Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Automation PVT LTD.: Fugitive Emission: Installation, Operation, Maintenance & Safety Manual

Caricato da

Danielle Johnson0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

36 visualizzazioni11 pagineINSTALLATION, OPERATION & MAINTENANCE MANUAL FOR FUGITIVE EMISSION

Titolo originale

Fugitive Emission IOM

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoINSTALLATION, OPERATION & MAINTENANCE MANUAL FOR FUGITIVE EMISSION

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

36 visualizzazioni11 pagineAutomation PVT LTD.: Fugitive Emission: Installation, Operation, Maintenance & Safety Manual

Caricato da

Danielle JohnsonINSTALLATION, OPERATION & MAINTENANCE MANUAL FOR FUGITIVE EMISSION

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 11

VAAS Automation Pvt Ltd.

Fugitive Emission: Installation, Operation, Maintenance & Safety Manual

Page 1 of 11 VAPL/IOM/Fugitive Emission/Rev 01/ September 14

Fugitive Emission:

Size range: to 6 (DN15 to DN 150)

1. GENERAL

This Installation, Operating, Maintenance manual present the instructions required for safe use of Fugitive Emission manufactured by Vaas Automation Private Limited-

India. Before using Fugitive Emission Kit, read the entire IOM carefully and make sure you understand everything. Where in doubt, please consult with Vaas

Representative.

WARNINGS & SAFETY INSTRUCTIONS:

Vaas Automation cannot anticipate all of the situations a user may encounter while installing and using Fugitive Emission Kit. The user MUST know and follow all

applicable industry specifications on the safe installation and use of this Fugitive Emission Kit. Misapplication of the product may result in injuries or property damage.

1. Utmost caution must be taken when handling a Fugitive Emission Kit that has toxic, corrosive, flammable or a contaminant nature media flowing

through its pipeline. The following safety precautions are recommended when dismantling Fugitive Emission Kit with hazardous media:

Wear eye shield, protective headgear, clothing, gloves and foot wear.

Have available running water

2. While assembly or dis-assembly of Fugitive Emission Kit, ensure that valve main line has been depressurized and drained.

VAAS Automation Pvt Ltd.

Fugitive Emission: Installation, Operation, Maintenance & Safety Manual

Page 2 of 11 VAPL/IOM/Fugitive Emission/Rev 01/ September 14

3. Do not use or substitute non Vaas automation components or Parts in Vaas automation Fugitive Emission Kit and assemblies

2. LIMITATIONS

As the extent of applications that these Fugitive Emission can be used in, is large, it is not possible to cover all installation and maintenance instructions for

service of the Fugitive Emission. It is the user's responsibility to use the Fugitive Emission Kit as recommended as stated in this manual. Where in doubt,

please consult with Vaas Representative.

CAUTION:

Do not allow dust layers to build up on the equipment.

The process fluid temperature shall not exceed the ignition temperature of the dust.

3. STORAGE

Prior to storage, inspect the Fugitive Emission for shipping damage. Keep all protective packaging and Dummy plugs attached to the Fugitive Emission Kit during

storage. Keep the kit in a clean and dry environment until ready for use.

4. OPERATING INSTRUCTIONS

To prevent leakage, malfunctions resulting from internal wear or seal degradation, the user must establish a preventive maintenance and inspection program. This

program must include, routine replacement of seals and inspection for proper operation.

5. INSTALLATION

5.1. General

The installation procedure for ball Fugitive Emission Kit is critical to ensuring both long life and satisfactory performance. Fugitive Emission Kit stored on site

awaiting installation should be kept in their original packing, in dry conditions, where damage will not occur. Before carrying out the installation, it is important to follow

the basic procedures described below:

Note: Before installation of these Fugitive Emission Kit, the worker must wear gloves.

Carefully unpack the Fugitive Emission Kit

Remove any special packing materials, which were used for packing.

Inspect the Fugitive Emission Kit interior through the end ports to determine it is clean and free from foreign matter.

