Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

32 - 40 - Four Stroke - 34210101

Caricato da

Mulyo Setiawan0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

224 visualizzazioni7 pagineMAN Diesel and Turbo is the world's leading designer and manufacturer of low and medium speed engines. Our engines cover an estimated 50% of the power needed for all world trade. MAN's development focus is the environment performance of our engines.

Descrizione originale:

Titolo originale

32_40_Four stroke_34210101

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoMAN Diesel and Turbo is the world's leading designer and manufacturer of low and medium speed engines. Our engines cover an estimated 50% of the power needed for all world trade. MAN's development focus is the environment performance of our engines.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

224 visualizzazioni7 pagine32 - 40 - Four Stroke - 34210101

Caricato da

Mulyo SetiawanMAN Diesel and Turbo is the world's leading designer and manufacturer of low and medium speed engines. Our engines cover an estimated 50% of the power needed for all world trade. MAN's development focus is the environment performance of our engines.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 7

32/40

Four-stroke diesel engine

MAN Diesel & Turbo

The responsible way in leading technology

MAN Diesel & Turbo is the worlds leading designer and manufacturer of low and

medium speed engines engines from MAN Diesel & Turbo cover an estimated

50% of the power needed for all world trade. We develop two-stroke and four-

stroke engines, auxiliary engines, turbochargers and propulsion packages that are

manufactured both within the MAN Diesel & Turbo Group and at our licencees.

More than ever before, MAN Diesel & Turbos development focus is the environ-

mental performance of our engines. Using our unrivalled grasp of large engine

technology, we aim to make our engines progressively cleaner, more powerful and

more efficient.

Our absolute commitment to reducing emissions while increasing fuel efficiency

and power density starts with our active partnership in the emissions law making

process and ends with the delivery of engines that achieve an ideal synthesis of

prime mover characteristics.

3 32/40 Four-stroke diesel engine

Core technologies in-house

As well as its expertise in engine design, develop-

ment and manufacture MAN Diesel & Turbo is also

a leading manufacturer of the key technologies which

determine the economic and ecological performance

of a diesel engine:

High-efficiency exhaust gas turbochargers

Advanced electronic fuel injection equipment

Electronic hardware and software for engine control,

monitoring and diagnosis

Our impressive array of computer-aided design tools

and one of the engine industrys largest, best-equipped

foundries allow us decisively to shorten product de-

velopment, and application engineering processes.

Our mastery of these engine technologies and, the

best brains in the large engine industry are the firm

foundation for

Low emissions

Low operating costs

Low life cycle costs

Long service life

The range of technical measures employed comprises:

Revised injection timing

Higher compression ratios

Variable Injection Timing (VIT)

Committed to the future

Technologies which promise compliance with the

IMO Tier III emission limits valid from 2016 com-

bined with further optimised fuel consumption

and new levels of power and flexibility are already

under development at MAN Diesel & Turbo.

With this level of commitment MAN Diesel & Turbo

customers can plan with confidence.

RI Retarded Injection

Retarded injection timing delays combustion heat re-

lease and thus lowers combustion chamber temperature

peaks.

New Piston for Increased Compression Ratio

The use of a new piston provides a higher compression

ratio and gives a faster reduction in temperature after

the ignition of the fuel, thus reducing NO

x

formation.

The increase in compression ratio also compensates

the reduction in firing temperature due to retarded

injection and hence the associated increase in SFOC.

Efficient, Clean and Compact

NO

X

Reduction measures 32/40

A notable reduction in NO

x

, CO

2

and soot emissions is a strategical factor for success

of modern diesel engines. The 32/40 combined all relevant features to significantly

reduce harmful emissions.

4 32/40 Four-stroke diesel engine

Engine Specifications

Modern and innovative technology

Marine main engines

Engine output is limited to 100% of rated output for

engines driving a propeller. Engine output is limited to

110% of rated output for engines driving a generator.

Overload above 100% permitted briefly to prevent a

frequency drop during sudden load application.

Fuels

The 32/40 engine can be operated on heavy fuel oil

with a viscosity up to 700 mm/s (cSt) at 50 C. It is

designed for fuel qualities up to the levels specified in

CIMAC 2003 H/K700/DIN ISO 8217.

