Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Rhodia - Tds - Technylstar S 218 v30 Black 31 N - en

Caricato da

nimonh0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

156 visualizzazioni5 paginePA6 Data sheet - high flow nylon6

Titolo originale

Rhodia_tds_technylstar s 218 v30 Black 31 N_en (1)

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoPA6 Data sheet - high flow nylon6

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

156 visualizzazioni5 pagineRhodia - Tds - Technylstar S 218 v30 Black 31 N - en

Caricato da

nimonhPA6 Data sheet - high flow nylon6

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 5

More info : www.rhodia.

com Tel: 00 800 55 400 600

Contact : engineeringplastics-business@eu.rhodia.com

Product Data Sheet

23.11.2011

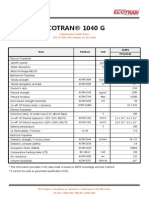

TECHNYLSTAR S 218 V30 BLACK 31N

Description

Key Properties

TECHNYLSTAR S 218 V30 Black 31N is

based on a patented high flow polyamide 6

resin (TechnylStar), heat stabilized, reinforced

with 30% of glass fibre, for injection moulding.

This product is available in black color.

High flow

Easy processing

Excellent surface aspect

Heat stabilised

Benefits

Due to its outstanding flow caracteristics, the product provides a significant productivity

improvement and allows more freedom in mould and part design versus a standard polyamide

solutions.

Applications

It is used in a wide variety of industries.

More info : www.rhodia.com Tel: 00 800 55 400 600

Contact : engineeringplastics-business@eu.rhodia.com

TECHNYLSTAR S 218 V30 BLACK 31N

Product Data Sheet

23.11.2011

Properties

Typical values of properties are for black grades

Standards Unit Values

d.a.m. Cond.

Physical

Water absorption(24h at 23C) ISO 62 % 0,95

Density ISO 1183/A g/cm3 1,34

Molding shrinkage Parallel RHODIA % 0,35

Molding shrinkage normal or perpendicular RHODIA % 0,65

Molding Shrinkage Isotropy RHODIA 0,54

Mechanical

Tensile Modulus ISO 527 Type 1A MPa 9600 6200

Tensile strength at break ISO 527 Type 1A MPa 190 110

Elongation at break ISO 527 Type 1A % 3,80 4,50

Flexural modulus ISO 178 MPa 8400 4900

ASTM D-790 MPa 8650 4750

Flexural maximum stress ASTM D-790 MPa 255 140

Charpy notched impact strength (23 C) ISO 179/1eA kJ/m2 15 31,5

Charpy unnotched impact strength (23 C) ISO 179/1eU kJ/m2 81 90

Izod notched impact strength (23 C) ISO 180/1A kJ/m2 12 21

ASTM D256 J/m 100 117

Izod notched impact strength (-30 C) ISO 180/1A kJ/m2 12 14

Flammability

Flammability (Thickness: 3,2 mm) ISO 1210 / UL94 HB

Glow Wire Flammability Index (Thickness: 1,6 mm) ISO 60695-2-12 C 650

Thermal

Melting Temperature ISO 11357 C 222

Heat deflection temperature (1,8 MPa) ISO 75/Af C 205

Heat deflection temperature (1,82 MPa) ASTM D-648 C 205

Electrical

Comparative tracking index (Sol A) IEC 60112 V 600 600

Specific

Identification code PA6-GF30

d.a.m. = dry as moulded

Cond = conditioned

More info : www.rhodia.com Tel: 00 800 55 400 600

Contact : engineeringplastics-business@eu.rhodia.com

TECHNYLSTAR S 218 V30 BLACK 31N

Product Data Sheet

23.11.2011

Disclaimer

The information contained in this document is given in good faith based on our current knowledge. It is only an indication and it is in no way binding. This

information must on no account be used as a substitutive for necessary prior tests which alone can ensure that a product is suitable for a given use. ANY

WARRANTY OF PRODUCT PERFORMANCE, MERCHANDABILITY OR FITNESS FOR A PARTICULAR PURPOSE IS EXPRESSLY EXCLUDED. Users

are responsible for ensureing compliance with local legislation and for obtaining the necessary certifications and authorizations. Users are requested to check

that they are in possession of the latest version of this document, and Rhodia is at their disposal to supply any additional information.

More info : www.rhodia.com Tel: 00 800 55 400 600

Contact : engineeringplastics-business@eu.rhodia.com

TECHNYLSTAR S 218 V30 BLACK 31N

Product Data Sheet

23.11.2011

Processing Guide

The material is supplied in airtight bags, ready for use. In case that the virgin material has absorbed

moisture, it must be dried with a dehumidified air drying equipment.