Operate the Fugitive Emission kit and inspect any functionally significant features.

Read all the literature and note any special warning tags or plates attached to the Fugitive Emission Kit.

Before installation check to insure the Stem is in the fully open position in order to prevent possible damage to the Main Fugitive Emission Kit. The

performance depends on its original conditions. At any stage do not leave the Fugitive Emission kit in the partially open position.

6. MAINTENANCE

Fugitive Emission Kit has a long and trouble free life, and maintenance is seldom required. When maintenance is necessary, Fugitive Emission Kit can be

refurbished on site.

To extend Fugitive Emission Kit performance and reduce possible plant problems, the following procedures should be followed:

If leakage at the stem is noted, tighten the gland nut about a

1

/6-turn as a routine maintenance procedure. This will compensate for any wear or settling of the

gland packing.

Caution: Excessive tightening of the stem nut can result in accelerated seal wear and high Fugitive Emission Kit operating torque.

If the Fugitive Emission Kit is removed from the line and disassembled, replacement of all seals is recommended using the appropriate Vaas Automation

Repair kit. Examine all metallic sealing surfaces such as stem, and corrosion or damage.

Only Vaas Automation's authorized spare parts should be used. Repair kits are available with Vaas Automation.

In addition to repair kits, other spare parts available from Vaas Automation are: Fugitive Emission Kit, stems, glands, bolts, screws and nuts. Should

additional parts be required, it is recommended that the complete Fugitive Emission Kit be replaced.

When ordering repair kits, please provide the Fugitive Emission Kit size and full figure number code and series.

VAAS Automation Pvt Ltd.

Fugitive Emission: Installation, Operation, Maintenance & Safety Manual

Page 3 of 11 VAPL/IOM/Fugitive Emission/Rev 01/ September 14

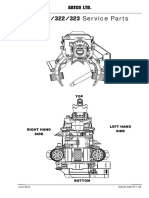

7. Exploded View & Bill of Materials:

Sizes: 3 to 6

Sizes: 1/2 to 2

Bill of Material Description:

Item Description Material Specifications Qty Item Description Material Specifications Qty

1 Body SS ASTM A351 CF8M 1 11 Handle Nut Stainless St. ASTM A194 Grade 8M 1

2 Stem

SS ASTM A479 Gr.316,SS ASTM A564 17-

4PH

1 12 Serrated washer SS 304 1

3 Thrust seal UHMPFE 1 13 Handle sleeve Vinyl Plastisol 1

4 Packing Graphite 1 14 Bonnet Seal Graphite 1

5 Follower Stainless St. ASTM A479 316 1 15 Stop Plate SS ASTM A240 430 1

6 Disc spring Stainless St. ASTM A693 17-7PH 2 16 Tab Lock Washer SS ASTM A240 304 1

7 Stem nut Stainless St. ASTM A194 Grade 8M 2 17 Wrench Head ASTM A47 Malleable Iron 1

8

Locking

clip

SS 304 2 18 Wrench Handle SS 304 1

9 Handle SS 304 4 19 Wrench Handle Bolt SS ISO 4014 A2-70 1

10 Stop pin Stainless St. ASTM A479 316 2 20 Dummy Plug Stainless St. ASTM A479 316 1

VAAS Automation Pvt Ltd.

Fugitive Emission: Installation, Operation, Maintenance & Safety Manual

Page 4 of 11 VAPL/IOM/Fugitive Emission/Rev 01/ September 14

8. DIS ASSEMBLY

The following instructions are for disassembly of kit sizes. {

1

/2 to2)}

SI.no Disassembly Instruction Disassembly Illustration

1

Remove the Bonnet Screws from

the valve body by using proper

Allen key.

2

Remove Bonnet Seal from the

Bonnet groove

3

Handle Nut & Serrated washer are

removed from the stem

4

Remove the Stop Pin & Handle

from the stem

5

Remove the Locking Clip & Gland

Nut from the stem

6

Remove the two Disc Spring &

follower from the stem

VAAS Automation Pvt Ltd.