Stepped piston

Forged dimensionally stable steel crown (with shaker

cooling) made from high grade materials and skirt in

spheroidal graphite cast iron (skirt also available in steel

upon request). The stepped piston and the fire ring

to gether prevent bore polishing of the cylinder liner,

thereby reducing operating costs by keeping lubrica-

ting oil consump tion consistently low. Chromium ceramic

coating of the first piston ring with wear resistant cera-

mic particles in the ring surface results in minimal wear

and tear, ensuring extremely long periods between

maintenance.

MAN Diesel & Turbo turbocharging system

Industry leading designed constant pres sure turbochar-

ging system using state-of-the-art MAN Diesel & Turbo

turbochargers with long bearing overhaul intervals.

High efficiency at full and part loads results in substan-

tial air surplus and complete combustion without resi-

dues and with low thermal stresses on the combustion

chamber components.

Cylinder head

The cylinder head has optimised com bustion chamber

geometry for improved injection spray atomisation. This

ensures balanced air-fuel mixture, reducing com bustion

residue, soot forma tion and improving fuel economy.

Valves

Exhaust valves are designed with armoured, water

cooled seats that keep valve temperatures down. Pro-

pellers on the exhaust valve shaft provide rotation by

exhaust gas, resulting in the cleaning effect of the valve

seat area during valve closing.

Service friendly design

Hydraulic tooling for tightening and loosening cylinder

head nuts; clamps with quick release fasteners and/or

clamp and plug connectors; generously sized access

covers.

Cylinder liner

The precision machined cylinder liner and seperate coo-

ling water collar rest on top of the engine frame and is

there isolated from any external deformation, ensuring

optimum piston performance and long service life.

SaCoS

one

All medium-speed marine engines from

MAN Diesel & Turbo are equipped with the SaCoS

one

safety and control system. This system undergoes a

workshop test at the factory together with the engine,

ensuring effortless fine tuning and functional testing

during ship commissioning.

Engine data for 32/40

General

Engine cycle: Four-stroke

Turbocharging system: Constant pressure

Number of cylinders, In-line engine: 6, 7, 8, 9

Number of cylinders, V-engine: 12, 14, 16, 18

Bore: 320 mm

Stroke: 400 mm

Swept volume per cyl: 32.2 dm

3

Power-to-weight ratio (MCR)

In-line engine: 11.3 12.7 kg/kW

V-engine: 9.4 10.2 kg/kW

Cylinder output (MCR)

at 750/ 720*

)

rpm: 500 kW

MCR = maximum continuous rating

*) For generator drive only

Cooling

Cylinder cooling: Fresh water

Charge-air cooler (two-stage): Fresh water

Fuel injector cooling: Fresh water, only when running on HFO

Starting method: Compressed air

ISO reference conditions:

Air temperature: 298 K (25 C)

Air pressure: 1 bar

Fresh water temperature upstream of charge-air

cooler: 298 K (25 C)

Relative humidity: 30%

For maritime engines, no power reduction

required below:

Air temperature: 318 K (45 C)

Air pressure: 1 bar

Fresh water temperature upstream of charge-air

cooler: 311 K (38 C)

IMO requirements:

The engine detailed herein will comly with the

emission limits refered to as IMO Tier II.

General performance defnition for diesel

engines as per ISO 3046/1-2002

The Work Horse 32/40 is in service 24 hours a day. With a power output range of

3,000 to 9,000 kW, it is ideal for small and medium sized applications. The interacting

of all important parts results to low wear rates and long maintanace intervals.

6 32/40 Four-stroke diesel engine

Technical Data

32/40

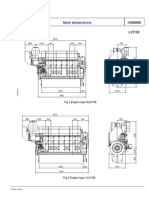

L32/40 V32/40

V-engine V32/40

Engine type No. of cyl. L L1 W H Wt.

mm mm mm mm t

12V32/40 12 6,915 5,890 3,140 4,100 61

14V32/40 14 7,545 6,520 3,140 4,100 68

16V32/40 16 8,365 7,150 3,730 4,420 77

18V32/40 18 8,995 7,780 3,730 4,420 85

All weights and dimensions are for guidance only and apply to dry engines without flywheel. Minimum centreline distance for twin engine installation: 4,000 mm

More information available upon request.