Recommended Maximum water content: 0,2 %

Drying conditions: 80 C

Recommended moulding conditions

Barrel Temperatures:

- feed zone 230 - 235 C

- compression zone 235 - 240 C

- mixing zone 240 - 245 C

Mould temperatures: 80 - 100 C

Steel advice for tools For glass fibers reinforced polyamide, Rhodia recommends the use of

steel with a high content of Carbon and purified for polishing to avoid or

limit the abrasion. For example: Z38CDV5W orZ160CDV12.

Safety information

Detailed information regarding safety are available on the safety data sheet (SDS).

SDS is sent with the first material order, or available by contacting our customer services

Regulations compliance

Grades produced or imported in Europe comply with directive 453/2010/EC, which amends REACH

directive 1907/2006/EC

This grade complies with RoHS directive 2002/95/EC

Unless specified, this grade is not suitable for food contact, medical devices or toy applications

Customer services

Our customer services are not only concerned with manufacturing and supply of Engineering

Plastics products. We are available to assist our customers in finding technical solutions that meet

their requirements. Specific support is in particular offered on:

- Material selection

- Material testing

- Parts design advice, training for design engineers

- Part testing

- Processing through different technologies

- Assembly and post-processing technology expertise

- Parts optimization through Computer Aided Design

You can find more information on Rhodia Product range on our internet product finder at the

following address:

http://www.rhodia.com/en/markets_and_products/product_finder

More info : www.rhodia.com Tel: 00 800 55 400 600

Contact : engineeringplastics-business@eu.rhodia.com

TECHNYLSTAR S 218 V30 BLACK 31N

Product Data Sheet

23.11.2011

Stress-strain

Potrebbero piacerti anche

- Rhodia - Tds - Technyl A 218 v30 Black 21ns - enDocumento5 pagineRhodia - Tds - Technyl A 218 v30 Black 21ns - enrquaibiNessuna valutazione finora

- Rhodia Tds Technyl C 548b v15 enDocumento2 pagineRhodia Tds Technyl C 548b v15 enDejan PekićNessuna valutazione finora

- Rhodia - Tds - Technyl A 718 v30 Black 61 - enDocumento3 pagineRhodia - Tds - Technyl A 718 v30 Black 61 - enFred SoaresNessuna valutazione finora

- Gehotex w8 enDocumento2 pagineGehotex w8 engoing22Nessuna valutazione finora

- WPC120 PDFDocumento2 pagineWPC120 PDFHamzaHashimNessuna valutazione finora

- Ultrasynt Atox 32 10785 Fds SP Es 6.0Documento2 pagineUltrasynt Atox 32 10785 Fds SP Es 6.0Iker BasqueadventureNessuna valutazione finora

- Grilamid Tr90 TdsDocumento2 pagineGrilamid Tr90 Tdsrumisethna9135Nessuna valutazione finora

- Mechanical Seals in AgitatorsDocumento6 pagineMechanical Seals in AgitatorsLy Ca TieuNessuna valutazione finora

- 4011 TDDocumento2 pagine4011 TDFernando HalaburaNessuna valutazione finora

- 1121 1122 1122BC 1123 ATEX VersionDocumento1 pagina1121 1122 1122BC 1123 ATEX VersionNazrul IslamNessuna valutazione finora

- Brand+Ultradur Range+Chart Ultradur+PBT EnglishDocumento20 pagineBrand+Ultradur Range+Chart Ultradur+PBT EnglishLuciano Augusto Gerling GarzaNessuna valutazione finora

- 3NA7832 Datasheet enDocumento6 pagine3NA7832 Datasheet enMARIAMNessuna valutazione finora

- Esd Jotun PaintDocumento3 pagineEsd Jotun PaintMohd Ridzuan Abdul AzizNessuna valutazione finora

- APD Cat 26Documento34 pagineAPD Cat 26MAC DIAGNessuna valutazione finora

- Lldpe Ga564189Documento3 pagineLldpe Ga564189xy2zjgNessuna valutazione finora

- Sika Plan - 12GDocumento3 pagineSika Plan - 12Gthe pilotNessuna valutazione finora

- Carta FuturaDocumento3 pagineCarta FuturaCarlosSánchezNessuna valutazione finora

- DS Flex Rev7 0309 PDFDocumento2 pagineDS Flex Rev7 0309 PDFDavid GonzaloNessuna valutazione finora

- Steel Master 1200 WF PDSDocumento5 pagineSteel Master 1200 WF PDSshameelNessuna valutazione finora

- Skolan Safe - Submittal 2023-3Documento38 pagineSkolan Safe - Submittal 2023-3AdarshNessuna valutazione finora