Fugitive Emission: Installation, Operation, Maintenance & Safety Manual

Page 5 of 11 VAPL/IOM/Fugitive Emission/Rev 01/ September 14

7

Remove the Packing from the

Bonnet grooves

8

Push down the stem and the thrust

seal from the bonnet

9

Dummy plugs or Other accessories

are removed from the Bonnet Port

VAAS Automation Pvt Ltd.

Fugitive Emission: Installation, Operation, Maintenance & Safety Manual

Page 6 of 11 VAPL/IOM/Fugitive Emission/Rev 01/ September 14

The following instructions are for disassembly of kit sizes. {3 to 6}

SI.no Disassembly Instruction Disassembly Illustration

1

Remove the Bonnet Screws from

the valve body by using proper

Allen key.

2

Remove Bonnet Seal from the

Bonnet groove

3

Remove Wrench Head Bolt from

the stem

4

Remove Gland Nut and Tab lock

Washer from the stem

5

Remove the Stop plate & stop pin

from the Bonnet and the Stem

6

Remove the follower & Packing

from the stem

VAAS Automation Pvt Ltd.

Fugitive Emission: Installation, Operation, Maintenance & Safety Manual

Page 7 of 11 VAPL/IOM/Fugitive Emission/Rev 01/ September 14

7

Push down Stem & Thrust seal

are removed from the Bonnet

8

Dummy plugs or Other

accessories are removed from the

Bonnet Port

VAAS Automation Pvt Ltd.

Fugitive Emission: Installation, Operation, Maintenance & Safety Manual

Page 8 of 11 VAPL/IOM/Fugitive Emission/Rev 01/ September 14

9. ASSEMBLY

The following instructions are for Assembly of kit sizes. {

1

/2 to2)}

SI.no Assembly Instruction Assembly Illustration

1

Dummy plugs or Other

accessories are connected to

the Bonnet Port

2

Push up the stem and the

thrust seal to the bonnet

3

Insert the Packing to the

Bonnet Bores

4

Insert the follower & two Disc

Spring onto Stem

5

Insert the Locking Clip & Gland

Nut to the stem

6

Insert the Stop Pin & Handle to

the stem

VAAS Automation Pvt Ltd.

Fugitive Emission: Installation, Operation, Maintenance & Safety Manual

Page 9 of 11 VAPL/IOM/Fugitive Emission/Rev 01/ September 14

7

Handle Nut & Serrated washer

are Inserted to the stem

8

Insert Bonnet Seal to the

Bonnet groove on bottom side

9

Insert the Bonnet Screws to

the valve body by using proper

Allen key.

VAAS Automation Pvt Ltd.

Fugitive Emission: Installation, Operation, Maintenance & Safety Manual

Page 10 of 11 VAPL/IOM/Fugitive Emission/Rev 01/ September 14

The following instructions are for Assembly of kit sizes. {3 to 6}

SI.no Assembly Instruction Assembly Illustration

1

Dummy plugs or Other

accessories are connected to

the Bonnet Port

2

Push up the stem and the

thrust seal to the bonnet

3

Insert the Packing & Follower

onto Bonnet Bore

4

Insert the Stop plate & stop pin

onto the Bonnet mounting face

& Stem

5

Insert Gland Nut and Tab lock

Washer to the stem

6

Assemble Wrench Head Bolt to

the stem by wrench head

VAAS Automation Pvt Ltd.

Fugitive Emission: Installation, Operation, Maintenance & Safety Manual

Page 11 of 11 VAPL/IOM/Fugitive Emission/Rev 01/ September 14

7

Insert Bonnet Seal to the

Bonnet groove on the Bonnet

8

Assemble the Bonnet Screws

to the valve body by using

proper Allen key.

