Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PSV

Caricato da

veerappapanchalDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

PSV

Caricato da

veerappapanchalCopyright:

Formati disponibili

PSV Reaction Forces and Direction

Miyamoto

Member

Registered:

09/13/11

Posts: 69

Loc: Brazil

Hi all,

I know this issue is an old discussion in this forum, but I have a lot of doubts

yet. I read a lot of thread but no one solved my problem. I didn't find threads

considering open discharge system for liquids. So, I'm here again. I'll be glad if

someone can answer any question.

First, my system consists in a single PSV (PRV to be more exact) in a pipeline

with water and Open Discharge System.

My question is:

I contacted some vendors and everybody said me the same: "For open discharge

system, the pressure at exit pipe is almost atmospheric". I think CAESAR II

uses ASME B31.1 equation for force calculations:

F1 = (W*V1)/gc + (P1 - Pa)*A1

Being, P1 the static pressure at exit pipe, and this value is almost 1 kgf/cm2, the

second term will be zero.

So,

F1 = (W*V1)/gc

In other words this force may be calculated only with mass flow vs fluid sonic

velocity?

Someone knows any equation that I can calculate pressure at exit pipe and fluid

sonic velocity for liquid? All equations that I saw is specific for vapor/gases.

Vendors said me also, for liquids the PSV don't "pop". Is this right?

For conclude, the only reaction force that acts in this system is F1 and this force

is applied in last elbow of pipe exit?

Thanks in advance,

Miyamoto

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#50313 - 08/18/12 01:40 AM Re: PSV Reaction Forces and Direction [Re: Miyamoto]

mariog

Member

For liquid, the flow does not accelerate to sonic speed in the exit section, so in

your case

exit_speed=[vol flow-rate]/[exit area]

Registered:

09/29/07

Posts: 333

Loc: Romania

You must know the mass flowrate and density and calculate the volumetric

flowrate- anyway this info is specific to PRV "process" calculation.

You may evaluate dP (difference between pressure in the protected equipment

and pressure in exit section) by Bernoulli; an approximate form is:

exit_speed=SQRT(2*dP/Density)

Just as a little more advanced topic: to calculate dP seems to be very simple,

however the "trick" here is based on the fact a correct "process" calculation

already considers the actual dP when evaluate the actual flowrate- so when we

know the actual flowrate we know also dP and by calculation we count also the

energy lost through PSV/PRV. I would add that a process calculation is not

focused on the "actual flowrate" but to a conservative procedure to select

PSV/PRV orifice and the last step- a calculation with actual orifice isn't

performed under normal circumstances... eventually your calculation is strong

linked to the quality of that process calculation. So isn't so simple, but the

conclusion is you may go ahead based on the process calculation!

You may review this post where is discussed a result from Cheresources. For

your case that "D" is the diameter of exit section.

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#50321 - 08/18/12 04:19 PM Re: PSV Reaction Forces and Direction [Re: Miyamoto]

mariog

Member

Registered:

09/29/07

Posts: 333

Loc: Romania

About the explanation on Pressure discharge in the end of PSV liquid piping, I

should have explained it better- even it is not a "big issue".

Rigorously speaking, Bernoulli equation has to include also the pressure loss

through PSV and also pressure loss through inlet piping and discharge piping of

PSV (for the last ones their values are limited by constructive rules).

By PSV Liquid Sizing procedure, the difference between pressure in the

protected equipment and pressure in discharge section (lets say it is "DP") is

the basis of the calculation of the PSV minimum required orifice area. That

means that the basis of PSV orifice dimensioning is the idea that PSV shall

consume almost all that DP. It would follow that the discharge pressure is near

"zero"- as your Vendor said.

However, the calculation of PSV orifice includes coefficients to dimension the

orifice a little bit larger than necessary, and in the end, it is selected a

"commercial" (standardized) PSV orifice valve bigger than the calculated one.

Consequently, PSV will be a "hydraulic resistance" with a value less than is

required and that means also the flow-rate will be greater that it was counted as

"required to relief" the equipment.

Normally, the calculation does not consider "actual values", since the

calculation goal is to dimension the PSV and this is achieved by the calculation

algorithm. However, if you want to see how much is the pressure discharge, you

have to repeat the hydraulic calculation with the actual orifice, actual PSV

coefficients, actual piping configuration, liquid viscosity, etc and the result of

that hydraulic calculation will show also the actual flow-rate released. In my

opinion, this is far exceeding the stress engineer duty and its likely that

"process" department will not be supporting you for a calculation that is

"unnecessary" for them...

I would underline that the above written ideas are specific to liquid PSVs. For

gas or steam, a supplementary issue is the fact the fluid accelerates to critical

speed and density is also changed, so a calculation of "exit pressure" must

follow other rules than a simple hydraulic calculation specific to liquids.

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#50334 - 08/20/12 08:00 AM Re: PSV Reaction Forces and Direction [Re: Miyamoto]

Miyamoto

Member

Registered:

09/13/11

Posts: 69

Loc: Brazil

mariog,

Thank you very much. You explanation was very clear.

Due relief is very slowly for liquid, I can't consider "pop condition" right? So, what

is the direction of these forces? I understand should have a reaction force against

pipe direction acting on valve and another in last elbow of the system. Please, look at

draft attached.

At node 10 only F2 act (DLF x F1)

At node 20 all forces are balanced.

At node 30, vertical force is balanced and horizontal force act at the elbow.

Is my understand right?

Regards,

Miyamoto

Attachments

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#50346 - 08/20/12 11:20 AM Re: PSV Reaction Forces and Direction [Re: Miyamoto]

Miyamoto

Member

Registered:

09/13/11

Posts: 69

Loc: Brazil

Forgot to mention, CAESAR II uses flow velocity at orifice to calculate Thrust

Force. So, may I use this velocity as v1 (exit velocity at Point 1)?

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#50355 - 08/21/12 01:32 PM Re: PSV Reaction Forces and Direction [Re: Miyamoto]

mariog

Member

Registered:

09/29/07

Posts: 333

Loc: Romania

The "reaction force" formula (as is given in B31.1, for example) is linked to the

"free jet" assumption. So the horizontal force in node 30 is a steady-state force

as a consequence of the third law of dynamics.

At node 10 you may consider a similar horizontal force; however that means

you consider there is a free-jet downstream PSV/PRV.

Velocity is [v-orifice]=[vol flow-rate]/[orifice-area],

multiplying by mass-flow-rate gives a force, etc.

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#50362 - 08/22/12 01:49 AM Re: PSV Reaction Forces and Direction [Re: Miyamoto]

danb

Member

Registered:

04/22/05

Posts: 1059

Loc: ...

One side note. If is liquid, the dowstream line need to go down, not up.

_________________________

Dan

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#50369 - 08/22/12 06:47 AM Re: PSV Reaction Forces and Direction [Re: Miyamoto]

Miyamoto

Member

Registered:

09/13/11

Posts: 69

Loc: Brazil

danb,

I need downstream up because this line will discharge in a open tank that is a

little bit tall.

May I have any problems with downstream up?

Regards,

Miyamoto

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#50390 - 08/23/12 02:26 AM Re: PSV Reaction Forces and Direction [Re: Miyamoto]

danb

Member

The line need to be self-draining.

Registered:

04/22/05

Posts: 1059

Loc: ...

In your case you need to place the psv at an elevation above the tank, then to go

down with the discharge line.

_________________________

Dan

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#50393 - 08/23/12 06:48 AM Re: PSV Reaction Forces and Direction [Re: Miyamoto]

Miyamoto

Member

Registered:

09/13/11

Posts: 69

Loc: Brazil

danb,

As mentioned in API 520, I can install a manual drainage at discharge line.

