Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Per Acetic Acid

Caricato da

Maruthi KCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Per Acetic Acid

Caricato da

Maruthi KCopyright:

Formati disponibili

9/24/2014 Patent US4904821 - Distillation, vapor absorbing by organic phosphate to remove water; nonexplosive - Google Patents

http://www.google.co.in/patents/US4904821 1/5

Patents

Publication number US4904821 A

Publication type Grant

Application number US 07/206,488

Publication date 27 Feb 1990

Filing date 14 Jun 1988

Priority date 22 Jun 1987

Fee status Paid

Also published as DE3720562A1, DE3720562C2,

EP0296328A1, EP0296328B1

Inventors Georg Boehme, Willi Hofen, Guenther

Prescher, Rainer Siegmeier

Original Assignee Degussa Aktiengesellschaft

Export Citation BiBTeX, EndNote, RefMan

Patent Citations (2), Referenced by (2), Classifications (8),

Legal Events (6)

External Links: USPTO, USPTO Assignment, Espacenet

CLAIMS (9)

We claim:

1. A method of preparing peracetic acid in organic solution in a continuous

manner comprising hydrogen peroxide and acetic acid in the presence of

sulfuric acid as reactants in a simple distillation zone in such a manner that (a)

hydrogen peroxide and acetic acid are in a molar ratio of 1 to 2:1 and (b)

hydrogen peroxide is in a 30-35% by weight aqueous solution whereby the

weight ratio of hydrogen peroxide to water is between 0.43 and 0.54, and the

reactants are placed in the bottom of said distillation zone before the start of

said reaction,

(c) the concentration of sulfuric acid is adjusted to 20-30% by weight in

relation to the entire solution,

maintaining this (a)(b)(c) mix state of the above-defined reactants in the

bottom of the column in a stationary manner so as to remain constant

during the reaction, carrying out the reaction at temperatures of 55 to 70

C. and at system pressures of 100-200 mbars,

removing a vapor phase of peracetic acid, acetic acid and water from the

distillation zone,

conducting said zone vapor phase into an absorption zone in

countercurrent contact with organic phosphate having 3-30 carbon atoms

which takes up the portion of peracetic acid and acetic acid, thereby

forming a solution of peracetic acid and acetic acid in the phosphate, and

removing the non-absorbed water vapor.

2. The method according to claim 1, wherein said reactants are placed

in a plate column with a dephlegmator set on top as a distillation zone.

3. The method according to claim 1, wherein hydrogen peroxide and

acetic acid are placed in said zone before the start of the reaction in a

molar ratio of 1.5:1, the weight ratio of hydrogen peroxide to water is

adjusted to 0.54 and the concentration of sulfuric acid in the entire

Distillation, vapor absorbing by organic

phosphate to remove water; nonexplosive

US 4904821 A

ABSTRACT

In order to safely prepare peracetic acid in an organic solvent, the bottom is

maintained in a certain stationary state during the preparation of aqueous

peracetic acid, whereupon the vapor current of peracetic acid, acetic acid and

water is absorbed with an organic phosphate with 3-30 carbon atoms. The

solution obtained in this manner can be transferred by means of desorption with

a low-boiling compound, e.g. an alkyl ester, into this lower-boiling solvent.

DESCRIPTION

INTRODUCTION AND BACKGROUND

The present invention relates to the method of preparing peracetic acid.

One of the best-known oxidation agents is peracetic acid, especially for the

preparation of epoxides or lactones from ketones via the Baeyer-Villiger

reaction.

Peracetic acid is generally prepared in a classical manner by reacting acetic

acid with hydrogen peroxide in the presence of an acidic catalyst, usually

sulfuric acid. More or less pure aqueous solutions of peracetic acid accumulate

thereby, depending on the type of performance, such as, for example, the so-

called equilibrium peracetic acid consisting of approximately 40-42% peracetic

acid, 37-40% acetic acid, 10-14% water, 4-6% hydrogen peroxide and 0.5-1%

sulfuric acid. ("Ullmann's Enzyklopadie der technischen Chemie", 3d edition,

vol. 13, p. 254)

Very pure aqueous solutions are obtained if a reaction mixture is used which

contains, in addition to water and the acidic catalyst, more than 1 mole

hydrogen peroxide per mole acetic acid and if the peracetic acid is distilled off

under reduced pressure with water, cf. loc. cit., Supplementary Volume, 3d

edition, page 181. These very pure solutions can be converted by means of

azeotropic entrainer agent distillation into water-free organic peracetic acid

solutions, cf. loc. cit. and DE-PS 11 65 576.

A water-free, organic solution of peracetic acid can also be obtained by

azeotropically removing the water by means of the simultaneous presence of an

organic solvent which forms an azeotrope with water in the reaction of hydrogen

peroxide and acetic acid in the presence of an acidic catalyst, cf. Ullmann,

Supplementary Volume, loc. cit.

However, there are also known industrial safety risks involved in the preparation

of organic percarboxylic acid solutions. For this reason, the attempt was made

to obtain the corresponding organic solutions by means of the direct extraction

of aqueous mixtures of percarboxylic acid, which solutions were azeotropically

Find prior art Discuss this patent View PDF Download PDF

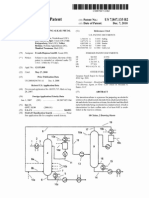

IMAGES (1)

prasad@metsartechnologies.

