Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

An Accurate Grinder For Your Lathe

Caricato da

twinscrewcanoeTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

An Accurate Grinder For Your Lathe

Caricato da

twinscrewcanoeCopyright:

Formati disponibili

An Accurate Grinder for your lathe

By C.W. Woodson

From the pages of Model Craftsman magazine June, 1937

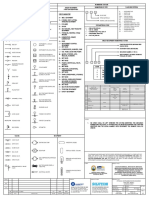

As shown in Fig. 1, the tool post grinder for which plans are given here can be used to finish up delicate

work to more accurate dimensions than can be done with a lathe tool. For such operations as lapping

cylinders, facing surface plates, and other work, nothing can take the place of a grinder. A h.p. motor

should be used, as this amount of power is necessary to make good cuts.

As can be seen from the drawing in Fig. 2, the elements are very simple. There is a casting (see Fig. 7)

which attaches to the shoulder piece, shown in Fig. 13. Attached to this casting (as may be seen in

Fig.4)is a rocker cradle, Fig. 8, which may be a casting, or built up of plate.

The live spindle, shown in Fig. 12, is a simple piece of hardened cold rolled steel, " in diameter and

mounted in ball bearings by simple retainers.

The belt adjustment is taken up by the screw, shown in Fig. 4. The idea of a V-belt drive may at once

suggest itself, but I strongly advise the use of a woven flat belt because of the speed involved. V-belts at

high speeds use considerable power.

The grinding wheels may be obtained in standard sizes from any local abrasive store, or your hardware

dealer will be able to get them by mail order.

To construct the grinder proceed as follows: Make a pattern for the piece shown in Fig. 10. The 1 1/8"

hollow portion should be cored out. Have this poured in iron and then drill the stud holes. Turn the "

shoulders on each end down to outer thread size at which point the job will look as shown in Fig. 7.

Make bronze retainer caps for the shoulder ends. These caps are shown in Fig. 14, and their application

to the castings is shown in Fig. 12. The bearings can be purchased from any automotive supply for

around 75 cents apiece. The socket size for the bearing can be worked out on the lathe by taking light

cuts until the bearing is a sliding fit in the socket. Do not drive fit this, because any heat will affect the

accuracy of the outer ring, and make the grinder run out of true.

The 3/8" end plates of the motor carriage are shown in Figs. 8 and 9, are bored so that screws can be

tapped into the motor housing. The slide rest gib, shown in Fig. 13, will fit the slide rest of a popular 9"

lathe.

The pulley diameters,shown in Figs. 5 and 6, will give the proper spindle speed with a motor turning

1750 r.p.m.

A hex head nickle steel bolt will have to be provided in the proper length for the gib and carriage casting.

See to it that the thread on the driving pulley end of the spindle is in opposite rotation to the rotation of

the motor.

The up and down adjustment to allow centering height for the axis of the grinder can be taken care of by

shimming between the casting and the gib with washers. As shown, the casting height brings the axes

coincident. The driven pulley on the spindle is made tight by the nut on the end of the shaft. This pulls

the pulley up against the collar, which in turn rests against the inside ring of the bearing. In fastening

the pulley do not tighten it too hard--slight pressure is sufficient.

You will note that a large wheel and a small wheel are shown in Fig. 12. To drive the large wheel a

variation of the pulley in Fig. 6 can be applied to the long end using a taper collar pulley with a taper

sufficiently large to bring the pulley in line with the motor pulley. The taper of this will be sufficient to

give tight fit.

The compound fit on the slide rest will allow a number of operations to be performed; such as grinding

cylinders, valve faces, dead center spindles, check valves, and the like.

Constructed as shown, this post grinder can be built for less than 15 dollars and will make a valuable

adjunct for engine builders, who require accuracy in fitted surfaces.

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Martini Action DiagramDocumento1 paginaMartini Action DiagramtwinscrewcanoeNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Basics of How A Lever Action Works PDFDocumento5 pagineThe Basics of How A Lever Action Works PDFtwinscrewcanoeNessuna valutazione finora