In-line engine L32/40

Engine type No. of cyl. L L1 W H Wt.

mm mm mm mm t

6L32/40 6 5,940 5,140 2,630 4,010 38

7L32/40 7 6,470 5,670 2,630 4,010 42

8L32/40 8 7,000 6,195 2,715 4,490 47

9L32/40 9 7,530 6,725 2,715 4,490 51

All weights and dimensions are for guidance only and apply to dry engines without flywheel. Minimum centreline distance for twin engine installation: 2,500 mm

Minimum centreline distance for twin engine installation with turbocharger on counter coupling side: 3,000 mm. More information available upon request.

Outputs MCR (maximum continuous rating)

Engine speed 750 rpm 720*

)

rpm

Mean piston speed 10.0 m/s 9.6 m/s

Mean effective pressure 24.9 bar 25.9 bar

kW kW

6L32/40 6 cyl. 3,000 3,000

7L32/40 7 cyl. 3,500 3,500

8L32/40 8 cyl. 4,000 4,000

9L32/40 9 cyl. 4,500 4,500

12V32/40 12 cyl. 6,000 6,000

14V32/40 14 cyl. 7,000 7,000

16V32/40 16 cyl. 8,000 8,000

18V32/40 18 cyl. 9,000 9,000

*) For generator drive only

Fixed Pitch Propeller: 450kW/Cyl

Specific Fuel Oil Consumption (SFOC) to ISO conditions

100% load 85% load

L32/40 185 g/kWh 182 g/kWh

L32/40 FPP 189 g/kWh 184 g/kWh

V32/40 183 g/kWh 181 g/kWh

V32/40 FPP 187 g/kWh 183 g/kWh

Engine type specific reference charge air temperature before cylinder 43 C

The fuel consumption is based on a lower calorific value (LHV) of the fuel of 42,700 kJ/kg without attached pumps. Tolerance +5%.

Specific lubricating oil consumption

L+V32/40 0.5 g/kWh

L+V32/40 FPP 0.5 g/kWh

The lube oil consumption is given with a tolerance of +20%

Dimensions and Weights

All cylinder numbers

9 8 32/40 Four-stroke diesel engine 32/40 Four-stroke diesel engine

World Class Service

Marine propulsion and GenSets

PrimeServ peace of mind for life

With more than 150 PrimeServ service stations and

service partners worldwide, plus our growing network

of PrimeServ Academies, the MAN Diesel & Turbo after-

sales organisation is committed to maintaining the most

efficient and accessible after-sales organisation in the

business.

PrimeServs aim is to provide:

Prompt delivery of high demand OEM spare parts

within 24 hours

Fast, reliable and competent customer support

Individually tailored O&M contracts

Ongoing training and qualification of service personnel

Global service, open 24 hours-a-day, 365 days-a-year

Diagnosis and troubleshooting with our high perfor-

mance Online Service

The PrimeServ Offering

Based on almost 110 years of service experience

with marine diesel engines, our sophisticated lo-

gistics system ensures that all frequently requested

spare parts are available worldwide within 24 hours.

In addition, MAN Diesel & Turbo Online Service

helps to optimise maintenance cycles by the use of

remote engine monitoring, diagnostics and calibra-

tion. The resulting condition-based maintenance

(CBM) promotes high availability, increases opera-

tional safety, shortens downtimes and enhances the

performance of MAN Diesel & Turbo marine engines.

The bottom line: leaner operating costs and better

planning for you.

When service is required, the MAN PrimeServ network

responds to organise assistance as fast as possible.

This guarantees rapid completion of maintenance

work and high availability of MAN Diesel & Turbo en-

gines, GenSets, turbochargers, gears, propellers and

marine propulsion packages.

In short: MAN PrimeServ gives you the benefit of our

specialist expertise in marine power so that you can

concentrate on your own core business.