TABLE 1

Gland Nut Tightening Torque

TABLE 2

Fugitive Emission Bonnet Screw Tightening Torque

Size Bolt Thread NM In.lb

1/2" M5 6 55

1" - 11/2" M6 9 80

2" M10 39 345

21/2" - 4" M12 65 575

6 M16 160 1416

Size Nut thread

PTFE

seals

Graphite

seals

Nm In.lb Nm In.lb

1/2'' 3/8'' UNF-24 UNF 4 35 6-4 53-35

1'' 7/16'' UNF-20 UNF 9 80 11-9 97-80

11/2'' 9/16'' UNF-18 UNF 13 115 16-13 140-115

2'' M20 X 2.5 30 265 36-30 320-265

3''-4'' 1''-14 UNS 60 530 72-60 637-530

6 1-1/2 -12 UNF 120 1060 120-145 1060-1280

Potrebbero piacerti anche

- ATS73 Maint ManDocumento12 pagineATS73 Maint Manpr_oilNessuna valutazione finora

- C47 Series IOMDocumento8 pagineC47 Series IOMKannan KrisNessuna valutazione finora

- Flame ArresterDocumento16 pagineFlame Arresteriran1362Nessuna valutazione finora

- Actuador de Válvula FlowserveDocumento8 pagineActuador de Válvula FlowserveemanuellesanchezNessuna valutazione finora

- VAAS Fig 740 and 730 Series IOMDocumento9 pagineVAAS Fig 740 and 730 Series IOMCarlos GutierrezNessuna valutazione finora

- Caterpillar Cat 320D L Excavator (Prefix A9F) Service Repair Manual (A9F00001 and Up)Documento23 pagineCaterpillar Cat 320D L Excavator (Prefix A9F) Service Repair Manual (A9F00001 and Up)kfmuseddk0% (1)

- Akrapovic Slip On Exhaust Ducati Multistrada1200 s20152016Documento14 pagineAkrapovic Slip On Exhaust Ducati Multistrada1200 s20152016mcbuinNessuna valutazione finora

- Weflo Nrs Gate Op and MaintDocumento5 pagineWeflo Nrs Gate Op and MaintyusufNessuna valutazione finora

- 08 6.H Pressure VesselDocumento32 pagine08 6.H Pressure VesselstargaxxxxNessuna valutazione finora

- Series 808Y Installation InstructionsDocumento4 pagineSeries 808Y Installation InstructionsFEBCONessuna valutazione finora

- ZT 6000 VSDocumento14 pagineZT 6000 VSdesign_artNessuna valutazione finora

- Service Manual Salisbury 5ha AxlesDocumento44 pagineService Manual Salisbury 5ha AxlesCarlos Gabriel EstergaardNessuna valutazione finora

- AE14 Automatic Air Vents For Liquid SystemsDocumento8 pagineAE14 Automatic Air Vents For Liquid SystemsUtku KepcenNessuna valutazione finora

- Filtro Onga Series IIDocumento24 pagineFiltro Onga Series IIRicardo Cesar Bueno BertichevicNessuna valutazione finora

- 3 Hartindo AF11E Post Fire MaintenaceDocumento17 pagine3 Hartindo AF11E Post Fire Maintenacebudi utamaNessuna valutazione finora

- Akrapovic Racing & Evolution Exhaust System: Installation InstructionsDocumento17 pagineAkrapovic Racing & Evolution Exhaust System: Installation InstructionscarlosNessuna valutazione finora

- Microfinish Valve Maintenance Manual PDFDocumento14 pagineMicrofinish Valve Maintenance Manual PDFrajputashiNessuna valutazione finora

- Welded Body Ball ValveDocumento20 pagineWelded Body Ball ValveBisoyiNessuna valutazione finora

- Rotary Valve FabricatedDocumento11 pagineRotary Valve FabricatedAdem AltanNessuna valutazione finora

- Iom Cam Ball t31Documento20 pagineIom Cam Ball t31Albino Felix HernandezNessuna valutazione finora

- Geith - Acople Ec460bDocumento25 pagineGeith - Acople Ec460bjrincon26Nessuna valutazione finora