Regards,

Miyamoto

Edited by Miyamoto (08/23/12 06:50 AM)

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#50394 - 08/23/12 07:04 AM Re: PSV Reaction Forces and Direction [Re: Miyamoto]

danb

Member

Registered:

04/22/05

Posts: 1059

Loc: ...

Then you do not need the tank.

_________________________

Dan

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#50620 - 09/05/12 10:46 AM Re: PSV Reaction Forces and Direction [Re: Miyamoto]

Ltorrado

Member

Registered:

10/19/10

Posts: 10

Loc: Metairie,

LA

I would like to open this topic back up regarding the proper method of

perfmorming a "static analysis" on relief valve discharge piping. We have an

ongoing discussion at work on how to do it. My opinion is that, when dealing

with a discharge pipe that has multiple turns before it discharges either to

atmosphere or to a larger relief header, all the vector forces should NOT be

applied at the same time but instead as different vectors AT different points in

time (i.e F1 at t1, F2 at t2, etc.). Of course, assuming F1 = F2 = F3 if cross

sectional area stays constant throughout.

So let's say you have Miyamoto's piping but relief being passed is gas. I agree

the fluid will be traveling at extremely high velocities, but unless the spools are

very short, the metal will NOT feel these at the same time (even if it's only

miliseconds). But yet I see everyone's standard practice is to apply them all at

once at every turn in direction as one single vector force (F1 at t1, t2, t3, etc.).

There is one post in particular from Loren Brown that I believe backs my

reasoning up, see below:

"For an open system, if you have more than one bend in your vent stack then

apply this force at each bend under a separate load vector.

For a closed system you would apply this force on bends on each long leg of

pipe. The only way to truly figure out which pipe leg is short enough to ignore

the PSV force is to run the force/time profile through Caesar II's DLF generator

in the dynamics module, but then you might as well perform this analysis

dynamically. For short pipes the duration of the unbalanced PSV force is small

and this shifts the DLF peak to the right (higher frequency) which at some point

is past the majority of your piping system natural frequencies of interest. But if

you are going to do this statically you might simply take the nine longest pipe

legs and apply your force to each bend corresponding to these longest legs. This

would be the "brute force" approach, not really an approach based on physics.

You have 9 different force vectors to choose from so apply your PSV force

under a different force vector for each bend because we want to only examine

the effect on one bend at a time. Then set up separate OPE cases that include

your different force vectors."

Ignoring the calculation method of the actual thrust loads (which I calculate

based on Process Engineering's computer modeled fluid conditions at discharge

of PSV and at downstream points and also applying a conservative DLF of 2.0),

what do the experts think is the correct way of doing this static analysis?

Shouldn't it be like this (in Miyamoto's example):

L1 = W+P1+T1 (OPE)

L2 = W+P1+T1+F1 (OPE)

L3 = W+P1+T1+F2 (OPE)

L4 = W+P1+T1+F3 (OPE)

L5 = W+P1+T1+F4 (OPE)

L6 = W+P1 (SUS)

L7 = L1-L6 (EXP)

L8 = L2-L1 (OCC) segregated effect of F1

L9 = L3-L1 (OCC) segregated effect of F2

L10 = L4-L1 (OCC) segregated effect of F3

L11 = L5-L1 (OCC) segregated effect of F4

L12= L6+L8 (OCC) use Scalar Combination Method

L13= L6+L9 (OCC) scalar combination

L14= L6+L10 (OCC) scalar combination

L15= L6+L11 (OCC) scalar combination

Thanks.

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#50636 - 09/06/12 04:39 AM Re: PSV Reaction Forces and Direction [Re: Ltorrado]

mariog The reaction force as a result of a free jet existence is "physics" and nobody can

Member

Registered:

09/29/07

Posts: 333

Loc: Romania

deny it.

The assumption F1 = F2 = F3= reaction force of "free jet" as describing the

"traveling wave" is not "physics", is just an assumption based on our limited

knowledge about the real phenomenon- this is my opinion.

Of course, nothing wrong to be conservative; the only question is how we can

realize when we are too conservative...

But when it works with a reasonable piping layout , will be OK.

Best regards.

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#50641 - 09/06/12 07:47 AM Re: PSV Reaction Forces and Direction [Re: Miyamoto]

Ltorrado

Member

Registered:

10/19/10

Posts: 10

Loc: Metairie,

LA

As I feared, we are steering away from the static analysis method topic and

more into the fluid dynamics and physics of the phenomenon. I always say

begin doing analysis very conservatively, and if you encounter problems, only

then begin to step away from conservatism and more into "reality".

Now when the gas exits the relief valve it will lose most of its pressure due to

frictional losses in the initial length of the discharge piping. As the gas travels

down the piping it will lose pressure, which will lower the density, and in turn

will increase velocity. So the assumption of F1 = F2 = F3 is not "real" because

as the flow reaches higher velocities, the thrust load will increase. That is why I

tell our Process Engineers to provide us with the maximum velocity exhibited in

the discharge piping which in a closed system is usually right before entering

the larger diameter relief header.

As far as the DLF goes, I begin with a conservative 2.0 and only in situations

where I am forced to reduce the thrust loads due to problems do I start looking

at PSV opening times, piping periods, etc. to calculate an approximate DLF.

And correct me if I'm wrong, but doesn't the DLF stem from the traveling

pressure wave due to the unbalanced system pressures?

But what I am more interested really is the way of applying these loads in

CAESAR if you are not performing the dynamic analysis. I have not found

much guidance in COADE's literature. The best advice I've encountered is

Loren's method I quoted above.

Regards.

Edited by Ltorrado (09/06/12 07:48 AM)

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#50644 - 09/06/12 09:06 AM Re: PSV Reaction Forces and Direction [Re: Ltorrado]

mariog

Member

It seems you are interested in the implementation of these loads in CAESAR

static analysis.

Mr. Loren Brown has a post where he detailed the procedure:

Registered:

09/29/07

Posts: 333

Loc: Romania

http://65.57.255.42/ubbthreads/ubbthreads.php?ubb=showflat&Number=2148

About flow dynamics you've mentioned. IMO the gas that exits the relief valve

already lost most of its pressure due to frictional losses in PSV. Is not a rule the

fluid will accelerate so much in the initial length of the discharge piping, it will

accelerate in the end of system where the boundary conditions offers conditions

for such acceleration to critical speed. As you said, some software is available

for steady state calculation. About the transient calculation for gases exiting the

PSV- well... this is an endless discussion.

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#52507 - 01/16/13 02:32 AM Re: PSV Reaction Forces and Direction [Re: Miyamoto]

danb

Member

Registered:

04/22/05

Posts: 1059

Loc: ...

Is anyone that saw this paper: "Flow Reaction Forces upon Blowdown of Safety

Valves"?

What formula use?

In addition it mention a tee piece at the outlet but this is not a common layout,

even it sound quite interesting.

Regards,

_________________________

Dan

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#52538 - 01/18/13 05:09 AM Re: PSV Reaction Forces and Direction [Re: Miyamoto]

SJ

Member

Registered:

11/14/09

Posts: 163

Loc: India

Dan,

The reasoning behind using a tee at the outlet end is to nullify the forces which

are of equal maginitude.

I,too, was naive on this issue till I found such layouts in my current

organisation.

Seems, interesting...huh...

_________________________

Keep Smiling

SJ

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#52539 - 01/18/13 05:29 AM Re: PSV Reaction Forces and Direction [Re: Miyamoto]

danb

Member

Registered:

SJ,

There are also some PSV with two discharge nozzles at 180 degree.

04/22/05

Posts: 1059

Loc: ...

My question is: Why is not a standard layout if the advantage exists? Still, it is

not common.

_________________________

Dan

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#52584 - 01/21/13 08:02 AM Re: PSV Reaction Forces and Direction [Re: danb]

Ltorrado

Member

Registered:

10/19/10

Posts: 10

Loc: Metairie,

LA

I've only seen the dual-outlet type tail pipes a couple of times. It is definitely not

standard practice.