9/24/2014 Patent US4904821 - Distillation, vapor absorbing by organic phosphate to remove water; nonexplosive - Google Patents

http://www.google.co.in/patents/US4904821 2/5

mixture is adjusted to 25-30% by wt.

4. The method according to claim 1, wherein the reaction is performed

at a system pressure of 100-150 mbars, a reflux ratio of 0.3 to 0.5 and

a continuous infeed of 40-50% by wt. aqueous hydrogen peroxide

solution and acetic acid in a weight ratio of 0.7 to 0.8:1.

5. The method according to claim 1, wherein trisubstituted alkyl,

cycloalkyl or aryl phosphates are used in the absorption zone.

6. The method according to claim 5, wherein trialkyl phosphate in

which alkyl contains 1-10 carbon atoms is used.

7. The method according to claim 6, wherein trimethyl, triethyl, tributyl

or trioctyl phosphate is used.

8. The method according to claim 7, wherein a solution of peracetic

acid and acetic acid in tributyl phosphate is transferred by desorption

with aliphatic esters into a solution of the said aliphatic esters.

9. The method as claimed in claim 8, wherein said aliphatic ester is

ethyl acetate.

dewatered by the addition of an entrainer agent. Suitable extraction agents

were aliphatic, cycloaliphatic and aromatic hydrocarbons as well as chlorinated

hydrocarbons, cf. DE-OS 21 45 603. Hydrogen peroxide was added as a 30 to

90% by weight, preferably as 45 to 70% by weight aqueous solution in excess

over the carboxylic acid, preferably in highly concentrated, aqueous form.

Phosphoric ester, preferably trialkyl phosphates, were also used as extraction

agents and the extracts obtained were then desorbed with alkyl esters of lower

carboxylic acids. The percarboxylic acids used were 10-80, preferably 20-60%

by weight aqueous solutions, cf. U.S. Pat. No. 3,829,216.

A moment of danger was seen only in the fact that an organic solvent was

present in addition to hydrogen peroxide, percarboxylic acid and acidic catalyst

and the only attempt made was to avoid this combination. It turned out,

however, that the moment of danger also occurred without the presence of an

organic solvent. For this reason, in particular the molar ratio of hydrogen

peroxide to carboxylic acid used was set at certain values before the reaction

was started. It also turned out that the safety of the system did not, as assumed,

remain continuously constant after a certain value but rather that a distinct

safety gap occurred within the ranges of this molar ratio used, cf. DE-OS 25 19

299 and 25 19 300. The weight ratio of hydrogen peroxide to water also played

a part in this process.

SUMMARY OF THE INVENTION

The present invention therefore has the object of providing a method for the preparation of peracetic acid and its extraction

in an organic solvent in a manner which is unobjectionable from the standpoint of industrial safety.

It was found that this and other objects can be achieved if the reaction is performed in a simple distillation apparatus in

such a manner that hydrogen peroxide and acetic acid in a molar ratio of 1 to 2:1 and hydrogen peroxide in a 30-35% by

weight aqueous solution are placed in the bottom of the apparatus, i.e. the distillation zone, before the start of the reaction.

The concentration of sulfuric acid is adjusted to 20-30% by weight in relation to the entire solution. This state of the above-

defined quantities used is maintained in the bottom of the column in a stationary manner and the reaction is performed at

temperatures of 55 to 70 C. and system pressures of 100-200 mbars. Thus, no agitation implement is used. As a result

of the reaction, a vapor phase of peracetic acid, acetic acid and water is removed from the apparatus. This vapor phase is

then conducted in a countercurrent manner into an absorption column to contact an organic phosphate with 3-30 carbon

atoms which takes up the portion of peracetic acid and acetic acid. As a result thereof a solution of peracetic acid and

acetic acid is obtained in the phosphate involved while the non-absorbed water vapor is taken off over head and leaves

the system.

BRIEF DESCRIPTION OF DRAWING

The process of the present invention will be further understood with reference to the drawing which shows a schematic of

a simple distillation apparatus.

DETAILED DESCRIPTION OF INVENTION

The term "simple distillation apparatus" refers to the "distillation zone" and denotes all apparatuses which are known for a

simple or straight distillation such as e.g. boilers, evaporation flasks, bottom evaporators and which are preferably

connected to a condenser or dephlegmator. Even columns with or without dephlegmator, which are preferably designed as

a plate column, can be used. The apparatuses known in absorption technology can be considered as customary

absorption columns. The system comprising the reaction and the absorption is preferably run at temperatures of 45-65

C. If the absorption is run, for example, at 45-55 C., it is possible, via the absorption equilibrium, to obtain a 23% by

weight solution of peracetic acid in tributyl phosphate in bottom S II, as shown in the drawing. The higher the absorption

temperature, the lower the concentrations of peracetic acid in bottom S II.

The reaction part of the system is operated in such a manner that a weight ratio of peracetic acid to acetic acid of 2 to 3:1,

preferably 2.5 to 3:1, is adjusted in the vapor phase, the balance is water. The preferred composition of the vapor

corresponds to 45-47% by weight peracetic acid, 14-17% by wt. acetic acid, remainder water.