- Outlets and AccessoriesDocumento20 pagineOutlets and AccessoriesFelipe Gagliardi de PaulaNessuna valutazione finora

- Manual de Montacarga CatDocumento20 pagineManual de Montacarga CatJulio Elias Mayta Ramos67% (6)

- Ultra-Flow ManualDocumento16 pagineUltra-Flow ManualLU DustinNessuna valutazione finora

- Valvework Usa. Model M MSGDocumento7 pagineValvework Usa. Model M MSGLuis Enrique RicoNessuna valutazione finora

- UBC Owner's Manual.v3.BLDocumento16 pagineUBC Owner's Manual.v3.BLKito CanadaNessuna valutazione finora

- Akrapovic Slip On Exhaust Ducati8991199 PanigaleDocumento18 pagineAkrapovic Slip On Exhaust Ducati8991199 PanigaleDeSmO ManUNessuna valutazione finora

- Iom MVT ValvesDocumento5 pagineIom MVT ValvesNaser JahangiriNessuna valutazione finora

- 390 InstructionsDocumento48 pagine390 InstructionsemaanazeemNessuna valutazione finora

- Fisher Design ETR ValveDocumento24 pagineFisher Design ETR ValveTanuTiganuNessuna valutazione finora

- TopyDocumento64 pagineTopyChristiano Calijorne de BarrosNessuna valutazione finora

- K38 Rocker HousingDocumento13 pagineK38 Rocker HousinghindraNessuna valutazione finora

- EGV ManualDocumento15 pagineEGV ManualT.MuthuvijayapandiNessuna valutazione finora

- Compresor Ingersoll Rand P900a WcuDocumento112 pagineCompresor Ingersoll Rand P900a Wcuangel de mi guardaNessuna valutazione finora

- Series B6800 Installation InstructionsDocumento2 pagineSeries B6800 Installation InstructionsWattsNessuna valutazione finora

- Load Cell Sensator E80 TW561Documento8 pagineLoad Cell Sensator E80 TW561pwmvsi100% (9)

- Installation Instructions Oil Filter Relocation Kit PART # 15749Documento2 pagineInstallation Instructions Oil Filter Relocation Kit PART # 15749Alex BernalNessuna valutazione finora

- Agilent Rotor SealDocumento5 pagineAgilent Rotor SealpoiuytNessuna valutazione finora

- Gate Valve Installation Operation & Maintenance ManualDocumento5 pagineGate Valve Installation Operation & Maintenance ManualViba Fluid ControlNessuna valutazione finora

- 7.06 EC 10M SINGLE BOP ManDocumento20 pagine7.06 EC 10M SINGLE BOP ManRafael BolivarNessuna valutazione finora

- p077 02 PDFDocumento8 paginep077 02 PDFJuan ZamoraNessuna valutazione finora

- Codeline - 80E Series: 8 Inch End Entry Membrane Housing For Ro ApplicationsDocumento29 pagineCodeline - 80E Series: 8 Inch End Entry Membrane Housing For Ro ApplicationsCecilia Guerra AburtoNessuna valutazione finora

- Butterfly Valve User ManualDocumento10 pagineButterfly Valve User ManualEduardoAscencioNessuna valutazione finora

- HP2211Documento2 pagineHP2211Francisco AbreuNessuna valutazione finora

- RD Circulating ValveDocumento6 pagineRD Circulating ValvearslanadeelNessuna valutazione finora

- 002-004 Tapa de Cilindro-3Documento34 pagine002-004 Tapa de Cilindro-3Jose Leandro Del ZarNessuna valutazione finora

- 002-004 Tapa de Cilindro-2Documento34 pagine002-004 Tapa de Cilindro-2Jose Leandro Del ZarNessuna valutazione finora

- Technical Manual Rotary ValveDocumento8 pagineTechnical Manual Rotary ValvexichengrenNessuna valutazione finora