Although how much of a benefit would it really be? It would seem that you

would still experience the impact force due to the momentum of the fluid hitting

the end before shooting out the sides. It would also seem that you'd need some

kind of clamp or something to dampen the vibrations from a possible imbalance

upon the fluid exits to atmosphere. Only in theory it would cancel the forces out

perfectly.

Top Reply Quote Quick Reply Quick Quote Notify Email Post

Search Results

Quick Reply:

HTML is

enabled

UBBCode is

enabled

Add

Signature

Dear All,

there is some issue that i need to clarify in this forum since i see that many

expert in Piping Stress Engineering and COde Committe are visited this forum.

The issue is about Force on PSV Closed system.

As what i know that Force that show up when PSV in closed system begin to

firing is including in Impact Force so it is a dynamic event, but still we can use

the quasi static method to analyze it by use the DLF factor.

As long as i know this event also not a static condition because the pressure will

change rapidly when the PSV first firing.

The problem of my concern is for this PSV Closed system i usually used and

consider not only the first impact/unbalanced forced in first elbow or

obstruction but also in the second elbow and other downstream this PSV.

I also read in Peng book, that he mentioned that the event when PSV in closed

system firing still consider as Non static condition, so from here i can take the

conclusion there will be no Balanced force, it means Impact force will occurs in

each elbow or obstruction but in opposite direction.

We can measure each of this Force if we know the opening time of the PSV and

multiply it with the length of each pipe section to get the Max. Unbalanced

force in each elbow or obstruction.

But here in my new assignement i found a different method for client method,

where Force downstream of PSV (other than force on first elbow) are consider

to be balanced each other.

I also found this method in one Engineering company that become a trade mark

for Piping Engineering.

So for all Expert and Collegues here, i ask for your advice, amybe opinion about

this Issue.

Hope that it can give another value for all of us here.

Thanks.

With Regards

Nalibsyah

Top

Reply Quote

Quick Reply

Quick Quote

Notify Email

Post

#40429 - 01/25/11 04:22 AM Re: PSV Closed system Force [Re: Nalibsyah]

stressguy8

1

Member

Registered:

07/03/08

Posts: 71

As per API 520 Part 2, Cl. 4.4.2

"

Pressure-relief devices that relieve under steady-state flow conditions into a closed

system usually do not transfer large forces and bending moments to the inlet system,

since changes in pressure and velocity within the closed system components are

small.

Loc: India .....

A complex time history analysis of the piping system may be required to

obtain the reaction forces and associated moments that are transferred to the inlet

piping system."

As you said in general practice, the momentum component is imposed as a reaction

force at PSV.

generally divided as two cases,

Case1: When PSV pops up (Force imposed at PSV) and

Case2: When there is established flow (When the forces cancel each other)

You might find this topic interesting

http://65.57.255.42/ubbthreads/ubbthreads.php?ubb=showflat&Number=11775#Post

11775

http://65.57.255.42/ubbthreads/ubbthreads.php?ubb=showflat&Number=24685#Post

24685

I case of having a long run reaction forces can be imposed at the first elbow at a

different case, ex: F1 at PSV and F2 at first elbow in the establised flow condition,

conservatively.

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#40430 - 01/25/11 06:35 AM Re: PSV Closed system Force [Re: stressguy81]

mariog

Member

Registered:

09/29/07

Posts: 333

Loc: Romania

The only accident with PSVs in closed systems I know it is one in which the

PSV was wrong chosen and was chattering for years before piping was broken.

It was a fatigue damage "assisted" by poor supports- this was the conclusion of

investigations. In my opinion it would have been avoided by common sense

process/piping experience but also by field operators feedback.

Reversing the point of view, you can see in field PSV arrangements that cannot

be qualified by today calculations but have had a satisfactorily service for long

time.

I think any calculation for PSV in closed systems is good because offers the

opportunity to review the related piping and helps providing stiff supports. For

this point of view the calculation must be encouraged.

In the same time, Im in doubt that 99% of these calculations would simulate

what its happening in field with PSV in a closed system. That's why I don't

want to say one approach is wrong and another one is good.

In addition, when the Client/Company regulations are hard (and usually it is the

case, because it seems to be o hot topic!) you have to comply with.

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#40431 - 01/25/11 07:33 AM Re: PSV Closed system Force [Re: mariog]

danb

Member

Registered:

04/22/05

Posts: 1059

Loc: ...

I agree with mariog and stressguy81.

I'd like to add the following.

Check should be done for pop forces and if the velocities are close to 1 mach,

apply forces at elbows equal with w x v (flow times velocity)

Regards,

_________________________

Dan

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#40434 - 01/25/11 07:46 AM Re: PSV Closed system Force [Re: danb]

MoverZ

Member

Registered:

11/22/06

Posts: 978

Loc: Hants, UK

A further warning about Mach speed ..... it cannot in most cases be exceeded in

a PSV body due to choking. Since velocity is not directly addressed in the

equations given, the formulas in API RP 520 used to calculate reaction forces

can give incredible results. If you check the associated velocity it may be well in

excess of Mach speed and thus impossible. A reduction to a realistic mass flow

rate should give better force results.

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#40435 - 01/25/11 08:17 AM Re: PSV Closed system Force [Re: MoverZ]

danb

Member

Registered:

04/22/05

Posts: 1059

Loc: ...

Indeed, and this is in line with Norsok P-001 limiting criteria ro x v2 less than

200 000.

However a rough formula w x v = ro x v2 x A is quite reasonable. (e.g. for a 8"

line and a ro x v2= 200 000, force will be 7534 N) Not big, not small, but will

lead to a lot of guides and/or stops.

_________________________

Dan

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#40440 - 01/25/11 09:56 AM Re: PSV Closed system Force [Re: MoverZ]

mariog

Member

Registered:

09/29/07

Posts: 333

Loc: Romania

Dear MoverZ

You say

Quote:

Since velocity is not directly addressed in the equations given, the formulas in

API RP 520 used to calculate reaction forces can give incredible results.

Well, I cannot blame the API formulas. Maybe the people applying API

formulas.

API formulas are based on "free jet" approach.

If a free jet is released in atmosphere or in a large volume, the piping system

will receive a reactive force.

This is the force that API counts as:

Reactive_Force= [mass flow-rate]*[jet_velocity]+ [p_jet]*[area_jet]

where

- mass flow rate must be the actual value (it is greater than the designed flow

rate, because the actual PSV orifice is larger than minimum required!)

- jet_velocity is the critical speed when the jet gas flow has Mach=1 feature (is

counted in Fluid Mechanics as jet_velocity= sqrt(2*R*k*T/ ((k+1)*M)), where

notations are as in API, R is the universal perfect-gas constant , in SI is

R=8314.5 J/kg mol/K.

- p_jet is the gauge pressure in the released jet

- area_jet is the internal area of piping at the point where the jet is released

This is exactly the API formula, where the numerical coefficient is sqrt(2*R), in

SI units sqrt(2*8314.5)=129

Obviously, the formula is based on the "choked" condition i.e. Mach=1 and this

is taken into consideration by counting jet_velocity= sqrt(2*R*k*T/ ((k+1)*M)

A possible source of errors may be the term [p_jet]*[area_jet], because it seems

that "p" in chocked flow is somehow out of common engineering perception and

API does not give details on the subject.

I reattach a paper showing a simple way to evaluate pressure in isentropic

choked flow (Mach=1). You can see the same result in some articles, but the

fluid mechanics model is more complicated there.

My best regards.

