Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

MM YAD 00 DORI 434500 - Rev01

Caricato da

Aditya PranotoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

MM YAD 00 DORI 434500 - Rev01

Caricato da

Aditya PranotoCopyright:

Formati disponibili

Doc. Ref.

: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 2 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

TABLE OF CONTENT

1 Introduction.................................................................................................................................... 3

1.1 Purpose.............................................................................................................................. 3

1.2 General description of actuated On/Off Valves ................................................................. 3

1.3 Context............................................................................................................................... 5

2 Reference Documents................................................................................................................... 7

3 Definitions and abbreviations ...................................................................................................... 7

4 General ........................................................................................................................................... 7

4.1 Omissions .......................................................................................................................... 8

4.2 VENDOR selection ............................................................................................................ 8

4.3 Responsibility matrix.......................................................................................................... 8

5 ESV / SDV Protection Enclosures requirements........................................................................ 9

5.1 General description of Protection Enclosures.................................................................... 9

5.2 Environmental conditions................................................................................................. 10

5.2.1 Air characteristics................................................................................................................................................ 10

5.2.2 Seawater properties............................................................................................................................................ 10

5.3 Strength............................................................................................................................ 10

5.4 Fire rating......................................................................................................................... 10

5.5 Ventilation ........................................................................................................................ 10

5.6 Fixing arrangement .......................................................................................................... 11

5.7 Easiness of installation .................................................................................................... 11

5.8 Accessibility for inspection............................................................................................... 11

5.9 Corrosion.......................................................................................................................... 11

5.10 Earthing system............................................................................................................... 11

5.11 Design life ........................................................................................................................ 11

6 Scope of work .............................................................................................................................. 12

6.1 Survey, Engineering and Design ..................................................................................... 12

6.2 Supply of Protection Enclosures..................................................................................... 12

6.3 Test assembly.................................................................................................................. 12

6.4 Site work and installation ................................................................................................. 12

6.5 Documentation................................................................................................................. 13

7 PP ESV / SDV to be protected .................................................................................................... 14

8 WP1 ESV / SDV to be protected ................................................................................................. 19

9 WP2 ESV to be protected............................................................................................................ 23

10 PP Electrical cable and OTU to be protected ........................................................................... 25

11 WP2 Electrical cable to be protected......................................................................................... 27

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 3 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

Introduction

1.1 Purpose

The purpose of this specification is to provide the minimum technical requirements for the design,

construction and assembly of ESV / SDV Protection Enclosures against wave impact on PP, WP1 and WP2

platforms, in the frame of YADANA brownfield modifications. The specified Protections Enclosures consist of

local composite boxes surrounding each valve and its associated actuator.

This specification is also applicable for the protection of :

- existing 6.6 kV electrical cable between J-Tube splitter box and Main Deck on WP2 platform,

- existing 6.6 kV electrical cable between J-Tube splitter box and Lower Deck on PP platform,

- existing OTU for optical fibres located above J-Tube on PP platform,

It is highlighted that ESV / SDV Protection Enclosures shall be extended to protect instruments, valves and

all relevant tubings located in the vicinity of ESV and SDV.

1.2 General description of actuated On/Off Valves

Twelve different SDV and ESV are located on PP Drain Deck and WP1 / WP2 Cellar Decks. These valves

provide the ultimate hydrocarbon inventory isolation from the risers in case of shutdown.

The valves are ranging from 10" to 36" nominal diameters (and one 4 by-pass) with a pressure range from

900 Lbs to 1500 Lbs and are fitted with single acting, spring return, piston hydraulic actuators.

The control of the valve is performed through a local control panel, including the pneumatic and hydraulic

devices necessary for the valve operation. The air is used for the pilot circuits which is triggered by solenoid

valves connected to the platform safety system. The hydraulic fluid is used as a motive power for the valve

actuators.

The local panels receive an air supply from the platform instrument air network. The hydraulic power is

supplied by the HPU. A hydraulic return circuit to the HPU is also needed from each local control panel. The

interface signals between the local control panels and the platform safety are made through electrical cables.

Three hydraulic tubings are connecting the valve local control panels to the valve actuators. One for the

piston movement and two for the partial stroking facility requiring a cam operated valve mounted on the

actuator.

Actuators are also receiving electrical cables for the valve limit switches connection to the safety system.