10 32/40 Four-stroke diesel engine

MAN Diesel Powering the World MAN Diesel & Turbo a member of the MAN Group

MAN Diesel & Turbo

86224 Augsburg, Germany

Phone +49 821 322-0

Fax +49 821 322-3382

marineengines-de@mandieselturbo.com

www.mandieselturbo.com

All data provided in this document is non-binding. This data serves informational

purposes only and is especially not guaranteed in any way. Depending on the

subsequent specific individual projects, the relevant data may be subject to

changes and will be assessed and determined individually for each project. This

will depend on the particular characteristics of each individual project, especially

specific site and operational conditions. Copyright MAN Diesel & Turbo.

D2366308EN-N9 Printed in Germany GMC-AUG-08122

Potrebbero piacerti anche

- Common Rail Fuel Injection Technology in Diesel EnginesDa EverandCommon Rail Fuel Injection Technology in Diesel EnginesNessuna valutazione finora

- Man BWDocumento24 pagineMan BWDhanie KhruxzNessuna valutazione finora

- MAN B&W Alpha DieselDocumento12 pagineMAN B&W Alpha Dieselamin_corporation100% (3)

- Start Man B&W ManualDocumento1 paginaStart Man B&W ManualSudarshan AgnihotriNessuna valutazione finora

- Project Guide C25 33 Propulsion EnginesDocumento138 pagineProject Guide C25 33 Propulsion EnginesJose RamonNessuna valutazione finora

- SL2020-692 LDCL Update PDFDocumento7 pagineSL2020-692 LDCL Update PDFg arvNessuna valutazione finora

- L32-40 GenSet TierIIDocumento262 pagineL32-40 GenSet TierIINurettin Savruk100% (1)

- MAN Diesel EngDocumento164 pagineMAN Diesel EngRAJESH GANESANNessuna valutazione finora

- D628 Maintenance ScheduleDocumento3 pagineD628 Maintenance ScheduleDPNessuna valutazione finora

- MAN Tech Paper Low SpeedDocumento16 pagineMAN Tech Paper Low SpeedfusedNessuna valutazione finora

- E-GICS System For ShipsDocumento4 pagineE-GICS System For Shipsravilulla100% (1)

- GE L250 BrochureDocumento6 pagineGE L250 BrochureMartin KratkyNessuna valutazione finora

- 48 60B Project GuideDocumento520 pagine48 60B Project Guidenckpourlas100% (2)

- CR Presentation PDFDocumento100 pagineCR Presentation PDFPolStone100% (1)

- Man BW LargeDocumento20 pagineMan BW LargeVictor EugenNessuna valutazione finora

- 706 - Performance Evaluation and General Operation - 007Documento72 pagine706 - Performance Evaluation and General Operation - 007Vignesh SivaNessuna valutazione finora

- K 98 MCC 7Documento383 pagineK 98 MCC 7Мария ЗинченкоNessuna valutazione finora

- 2007 - ΜΑΝ - ΣΤΟΙΧΕΙΑ ΚΙΝΗΤΗΡΑDocumento14 pagine2007 - ΜΑΝ - ΣΤΟΙΧΕΙΑ ΚΙΝΗΤΗΡΑPariotis EfthimiosNessuna valutazione finora

- C10751289 PDFDocumento16 pagineC10751289 PDFIrfan ZidniNessuna valutazione finora

- 2016Q020 02gbDocumento3 pagine2016Q020 02gbDenim102Nessuna valutazione finora

- S80 MCCDocumento236 pagineS80 MCCAnonymous 8rb48tZS100% (1)

- Himsen H46 60VDocumento4 pagineHimsen H46 60VairtupasNessuna valutazione finora

- Seatboat Sample ArticleDocumento31 pagineSeatboat Sample ArticleJoseph AlimNessuna valutazione finora

- K90MC-C MK 6 Project Guide Two-Stroke Engines: 4th Edition December 2000Documento279 pagineK90MC-C MK 6 Project Guide Two-Stroke Engines: 4th Edition December 2000faintaresNessuna valutazione finora