Attachments

Choked_flow_pressure.pdf (321 downloads)

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#40441 - 01/25/11 10:10 AM Re: PSV Closed system Force [Re: mariog]

MoverZ

Member

Thanks for the fluid mechanics lesson Mariog, I am well aware of theory. My

note was a warning since I have had occasion to check calculations where a

Registered:

11/22/06

Posts: 978

Loc: Hants, UK

small PSV apparently attracted a huge force, due exactly to the error I outlined.

People do make mistakes and far too many 'engineers' apply equations blindly,

because all too often they have found an unchecked and non-validated Excel

spreadsheet solution on some dodgy company drive.

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#40449 - 01/25/11 03:56 PM Re: PSV Closed system Force [Re: danb]

mariog

Member

Registered:

09/29/07

Posts: 333

Loc: Romania

Dan,

I think your example may be written as "if there is a free-jet exiting 8" piping

area with (choked) parameters complying with rho*v^2=200000 kg/(ms^2), the

reaction force would be 7534 N".

For a closed system I would say it is a "better than nothing" criteria.

PS. I have a funny story with a PSV process issue in a big company that after 2

months of Olga software calculation decided to have 24" size line downstream

of the 2"x4" piloted PSV. So 24" wasn't the subheader size, it was the size

connection to the subheader. The model was a visual aggression and the

calculation was "worse than nothing".

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#40455 - 01/26/11 05:40 AM Re: PSV Closed system Force [Re: mariog]

danb

Member

Registered:

04/22/05

Posts: 1059

Loc: ...

I think that I will not rephase as the purpose of this was more trivial.

I was talking about flow induced forces. Decent problems require decent

solutions, sort of "better than nothing". For complex problems, there are other

solutions and I am not one of the specialists that can solve them.

_________________________

Dan

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#40462 - 01/26/11 08:52 AM Re: PSV Closed system Force [Re: danb]

mariog

Member

Registered:

09/29/07

Posts: 333

Loc: Romania

Dan,

You were talking about flow induced forces in closed systems and I was talking

on the fact rho*v^2 transposed in "force criteria" would be a criteria for forces

due to "free-jet" effect in open systems. I think also that rho*v^2 is a steady-

state criteria and does not address to the "momentary, instantaneous forces that

result when the valve first opens".

The point is I have no evidence such criteria is a decent one in closed system

except the connection with subheader/header where a "free jet" may exist.

The only certitude I have is that every stress specialist and Company has the

certitude that his/her/their criteria is decent. I'm not in position to say they are

right or not, so I accept their approach, criteria, etc.

It is interesting (for me) to see that the process people have the certitude they

don't know such decent criteria to evaluate roughly the magnitude of forces in a

closed system. I accept also their position.

Best regards.

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#43155 - 06/02/11 08:40 AM Re: PSV Closed system Force [Re: Nalibsyah]

Tengku_Syahdilan

Member

Registered:

12/26/09

Posts: 56

Loc: Indonesia

Stress guy and others, i think i need to clarify what asked. My concern is

that when PSV first pop up there will be a travelling wave downstream the

PSV discharge or RV discharge. This load is not balanced each other. This

force will have the same history shape throught out the system but the

arriving time is different in each point. This is why in API 520 as stress guy

taken above mention :

A complex time history analysis of the piping system may be required to

obtain the reaction forces and associated moments that are transferred to the

inlet piping system."

and in ASME B31.1 Non Mandatory App. II Para II.2.2.2 :

...."However when a safety valve discharge is connect to a relatively long

run of pipe and suddenly opened, there is a period of transient flow until the

steady state discharge condition is reached.

and in Para II.2.3.2 :

......"Relief Valves discharging into an enclosed piping system create a

momentary unbalanced forces which act on the piping system during the

first few milliseconds following relief valve lift. The pressure waves

travelling through the piping system following rapid opening of the safety

valve will cause bending moments in the safety valve discharge piping and

the reminder of the piping system. In such a case, the designer must compute

the magnitude of the loads and perform approriate evaluation of their

effects."

LC Peng book page 401-403 so talk about this, where there will be a net

force impact on each leg (elbow or other obstruction) downstream the RV or

PSV discharge as a result of the traveling wave or transient condition.

So what i mean is that we also have to considered the effect of this transient

load during pop not only at the first elbow ( i see in some company standard

they apply this two condition, during steady state and pop up, but during pop

up they only apply the force directly upward and horisontal at the body of

the Rv or PSV.....i also have see some one post this kind of pictures in other

thread about PSV too).

Apply the load at n elbow/obstruction and n+1 elbow/obstruction, but

because it is quite complicated and we will not know the limit of this

travelling wave unless we perform simulation (maybe with Boss fluid) or do

the time history analysis for better and realistic result, then it is common to

assume to apply until the third elbow/obstruction.

I have found a case where previous engineering company apply the usual

method (apply upward, and horizontal at valve body), and the result the

pump downstream of this RV system having a trouble. so we fix it by apply

and considered the transient effect that not considered by previous company

and now have been 3 years the pump still run smoothly.

_________________________

Tengku_Syahdilan

"From Failure we Learn"

Top Reply Quote Quick Reply Quick Quote Notify Email Post

Search Results

Quick Reply:

HTML is

enabled

UBBCode is

enabled

Add

Signature

I am looking for any book, paper or code to know a bit more how to calculate

the transient loads during the discharge of safety valves, specially in closed

discharge systems. Could you recommend m any?

Thanks in advance

_________________________

Carletes

Top

Reply Quote

Quick Reply

Quick Quote

Notify Email

Post

#3648 - 09/02/05 01:14 PM Re: Safety valve discharge loads

Sun Wee

Member

Registered:

12/20/99

Posts: 75

Loc:

Calgary,Canada

I would like to recommend following;

1) Analysis of Power Plant Safety and Relief Valve Vent Stacks, Transaction of

the ASME, 1975, G.S.Liao

2) ASME B31.1 Appendix II

3) Time-Dependent Pipe Forces Caused by Blowdown and Flow Stoppage,

F.J.Moody, Transaction of the ASME 1973

4) Transient Analysis of water Slug Discharge in PWR safety/Relief Valve

Piping, D.A.Van Duyne, ASME 1981

5) Flow of Fluids through Valves, Fittings, and Pipe, CRANE, 1985

Other member may give better idea.

_________________________

Sun Wee

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#3649 - 09/02/05 03:01 PM Re: Safety valve discharge loads

John Breen

Member

Registered:

03/09/00

Posts: 482

Loc: Pittsburgh,

PA (& Texas)

Hello Carletes,

Sun Wee has it covered. I can only add American Petroleum Institute Standard

RP-520.

If you want to really get serious about the topic seek out the DIERS

publications:

http://www.aiche.org/diers/

Regards, John.

_________________________

John Breen

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#3650 - 09/04/05 10:01 PM Re: Safety valve discharge loads

anindya stress

Member

Registered:

04/12/04

Posts: 493

Loc: London,

I would like to add one more to the list:

Steam Flow through safety valve vent pipes by Brandmaier and Knebel- Journal

of Fluids engineering-June 1976.

Regards

_________________________

anindya

UK

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#3651 - 09/21/05 04:39 PM Re: Safety valve discharge loads

tubecomp

Member

Registered:

05/27/04

Posts: 42

Loc: spain

Thank you all.

I think I have got all the papers you have suggested (except Transient Analysis

of water Slug Discharge in PWR safety/Relief Valve Piping), but I still don't see

it clear how to get the transient forces in the discharge of my closed system. I

would desire a document with any "example" about how to apply all those hard

differential equations to a real system (perhaps I am dreaming..) Do you know

any?

regards,

_________________________

Carletes

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#3652 - 09/22/05 02:54 AM Re: Safety valve discharge loads

SUPERPIPER

Member

Registered:

08/13/03

Posts: 404

Loc: Europe

Look in the back of the piping codes at the

section marked 'how to guess your way through common analytical problems'

You'll probably find out there how to do trunnions and pipe attachments as well.