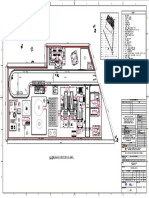

These principles are illustrated in the Figure 1-1 hereafter.

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 4 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

Figure 1-1: Actuated on/off valve principle

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 5 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

Picture 1-1 : WP1 Cellar Deck - ESV 10012 on 20 gas line with associated control panel

1.3 Context

Under 6m subsidence scenario, ESV / SDV located at Drain Deck of PP Platform and Cellar Deck of WP1

and WP2 platforms will be located in the splash zone and impacted by extreme waves. The twelve ESV /

SDV listed in Table 1-1 hereunder shall be protected. Existing control panels will be removed and

replaced by new panels installed at Lower Deck, and associated tubing will be rerouted.

Some ESV / SDV already include blanket PFP which will have to be removed prior installation of new

enclosures.

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 6 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

Platform ESV / SDV Location Line No

PID

Ref.

Deck elevation

ESV 40267 Drain Deck - 36 export gas line 36-HC-2040-0-PG01S [3] +16.822 m LAT

ESV 40137 Drain Deck - 36 export gas line 36-HC-2040-0-PG01S [3] +16.822 m LAT

SDV 40266 Drain Deck - 20 gas line from WP2 20-HC-2003-0-PH03S [2] +16.822 m LAT

ESV 40021 Drain Deck - 20 gas line from WP2 20-HC-2003-0-PH03S [2] +16.822 m LAT

ESV 40268 Drain Deck - 20 domestic line 20-HC-2049-0-PG01S [4] +16.822 m LAT

PP

ESV 40157 Drain Deck - 20 domestic line 20-HC-2049-0-PG01S [4] +16.822 m LAT

ESV 10012 Cellar Deck - 20 gas line 20-HC-0122-0-H48 [5] +17.058 m LAT

SDV 10601 Cellar Deck - 20 gas line 20-HC-0122-0-H48 [5] +17.058 m LAT

ESV 10951 Cellar Deck - 10 line from WP3 10-HC-0132-0-PH06N [6] +17.058 m LAT

SDV 10952 A Cellar Deck - 10 line from WP3 10-HC-0132-0-PH06N [6] +17.058 m LAT

WP1

SDV 10952 B Cellar Deck - 4 By-pass line 4-HC-0150-0-H48 [6] +17.058 m LAT

WP2 ESV 20039 Cellar Deck 20 gas line 20-HC-0233-0-PH03S [7] +17.061 m LAT

Table 1-1 List of ESV / SDV to be protected against wave impact

According to the metocean report ref. [1], the maximum wave crest elevation of the Most Probable extreme

wave is +18.6m LAT. The magnitude of wave impact pressures is around 5 t/m

2

.

ESV / SDV actuators and in particular the connection between valve and actuator are not designed to

withstand hydrodynamic pressures (drag loads and slamming effect) and shall be protected.

Following items shall also be protected form wave impact :

- existing 6.6 kV electrical cable between J-Tube splitter box and Main Deck on WP2 platform,

- existing 6.6 kV electrical cable between J-Tube splitter box and Lower Deck on PP platform,

- existing OTU for optical fibres located above J-Tube on PP platform,

It is highlighted that ESV / SDV Protection Enclosures shall be extended to protect instruments, valves and

all relevant tubings located in the vicinity of ESV and SDV.

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 7 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

2 Reference Documents

[1] DGEP/TDO/TEC/GEO/MOW10298 rev.1 Yadana Field Metocean Criteria

[2] PID-YAD3-PP-PR-3001 rev.M04 PP Inlet Manifold PID

[3] PID-YAD3-PP-PR-3007 rev.M04 PP Export Gas Pig Launcher PID

[4] PID-YAD3-PP-PR-3009 rev.M04A PP Domestic Gas Pig Launcher PID

[5] PID-YAD3-WP1-PR-0107 Rev.M04 WP1 Wellheads Manifolds PID

[6] PID-YAD3-WP1-PR-0110 Rev.M04 WP1 Pig Receiver PID

[7] PIP-YAD3-WP2-PR-0210 Rev.M04 WP2 Pig Launcher PID

[8] MM-YAD-50-DORI-439531 PP - Drain Deck - Plot Plan

[9] MM-YAD-40-DORI-439431 WP1 - Cellar Deck - Plot Plan

[10] MM-YAD-60-DORI-439631 WP2 - Cellar Deck - Plot Plan

[11] GS-EP-SAF-337 Passive fire protection: Basis of design

3 Definitions and abbreviations

In the present document Protection Enclosure means the complete protection system including composite

panels, structural supporting framing and fittings.