- Man B&W K90Me9-Tii: Project Guide Electronically Controlled Two Stroke EnginesDocumento347 pagineMan B&W K90Me9-Tii: Project Guide Electronically Controlled Two Stroke EnginesNguyễn Công HùngNessuna valutazione finora

- Pci 389Documento2 paginePci 389ZitaPNessuna valutazione finora

- RT Flex 11 PDFDocumento4 pagineRT Flex 11 PDFMarijaŽaperNessuna valutazione finora

- fV-Operator Manual PDFDocumento28 paginefV-Operator Manual PDFAbhishek KumarNessuna valutazione finora

- Himsen Micro Pilot System Injector MaintenanceDocumento40 pagineHimsen Micro Pilot System Injector MaintenancePeteNessuna valutazione finora

- MANDocumento141 pagineMANFirman Maulana Erawan HakamNessuna valutazione finora

- Himsen H25 33V PDFDocumento12 pagineHimsen H25 33V PDFArun50% (2)

- P51702-10-Kit For Overhaul of Fuel Valve TIER IIDocumento2 pagineP51702-10-Kit For Overhaul of Fuel Valve TIER IIFilipe FilipeNessuna valutazione finora

- Wartsila 50 DFDocumento96 pagineWartsila 50 DFimant197812gmail.comNessuna valutazione finora

- Instruction Book L2738ed080120Documento252 pagineInstruction Book L2738ed080120GiovanniJaraNessuna valutazione finora

- G60me C10 - 5 LgipDocumento594 pagineG60me C10 - 5 LgipKhải Nguyễn MinhNessuna valutazione finora

- RT 133 PDFDocumento6 pagineRT 133 PDFRaul DiazNessuna valutazione finora

- Rta 70Documento6 pagineRta 70George Domusciu100% (1)

- Programme PDFDocumento71 pagineProgramme PDFAnjali Seth100% (1)

- K 98 Mec 7Documento369 pagineK 98 Mec 7Luis MillerNessuna valutazione finora

- L23 30Documento1.155 pagineL23 30Дима Скоробогатый100% (1)

- S65me C8 - 2 GiDocumento395 pagineS65me C8 - 2 GiVipul AgarwalNessuna valutazione finora

- V222TI Operation & Maintenance ManualDocumento294 pagineV222TI Operation & Maintenance ManualLisandroNessuna valutazione finora

- Wartsila RTA96C Engine Technology ReviewDocumento24 pagineWartsila RTA96C Engine Technology ReviewVolodymyr SavchukNessuna valutazione finora

- Cylinder Lubrication of Two Stroke Crosshead Marine Diesel EnginesDocumento12 pagineCylinder Lubrication of Two Stroke Crosshead Marine Diesel EnginesdiansulaemanNessuna valutazione finora

- 350 - Survey ULJ S50C 03 1Documento8 pagine350 - Survey ULJ S50C 03 1Gaurav WaliaNessuna valutazione finora

- WinGD - X92Documento73 pagineWinGD - X92chaseNessuna valutazione finora

- Dimensi MesinDocumento28 pagineDimensi MesinSyahrir QoimNessuna valutazione finora

- RT Flex 05Documento12 pagineRT Flex 05George Domusciu100% (1)

- Big End Bore MeasurementDocumento1 paginaBig End Bore MeasurementmohamedNessuna valutazione finora

- Ue60ls IiDocumento5 pagineUe60ls IiHaziq IsmailNessuna valutazione finora

- Engine Performance Data: Safety Precautions Special ToolsDocumento184 pagineEngine Performance Data: Safety Precautions Special ToolsHtooThar AungNessuna valutazione finora

- MAN Marine Diesel Engine - enDocumento1.566 pagineMAN Marine Diesel Engine - enYacine GhanemiNessuna valutazione finora

- HOUTTUIN Catalog GeneralDocumento12 pagineHOUTTUIN Catalog GeneralRelu123Nessuna valutazione finora

- G Type EnginesDocumento16 pagineG Type Enginespavlo_790317697Nessuna valutazione finora

- Damper-D 90 45 ENDocumento38 pagineDamper-D 90 45 ENaps100% (1)