:p

(only joking)

_________________________

Best Regards T.J.N

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#3653 - 09/22/05 11:51 AM Re: Safety valve discharge loads

tubecomp

Member

Registered:

05/27/04

Posts: 42

Loc: spain

So, there is not any book, paper, etc where these problems are discussed from a

more "peactical" point of view? Something like "differential equations applied

to the real world"?

Regards

_________________________

Carletes

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#3654 - 09/23/05 02:01 AM Re: Safety valve discharge loads

RS

Member

Registered:

09/15/04

Carletes, the formula in ASME B31.1 Appendix II is very straight forward and

practical.

I normally get the force from the RV supplier, when available.

Dynamic analysis is described in detail in the Caesar Application Manual.

_________________________

Posts: 81

Loc: South

Africa,

Johannesburg

Regards

Ranka

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#3655 - 09/23/05 09:52 AM Re: Safety valve discharge loads

tubecomp

Member

Registered:

05/27/04

Posts: 42

Loc: spain

RS,

The problem is that the B31.1 formula is valid for steady discharge but there are

transient forces that must be evaluated for those systems whose discharge is not

straight forward to the atmosphere. I suppose that a software of compressible

flow transients will make it quite esay but when you don't have that...That/s my

problem...

regards,

_________________________

Carletes

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#3656 - 09/23/05 10:44 AM Re: Safety valve discharge loads

John C. Luf

Member

Registered:

03/25/02

Posts: 1110

Loc: U.S.A.

anyone want to volunteer writing up a method for inclusion in the code, attend

all the meetings, resolve all comments etc.? I thought not...

But in all seriousness this is a topic that should be covered but nobody has

"volunteered" so we all are left wanting....

_________________________

Best Regards,

John C. Luf

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#3657 - 09/28/05 01:58 AM Re: Safety valve discharge loads

RS

Member

Registered:

09/15/04

Posts: 81

Loc: South

Africa,

Johannesburg

Yes Carletes, that is why we have Caesar and time history analysis. The time

history analysis is suggested in the ASME B31.1 for the closed systems.

You should use Caesar's Time History analysis to calculate stresses and forces

in the piping system due to a short duration precalculated dynamic force.

Another analysis is the calculation of dynamic force due to a dynamic event.

This is science in itself for which we "pipers" use approximate methods as one

referenced in ASME Code. Dynamic piping stress analysis does not involve

analysis of the fluido-dynamic phenomena induced by the process fluids flow.

The phenomena is to be analysed and relevant dynamic loads are to be provided

by the Process Department if approximate methods are not sufficient. There are

specialised software packages for calculations of transients in fluids used by

process guys.

_________________________

Regards

Ranka

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#3658 - 09/28/05 04:30 AM Re: Safety valve discharge loads

sam

Member

Registered:

02/25/04

Posts: 463

You can read the following article .

http://www.pipingdesign.com/articles/piping_surges.pdf

But, unless you have some knowledge about transient analysis, you will not be

able to run the softwares viz. pipenet-transient, AFT-Impulse in public domain

correctly.

Many in the nuclear industry have dedicated their whole life in this field just to

ensure plant safety. It is better not to trivialize this field. If you are really

interested, go back to your engineering school once more for learning the same.

regards,

sam

_________________________

_

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#3659 - 09/28/05 11:14 AM Re: Safety valve discharge loads

Jackdliu

Member

Registered:

09/21/05

Posts: 4

Loc: Calgary

Engineering design is about safety without waste of too much money.

The easiest solution for this problem is using the reaction force supplied by the

safety valve manufacturer and taking 2 as DLF to run static analysis. The reason

for this is that most of safety valve piping systems can be considered as one

degree freedom system, in which the greatest DLF is 2.

Jack

_________________________

JDL

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#42071 - 03/31/11 05:09 PM Re: Safety valve discharge loads [Re: John C. Luf]

danb

Member

Registered:

04/22/05

Posts: 1059

Loc: ...

How about the fact that some huge companies consider POP forces while here

in this forum nobody mention it?

Regards,

_________________________

Dan

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#42108 - 04/01/11 01:11 PM Re: Safety valve discharge loads [Re: danb]

Crusader911

Member

Registered:

11/22/09

Posts: 25

Loc: Louisiana,

USA

"We are but warriors for the working day..."

With the time I am given to do most analysis, I follow Jackdliu's method.

However, many times I do not have the manufacturer's information, so I

calculate a thrust load from the formula in API 520, put it in the model as a

static load, and get on to the next job. Don't forget to double it, like he said.

The problem, of course, is that although you didn't have time to do anything

more sophisticated, if something goes wrong the company that sues you will

have plenty of money to pay some engineer who's never been outside the walls

of a university to do some unbelievably impressive dynamic analysis that shows

that the failure could have been anticipated if you had spent ten times the man-

hours analyzing it.

If anyone has a better practical method I would love to hear it.

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#42119 - 04/03/11 01:51 PM Re: Safety valve discharge loads [Re: Crusader911]

danb

Member

Registered:

04/22/05

Posts: 1059

Loc: ...

Many engineers seems to be atracted by the dynamic analysis, but from my

experience is quite unusual to be really required.

Regards,

P.S. And yes, at a rate of few hours per line, is anyone expecting full analysis?

_________________________

Dan

Top Reply Quote Quick Reply Quick Quote Notify Email Post

#42235 - 04/06/11 10:29 AM Re: Safety valve discharge loads [Re: danb]

Carter

Member

Registered:

08/08/09

Posts: 21

Loc: Ontario,

Canada

http://www.aft.com/products/impulse/

Carletes,

I have a similar concern regarding relief valve loading. From the instruction, it

looks like the software AFT Impulse has this fuction. I have used AFT Fathom

and others from AFT. They are good and easy to use.

Carter

Top Reply Quote Quick Reply Quick Quote Notify Email Post

Search Results

Quick Reply:

HTML is

enabled

UBBCode is

enabled

Add

Signature

Hello Everyone,

I have been searching through this forum a discussion about

PSV reaction force but unfortunately I can't find the specific

one. If you do have a link please do send it to me.

My concern is PSV Reaction Force:

I am analysing an open system PSV directly above an

equipment vessel by static analysis. I have referred to API

RP520 for obtaining this force, what I'd like to understand is

do we need to multiply this Force by 2 times for

consideration of "dynamic load factor"? What is dynamic

load factor and what part in the code can I read about it. By

the way, I have read this in our project standard.

Thanks.

Top

Reply

Quote

Quick

Reply

Quick

Quote

Notify

Email Post

#11775 - 06/20/07 10:48 AM Re: PSV Reaction Force [Re: ichigo]

Loren

Brown

Member

Registered:

10/18/01

pinoy,

The dynamic load factor (DLF) is a characteristic of the

applied load shape (your PSV force versus time curve) which

is plotted vs. system natural frequency. It is determined by a

Time History integration of the dynamic equations of

Search

Who's Online

0 registered (), 6

Guests and 1

Spider online.

Key: Admin,

Global Mod, Mod

March

Su M Tu W Th F Sa

1 2

3 4 5 6 7 8 9

10 11 12 13 14 15 16

17 18 19 20 21 22 23

24 25 26 27 28 29 30

31

Forum Stats

8938 Members

13 Forums

11306 Topics

51424 Posts

Max Online: 57 @

12/06/09 11:14

AM

Posts: 281

Loc:

Houston,

TX

motion. For impulse loads, such as your PSV, the maximum

DLF is usually less than or equal to 2.0 (which is why this

value shows up in your project standard).

To perform your PSV analysis statically, multiply your PSV

thrust force by 2.0 (check your API RP520 standard as it

may already be applying this DLF=2.0 factor) and apply this

at your bend midpoint downstream of the PSV in your vent

stack. The direction of the force is opposite the direction of

fluid flow in your vent stack.