ATEX ATmosphere EXplosive

ESV Emergency Shutdown Valve

HPU Hydraulic Power Unit

LAT Lowest Astronomical Tide

OTU Optical Termination Unit

PFP Passive Fire Protection

PID Piping and Instrumentation Diagram

PP Production Platform

SDV Shutdown Valve

WP Wellhead Platform

4 General

CONTRACTOR shall be responsible for the technical integrity of the ESV / SDV protections, including

design, materials, manufacture, assembly, testing, performance, and specified ENGINEERING services and

for ensuring that the goods and services supplied meet all applicable regulations on health, safety and the

environment.

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 8 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

4.1 Omissions

Any omission in the requirements detailed herein shall not relieve CONTRACTOR of any responsibility to

deliver a complete system delivering the specified performance.

4.2 VENDOR selection

VENDOR selection for ESV / SDV protections shall be carried out in accordance with the Project VENDOR

list.

4.3 Responsibility matrix

Responsibilities of CONTRACTOR and VENDOR are presented in the table hereunder

CONTRACTOR VENDOR

Control panel relocation X

ESV / SDV tubing / cabling rerouting X

ESV / SDV enclosure 12 off Installation Fabrication

Splitter box / OTU enclosure 3 off Installation Fabrication

Removal of existing PFP blankets X

Certification of enclosure design X

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 9 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

5 ESV / SDV Protection Enclosures requirements

5.1 General description of Protection Enclosures

The solution to protect ESV / SDV valves and actuators from wave impact consists in installing composite

protection enclosures with removable panels as presented in Picture 5-1 hereunder. The protection

enclosure shall incorporate ventilation details, lift-off panels, access hatch and pipe and instrumentation

penetrations. Lift off panels shall offer rapid and easy access to ESV / SDV inspection.

Picture 5-1 : Typical protection enclosure

The protection enclosures are made up of a steel support frame with composite panels attached (typically

50mm thick). The steel supporting structure consists of posts bolted to Drain/Cellar Deck and Lower Deck

members.

Protections shall be designed to fit closely around ESV / SDV and associated actuator. Connections

between hydraulic tubings / electrical wires and the actuator shall be included within the protection

enclosure.

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 10 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

5.2 Environmental conditions

The following environmental conditions shall be taken into account in the design of protection enclosures.

5.2.1 Air characteristics

MINIMUM MEAN MAXIMUM

Air Temperature 20.6 C 26.5 to 29.5 C 32.2 C

Relative Humidity 45.7 % 70 to 85 % 98.9 %

Table 5-1 Air characteristics

5.2.2 Seawater properties

MINIMUM MEAN MAXIMUM

Salinity 24.3 PSU 31.2 PSU 35.3 PSU

Table 5-2 Seawater properties

5.3 Strength

The protection shall resist to a wave impact pressure up to 50 kN/m

2

and blast pressure up to 0.3 barg.

It is pointed out that the lower part of protection enclosures shall be designed to withstand the wave

slamming effect. The protection enclosure shall be particularly reliable as its failure could induce impact of a

composite panel on ESV / SDV under extreme storms and generate serious damage. Wave loads onto

protection enclosures shall be transmitted to Cellar Deck and Lower structures. The protection enclosure

shall be designed to avoid any relative displacement between valve and actuator.

A sufficient clearance between protected ESV / SDV and the protection enclosures shall be taken into

account to avoid any contact due to composite panel deflection under wave impact.

5.4 Fire rating

The fire rating of the protection enclosures shall be 200 / JF / 60 (see ref. [7]).

Tubes and cables shall be routed to the actuator inside the enclosure through fire resistant openings on

panel split lines. The enclosure shall be designed to be dismantled without the need to disconnect actuator.

5.5 Ventilation

The protection enclosure shall provide natural ventilation through ventilation holes to avoid condensation and

corrosion issues on protected ESV / SDV. These holes shall close automatically in case of fire or shall be

outfitted with intumescent materials. Protection shall be outfitted with blast shielded grills promoting natural

ventilation of the enclosure and providing suitable locations for use of gas detection devices.

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 11 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

5.6 Fixing arrangement

The supporting structure of the protection enclosure shall be attached to Drain/Cellar Deck and Lower Deck

members with bolts.