- 701 Me DoosanDocumento37 pagine701 Me DoosanRonald Sol Salen JordasNessuna valutazione finora

- Wingd Low Speed Engines Booklet 2017Documento39 pagineWingd Low Speed Engines Booklet 2017mohd badri bahari100% (1)

- Summary of MAN Service Letter 16/24: Technical Information L InformationDocumento10 pagineSummary of MAN Service Letter 16/24: Technical Information L InformationPrinceSadhotraNessuna valutazione finora

- 32 - 44 CRDocumento12 pagine32 - 44 CRMunteanu Sylvèr RobèrtNessuna valutazione finora

- Flow Capacities of Parker Hose at Recommended Flow VelocitiesDocumento1 paginaFlow Capacities of Parker Hose at Recommended Flow VelocitiesMulyo SetiawanNessuna valutazione finora

- TDRDocumento1 paginaTDRMulyo SetiawanNessuna valutazione finora

- PC FanDocumento2 paginePC FanMulyo SetiawanNessuna valutazione finora

- Specifications ME NewDocumento3 pagineSpecifications ME NewMulyo SetiawanNessuna valutazione finora

- Anchor Chain Arrangement International StandardDocumento1 paginaAnchor Chain Arrangement International StandardMulyo SetiawanNessuna valutazione finora

- Sestrel NavCompassDocumento2 pagineSestrel NavCompassMulyo SetiawanNessuna valutazione finora

- 7 20130802 2026075Documento4 pagine7 20130802 2026075Rizky Aprianto SetiawanNessuna valutazione finora

- Bow Access Solutions (Technical Datasheet - Screen) - Original - 37180Documento4 pagineBow Access Solutions (Technical Datasheet - Screen) - Original - 37180Mulyo SetiawanNessuna valutazione finora

- SBM AnchorDocumento4 pagineSBM AnchorMulyo Setiawan100% (1)

- Wind Display With AlarmsDocumento2 pagineWind Display With AlarmsMulyo SetiawanNessuna valutazione finora

- Outline MANDocumento2 pagineOutline MANMulyo SetiawanNessuna valutazione finora

- Electrical Rice Warmer IDocumento2 pagineElectrical Rice Warmer IMulyo SetiawanNessuna valutazione finora

- List of LubricantsDocumento1 paginaList of Lubricantss_barriosNessuna valutazione finora

- Micro Filtration and Ultra FiltrationDocumento5 pagineMicro Filtration and Ultra FiltrationMulyo SetiawanNessuna valutazione finora

- Turbo ChargerDocumento18 pagineTurbo ChargerMulyo SetiawanNessuna valutazione finora

- How To Size The Correct Bow ThrusterDocumento3 pagineHow To Size The Correct Bow ThrusterMulyo SetiawanNessuna valutazione finora

- G Hawsers: Taut Leg MooringsDocumento5 pagineG Hawsers: Taut Leg MooringsMulyo SetiawanNessuna valutazione finora

- Price ListDocumento6 paginePrice ListMulyo SetiawanNessuna valutazione finora

- Price ListDocumento6 paginePrice ListMulyo SetiawanNessuna valutazione finora

- Price ListDocumento6 paginePrice ListMulyo SetiawanNessuna valutazione finora

- Aircraft Gas Turbine Engine Technology by TraegerDocumento6 pagineAircraft Gas Turbine Engine Technology by TraegerSharan Raj0% (1)

- Manual de Partes 6aDocumento48 pagineManual de Partes 6aFernando FloresNessuna valutazione finora

- Mgnt-14 Ca Spare Parts: Gato Oleoneumático de GarajeDocumento3 pagineMgnt-14 Ca Spare Parts: Gato Oleoneumático de GarajeAlain DefoeNessuna valutazione finora

- Base Line: Air. Anytime. AnywhereDocumento4 pagineBase Line: Air. Anytime. Anywheremogwai71Nessuna valutazione finora

- Cam and Tappet WearDocumento21 pagineCam and Tappet WearSohaib AhmedNessuna valutazione finora