For an open system, if you have more than one bend in your

vent stack then apply this force at each bend under a separate

load vector.

For a closed system you would apply this force on bends on

each long leg of pipe. The only way to truly figure out

which pipe leg is short enough to ignore the PSV force is to

run the force/time profile through Caesar II's DLF generator

in the dynamics module, but then you might as well perform

this analysis dynamically. For short pipes the duration of the

unbalanced PSV force is small and this shifts the DLF peak

to the right (higher frequency) which at some point is past

the majority of your piping system natural frequencies of

interest. But if you are going to do this statically you might

simply take the nine longest pipe legs and apply your force to

each bend corresponding to these longest legs. This would be

the "brute force" approach, not really an approach based on

physics.

You have 9 different force vectors to choose from so apply

your PSV force under a different force vector for each bend

because we want to only examine the effect on one bend at a

time. Then set up separate OPE cases that include your

different force vectors.

The OPE load cases should be used to determine your

equipment and restraint loads. Subtract your standard OPE

case from each of these, then add that result to SUS to obtain

OCC code stress (note some codes use the OPE+F1 load case

directly for comparison to the allowable stress, so how you

need to review the particular code you are using to determine

the proper approach here). Here is an example of load cases

for B31.1 or B31.3 assuming 3 PSV forces, F1, F2, and F3,

each applied at a different bend:

L1 = W+P1+T1 (OPE)

L2 = W+P1+T1+F1 (OPE)

L3 = W+P1+T1+F2 (OPE)

L4 = W+P1+T1+F3 (OPE)

L5 = W+P1 (SUS)

L6 = L1-L5 (EXP)

L7 = L2-L1 (OCC) segregated effect of F1

L8 = L3-L1 (OCC) segregated effect of F2

L9 = L4-L1 (OCC) segregated effect of F3

L10= L5+L7 (OCC) use Scalar Combination Method

L11= L5+L8 (OCC) scalar combination

L12= L5+L9 (OCC) scalar combination

Note that L10 through L12 are code compliance cases. L7

through L9 are interemediate load cases and not used for

anything other than determining the stress results for L10

through L12.

_________________________

Loren Brown

Director of Technical Support

CADWorx & Analysis Solutions

Intergraph Process, Power, & Marine

12777 Jones Road, Ste. 480, Houston, TX 77070 USA

Top

Reply Quote Quick Reply Quick Quote Notify Email

Post

#11794 - 06/21/07 07:29 AM Re: PSV Reaction Force [Re: Loren

Brown]

ichigo

Member

Registered:

12/22/05

Posts: 51

Loc: USA-

Philippines

Hello Loren,

Thanks for the quick reply, this is what I love about this

forum... and thanks to COADE for making this possible.

Keep up the good work!

Top

Reply Quote Quick Reply Quick Quote Notify Email

Post

#12035 - 07/04/07 04:45 AM Re: PSV Reaction Force [Re: ichigo]

ajaykumar

Member

Registered:

06/23/07

Posts: 1

Hello Loren,

Thanks for your reply regarding PSV,I faced this problem

while working on a project,I searched this form and got

valuable information.

and thanks for Ianpinoy for asking this question.

Loc:

AP,INDIA

with regards

ajay

Top

Reply Quote Quick Reply Quick Quote Notify Email

Post

#16292 - 02/27/08 02:03 AM Re: PSV Reaction Force [Re:

ajaykumar]

supremo

Member

Registered:

06/18/07

Posts: 12

Loc: --

Mr. Brown,

Do we really need to consider the temperature for stress

evaluation of thrust force?

Top

Reply Quote Quick Reply Quick Quote Notify Email

Post

#16317 - 02/27/08 11:40 AM Re: PSV Reaction Force [Re: Loren

Brown]

Dylan

Member

Registered:

09/23/07

Posts: 99

Loc:

Indonesia

Mr.Loren,

You wrote:

Php Code:

L1 = W+P1+T1 (OPE)

L2 = W+P1+T1+F1 (OPE)

L3 = W+P1+T1+F2 (OPE)

L4 = W+P1+T1+F3 (OPE)

L5 = W+P1 (SUS)

L6 = L1-L5 (EXP)

L7 = L2-L1 (OCC) segregated effect of F1

L8 = L3-L1 (OCC) segregated effect of F2

L9 = L4-L1 (OCC) segregated effect of F3

L10= L5+L7 (OCC) use Scalar Combination Method

L11= L5+L8 (OCC) scalar combination

L12= L5+L9 (OCC) scalar combination

Note that L10 through L12 are code compliance

cases. L7 through L9 are interemediate load cases

and not used for anything other than determining

the stress results for L10 through L1

My question is this example a case for Non-Liniear bondary

condition?(because you take F from subtracting it with Basic

OPE) and which Paragraph of B31.1 or B31.3? Para for

Occasional Loads?

Top

Reply Quote Quick Reply Quick Quote Notify Email

Post

#16333 - 02/28/08 12:53 AM Re: PSV Reaction Force [Re: Loren

Brown]

Dylan

Member

Registered:

09/23/07

Posts: 99

Loc:

Indonesia

Dear Mr.Loren,

I want to ask, if you have 2 pumps running together and have

to analysis the worst case, Pump A & B ON (T1), Pump A

on Pump B off(T2), Pump B on Pump A Off(T3) and Pump

A B OFF(T4) with design temp -39/45 deg c and Amb Temp

-39/39 deg C. You have 2 piping spec here with Spec1 P=12

bar, Spec2 P=230 bar. This system has 3 PSVF1,F2,F3.

Boundary condition Liniear.

So Please can you give an example how to build the case for

PSV in Load case editor?

Because i confused, when T1 all 3 PSV are open, but when

T2 it is only F1 and F3 will act, so does at T3 F2 and F3, for

T4 it is only F3 act. I hope you understand my question.

Here i attached my example input for your review.

Attachments

264-B.O.T.P.System.zip (446 downloads)

Top

Reply Quote Quick Reply Quick Quote Notify Email

Post

#16345 - 02/28/08 12:08 PM Re: PSV Reaction Force [Re: Dylan]

SUPERPIPER

Member

Registered:

08/13/03

Posts: 404

Loc: Europe

People,

When doing load cases, try to think about all of the

reasonable and possible real life situations which could

happen in the system.

whatever about the accademics, if your scenarios are over

or under cautious, your wasting your time.

Example:

Some relief valves only open once at which you have to

physically go and close it, therefore how can the reaction

forces act on hot pipe? its impossible. (same as a Bursting

Disk)

Why apply 3 valve reliefs at once? these things are quick

and statistically, is it impossible for all 3 to open at

exactly the same time?

So turn off the computer, get a pen, paper and a strong

coffee and think about the design and operating regimes

before pilling into caesar.