Suitable organic phosphates for purposes of the invention are those with 3-30 carbon atoms such as trisubstituted

phosphates, namely either alkyl, cycloalkyl or aryl phosphates, which can also be added as mixtures. Useful phosphates

are e.g. trialkylesters of phosphoric acid with alkyl containing 1-10 C atoms as well as tricyclohexyl phosphate or triphenyl

phosphate, tricresyl phosphate, diphenylcresyl phosphate. Trimethyl, triethyl, tributyl and tiroctyl phosphate are preferred.

Mixtures can be used.

Since only as much water can be distilled out of the system as corresponds to the portion of hydrogen peroxide solution

introduced and the reaction water, any commercially available solution, e.g. a 50-70% solution, can be fed in for the

continuous reaction, independently of the usage of a 30-35% by wt. aqueous hydrogen peroxide solution placed initially in

the receiver.

If the peracetic acid is not to be used as solution in a phosphoric ester, it is possible to transfer the peracetic acid from the

9/24/2014 Patent US4904821 - Distillation, vapor absorbing by organic phosphate to remove water; nonexplosive - Google Patents

http://www.google.co.in/patents/US4904821 3/5

phosphate into another organic solvent such as e.g. aliphatic esters in a customary manner. These solvents must be

stable against oxidations under customary desorption conditions and must be easy to separate in a distillative manner

from acetic acid. Methyl to propyl acetates are preferred. Aromatic hydrocarbons, e.g. benzene, or chlorinated

hydrocarbons, even in a mixture with esters, can also be used. In general mixtures can be used.

The desorption of peracetic acid and acetic acid from the phosphate solution can be performed in a known manner by

introducing the vaporous second solvent. The desorbates produced can, if desired, be completely dewatered by

azeotropic distillation.

The method of the invention, which is preferably performed in a continuous manner, will now be explained in more detail

with reference made to the drawing. The numerical values contained in the description of this drawing are given solely by

way of example.

Illustratively, the distillation apparatus used is a bottom column K I (with dephlegmator set on top). Hydrogen peroxide and

acetic acid (AC) in a molar ratio of 1.5:1 are placed in bottom S I of the column before the start of the reaction. A 40-50%

by wt. hydrogen peroxide is used. The weight ratio of hydrogen peroxide to water is adjusted to 0.54 by the addition of

water. This corresponds to a 35% by wt. hydrogen peroxide solution. Sulfuric acid is added to the mixture in such an

amount that its concentration in the mixture is e.g. 25-30% by wt.

This bottom mixture placed in a receiver before the start of the reaction is maintained constant during the duration of the

reaction to such a degree by using a system pressure of 100-150 mbars, a reflux ratio of 0.3-0.5 and the continuous

addition of 40-50% by weight hydrogen peroxide solution and acetic acid in a feed ratio (weight ratio) of 0.7 to 0.8:1 that

the quantities of molar quotient (H

2

O

2

/AC) and weight ratio (H

2

O

2

/H

2

O) calculated for use before the start of the

reaction remain preserved. The bottom temperature is e.g. 60 C. and is maintained with the aid of forced-circulation

reboiler W 1 via lines 3, 3a.

A vapor current is obtained under these conditions which consists of approximately 47% by wt. peracetic acid (PAC),

approximately 16% by wt. acetic acid, approximately 37% by wt. water and less than 0.1% by wt. hydrogen peroxide and

is conducted via line 4 into the lower part (bottom S II) of absorption column K II. An organic phosphate, e.g. tributyl

phosphate (TBF) is added via line 5 at the column head and conducted in countercurrent flow to the rising vapor current.

The phosphate absorbs both the peracetic acid and the acetic acid from the vapor current but only slight amounts of water

(they correspond at a maximum to the solubility of water in tributyl phosphate). Almost the entire amount of water present

in the vapor current leaves absorption column K II via line 6, is condensed in condenser W 3, passes via line 6a into

separator B 1 and is removed from it via line 6c. A small partial amount is fed as reflux to column K I in order to retain

hydrogen peroxide in bottom S I (via line 6b).

Bottom S II of absorption column K II contains, as stated, the peracetic acid and acetic acid, absorbed in tributyl

phosphate. The absorption agent should always be used in such an amount that practically no peracetic acid and acetic

acid escape together with the water vapor at the head of column K II in a single passage of the vapor current from

distillation apparatus K I at a given temperature and pressure. This can be readily determined by a preliminary test as will

be apparent to those skilled in the art.

In the instant case given by way of example a 23% by wt. solution of peracetic acid in addition to 7% by wt. acetic acid in

tributyl phosphate was obtained with tributyl phosphate at a temperature of 45-55 C. and a pressure of 100-150 mbars

(since the columns K I and K II form a coherent system). The stable solution of peracetic acid in tributyl phosphate

obtained in this manner can be used in this form. It is removed from bottom S II (not shown).

However, if peracetic acid is to be used in another solvent, e.g. in an aliphatic ester such as ethyl acetate, then the

solution obtained in tributyl phosphate is conducted via line 7, pump 2 and line 7a to the head of evaporator system W 4

and W 5, which illustratively consists of falling-film evaporators, and desorbed with the aid of vapors of ethyl acetate

introduced via line 10 which are introduced via W 5 and line 9 into W 4. The vapor currents of the desorption system pass

via line 8 into column K III. The tributyl phosphate freed to a large extent of peracetic acid and acetic acid passes via line

8a from W 4 to W 5 and leaves bottom S V via line 13. The tributyl phosphate running out of S V is preferably almost

completely freed of dissolved ethyl acetate by means of water vapor stripping (not shown).