- Home N Ew Arrivals C Loseouts Schem Atics Sell Your PartsDocumento2 pagineHome N Ew Arrivals C Loseouts Schem Atics Sell Your Partstwinscrewcanoe100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- P-380 Accessories - Numrich Gun PartsDocumento2 pagineP-380 Accessories - Numrich Gun Partstwinscrewcanoe100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- My DIY Iron Glock - The Firearm BlogDocumento9 pagineMy DIY Iron Glock - The Firearm Blogtwinscrewcanoe67% (9)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Reinstalling The BreechblockDocumento3 pagineReinstalling The BreechblocktwinscrewcanoeNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Joseph Mohr Penned The Carol "Silent Night" - 1792Documento2 pagineJoseph Mohr Penned The Carol "Silent Night" - 1792twinscrewcanoeNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Lutheran What Separates The LCCF From Other Lutheran Church Bodies?Documento2 pagineLutheran What Separates The LCCF From Other Lutheran Church Bodies?twinscrewcanoeNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Advanced Tactica Handgun Instructor ManualDocumento156 pagineAdvanced Tactica Handgun Instructor ManualCarlos Eduardo López Suchite80% (10)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Theology and Practice of The Lord's Supper (I) - LCMSDocumento8 pagineTheology and Practice of The Lord's Supper (I) - LCMStwinscrewcanoeNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Theology and Practice of The Lord's Supper (III) - LCMSDocumento12 pagineTheology and Practice of The Lord's Supper (III) - LCMStwinscrewcanoeNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- M-H Quick Breechblock RemovalDocumento3 pagineM-H Quick Breechblock RemovaltwinscrewcanoeNessuna valutazione finora

- Why Evangelicalism Is Almost Certainly Doomed - EvangolicDocumento2 pagineWhy Evangelicalism Is Almost Certainly Doomed - EvangolictwinscrewcanoeNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- What Did Luther Believe About PredestinationDocumento5 pagineWhat Did Luther Believe About PredestinationtwinscrewcanoeNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Lutheran What Separates The LCCF From Other Lutheran Church Bodies?Documento2 pagineLutheran What Separates The LCCF From Other Lutheran Church Bodies?twinscrewcanoeNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- MAC-11 9mm Construction Conversion Iron Wulf PublishingDocumento86 pagineMAC-11 9mm Construction Conversion Iron Wulf PublishingJordan Voller100% (5)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Johann Blumhardt's Spiritual Warfare - 1843Documento2 pagineJohann Blumhardt's Spiritual Warfare - 1843twinscrewcanoe100% (1)

- Ejector Wire Gage For Marlin 60 - RimfireCentralDocumento8 pagineEjector Wire Gage For Marlin 60 - RimfireCentraltwinscrewcanoeNessuna valutazione finora

- 6 in 1 PatternDocumento4 pagine6 in 1 PatterntwinscrewcanoeNessuna valutazione finora

- Blowback Gun Design PDFDocumento5 pagineBlowback Gun Design PDFwienslaw5804Nessuna valutazione finora

- Thin Sections Minerals & Volcanic MicrotexturesDocumento6 pagineThin Sections Minerals & Volcanic MicrotexturestwinscrewcanoeNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Reinstalling The BreechblockDocumento3 pagineReinstalling The BreechblocktwinscrewcanoeNessuna valutazione finora

- Medi RabbitDocumento7 pagineMedi RabbittwinscrewcanoeNessuna valutazione finora

- Hi Point Pistol Armorer GuideDocumento101 pagineHi Point Pistol Armorer Guidetwinscrewcanoe100% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- 4 in 1 PatternDocumento5 pagine4 in 1 PatterntwinscrewcanoeNessuna valutazione finora

- How To Make Rock Thin Sections, Without Much Equipment - How - To - Make - Rock - Thin - SectionsDocumento2 pagineHow To Make Rock Thin Sections, Without Much Equipment - How - To - Make - Rock - Thin - SectionstwinscrewcanoeNessuna valutazione finora

- Martini Action DiagramDocumento1 paginaMartini Action DiagramtwinscrewcanoeNessuna valutazione finora

- Animal Care and Use Policies and GuidelinesDocumento2 pagineAnimal Care and Use Policies and GuidelinestwinscrewcanoeNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Greener GP EG Police Gun ReassemblyDocumento6 pagineGreener GP EG Police Gun ReassemblytwinscrewcanoeNessuna valutazione finora

- Blowback Gun Design PDFDocumento5 pagineBlowback Gun Design PDFwienslaw5804Nessuna valutazione finora

- KPM2 Adjustment For LEDDocumento1 paginaKPM2 Adjustment For LEDMichael S.W. WindebankNessuna valutazione finora

- CCMU As BuiltDocumento1 paginaCCMU As BuiltterryNessuna valutazione finora

- DUSS Katalogus PDFDocumento92 pagineDUSS Katalogus PDFRegieNessuna valutazione finora

- Bosch 20162017 Catalog - DrillingfasteningDocumento60 pagineBosch 20162017 Catalog - DrillingfasteningAbhisek RoyNessuna valutazione finora

- M&E Outstanding WorkDocumento10 pagineM&E Outstanding WorkanipchinNessuna valutazione finora