- TB Mag ManualDocumento60 pagineTB Mag Manualyanina25Nessuna valutazione finora

- Service Instruction: LycomingDocumento4 pagineService Instruction: LycomingGANessuna valutazione finora

- Pulper Rotor ManualDocumento10 paginePulper Rotor ManualhenryhariyadiNessuna valutazione finora

- Inlet and Exhaust Valves - Remove and Install: Shutdown SIS Previous ScreenDocumento5 pagineInlet and Exhaust Valves - Remove and Install: Shutdown SIS Previous ScreenbejoythomasNessuna valutazione finora

- Service Manual: Spring Brake ActuatorDocumento24 pagineService Manual: Spring Brake ActuatorPatricio G. ArrienNessuna valutazione finora

- 17 - Booster Pump Operational ManualDocumento6 pagine17 - Booster Pump Operational ManualDevaj NahkNessuna valutazione finora

- Enviro Seal System Rotary ValavesDocumento16 pagineEnviro Seal System Rotary ValavesJhne OkNessuna valutazione finora

- Installation Instructions Winch Mounting Kit: Part Number: 74180 Application: Honda Foreman 500 & Honda RubiconDocumento14 pagineInstallation Instructions Winch Mounting Kit: Part Number: 74180 Application: Honda Foreman 500 & Honda RubiconManuel Castro EdiolaNessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideDa EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideValutazione: 4.5 su 5 stelle4.5/5 (8)

- Gate Valve VC1500BBDocumento4 pagineGate Valve VC1500BBDanielle JohnsonNessuna valutazione finora

- Gate Valve - 800# PDFDocumento4 pagineGate Valve - 800# PDFDanielle JohnsonNessuna valutazione finora

- Gate Valve - 800#Documento4 pagineGate Valve - 800#Danielle JohnsonNessuna valutazione finora

- Tank Bottom Valves 1" and 1 / " TB59: Installation, Operation and Maintenance InstructionsDocumento4 pagineTank Bottom Valves 1" and 1 / " TB59: Installation, Operation and Maintenance InstructionsDanielle JohnsonNessuna valutazione finora

- Floating Ball 715,730Documento4 pagineFloating Ball 715,730Danielle JohnsonNessuna valutazione finora

- VAAS C47 Series Cryo Ball Valve CatalogueDocumento8 pagineVAAS C47 Series Cryo Ball Valve CatalogueDanielle JohnsonNessuna valutazione finora

- Flow Tek C4700 Series Cryo Ball ValveDocumento8 pagineFlow Tek C4700 Series Cryo Ball ValveDanielle JohnsonNessuna valutazione finora

- Vaas Head Office DetailsDocumento8 pagineVaas Head Office DetailsDanielle JohnsonNessuna valutazione finora

- Anderson Greenwood Needle ValvesDocumento14 pagineAnderson Greenwood Needle ValvesDanielle JohnsonNessuna valutazione finora

- Vaas Automation PVT LTD: 90 Series Installation, Operating & Maintenance ManualDocumento5 pagineVaas Automation PVT LTD: 90 Series Installation, Operating & Maintenance ManualDanielle JohnsonNessuna valutazione finora

- 2 Seat Diverter ValvesDocumento4 pagine2 Seat Diverter ValvesDanielle JohnsonNessuna valutazione finora

- MDSP Elements Part 1Documento101 pagineMDSP Elements Part 1Kira YagamiNessuna valutazione finora

- Manual de Roscas EstandaresDocumento136 pagineManual de Roscas EstandaresDavid AgNessuna valutazione finora

- Es 9-54 Fastener Installation and Torque ValuesDocumento33 pagineEs 9-54 Fastener Installation and Torque ValuesCarlosFernandoMondragonDominguezNessuna valutazione finora

- Nut and Bolt TutorialDocumento7 pagineNut and Bolt TutorialPraveen Kumar SharmaNessuna valutazione finora

- 13-Elora Different ToolsDocumento34 pagine13-Elora Different ToolsLokesh ModemzNessuna valutazione finora