The vapor current of peracetic acid and acetic acid in ethyl acetate is removed, as stated, in the bottom of W 4 via line 8

and can also be optionally dewatered in column K III by formation of an azeotrope from the slight residue of water with a

part of the ethyl acetate which is removed via the head of column K III. The heteroazeotropic mixture of water and ethyl

acetate distilled off during the dewatering is condensed in a customary manner, water is removed and ethyl acetate

returned (not shown). Otherwise, it can be directly condensed.

A practically water-free solution of peracetic acid and acetic acid in ethyl acetate is removed from bottom S III of column K

III via line 11, pump 4 and line 12. A 23% by wt. solution of peracetic acid in ethyl acetate was obtained at a column

pressure of 300 mbars which also contained 7% by wt. acetic acid in addition. Thus, the entire amount of peracetic acid

present in tributyl phosphate can be transferred into ethyl acetate.

Very different concentrations of peracetic acid in trialkyl phosphate or another solvent (by desorption of the trialkyl

phosphate solution) can be obtained, according to the conditions of the "K I and K II" system. The tributyl phosphate, freed

to a great extent of peracetic acid, that is in the exemplary instance down to 0.02% by wt. peracetic acid, and of acetic

acid, that is, down to 1.5% by wt. acetic acid, collects in bottom S V of evaporator W 5, is returned via line 13, pump 3 and

line 13a and 13b into cooler W 8 and cooled off there to the absorption temperature of e.g. 45 C. Thereafter, the tributyl

9/24/2014 Patent US4904821 - Distillation, vapor absorbing by organic phosphate to remove water; nonexplosive - Google Patents

http://www.google.co.in/patents/US4904821 4/5

phosphate passes back to the head of column K II (via line 5).

A partial current of tributyl phosphate is periodically removed via line 13c and cleaned, in which manner the amount of

accumulating impurities is held to a low level.

In order to keep the accumulation of impurities in bottom S I low, a low removal rate must be generated via line 3b, e.g.

2% by wt. in relation to the feed of hydrogen peroxide, water and acetic acid, which can be returned after cleaning to K I

(not shown).

The technical advance of the method of the invention resides in the absolutely safe performance of the method since the

hydrogen peroxide concentration is controlled and held from the beginning to a low level during the preparation of

peracetic acid in the bottom of the preparation apparatus and is held at this level during the reaction. In this manner, the

dangerous occurrence of safety gaps is completely avoided. This safety is increased even more by processing the vapor

current containing water vapor by means of absorption in an organic solvent, which makes it impossible for a condensed,

high-percentage aqueous phase of peracetic acid to be produced.

The solutions of peracetic acid in alkyl phosphates obtained in accordance with the method of the invention are

remarkably stable, even at rather high temperatures. Thus, the decomposition rate of a solution containing 23% by wt.

peracetic acid in addition to 7% by wt. acetic acid is only 0.5-0.8% by weight/h at 55 C. in tributyl phosphate.

Another advantage of the peracetic acid solutions prepared according to the invention in alkyl phosphates resides in the

low evaporation speed of these phosphates, so that no concentration of the solutions due to evaporation of the solvent can

occur.

Further variations and modifications of the present invention will become apparent to those skilled in the art and are

intended to be ecompassed by the appended claims.

German priority application P 37 20 562.5-42 herein by reference.

PATENT CITATIONS

Cited Patent Filing date Publication date Applicant Title

DE2141157A1 * 17 Aug 1971 22 Feb 1973 Degussa

Anhydrous percarboxylic acid solns - from aq solns by extraction with

phosphate,desorption and distillation

GB949094A * Title not available

* Cited by examiner

REFERENCED BY

Citing Patent Filing date Publication date Applicant Title

US6677478 3 Apr 2002 13 Jan 2004 Kemira Chemicals Oy Process for the production of percarboxylic acid

US8029693 30 Jan 2009 4 Oct 2011 Fmc Corporation Rapid dilution of peracid solutions to equilibrated solutions

CLASSIFICATIONS

U.S. Classification 562/6

International Classification C07C67/00, C07C409/26, C07C407/00

Cooperative Classification C07C407/00, C07C409/26, C07C407/003

European Classification C07C409/26

LEGAL EVENTS

Date Code Event Description

6 Oct 2001 AS Assignment

Owner name: DEGUSSA AG, GERMANY

Free format text: MERGER;ASSIGNOR:DEGUSSA-HULS

AKTIENGESELLSCHAFT;REEL/FRAME:012322/0909

Effective date: 20010209

Owner name: DEGUSSA AG BENNIGSENPLATZ 1 DE-40474 DUSSELDORF GE

7 Aug 2001 FPAY

Fee

payment

Year of fee payment: 12

18 Apr 2000 AS Assignment

Owner name: DEGUSSA-HULS AKTIENGESELLSCHAFT, GERMANY

Free format text: ASSIGNMENT OF ASSIGNORS INTEREST;ASSIGNOR:DEGUSSA

AKTIENGESELLSCHAFT;REEL/FRAME:010719/0914

Effective date: 19981109

Owner name: DEGUSSA-HULS AKTIENGESELLSCHAFT WEISSFRAUENSTRASSE

15 Jul 1997 FPAY

Fee

payment

Year of fee payment: 8

22 Jul 1993 FPAY

Fee

payment

Year of fee payment: 4

9/24/2014 Patent US4904821 - Distillation, vapor absorbing by organic phosphate to remove water; nonexplosive - Google Patents