_________________________

Best Regards T.J.N

Top

Reply Quote Quick Reply Quick Quote Notify

Email Post

#27868 - 06/02/09 10:29 AM Re: PSV Reaction Force [Re:

SUPERPIPER]

Umair

Member

Registered:

04/16/09

Posts: 13

Loc:

Pakistan

Hello Lauren

Could you please clarify as to what practical situation do

these load cases refer to

L10= L5+L7 (OCC) use Scalar Combination Method

L11= L5+L8 (OCC) scalar combination

L12= L5+L9 (OCC) scalar combination

Top

Reply Quote Quick Reply Quick Quote Notify Email

Post

#27903 - 06/03/09 12:16 PM Re: PSV Reaction Force [Re: Umair]

manu

Member

Registered:

06/03/09

Posts: 28

Loc: india

Dear Umair

L5+L7 is the sum of principal stresses in the system. You

must be knowing that principal stresses are different from

secondary stresses in a way that the pipe may not fail if the

secondary stresses exceeds the limiting stress value(they are

self limiting). But it can fail if the sum of principal stresses

exceeds the limiting value.

now earthquake is a principal stress and so is the stress due

to pipe wt(L5) hence they need to be added before they can

be evaluated..

this is basic..asking Lauren for this is like asking God for

coffee [:)]

Top

Reply Quote Quick Reply Quick Quote Notify Email

Post

#27925 - 06/03/09 11:57 PM Re: PSV Reaction Force [Re: manu]

Umair Thank you for the reply manu ..the metaphor used in the end

Member

Registered:

04/16/09

Posts: 13

Loc:

Pakistan

was pretty logical

Top

Reply Quote Quick Reply Quick Quote Notify Email

Post

Previous Topic Index Next Topic

Quick Reply:

HTML is

enabled

UBBCode

is enabled

Add

Signature

Hop to:

Moderator: Dave Diehl, Richard Ay

Privacy statement Board Rules Mark all read

Contact Us Home Page Top

Generated in 0.043 seconds in which 0.006 seconds were spent on a total of 14 queries. Zlib

compression disabled.

Powered by UBB.thr

Potrebbero piacerti anche

- Dorin Popescu FRP Allowable Stress - Intergraph CADWorx & AnalysisDocumento7 pagineDorin Popescu FRP Allowable Stress - Intergraph CADWorx & Analysisxaaabbb_550464353Nessuna valutazione finora

- Rupture DiscDocumento4 pagineRupture DiscsaichandrakanthanNessuna valutazione finora

- Load Cases For Typical Piping System Using CAESAR IIDocumento4 pagineLoad Cases For Typical Piping System Using CAESAR IIsj22Nessuna valutazione finora

- Na 131121Documento50 pagineNa 131121Mukund KashyapNessuna valutazione finora

- Lesson Learnt From SNC On Stress AnalysisDocumento3 pagineLesson Learnt From SNC On Stress AnalysiszahoorNessuna valutazione finora

- Pressure VesselsDocumento31 paginePressure VesselsRho Natta MatahariNessuna valutazione finora

- v1.0 Rishabh Engineering CS 37 Piping Stress Analysis Horizontal HeaterDocumento4 paginev1.0 Rishabh Engineering CS 37 Piping Stress Analysis Horizontal HeaterJasonChong212Nessuna valutazione finora

- Nozzle loading guidelines and reducing methodsDocumento2 pagineNozzle loading guidelines and reducing methodsaap1Nessuna valutazione finora

- Input Data Required For Pipe Stress AnalysisDocumento4 pagineInput Data Required For Pipe Stress Analysisnor azman ab azizNessuna valutazione finora

- MOTS-08 Squirrel Cage Induction Motors - Rev 4.0Documento17 pagineMOTS-08 Squirrel Cage Induction Motors - Rev 4.0Kingston RivingtonNessuna valutazione finora

- Design Change Request Form 2013-08 Rev 2Documento5 pagineDesign Change Request Form 2013-08 Rev 2Amjid AliNessuna valutazione finora

- Pipe SupportDocumento6 paginePipe SupportEshant Rane RaneNessuna valutazione finora

- Tips On Tensioning Anchor BoltsDocumento2 pagineTips On Tensioning Anchor BoltsAnonymous TxhyGfNessuna valutazione finora

- Section IDocumento58 pagineSection IARAVINDRAJ V RNessuna valutazione finora

- UI 9253-06 Part 1 E (2009-11) - WeldingAndWeldExaminationOfMetallicPipingDocumento12 pagineUI 9253-06 Part 1 E (2009-11) - WeldingAndWeldExaminationOfMetallicPipingmahmoud_allam3100% (1)

- Properties of Pure SubstancesDocumento12 pagineProperties of Pure SubstancesDSNessuna valutazione finora

- Relief Valve - TypesDocumento2 pagineRelief Valve - Typesyushveer002Nessuna valutazione finora

- Temp and Pressure InstrumentDocumento5 pagineTemp and Pressure InstrumentAnniza Cornelia AugustyNessuna valutazione finora

- Piping FormulaDocumento5 paginePiping Formulawarshipvn100% (1)

- API 598, EN 12266-1 Leakage RatesDocumento2 pagineAPI 598, EN 12266-1 Leakage RatesjshadwanNessuna valutazione finora

- PSV Selection For Beginner The Weby'sDocumento11 paginePSV Selection For Beginner The Weby'sGreg GolushkoNessuna valutazione finora

- End Effects of Elbows Subjected To Moment LoadingsDocumento75 pagineEnd Effects of Elbows Subjected To Moment LoadingsA. VenugopalNessuna valutazione finora

- Valve Cavity Relief 2Documento2 pagineValve Cavity Relief 2Azar DeenNessuna valutazione finora

- List of Nozzles List of Nozzles: T T 1 T T 1Documento1 paginaList of Nozzles List of Nozzles: T T 1 T T 1גרבר פליקס100% (1)

- Overview Part 1 PDFDocumento65 pagineOverview Part 1 PDFKim NamjoonNessuna valutazione finora

- Steam Trap and Drain Trap FunctionsDocumento23 pagineSteam Trap and Drain Trap FunctionsMallela Sampath KumarNessuna valutazione finora

- Hi Force CatalogDocumento68 pagineHi Force CatalogmjscarNessuna valutazione finora

- Properties of AirDocumento4 pagineProperties of AirRhea FayeNessuna valutazione finora

- Orifice Plate Showing VenaDocumento6 pagineOrifice Plate Showing VenahugepotatoNessuna valutazione finora

- Good-Comparison of Friction Models Applied To A Control ValveDocumento13 pagineGood-Comparison of Friction Models Applied To A Control ValvesayproNessuna valutazione finora

- Flange Leakage 6Documento2 pagineFlange Leakage 6hamid sobirinNessuna valutazione finora

- Process Piping Inspection and Test PlanDocumento6 pagineProcess Piping Inspection and Test Planmanoj thakkarNessuna valutazione finora

- Hydrogen Piping Pipeline Hardness TestingDocumento19 pagineHydrogen Piping Pipeline Hardness TestingsaravananNessuna valutazione finora

- Design Requirements For Pressure Safety Relief ValvesDocumento5 pagineDesign Requirements For Pressure Safety Relief Valvesvela vanNessuna valutazione finora

- Nabl 100Documento39 pagineNabl 100Vishal Sharma67% (3)

- Reaction Forces Pressure Relief SystemDocumento2 pagineReaction Forces Pressure Relief SystemkhaliliNessuna valutazione finora

- USe of Higher PSV Set PressureDocumento12 pagineUSe of Higher PSV Set Pressurezubair195Nessuna valutazione finora

- Coupling Alignment Kit by Syed JafferDocumento25 pagineCoupling Alignment Kit by Syed Jafferar0131083804Nessuna valutazione finora

- Pipe Stress AnalysisDocumento3 paginePipe Stress AnalysismaniaxpdfNessuna valutazione finora

- Eqpt Check List-Pre InspectionDocumento51 pagineEqpt Check List-Pre Inspectionarifayee-1Nessuna valutazione finora

- Sec 05100 - Structural SteelDocumento10 pagineSec 05100 - Structural Steeltiju2005hereNessuna valutazione finora

- Piping Specifications HarrisDocumento27 paginePiping Specifications Harrisrensieovi100% (2)

- Design Task Crane tmhp02 2014 PDFDocumento7 pagineDesign Task Crane tmhp02 2014 PDFMiguel Angel Munguia FloresNessuna valutazione finora

- Oisd STD-226Documento76 pagineOisd STD-226rsb72100% (1)

- Piping Design PracticeDocumento347 paginePiping Design PracticeRey Bernales100% (2)