5.7 Easiness of installation

In order to minimize offshore works, easy and quick offshore installation is required.

Enclosure shall be fully dismountable and each element tagged.

5.8 Accessibility for inspection

As ESV / SDV shall remain accessible for inspection and maintenance, the protection shall be easily and

quickly removable. The protection shall be outfitted with lift off panels offering rapid and easy access to valve

and actuator.

Enclosure panels shall be designed to be handled without special machinery and shall be demountable for

inspection and maintenance purposes without the need for special tools or specialist personnel.

5.9 Corrosion

The protection enclosure shall be corrosion resistant. Corrosion resistant nickel alloys shall be selected such

as Alloy 625 (UNS NO6625) or Alloy 725 (UNS N07725) for bolting. Stainless or galvanized steel material

shall be used for the supporting structure sections.

5.10 Earthing system

Enclosure support legs shall incorporate a steel earthing boss to satisfy ATEX requirements for use in

hazardous zones.

Picture 5-2 : Typical steel earthing boss

5.11 Design life

The design life of the protection enclosure is 20 years.

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 12 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

6 Scope of work

6.1 Survey, Engineering and Design

Point cloud from 3D laser scan of the valves and actuators area will be provided by COMPANY.

CONTRACTOR / VENDOR will conduct a survey of the valves and actuators in order to design protection

enclosure arrangement and ensure that each enclosure is designed to accommodate any nearby equipment

or structure. The enclosure shall be in particular designed to allow for penetration of piping / tubing and

cables.

VENDOR shall produce a 3D model of enclosure for integration into overall CONTRACTOR 3D model.

CONTRACTOR shall ensure the overall integration of enclosures into the platforms including all interfaces

with structure, piping and cables.

CONTRACTOR shall issue engineering drawings to reflect fixing arrangements and interface details with

supporting steelwork. This design work will be based upon details that meet the wave loading requirements

and will result in a set of fabrication drawings. Design will comprise a number of standard panel sizes that

are bolted to steel members.

VENDOR shall produce and issue an installation manual and drawings for the protection panels covering the

enclosure first installation and further phases when access to valves is required for inspection / maintenance

activities.

6.2 Supply of Protection Enclosures

Protection enclosures will be manufactured to detailed engineering and design drawings produced and

approved as a result of the site survey.

The protection enclosures will be engineered to meet the requirements and performance criteria listed in

previous section. Enclosure overall design shall be certified by Certifying Authority including :

Structural design of enclosures certified by a third-party,

Fire and blast rated component including assembly details of a type which is fire-tested and certified

by an independent, nationally accredited third party.

6.3 Test assembly

CONTRACTOR shall perform a test assembly of each Protection Enclosure at the VENDOR factory.

6.4 Site work and installation

CONTRACTOR shall arrange the following activities at site :

Engineering survey if required

Review and resolution of clashes and interface details

Preparation and agreement of Installation drawings

Supervision of the installation by local site personnel

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 13 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

6.5 Documentation

VENDOR shall provide the following documentation as part of the scope of supply:

General Arrangements and Interface Drawings

Weight Data Sheets

Operations and Installation Manual

Quality, Inspection & Test plan

General fire and blast certification dossier

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 14 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

7 PP ESV / SDV to be protected

Six ESV / SDV shall be protected from wave impact on PP Drain Deck. Location of these valves is presented

in Figure 7-1 hereunder. The different valves and associated actuators are presented through Picture 7-1 to

Picture 7-6 hereafter.

Figure 7-1 PP Drain Deck Plot Plan

Based on preliminary investigations, main dimensions for ESV / SDV Protection Enclosures listed in Table

7-1 are anticipated. These figures are given for information only and shall be confirmed during detail

engineering.

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 15 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

ESV / SDV Tag No Length x Width x Height (mm)

ESV 40267 4,700 x 2,200 x 3,400

ESV 40137 4,700 x 2,200 x 3,400

SDV 40266 4,500 x 1,550 x 2,200

ESV 40021 4,500 x 1,550 x 2,200

ESV 40268 4,550 x 1,300 x 2,450

ESV 40157 4,800 x 1,650 x 2,450

Table 7-1 : PP ESV / SDV - Preliminary Protection Enclosure dimensions

Blanket PFP surrounding ESV 40157 shall be removed by CONTRACTOR prior enclosure installation.