http://www.google.co.in/patents/US4904821 5/5

19 Dec 1988 AS Assignment

Owner name: DEGUSSA AKTIENGESELLSCHAFT, WEISS-FRAUENSTRASSE 9,

Free format text: ASSIGNMENT OF ASSIGNORS INTEREST.;ASSIGNORS:BOEHME, GEORG;HOFEN,

WILLI;PRESCHER, GUENTHER;AND OTHERS;REEL/FRAME:004989/0729;SIGNING DATES FROM

19881115 TO 19881201

Google Home - Sitemap - USPTO Bulk Downloads - Privacy Policy - Terms of Service - About Google Patents - Send Feedback

Data provided by IFI CLAIMS Patent Services

2012 Google

Potrebbero piacerti anche

- AlkylationDocumento9 pagineAlkylationabhishek sharma100% (1)

- Mdp2p PatentDocumento4 pagineMdp2p PatentPelado JavierNessuna valutazione finora

- Legal Chemistry: A Guide to the Detection of Poisons, Examination of Tea, Stains, Etc., as Applied to Chemical JurisprudenceDa EverandLegal Chemistry: A Guide to the Detection of Poisons, Examination of Tea, Stains, Etc., as Applied to Chemical JurisprudenceNessuna valutazione finora

- Advanced Pharmaceutical analysisDa EverandAdvanced Pharmaceutical analysisValutazione: 4.5 su 5 stelle4.5/5 (2)

- Unit Operations in Chemical Industries: November 2019Documento20 pagineUnit Operations in Chemical Industries: November 2019Jhon NeverNessuna valutazione finora

- Ethyl Acetate Design ProjectDocumento60 pagineEthyl Acetate Design ProjectAhmed Ali100% (4)

- Remedial For IPE de GuzmanDocumento38 pagineRemedial For IPE de GuzmanJhiGz Llausas de GuzmanNessuna valutazione finora

- MetoxidoDocumento8 pagineMetoxidocessavelinoNessuna valutazione finora

- Estimation of Measurement Uncertainty For Total PH in Water: U1 (Relative)Documento4 pagineEstimation of Measurement Uncertainty For Total PH in Water: U1 (Relative)Maruthi K100% (1)

- Topical and Prospective Processes of Acetoxylation: Grzegorz Lewandowski, Marcin Bartkowiak, Eugeniusz MilchertDocumento6 pagineTopical and Prospective Processes of Acetoxylation: Grzegorz Lewandowski, Marcin Bartkowiak, Eugeniusz MilchertAnonymous b9fcR5Nessuna valutazione finora

- Azeotropic DistillationDocumento29 pagineAzeotropic DistillationHafiz Sheikh Ahmad FayyazNessuna valutazione finora

- Estimation of Measurement Uncertainty For Electrical Conductivity in WaterDocumento4 pagineEstimation of Measurement Uncertainty For Electrical Conductivity in WaterMaruthi KNessuna valutazione finora

- XII-M-1 JEE Chemistry FinalDocumento312 pagineXII-M-1 JEE Chemistry FinalADITYA PRATAP100% (1)

- Supercritical Fluid Extraction of Ethanol From Aqueous SolutionsDocumento11 pagineSupercritical Fluid Extraction of Ethanol From Aqueous SolutionsPedro LisboaNessuna valutazione finora

- Types of DistillationDocumento25 pagineTypes of Distillationdankshavali shaikNessuna valutazione finora

- Biodata of Assessors: National Accreditation Board For Testing and Calibration Laboratories (NABL)Documento7 pagineBiodata of Assessors: National Accreditation Board For Testing and Calibration Laboratories (NABL)Maruthi KNessuna valutazione finora

- Boiler Water BBGS PDFDocumento32 pagineBoiler Water BBGS PDFproloy12Nessuna valutazione finora

- Process For Ethyl Acetate ProductionDocumento9 pagineProcess For Ethyl Acetate ProductionMuhammad Yanuar AnantaNessuna valutazione finora

- Estimation of Measurement Uncertainty For Total Alkalinity in WaterDocumento4 pagineEstimation of Measurement Uncertainty For Total Alkalinity in WaterMaruthi KNessuna valutazione finora

- Aspen Plus ExercisesDocumento215 pagineAspen Plus Exercisesramsrivatsan100% (3)

- US3718545 (1) PatenteDocumento8 pagineUS3718545 (1) PatenteAndrés BelloniNessuna valutazione finora

- Arease: Nov. 8, 1966 W. Wogt Et Al 3,284,495 Process For The Continuous Manufacture, Purification andDocumento3 pagineArease: Nov. 8, 1966 W. Wogt Et Al 3,284,495 Process For The Continuous Manufacture, Purification andRachmad HermawanNessuna valutazione finora

- Process For The Liquid Phase Oxidation of Toluene To Benzaldehyde - Patent # 7411099 - PatentGeniusDocumento6 pagineProcess For The Liquid Phase Oxidation of Toluene To Benzaldehyde - Patent # 7411099 - PatentGeniuswifeforstudNessuna valutazione finora