- TRU Waste Processing Center PBVS Design DescriptionDocumento37 pagineTRU Waste Processing Center PBVS Design DescriptionShaimaa SaadNessuna valutazione finora

- VFD Minimum Speed EquationDocumento4 pagineVFD Minimum Speed Equationforevertay2000Nessuna valutazione finora

- Chemical Process Safety IndexDocumento30 pagineChemical Process Safety IndexakarczNessuna valutazione finora

- Pipe Stress Engineering2Documento295 paginePipe Stress Engineering2DAVID891212Nessuna valutazione finora

- PIPE RACK Design and Layout Guide for RefineriesDocumento50 paginePIPE RACK Design and Layout Guide for Refineries124swadeshiNessuna valutazione finora

- Din 17177-79Documento8 pagineDin 17177-79savanNessuna valutazione finora

- A New Method For Calculating The Busemann Head Coefficients For Radial ImpellersDocumento7 pagineA New Method For Calculating The Busemann Head Coefficients For Radial ImpellersIvan RaulNessuna valutazione finora

- Surge Analysis: What Is Pressure Surge?Documento2 pagineSurge Analysis: What Is Pressure Surge?Yang Gul Lee100% (1)

- Piping Spec C ClassDocumento1 paginaPiping Spec C Classnestor ferrel floresNessuna valutazione finora

- Type of Pipe FittingsDocumento3 pagineType of Pipe Fittingssibi_s_rajNessuna valutazione finora

- Flow Induced Vibration Effects On Piping SystemsDocumento1 paginaFlow Induced Vibration Effects On Piping Systemsfea.uk.20098542Nessuna valutazione finora

- Piping Dimension Chart UsefulDocumento1 paginaPiping Dimension Chart UsefulrizkiNessuna valutazione finora

- PSV Reaction Forces and DirectionDocumento29 paginePSV Reaction Forces and Directionpvmsson100% (1)

- PSV Closed System Force - Intergraph CADWorx & AnalysisDocumento12 paginePSV Closed System Force - Intergraph CADWorx & Analysist_rajith1179Nessuna valutazione finora

- PSV - Second Term of API FormulaDocumento5 paginePSV - Second Term of API FormuladebjpaulNessuna valutazione finora

- Quick Guide Into The ISO 14692 Revision 2016 Edition 26 May 2016Documento44 pagineQuick Guide Into The ISO 14692 Revision 2016 Edition 26 May 2016pmr80_2004100% (1)

- Modeling FRP and Plastic Piping-R11Documento15 pagineModeling FRP and Plastic Piping-R11balas838541Nessuna valutazione finora

- Trunnion Modeling Philosophy PDFDocumento5 pagineTrunnion Modeling Philosophy PDFveerappapanchalNessuna valutazione finora

- Modeling FRP and Plastic Piping-R11Documento15 pagineModeling FRP and Plastic Piping-R11balas838541Nessuna valutazione finora

- ASTM Materials Table for Carbon Steel, Stainless Steel & Alloy SteelDocumento1 paginaASTM Materials Table for Carbon Steel, Stainless Steel & Alloy SteelveerappapanchalNessuna valutazione finora

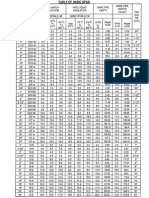

- Table of Basic SpanDocumento1 paginaTable of Basic SpanveerappapanchalNessuna valutazione finora

- ME4202501 Thermodynamics I, Fall Term 2015 Practice 5Documento1 paginaME4202501 Thermodynamics I, Fall Term 2015 Practice 5黃羿傑Nessuna valutazione finora

- Worksheet Gases III Answers 1Documento5 pagineWorksheet Gases III Answers 1Emilio JacintoNessuna valutazione finora

- TD Sheet 1 Math005Documento2 pagineTD Sheet 1 Math005sentia almqNessuna valutazione finora

- E3 Vector AdditionDocumento6 pagineE3 Vector AdditionMahir MahmoodNessuna valutazione finora

- On Modelling Iron Core NonlinearitiesDocumento9 pagineOn Modelling Iron Core Nonlinearitiesjdjjarami100% (1)

- Fracture Mechanisms of S355 Steel-Experimental Research, FEM Simulation and SEM ObservationDocumento17 pagineFracture Mechanisms of S355 Steel-Experimental Research, FEM Simulation and SEM Observationserkan_apayNessuna valutazione finora

- Strength of MaterialDocumento163 pagineStrength of MaterialJackKiaNessuna valutazione finora

- Design of Double Slab at SHC-A1Documento24 pagineDesign of Double Slab at SHC-A1dhee2608Nessuna valutazione finora

- Atomic Emission Spectroscopy AsdaDocumento18 pagineAtomic Emission Spectroscopy AsdaMark Cliffton BadlonNessuna valutazione finora

- Physics Question Bank Kvpy PDFDocumento97 paginePhysics Question Bank Kvpy PDFaswin sivakumarNessuna valutazione finora

- Cells and Batteries: How Electrochemistry WorksDocumento161 pagineCells and Batteries: How Electrochemistry WorksamanNessuna valutazione finora

- Vibration of Deckhouse StructuresDocumento10 pagineVibration of Deckhouse StructuresrthyhtNessuna valutazione finora

- Interaction of Ultrasounds Wave With MatterDocumento4 pagineInteraction of Ultrasounds Wave With MatterbjhbjhNessuna valutazione finora

- Chemical Bonding DocumentDocumento33 pagineChemical Bonding DocumentL GoldenmasterNessuna valutazione finora

- Fabry-Perot InterferometerDocumento6 pagineFabry-Perot InterferometerChandan ThakurNessuna valutazione finora

- Section 3Documento5 pagineSection 3Aduchelab AdamsonuniversityNessuna valutazione finora

- What Is Net Metering And.9450282.powerpointDocumento4 pagineWhat Is Net Metering And.9450282.powerpointAnuj SharmaNessuna valutazione finora

- The Affinity Laws of Centrifugal PumpsDocumento8 pagineThe Affinity Laws of Centrifugal PumpsArunkumar SubramanianNessuna valutazione finora

- Atomic Structure (L3) - StudentDocumento28 pagineAtomic Structure (L3) - StudentdzikranNessuna valutazione finora

- 1291 Guide For Partial Discharge Measurement Power SwtgearDocumento26 pagine1291 Guide For Partial Discharge Measurement Power SwtgearZhaqir HusseinNessuna valutazione finora

- Freeze Drying GuideDocumento12 pagineFreeze Drying GuidePedro CostaNessuna valutazione finora

- Chapter 2rrDocumento40 pagineChapter 2rrShen YenNessuna valutazione finora

- ENSC 3233 HW #1 Solution PDFDocumento10 pagineENSC 3233 HW #1 Solution PDFheem bashaNessuna valutazione finora

- Vectors Tensors 15 Tensor Calculus 2Documento11 pagineVectors Tensors 15 Tensor Calculus 2Felipe Carrasco DuránNessuna valutazione finora

- SM PDF Chapter14 PDFDocumento37 pagineSM PDF Chapter14 PDFsuryapmohantyNessuna valutazione finora

- Esas Module (Concepts) : Encoded By: Fausto, Dimazana, Matuto, Maniquis, Montanno, MalicdemDocumento313 pagineEsas Module (Concepts) : Encoded By: Fausto, Dimazana, Matuto, Maniquis, Montanno, MalicdemAlven PullaNessuna valutazione finora

- Air PropertiesDocumento2 pagineAir PropertiesThanh ThuanNessuna valutazione finora

- Hydrometer Lab ReportDocumento6 pagineHydrometer Lab ReportMaica De ChavezNessuna valutazione finora

- Dmsytify E Mc2Documento64 pagineDmsytify E Mc2ahamednmsNessuna valutazione finora