- HMI Pin Assignment: Weintek Labs., IncDocumento18 pagineHMI Pin Assignment: Weintek Labs., IncMohtashim KazmiNessuna valutazione finora

- Installation and Operating Instructions: Controller Unit Esp-Sat and MAXICOM Interface Board (MIB) KitDocumento76 pagineInstallation and Operating Instructions: Controller Unit Esp-Sat and MAXICOM Interface Board (MIB) Kitajithkumarps85Nessuna valutazione finora

- Simbologia y Muestra de PLanos Electricos y ElectronicosDocumento13 pagineSimbologia y Muestra de PLanos Electricos y ElectronicosCristóbalGuzmánNessuna valutazione finora

- BQ Pengadaan Pertashop 3 KL Gen3 - Rev.1-DikonversiDocumento4 pagineBQ Pengadaan Pertashop 3 KL Gen3 - Rev.1-DikonversiArie WigunaNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Universal Alternators Catalog PDFDocumento56 pagineUniversal Alternators Catalog PDFChristopherNessuna valutazione finora

- Science7 Q2 M1A v4 No Key AnswerDocumento11 pagineScience7 Q2 M1A v4 No Key AnswerCastolo Bayucot Jvjc100% (1)

- Membrane/Bag Rupture Relay MBR CA-035 11/12/2008 Rev. 4Documento7 pagineMembrane/Bag Rupture Relay MBR CA-035 11/12/2008 Rev. 4Mila CalderónNessuna valutazione finora

- Jib CranesDocumento12 pagineJib CranesGloria RomicNessuna valutazione finora

- Online Technical Bulletin: Automatic Transmission Service GroupDocumento4 pagineOnline Technical Bulletin: Automatic Transmission Service Groupvit83881825Nessuna valutazione finora

- Pricelist Implant Ortopedi Pt. Hanif Putra Perkasa Harga User No Nama Produk Satuan Total Harga 1 Cortical Screw 3.5mmDocumento6 paginePricelist Implant Ortopedi Pt. Hanif Putra Perkasa Harga User No Nama Produk Satuan Total Harga 1 Cortical Screw 3.5mmasriNessuna valutazione finora

- Utilities - Flashcards - QuizletDocumento20 pagineUtilities - Flashcards - QuizletrjeepanaderoNessuna valutazione finora

- Master Copy of Saad Othman JSADocumento11 pagineMaster Copy of Saad Othman JSAM. MagnoNessuna valutazione finora

- Dd2 (Detailed) Station - The White Palace Chilled Water Systems Schematic (East)Documento1 paginaDd2 (Detailed) Station - The White Palace Chilled Water Systems Schematic (East)Muhammad IshtiaqueNessuna valutazione finora

- Model No. 9553B 100MM ANGLE GRINDERDocumento3 pagineModel No. 9553B 100MM ANGLE GRINDERG Dimas PGoonersNessuna valutazione finora

- Scheme Selection Logic Diagram Pressure Control For Liquid Storage TanksDocumento46 pagineScheme Selection Logic Diagram Pressure Control For Liquid Storage Tanksanto3harrish3fdoNessuna valutazione finora

- VX 2Documento2 pagineVX 2jasongharteyNessuna valutazione finora

- CBSE Class 12 Physics Practicals 2023 24Documento4 pagineCBSE Class 12 Physics Practicals 2023 24Ayush SharmaNessuna valutazione finora

- Instrument Panel Cluster (IPC)Documento2 pagineInstrument Panel Cluster (IPC)lamping_apNessuna valutazione finora

- Lab 2 Data c0mDocumento7 pagineLab 2 Data c0mMuhamad PogieNessuna valutazione finora

- CDU Plant Pipe & Instrumentation Diagram 9 Dec 2021Documento4 pagineCDU Plant Pipe & Instrumentation Diagram 9 Dec 2021Aimal HakeemiNessuna valutazione finora

- Stober Dimensionsheet Phq732sfss0280mb23ez404u En-UsDocumento2 pagineStober Dimensionsheet Phq732sfss0280mb23ez404u En-UsjanikeNessuna valutazione finora

- Core Drill ChartDocumento1 paginaCore Drill ChartJithinNessuna valutazione finora

- Safety Precaution On Drilling Machine at Mechanical Engineering DepartmentDocumento2 pagineSafety Precaution On Drilling Machine at Mechanical Engineering DepartmentRizky Esa Respati50% (2)

- CT Current Transformersip/5 A RatioDocumento19 pagineCT Current Transformersip/5 A RatioEngineerOmarNessuna valutazione finora

- IND5Documento14 pagineIND5ExperimentonomenNessuna valutazione finora