- Us20110065939a1 PDFDocumento17 pagineUs20110065939a1 PDFniralNessuna valutazione finora

- United States Patent Office: Nahfeii (Edta) )Documento2 pagineUnited States Patent Office: Nahfeii (Edta) )Giacomo AccomandoNessuna valutazione finora

- United States Patent (191: Schwabegger Et Al. (11) Patent Number: 5,437,776Documento4 pagineUnited States Patent (191: Schwabegger Et Al. (11) Patent Number: 5,437,776Oscar SobradosNessuna valutazione finora

- European Patent Specification: For The Production of Acetic AcidDocumento9 pagineEuropean Patent Specification: For The Production of Acetic AcidWisnu Rochman HidayatullahNessuna valutazione finora

- Lactic Acid Determination 1Documento24 pagineLactic Acid Determination 1madads25586100% (1)

- Us 3229777Documento4 pagineUs 3229777Parth AggarwalNessuna valutazione finora

- Jozmim: Feb. 17, 1953 B. V. Aller EtalDocumento7 pagineJozmim: Feb. 17, 1953 B. V. Aller EtalFatonaRifkyPNessuna valutazione finora

- Vol 43 - 3 0004Documento112 pagineVol 43 - 3 0004karamniaNessuna valutazione finora

- Sulfuric Acid TreatmentDocumento9 pagineSulfuric Acid TreatmentShankar AcharNessuna valutazione finora

- AAS Methods 2520of 2520 ProductionDocumento4 pagineAAS Methods 2520of 2520 Productionapi-3714811Nessuna valutazione finora

- Hong1998 Article DeterminationOfH2O2AndOrganicPDocumento5 pagineHong1998 Article DeterminationOfH2O2AndOrganicPArvindKumarNessuna valutazione finora

- Lab 20 Synthesis of Banana OilDocumento7 pagineLab 20 Synthesis of Banana OilgioNessuna valutazione finora

- A Novel Process To Recover Sulfur in Aqueous Phase Under Ambient Condition - SpringerLinkDocumento16 pagineA Novel Process To Recover Sulfur in Aqueous Phase Under Ambient Condition - SpringerLinkmodikiritNessuna valutazione finora

- Us 3642838 PatentDocumento3 pagineUs 3642838 PatentElsie XiaoNessuna valutazione finora

- Preparation and Assay of Acetyl PhosphateDocumento4 paginePreparation and Assay of Acetyl PhosphatecataawwwNessuna valutazione finora

- Ergot AlkaloidsDocumento8 pagineErgot AlkaloidsHofman HofmannNessuna valutazione finora

- Project 1 - Isopropanol and Acetone From Propylene PDFDocumento8 pagineProject 1 - Isopropanol and Acetone From Propylene PDFAnonymous RJkpep7D0rNessuna valutazione finora

- US3036885Documento2 pagineUS3036885pradipNessuna valutazione finora

- United States Patent PO: Patented Nov. 20, 1956Documento2 pagineUnited States Patent PO: Patented Nov. 20, 1956shenn0Nessuna valutazione finora

- cv1p0018 (Sudah)Documento4 paginecv1p0018 (Sudah)aris_nurhidayatNessuna valutazione finora

- US3816523Documento5 pagineUS3816523Argo Rizky Kusuma 2007110716Nessuna valutazione finora

- Process For The Production of High Purity Aromatic Carboxylic Acids Using A Benzoic Acid and Water Solvent For Oxidation and PurificationDocumento13 pagineProcess For The Production of High Purity Aromatic Carboxylic Acids Using A Benzoic Acid and Water Solvent For Oxidation and PurificationIsmail VohraNessuna valutazione finora

- March 9, 1965 L. Mavrovic: Filed June 16, 1961Documento6 pagineMarch 9, 1965 L. Mavrovic: Filed June 16, 1961baharuNessuna valutazione finora

- Propoxyphene Synthesis and PurificationDocumento4 paginePropoxyphene Synthesis and PurificationBrady MosherNessuna valutazione finora

- European Patent Application: Oxidizing Agent Composition For Epoxidation and Oxidation Method ThereofDocumento9 pagineEuropean Patent Application: Oxidizing Agent Composition For Epoxidation and Oxidation Method ThereofchidambaramrNessuna valutazione finora

- Downstream Processing 3PDocumento1 paginaDownstream Processing 3PEsteban GarcesNessuna valutazione finora

- United States: Patent OfficeDocumento3 pagineUnited States: Patent Officemehul10941Nessuna valutazione finora

- Pentaeritritol 2Documento6 paginePentaeritritol 2Ibnul BaasithNessuna valutazione finora

- L004 - Ritik Jain - MSDocumento6 pagineL004 - Ritik Jain - MSritikNessuna valutazione finora

- Us 2834811Documento2 pagineUs 2834811Juan David Marin ChiguachiNessuna valutazione finora

- To Whom Reprint Requests Should Be AddressedDocumento11 pagineTo Whom Reprint Requests Should Be AddressedAracely FloresNessuna valutazione finora

- United States Patent: Reimann Patent No.: Date of PatentDocumento5 pagineUnited States Patent: Reimann Patent No.: Date of PatentFernando Beer FrenkelNessuna valutazione finora