- Bayblend Fr3008 HR IsoDocumento3 pagineBayblend Fr3008 HR IsoBijesh VenugopalNessuna valutazione finora

- Sou Ficha Técnica Soudaseal 235SFDocumento2 pagineSou Ficha Técnica Soudaseal 235SFCarlos ChoqueNessuna valutazione finora

- Sikafloor - 264 EngDocumento5 pagineSikafloor - 264 Engbassem kooliNessuna valutazione finora

- Flowshield SL: Standard Colour ChartDocumento2 pagineFlowshield SL: Standard Colour ChartManjunath HrmNessuna valutazione finora

- 2628Documento3 pagine2628renebbNessuna valutazione finora

- Harmony Xap Xapa1120Documento2 pagineHarmony Xap Xapa1120Ginette BelangerNessuna valutazione finora

- Polyken 2000 High TempDocumento2 paginePolyken 2000 High TempKyaw Kyaw AungNessuna valutazione finora

- C C14 LD2420F PlusDocumento3 pagineC C14 LD2420F PlusJaime222Nessuna valutazione finora

- Optitemp HT 2 EP: DescriptionDocumento2 pagineOptitemp HT 2 EP: DescriptionWirawan Adi Setya RNessuna valutazione finora

- Date Sheet For PaintingDocumento5 pagineDate Sheet For PaintingAws MohamedNessuna valutazione finora

- Lacqare Technical DataDocumento3 pagineLacqare Technical DataMahmoud MassadNessuna valutazione finora

- (ENG) Product Catalogue: Push-Fit Polypropylene Wastewater SystemDocumento20 pagine(ENG) Product Catalogue: Push-Fit Polypropylene Wastewater SystemyaseraleweNessuna valutazione finora

- Me6052 PDS Reg - World en V4 PDS World 4158 10058878Documento3 pagineMe6052 PDS Reg - World en V4 PDS World 4158 10058878TANMAY NAYAKNessuna valutazione finora

- Dymax GA-142 UV Curable Gasket Data SheetDocumento3 pagineDymax GA-142 UV Curable Gasket Data SheetJoshua WallesNessuna valutazione finora

- Betaforce ™ 2850S: Technical DatasheetDocumento3 pagineBetaforce ™ 2850S: Technical Datasheetenrico_andreoli88Nessuna valutazione finora

- Datasheet - M22-DL-G: Part No. Article No. Catalog NoDocumento6 pagineDatasheet - M22-DL-G: Part No. Article No. Catalog NoMarcelo HernandezNessuna valutazione finora

- Tds - Jotun - Guard Classic EtDocumento3 pagineTds - Jotun - Guard Classic Etvijh van niemannNessuna valutazione finora

- ASATT07Documento3 pagineASATT07José Joaquín Muñoz videsNessuna valutazione finora

- Ultradur: Product InformationDocumento3 pagineUltradur: Product InformationirisNessuna valutazione finora

- SigmaCover 280Documento5 pagineSigmaCover 280ajuhaseenNessuna valutazione finora

- V22 300Documento2 pagineV22 300Ariani AmaliaNessuna valutazione finora

- HTLP Heat Shrinkable SleeveDocumento2 pagineHTLP Heat Shrinkable SleeveGanesh EshwarNessuna valutazione finora

- 3NA3812 Datasheet enDocumento4 pagine3NA3812 Datasheet enAnonymous OjDeGlsq5Nessuna valutazione finora

- DIN 7060 Curcular Sight Glass PDFDocumento14 pagineDIN 7060 Curcular Sight Glass PDFalathekoala100% (2)

- 22 Ohm ResistorDocumento11 pagine22 Ohm ResistorDwp BhaskaranNessuna valutazione finora

- Gore PTV Screwinvents r9 eDocumento4 pagineGore PTV Screwinvents r9 eKhổng MạnhNessuna valutazione finora

- Cell PackDocumento4 pagineCell PackKuchaiNessuna valutazione finora

- Epoxy Data SheetDocumento3 pagineEpoxy Data SheetShahroze IlyasNessuna valutazione finora

- RFID Glass Tag FamilyDocumento4 pagineRFID Glass Tag FamilyAbleIDLtdNessuna valutazione finora

- Toyolac ABS CatalogueDocumento15 pagineToyolac ABS Catalogueksharidas0% (1)

- TDS 10410005 en en Weicon-St PDFDocumento1 paginaTDS 10410005 en en Weicon-St PDFKJ SupplyNessuna valutazione finora

- 1N5231B Zener DiodeDocumento3 pagine1N5231B Zener DiodeCzar LimNessuna valutazione finora

