocumento20 pagineBuilding Construction Project 2 ReportCynthia Lee100% (1)

- Park Royal Hotel, Singapore AnalysisDocumento32 paginePark Royal Hotel, Singapore AnalysisCynthia Lee100% (4)

- ACI Catalogue 2002Documento104 pagineACI Catalogue 2002renramaNessuna valutazione finora

- EC2 - Combined Shear TorsionDocumento14 pagineEC2 - Combined Shear TorsionNgô Khánh Tiển100% (1)

- Edoc - Pub Solman Cost Accounting 1 Guerrero 2015 Chapters 1Documento46 pagineEdoc - Pub Solman Cost Accounting 1 Guerrero 2015 Chapters 1Jenevie CacayorinNessuna valutazione finora

- Building Construction FinalDocumento1 paginaBuilding Construction FinalCynthia LeeNessuna valutazione finora

- Setia International Centre AnalysisDocumento36 pagineSetia International Centre AnalysisCynthia LeeNessuna valutazione finora

- Government Rest House ReportDocumento136 pagineGovernment Rest House ReportCynthia LeeNessuna valutazione finora

- Government Rest House Photo BookDocumento126 pagineGovernment Rest House Photo BookCynthia Lee0% (1)

- Government Rest House Presentation SlidesDocumento62 pagineGovernment Rest House Presentation SlidesCynthia LeeNessuna valutazione finora

- Problem StatementDocumento6 pagineProblem StatementHailemariam WeldegebralNessuna valutazione finora

- Supply Chain CerealDocumento6 pagineSupply Chain Cereal'Anabel LeslyNessuna valutazione finora

- Beam To Beam Pinned SH-300Documento2 pagineBeam To Beam Pinned SH-300Tri Aditha NugrahaNessuna valutazione finora

- William PerryDocumento27 pagineWilliam Perryzara100% (1)

- Gridshell - Edge Truss Steel Size Legeccd: CC11 CC12 CC13 CC14 CC15 CC16 CC17 CC18 CC19 CC20 CC21 CC22 CC23Documento1 paginaGridshell - Edge Truss Steel Size Legeccd: CC11 CC12 CC13 CC14 CC15 CC16 CC17 CC18 CC19 CC20 CC21 CC22 CC23Faisal MuhammadNessuna valutazione finora

- Protectosil-Overview - JJIIDocumento3 pagineProtectosil-Overview - JJIIbhisma.nugerahNessuna valutazione finora

- Boundary Column Fire Design ExampleDocumento1 paginaBoundary Column Fire Design Examplesaman2580Nessuna valutazione finora

- RKG - The Ultimate Guide - EN PDFDocumento19 pagineRKG - The Ultimate Guide - EN PDFZoranNessuna valutazione finora

- Objective:: Experiment No. 3Documento4 pagineObjective:: Experiment No. 3T.MNessuna valutazione finora

- Superslim RMD Kwikform Hong Kong 16751 LowDocumento21 pagineSuperslim RMD Kwikform Hong Kong 16751 Lowtmg016Nessuna valutazione finora

- A. Requires Add-On Cost, Refer To MatrixDocumento13 pagineA. Requires Add-On Cost, Refer To MatrixJoshua GimaoNessuna valutazione finora

- Calcul Des Structures Acier: Eurocode 3 (ENV 1993-1-1:1992)Documento12 pagineCalcul Des Structures Acier: Eurocode 3 (ENV 1993-1-1:1992)khaoula bezzineNessuna valutazione finora

- Keselamatan Angkat AngkutDocumento42 pagineKeselamatan Angkat AngkutD Firansyah100% (1)

- Calculation Project HighwayDocumento15 pagineCalculation Project HighwayAliya OthmanNessuna valutazione finora

- Module 6 Training Module On Material Management Final1Documento28 pagineModule 6 Training Module On Material Management Final1Tewodros Tadesse100% (1)

- Pratt Truss ('N' Truss) : A Truss Is Essentially A Triangulated System of Straight Interconnected Structural ElementsDocumento3 paginePratt Truss ('N' Truss) : A Truss Is Essentially A Triangulated System of Straight Interconnected Structural Elementsaditi goenkaNessuna valutazione finora

- Cad Floor Plan-P1Documento1 paginaCad Floor Plan-P1raymond erasmoNessuna valutazione finora

- Group 9 - High Rise StructuresDocumento14 pagineGroup 9 - High Rise StructuresAarohi Sharma100% (1)

- Dead Load:: L L L L L LDocumento2 pagineDead Load:: L L L L L LJenna Mortel-DoligolNessuna valutazione finora

- EG Week 12 (1) (Autosaved)Documento36 pagineEG Week 12 (1) (Autosaved)Sachi DhanandamNessuna valutazione finora

- 525 AndrewsDocumento86 pagine525 Andrewsthe next miamiNessuna valutazione finora

- Excavation of BasementsDocumento32 pagineExcavation of Basements04BHANDIWAD SANJANANessuna valutazione finora

- Mughal Sheraton HotelDocumento2 pagineMughal Sheraton HotelSaumya BansalNessuna valutazione finora