- Hydroformylation of 1 OcteneDocumento6 pagineHydroformylation of 1 OcteneLucas TorregrosaNessuna valutazione finora

- TEPZZ 65 46ZA - T: European Patent ApplicationDocumento24 pagineTEPZZ 65 46ZA - T: European Patent ApplicationIrfan LutfiantoNessuna valutazione finora

- The Synthesis Dihydroxyacetone Phosphate: in DelawareDocumento3 pagineThe Synthesis Dihydroxyacetone Phosphate: in DelawareWhiteOak ComenziNessuna valutazione finora

- Acs74 - 46 56758gfhydnsmDocumento6 pagineAcs74 - 46 56758gfhydnsmAnn Nitha ChanNessuna valutazione finora

- Mixc?gg 33:3: Mexzmeqze EgesDocumento3 pagineMixc?gg 33:3: Mexzmeqze EgesSiswand BIn Mohd AliNessuna valutazione finora

- (R) - 3-Hydroxybutanoic Acid Methyl Ester Butanoic Acid, 3-Hydroxy-, (R) - Butanoic Acid, 3-Hydroxy-, Methyl Ester, (R)Documento6 pagine(R) - 3-Hydroxybutanoic Acid Methyl Ester Butanoic Acid, 3-Hydroxy-, (R) - Butanoic Acid, 3-Hydroxy-, Methyl Ester, (R)ArifSheriffNessuna valutazione finora

- Us3479310 PDFDocumento7 pagineUs3479310 PDFKhoi Nguyen DangNessuna valutazione finora

- Fischer EsterificationDocumento3 pagineFischer EsterificationDenisse Watt Cuarteros100% (1)

- Preparation of Butyl Acetate PDFDocumento6 paginePreparation of Butyl Acetate PDFjoiya100133% (3)

- Copie de US2899444-1Documento4 pagineCopie de US2899444-1KHALED KHALEDNessuna valutazione finora

- Exp 18Documento8 pagineExp 18nicolef_20Nessuna valutazione finora

- TEPZZ 9 9995A - T: European Patent ApplicationDocumento10 pagineTEPZZ 9 9995A - T: European Patent ApplicationAyub riyanNessuna valutazione finora

- United States: (12) Patent Application Publication (10) Pub. No.: US 2009/0005588 A1Documento10 pagineUnited States: (12) Patent Application Publication (10) Pub. No.: US 2009/0005588 A1sariNessuna valutazione finora

- March 7, 1967 C. H. Deal, JR 3,308,059: (Aqueous SulfolaneDocumento3 pagineMarch 7, 1967 C. H. Deal, JR 3,308,059: (Aqueous Sulfolaneremied87Nessuna valutazione finora

- July 20, 1954 J. L. Krieger 2,684,286: InventorDocumento4 pagineJuly 20, 1954 J. L. Krieger 2,684,286: InventorNurhafizah Abd JabarNessuna valutazione finora

- Transition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesDa EverandTransition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesNessuna valutazione finora

- Good Practice Guide For Improving Accuracy of Dissolved Oxygen MeasurementsDocumento18 pagineGood Practice Guide For Improving Accuracy of Dissolved Oxygen MeasurementsMaruthi KNessuna valutazione finora

- Electrodes Booklet HoribaDocumento24 pagineElectrodes Booklet HoribaMaruthi KNessuna valutazione finora

- Economy Handheld: Eutech 5+ & 6+ SeriesDocumento12 pagineEconomy Handheld: Eutech 5+ & 6+ SeriesMaruthi KNessuna valutazione finora

- Aflatoxin Standard 2 Mix PDF664516Documento3 pagineAflatoxin Standard 2 Mix PDF664516Maruthi KNessuna valutazione finora

- Standard: OperatingDocumento24 pagineStandard: OperatingMaruthi KNessuna valutazione finora

- Orion Star A214 PH - ISE Benchtop MeterDocumento2 pagineOrion Star A214 PH - ISE Benchtop MeterMaruthi KNessuna valutazione finora

- Ozone Generation Systems: Hi-Tech Hi-TechDocumento2 pagineOzone Generation Systems: Hi-Tech Hi-TechMaruthi KNessuna valutazione finora

- BRO Mass Comparators e PDFDocumento32 pagineBRO Mass Comparators e PDFMaruthi KNessuna valutazione finora

- Testr35series Leaflet - r0Documento4 pagineTestr35series Leaflet - r0Maruthi KNessuna valutazione finora

- Certificate of Analysis: Aflatoxin Mix 4 Solution Analytical Standard 34036 BCCC8504 Sigma-AldrichDocumento3 pagineCertificate of Analysis: Aflatoxin Mix 4 Solution Analytical Standard 34036 BCCC8504 Sigma-AldrichMaruthi KNessuna valutazione finora

- UV Spectro E Data SheetDocumento2 pagineUV Spectro E Data SheetMaruthi KNessuna valutazione finora

- SOP 4 Calibration Dwright V19Documento44 pagineSOP 4 Calibration Dwright V19Maruthi KNessuna valutazione finora

- Instrument: Make: Model Range & Accuracy: Instrument No.: Location: Instrumentation LabDocumento2 pagineInstrument: Make: Model Range & Accuracy: Instrument No.: Location: Instrumentation LabMaruthi KNessuna valutazione finora