- Thread Identifications Chart PDFDocumento2 pagineThread Identifications Chart PDFecavalinNessuna valutazione finora

- Sutton Tools Tapping Drill Size ChartDocumento2 pagineSutton Tools Tapping Drill Size ChartcncmancomNessuna valutazione finora

- Thread Specification ORFS SAE J1453Documento1 paginaThread Specification ORFS SAE J1453Kiran KadamNessuna valutazione finora

- Best Practice Bolting FMDocumento11 pagineBest Practice Bolting FMAlfonsus W.M.Nessuna valutazione finora

- SAT3series Parts Section-June2014Documento72 pagineSAT3series Parts Section-June2014Heidi Cuevas Venegas100% (2)

- Model S-20 High Performance Pressure Transmitter For General Industrial ApplicationsDocumento15 pagineModel S-20 High Performance Pressure Transmitter For General Industrial ApplicationsIndra PutraNessuna valutazione finora

- Thread Symbols (Short Form)Documento1 paginaThread Symbols (Short Form)SurajPachhadeNessuna valutazione finora

- Drill Bit Size ChartDocumento7 pagineDrill Bit Size ChartwilliaqNessuna valutazione finora

- EASA Module 6 - Detailed NotesDocumento37 pagineEASA Module 6 - Detailed NotesSteven J. SelcukNessuna valutazione finora

- Fasteners Handbook - Blacks - CatalogueDocumento88 pagineFasteners Handbook - Blacks - CatalogueRobert Stuart100% (2)

- W01 358 7327Documento29 pagineW01 358 7327MROstop.comNessuna valutazione finora

- Serie m103 RTC CouplingsDocumento8 pagineSerie m103 RTC CouplingsHIDRAFLUIDNessuna valutazione finora

- Unified Black Hexagon Bolts, Screws, Nuts - (UNC & UNF Threads) - Heavy SeriesDocumento18 pagineUnified Black Hexagon Bolts, Screws, Nuts - (UNC & UNF Threads) - Heavy SeriesraulNessuna valutazione finora

- Yale mp20x (07-2010)Documento234 pagineYale mp20x (07-2010)Rafał Ostrowski100% (1)

- 04 Catalog Krisbow9 Automotive-MinDocumento26 pagine04 Catalog Krisbow9 Automotive-MinEPhiê BâchêlorsNessuna valutazione finora

- Fastener Weight ChartDocumento9 pagineFastener Weight ChartTricolor C ANessuna valutazione finora

- Bladder Accumulators Standard Model: 1. DescriptionDocumento8 pagineBladder Accumulators Standard Model: 1. DescriptionbarryNessuna valutazione finora

- Manual de Partes 495HR2 PDFDocumento1.172 pagineManual de Partes 495HR2 PDFYuri Sanderson0% (1)

- 0120 Industrial enDocumento36 pagine0120 Industrial enPaulo C DamazoNessuna valutazione finora

- Https WWW - Google.com Amp S WWW - Engineeringtoolbox.Documento7 pagineHttps WWW - Google.com Amp S WWW - Engineeringtoolbox.BelalNorNessuna valutazione finora

- 4410 - Section B - Fittings PDFDocumento186 pagine4410 - Section B - Fittings PDFhansegvNessuna valutazione finora

- 990 Vibration Transmitter Datasheet - 141612Documento16 pagine990 Vibration Transmitter Datasheet - 141612ap16484Nessuna valutazione finora

- Watson-Marlow Fittings-Gb-04 PDFDocumento35 pagineWatson-Marlow Fittings-Gb-04 PDFcalejandrotgNessuna valutazione finora

- Bolt-Nut BrochureDocumento13 pagineBolt-Nut BrochureLong Beautéophile100% (1)

- Crouse Hinds Unf Unl Uny Unions El Elbows Catalog PageDocumento4 pagineCrouse Hinds Unf Unl Uny Unions El Elbows Catalog PagewillytNessuna valutazione finora