Picture 7-1 : PP Drain Deck - ESV 40267 on 36 export gas line

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 16 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

Picture 7-2 : PP Drain Deck - ESV 40137 on 36 export gas line

Picture 7-3 : PP Drain Deck - ESV 40021 on 20 gas line from WP2

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 17 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

Picture 7-4 : PP Drain Deck - ESV 40021 on 20 gas line from WP2

Picture 7-5 : PP Drain Deck - SDV 40266 on 20 gas line from WP2

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 18 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

Picture 7-6 : PP Drain Deck ESV 40268 on 20 domestic line

Picture 7-7 : PP Drain Deck ESV 40157 on 20 domestic line

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 19 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

8 WP1 ESV / SDV to be protected

Five ESV / SDV shall be protected on WP1 Cellar Deck. Location of these valves is presented in Figure 8-1

hereunder. The different valves and associated actuators are presented through Picture 8-1 to Picture 8-5

hereafter.

ESV 10012

SDV 10601

SDV 10952A

20" gas line

10" gas line

ESV 10951

SDV 10952B

Figure 8-1 WP1 Cellar Deck Plot Plan

Based on preliminary investigations, main dimensions for ESV / SDV Protection Enclosures listed in Table

8-1 are anticipated. These figures are given for information only and shall be confirmed during detailed

engineering.

Blanket PFP surrounding ESV 10951 shall be removed by CONTRACTOR prior enclosure installation.

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 20 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

ESV / SDV Tag No Length x Width x Height (mm)

SDV 10601 1,850 x 1,300 x 2,600

ESV 10012 5,550 x 1,800 x 2,450

SDV 10952B 1,750 x 600 x 1,250

ESV 10951 2,730 x 1,100 x 1,660

SDV 10952A 2,430 x 1,100 x 1,660

Table 8-1 : WP1 ESV / SDV - Preliminary Protection Enclosure dimensions

Picture 8-1 : WP1 Cellar Deck - ESV 10012 on 20 gas line

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 21 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

Picture 8-2 : WP1 Cellar Deck - SDV 10601 on 20 gas line

Picture 8-3 : WP1 Cellar Deck - ESV 10951 on 10 gas line from WP3

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 22 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

Picture 8-4 : WP1 Cellar Deck - SDV 10952A on 10 gas line from WP3

Picture 8-5 : WP1 Cellar Deck - SDV 10952B on 4 by-pass

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 23 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

9 WP2 ESV to be protected

One ESV shall be protected from wave impact on WP2 Cellar Deck. This ESV is presented in Figure 9-1 and

Picture 9-1 hereunder.

ESV 20039

Figure 9-1 WP2 Cellar Deck Plot Plan

Based on preliminary investigations, main dimensions for the ESV Protection Enclosure listed in Table 8-1

are anticipated. These figures are given for information only and shall be confirmed during detailed

engineering.

ESV Tag No Length x Width x Height (mm)

ESV 20039 4,400 x 1,700 x 2,500

Table 9-1 : WP2 ESV - Preliminary Protection Enclosure dimensions

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 24 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

Picture 9-1 : WP2 Cellar Deck - ESV 20039 on 20 gas line

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 25 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

10 PP Electrical cable and OTU to be protected

On PP platform, following items shall be protected from wave impact with a protection enclosure :

- existing 6.6 kV electrical cable between J-Tube splitter box and Lower Deck,

- existing OTU for optical fibres located above J-Tube

The location of the protection enclosure is presented in Figure 10-1 hereunder.

OTU and 6.6 kV cable

to be protected

Figure 10-1 PP Drain Deck Plot Plan

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 26 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

Picture 10-1 : PP Drain Deck OUT and 6.6 kV cable to be protected

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 27 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

11 WP2 Electrical cable to be protected

On WP2 platform, existing 6.6 kV electrical cable between J-Tube splitter box and Main Deck shall be

protected against wave impact with a protection enclosure

The location of this protection enclosure is presented in Figure 11-1 hereunder.

OTU and 6.6 kV cable

to be protected

Figure 11-1 WP2 Cellar Deck Plot Plan

Doc. Ref.: MM-YAD-00-DORI-434500

CTR Reference: NA

Revision: 01 Rev Date: 19-Dec-2011

Specification for ESV / SDV

Protections Enclosures on PP, WP1

and WP2 Platforms

Discipline: PVV Document Type: SPE

Phase: FE System / Subsystem: 03 Equipment Type: XE Status: AFD Class: 1 Page 28 of 28

This document is the property of TOTAL E&P MYANMAR. It must not be stored, reproduced or disclosed to others without written authorisation from the Company.