- Wiring Diagram PDFDocumento1 paginaWiring Diagram PDFMuhammad Eitch-BeeNessuna valutazione finora

- 3368441308-PZ Carb Tuning ManualDocumento8 pagine3368441308-PZ Carb Tuning Manualelektroz100% (1)

- Kobelco Mark IV: KobeicoDocumento41 pagineKobelco Mark IV: KobeicoVictor Hugo MezquitaNessuna valutazione finora

- Workshop Manual: C 2 (0) EFI RepairDocumento138 pagineWorkshop Manual: C 2 (0) EFI Repairerdem gulerNessuna valutazione finora

- 6 Stroke Diesel EngineDocumento16 pagine6 Stroke Diesel EngineadityaguptaaNessuna valutazione finora

- Scope: This Specification Shall Not Be Used For New Product Fuel System Components, Use CES 16602Documento6 pagineScope: This Specification Shall Not Be Used For New Product Fuel System Components, Use CES 16602pathinathanNessuna valutazione finora

- C50D 파트북Documento278 pagineC50D 파트북mt thanh nguyenNessuna valutazione finora

- TV2 - Kirloskar Oil Engines LTDDocumento2 pagineTV2 - Kirloskar Oil Engines LTDAnonymous 7twRifd0% (1)

- Catalogo Volvo L220G - PeçasDocumento666 pagineCatalogo Volvo L220G - Peçasnc341354100% (6)

- MAN Combustion ChamberDocumento2 pagineMAN Combustion ChamberJayesh Nayakanti100% (1)

- Instruction Manual PDFDocumento476 pagineInstruction Manual PDFنصار المقطري100% (1)

- 6P2 28197 3H 11 PDFDocumento377 pagine6P2 28197 3H 11 PDFAlex Vdbussche100% (2)

- Low Power/Poor or No Response To Throttle: Shutdown SISDocumento6 pagineLow Power/Poor or No Response To Throttle: Shutdown SISAntonio Mejicanos100% (1)

- Reciprocating Compressor I. What Is A Reciprocating Compressor?Documento13 pagineReciprocating Compressor I. What Is A Reciprocating Compressor?Bá TrườngNessuna valutazione finora

- Ranger / BT50 2.5L & 3.0L TD: Oil Leak at Rear of The HeadDocumento1 paginaRanger / BT50 2.5L & 3.0L TD: Oil Leak at Rear of The HeadMaster Xeoto67% (3)

- Air Powered EngineDocumento19 pagineAir Powered EngineSurjith Bharathi SelvakumarNessuna valutazione finora

- 2018 Jeep Truck Grand Cherokee 4WD V6-3.6LDocumento6 pagine2018 Jeep Truck Grand Cherokee 4WD V6-3.6Lmurtadha 2016Nessuna valutazione finora

- VGF L36Gsi: 620 - 800 BHP (460 - 600 KWB)Documento2 pagineVGF L36Gsi: 620 - 800 BHP (460 - 600 KWB)Gabrielito PachacamaNessuna valutazione finora

- Glossary of Terms: Diesel PowerDocumento1 paginaGlossary of Terms: Diesel PowerRucky AroraNessuna valutazione finora

- PU158TIDocumento2 paginePU158TITrevor BurnettNessuna valutazione finora

- INE ListDocumento8 pagineINE Listak autopartsNessuna valutazione finora

- CIMAC WG17 2014 Apr Position Methane and Formaldehyde EmissionsDocumento17 pagineCIMAC WG17 2014 Apr Position Methane and Formaldehyde EmissionsCamilo Andres Cardozo FajardoNessuna valutazione finora

- DC09 072A. 267-321 KW (304-361 kVA) : Fuel OptimizedDocumento2 pagineDC09 072A. 267-321 KW (304-361 kVA) : Fuel OptimizedJulio SullaymeNessuna valutazione finora

- 4045df120 PDFDocumento3 pagine4045df120 PDFAndy Jose TelleriaNessuna valutazione finora

- Catalogo de Partes NT855 - C280 PDFDocumento37 pagineCatalogo de Partes NT855 - C280 PDFCrespo JorgeNessuna valutazione finora