- True Value Calibration Services Private Limited: Has Been Assessed and Accredited in Accordance With The StandardDocumento19 pagineTrue Value Calibration Services Private Limited: Has Been Assessed and Accredited in Accordance With The StandardMaruthi KNessuna valutazione finora

- Legal Metrology (General Rules), 2011 Part-1Documento170 pagineLegal Metrology (General Rules), 2011 Part-1Maruthi KNessuna valutazione finora

- 1.WI PHDocumento2 pagine1.WI PHMaruthi KNessuna valutazione finora

- Operation and Calibration of UV-VIS SpectrophotometerDocumento8 pagineOperation and Calibration of UV-VIS SpectrophotometerMaruthi K100% (1)

- Initial Calculation of ConcentrationDocumento12 pagineInitial Calculation of ConcentrationMaruthi KNessuna valutazione finora

- Bsa224s CWDocumento1 paginaBsa224s CWMaruthi K100% (1)

- Recommended Practices For Calibration Laboratories - National Research Council CanadaDocumento10 pagineRecommended Practices For Calibration Laboratories - National Research Council CanadaMaruthi KNessuna valutazione finora

- Mahbubnagar Road Map: Close WindowDocumento1 paginaMahbubnagar Road Map: Close WindowMaruthi KNessuna valutazione finora

- Khammam Road Map: Close WindowDocumento1 paginaKhammam Road Map: Close WindowMaruthi KNessuna valutazione finora

- Karimnagar PDFDocumento1 paginaKarimnagar PDFMaruthi KNessuna valutazione finora

- C 02 Solutions 2Documento27 pagineC 02 Solutions 2SantanuNessuna valutazione finora

- Liquid Solutions-01 Theory (N)Documento27 pagineLiquid Solutions-01 Theory (N)Raju SinghNessuna valutazione finora

- Binous Al HarthiDocumento9 pagineBinous Al HarthiKaushal RamaniNessuna valutazione finora

- Simulation and Analysis of A Reactive Distillation Column For Removal of Water From Ethanol Water MixturesDocumento9 pagineSimulation and Analysis of A Reactive Distillation Column For Removal of Water From Ethanol Water MixturesBryanJianNessuna valutazione finora

- Org Chem Lab ManualDocumento62 pagineOrg Chem Lab ManualNowair TuanNessuna valutazione finora

- 3.sample Paper Chemistry 12, Set-3, 2022-23Documento10 pagine3.sample Paper Chemistry 12, Set-3, 2022-23sachinNessuna valutazione finora

- 23 Oct 2018 203940383R4D3OAIAPreFeasibilty FinalsaraswatiDocumento23 pagine23 Oct 2018 203940383R4D3OAIAPreFeasibilty FinalsaraswatiAnkush GiriNessuna valutazione finora

- Solns SulDocumento3 pagineSolns SulChutvinder LanduliyaNessuna valutazione finora

- 660 281proDocumento18 pagine660 281proFebri5awalsyahNessuna valutazione finora

- A Project Report Submitted By: in Partial Fulfilment For The Award of The DegreeDocumento91 pagineA Project Report Submitted By: in Partial Fulfilment For The Award of The DegreeHari BharathiNessuna valutazione finora

- Azeotropic DistillationDocumento3 pagineAzeotropic DistillationibikgibikNessuna valutazione finora

- Exercise - 1: Basic Objective Questions: Concentration TermsDocumento14 pagineExercise - 1: Basic Objective Questions: Concentration TermsJohn WickNessuna valutazione finora

- Laboratory Fractional Distillation CompressDocumento269 pagineLaboratory Fractional Distillation CompressDuvan CastañedaNessuna valutazione finora

- Xii ChemistryDocumento35 pagineXii ChemistryPratikNessuna valutazione finora

- Namma Kalvi 11th Chemistry Unit 11 Study Material em 215587Documento9 pagineNamma Kalvi 11th Chemistry Unit 11 Study Material em 215587prathiksha6660Nessuna valutazione finora

- Refrigerants, Refrigeration Cycles, and Refrigeration SystemsDocumento11 pagineRefrigerants, Refrigeration Cycles, and Refrigeration SystemsDwi Wahyu WibowoNessuna valutazione finora

- WORKSHEET (S.No. 1.5) SolutionsDocumento1 paginaWORKSHEET (S.No. 1.5) SolutionsAakarsha SinhaNessuna valutazione finora

- Chapter 1 Azeotrope and Multicomponent DistillationDocumento32 pagineChapter 1 Azeotrope and Multicomponent DistillationMUHAMMAD LUQMAN HAKIMI MOHD ZAMRINessuna valutazione finora

- Hand-Out: Chemistry Chapter 2: SolutionDocumento14 pagineHand-Out: Chemistry Chapter 2: SolutionLuisgarciaBerlangaNessuna valutazione finora

- Class12 SAQ Workshop RoorkeeDocumento130 pagineClass12 SAQ Workshop Roorkeeadityaaaaaa002Nessuna valutazione finora

- Comparison of The Main Ethanol Dehydration TechnolDocumento7 pagineComparison of The Main Ethanol Dehydration TechnolLuiz Rodrigo AssisNessuna valutazione finora

- Chemistry Exams 02Documento5 pagineChemistry Exams 02nassorussi9Nessuna valutazione finora