R:\652301\Typing\DOCS\NATIVE\DOCS\43-Piping (new)\MM-YAD-00-DORI-434500_rev01.doc

Picture 11-1 : WP2 Cellar Deck 6.6 kV electrical cable to be protected

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- ShopNotes No. 137 FullDocumento31 pagineShopNotes No. 137 FullKen Lock100% (3)

- RISA Training ManualDocumento352 pagineRISA Training ManualSergey100% (1)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Functional Safety ManagementDocumento8 pagineFunctional Safety ManagementasimozmaNessuna valutazione finora

- Fire Fighting Equipment Layout (Native)Documento1 paginaFire Fighting Equipment Layout (Native)Aditya Pranoto100% (1)

- PMG-ENG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part6 PDFDocumento1 paginaPMG-ENG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part6 PDFAditya PranotoNessuna valutazione finora

- PMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part4Documento1 paginaPMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part4Aditya Pranoto100% (1)

- Stainless Steel Pipe Dimensions and Weight ChartDocumento5 pagineStainless Steel Pipe Dimensions and Weight ChartArun Chopra33% (3)

- Utility List - Steam Consumption PR - Rev0Documento1 paginaUtility List - Steam Consumption PR - Rev0Aditya PranotoNessuna valutazione finora

- Part I Pre-BoardDocumento11 paginePart I Pre-Boardjo-an gidoNessuna valutazione finora

- PMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part11Documento1 paginaPMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part11Aditya PranotoNessuna valutazione finora

- Propeller & Propulsion TerminologyDocumento4 paginePropeller & Propulsion TerminologyjmvNessuna valutazione finora

- Fire Fighting Equipment MTODocumento1 paginaFire Fighting Equipment MTOAditya PranotoNessuna valutazione finora

- BC670 PDFDocumento225 pagineBC670 PDFMailin1981Nessuna valutazione finora

- Reservation SystemDocumento46 pagineReservation SystemUrvashi GoyalNessuna valutazione finora

- EP HSE SG 06 14 - EP HSE Technical Standard For Quantitative Risk Assessment (QRA) Rev 0Documento88 pagineEP HSE SG 06 14 - EP HSE Technical Standard For Quantitative Risk Assessment (QRA) Rev 0Kais Messaoudi100% (1)

- Fire Fighting Equipment LayoutDocumento1 paginaFire Fighting Equipment LayoutAditya PranotoNessuna valutazione finora

- BS en 14730-2-2017Documento22 pagineBS en 14730-2-2017Aneeq Sohaib83% (6)

- Patrol CarDocumento2 paginePatrol CarAditya PranotoNessuna valutazione finora

- PMG Eng C Cal U15 011 W.R1Documento23 paginePMG Eng C Cal U15 011 W.R1Aditya Pranoto100% (1)

- PMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part9Documento1 paginaPMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part9Aditya PranotoNessuna valutazione finora

- PMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part10Documento1 paginaPMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part10Aditya PranotoNessuna valutazione finora

- Shutdown HierarchyDocumento1 paginaShutdown HierarchyAditya Pranoto100% (1)

- PMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part3Documento1 paginaPMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part3Aditya PranotoNessuna valutazione finora

- PMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part5Documento1 paginaPMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part5Aditya PranotoNessuna valutazione finora

- PMG-ENG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part7 PDFDocumento1 paginaPMG-ENG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part7 PDFAditya PranotoNessuna valutazione finora

- PMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part8Documento1 paginaPMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part8Aditya PranotoNessuna valutazione finora

- PMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part12Documento1 paginaPMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part12Aditya Pranoto100% (1)

- PMG-ENG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part13 PDFDocumento1 paginaPMG-ENG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part13 PDFAditya PranotoNessuna valutazione finora

- PMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part1Documento1 paginaPMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part1Aditya PranotoNessuna valutazione finora

- Utility List - Water Circulation DF - Rev0Documento1 paginaUtility List - Water Circulation DF - Rev0Aditya PranotoNessuna valutazione finora

- Utility List - Motor Load PR - Rev0Documento1 paginaUtility List - Motor Load PR - Rev0Aditya PranotoNessuna valutazione finora

- PMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment DatasheetDocumento13 paginePMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment DatasheetAditya PranotoNessuna valutazione finora

- Utility List - NG Consumption PR - Rev0Documento1 paginaUtility List - NG Consumption PR - Rev0Aditya PranotoNessuna valutazione finora

- Utility List - Water Circulation PR - Rev0Documento2 pagineUtility List - Water Circulation PR - Rev0Aditya PranotoNessuna valutazione finora

- Utility List - BE & Chemical Consumption PR - Rev0Documento1 paginaUtility List - BE & Chemical Consumption PR - Rev0Aditya PranotoNessuna valutazione finora

- Utility List - Steam Consumption DF - Rev0Documento1 paginaUtility List - Steam Consumption DF - Rev0Aditya PranotoNessuna valutazione finora

- Utility List - Compressed Air Consumption DF - Rev0Documento1 paginaUtility List - Compressed Air Consumption DF - Rev0Aditya PranotoNessuna valutazione finora

- Utility List - Motor Load DF - Rev0Documento2 pagineUtility List - Motor Load DF - Rev0Aditya PranotoNessuna valutazione finora

- ROTORCOMP Company ProfileDocumento26 pagineROTORCOMP Company ProfileJose Santos0% (1)

- Specification For Bonding Fresh Concrete To Hardened Concrete With A Multi-Component Epoxy AdhesiveDocumento10 pagineSpecification For Bonding Fresh Concrete To Hardened Concrete With A Multi-Component Epoxy AdhesiveRandolph CamaclangNessuna valutazione finora

- Lecture07 RecoveryDocumento27 pagineLecture07 RecoveryHarsha PaniaNessuna valutazione finora

- Improving Kiva's Automated Warehouse SystemDocumento13 pagineImproving Kiva's Automated Warehouse SystemBụi ĐườngNessuna valutazione finora

- Ningbo LK Technology Co., LTDDocumento24 pagineNingbo LK Technology Co., LTDAlexander PrietoNessuna valutazione finora

- Productivity 1236Documento165 pagineProductivity 1236Sameer GuptaNessuna valutazione finora

- ACL Care Customer Support OverviewDocumento5 pagineACL Care Customer Support OverviewMohammad Mahmudur RahmanNessuna valutazione finora

- PSG Mewp Trapping Crushing 2023-02-08 SingleDocumento22 paginePSG Mewp Trapping Crushing 2023-02-08 Singleself disciplineNessuna valutazione finora

- Allan D. Cruzat: Position Applied: Pipe Fitter Educational AttainmentDocumento15 pagineAllan D. Cruzat: Position Applied: Pipe Fitter Educational AttainmentRaymond Manalo PanganibanNessuna valutazione finora

- 35 110 HwcpresentationactualDocumento43 pagine35 110 HwcpresentationactualEyock PierreNessuna valutazione finora

- Petsec Energy May-19 Investor PresentationDocumento40 paginePetsec Energy May-19 Investor Presentationnishant bhushanNessuna valutazione finora

- Ex Met Expired Company ProfileDocumento16 pagineEx Met Expired Company ProfileAbdulRazzak BarakeNessuna valutazione finora

- 18mec207t - Unit 5 - Rev - w15Documento54 pagine18mec207t - Unit 5 - Rev - w15Asvath GuruNessuna valutazione finora

- UPnewDocumento12 pagineUPnewhardik033Nessuna valutazione finora

- Redflex Contract With Paradise Valley 2013Documento104 pagineRedflex Contract With Paradise Valley 2013warondrivingNessuna valutazione finora

- KanBo Wins Best Office 365 Award at European SharePoint ConferenceDocumento3 pagineKanBo Wins Best Office 365 Award at European SharePoint ConferencePR.comNessuna valutazione finora

- Hybrid IDEF0 IDEF03 HoustonDocumento3 pagineHybrid IDEF0 IDEF03 HoustonHouston Mandar TrivediNessuna valutazione finora

- Foundations of Engineering EconomyDocumento50 pagineFoundations of Engineering EconomyOrangeNessuna valutazione finora

- OceanSaver AS - Kashif Javaid PDFDocumento28 pagineOceanSaver AS - Kashif Javaid PDFvangeliskyriakos8998Nessuna valutazione finora

- Module6-Detailed Project Report and EPCDocumento10 pagineModule6-Detailed Project Report and EPCJames K. BitokNessuna valutazione finora