- Model 120 Model 120: Tedea-HuntleighDocumento3 pagineModel 120 Model 120: Tedea-HuntleighEong Huat Corporation Sdn BhdNessuna valutazione finora

- Steelmaster 1200WF: Technical Data SheetDocumento4 pagineSteelmaster 1200WF: Technical Data SheetHarmandeep BhattiNessuna valutazione finora

- E 9114 - Sika Unitherm 7854Documento3 pagineE 9114 - Sika Unitherm 7854didapopescuNessuna valutazione finora

- Lanxess Durethan BC 40 Sr2 000000 Iso enDocumento3 pagineLanxess Durethan BC 40 Sr2 000000 Iso enDimaVaynNessuna valutazione finora

- Hawo Hd680de Dev Deiv - enDocumento4 pagineHawo Hd680de Dev Deiv - enSertgio Zapata EspinosaNessuna valutazione finora

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionDa EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionValutazione: 4.5 su 5 stelle4.5/5 (3)

- Bottles, Preforms and Closures: A Design Guide for PET PackagingDa EverandBottles, Preforms and Closures: A Design Guide for PET PackagingValutazione: 4.5 su 5 stelle4.5/5 (3)

- Compd Data Sheet 1040G ISO Ver 150106Documento1 paginaCompd Data Sheet 1040G ISO Ver 150106nimonhNessuna valutazione finora

- Type Test Method Unit: PhysicalDocumento1 paginaType Test Method Unit: PhysicalnimonhNessuna valutazione finora

- Compd Data Sheet 5060G ISO Ver 150106Documento1 paginaCompd Data Sheet 5060G ISO Ver 150106nimonhNessuna valutazione finora

- Ecotran PPT (English)Documento15 pagineEcotran PPT (English)nimonhNessuna valutazione finora

- Compd Data Sheet 1040G ASTM Ver 150106Documento1 paginaCompd Data Sheet 1040G ASTM Ver 150106nimonhNessuna valutazione finora

- Compd Data Sheet 5060G ASTM Ver 150106Documento1 paginaCompd Data Sheet 5060G ASTM Ver 150106nimonhNessuna valutazione finora

- PV701 Polyram ISODocumento1 paginaPV701 Polyram ISOnimonhNessuna valutazione finora

- Zytel 80G33HS1L BK104Documento3 pagineZytel 80G33HS1L BK104nimonhNessuna valutazione finora

- k224 hgr24Documento1 paginak224 hgr24nimonhNessuna valutazione finora

- TRVX50X9Documento2 pagineTRVX50X9nimonhNessuna valutazione finora

- EMS Long Fibre Reinforced PolyamidesDocumento44 pagineEMS Long Fibre Reinforced PolyamidesnimonhNessuna valutazione finora

- Week One To Five 11Documento105 pagineWeek One To Five 11Sathish KumarNessuna valutazione finora

- T50 800 01Documento5 pagineT50 800 01nimonhNessuna valutazione finora

- P1700 NTDocumento2 pagineP1700 NTnimonhNessuna valutazione finora

- DOE Optim2012Documento41 pagineDOE Optim2012nimonhNessuna valutazione finora

- Hdpe H355jaDocumento2 pagineHdpe H355janimonh100% (1)

- AW191 (Cosmoplene PP)Documento1 paginaAW191 (Cosmoplene PP)nimonhNessuna valutazione finora

- Eastman Polymers - Processing and Mold Design GuidelinesDocumento44 pagineEastman Polymers - Processing and Mold Design GuidelinesnimonhNessuna valutazione finora

- Injection Molding GuideDocumento33 pagineInjection Molding Guidethangkhungpro0% (1)

- Pj701 Pj702-Polyram Iso (Abs-Asa)Documento1 paginaPj701 Pj702-Polyram Iso (Abs-Asa)nimonhNessuna valutazione finora

- Engenharia PolimerosDocumento263 pagineEngenharia PolimerosmarcioufcgNessuna valutazione finora

- PolymersDocumento80 paginePolymersnimonhNessuna valutazione finora

- Mech3100 L 1 2007Documento24 pagineMech3100 L 1 2007nimonhNessuna valutazione finora

- Design With Plastics. Focus - Injection MoldingDocumento72 pagineDesign With Plastics. Focus - Injection MoldingPrithviraj Daga100% (6)

- Assigment Sheet Tast 2 Aina MardianaDocumento10 pagineAssigment Sheet Tast 2 Aina MardianaAina MardianaNessuna valutazione finora

- Three Way Conference Template 2019Documento4 pagineThree Way Conference Template 2019api-313701922Nessuna valutazione finora

- How To Implement A Distributed CommonJ Work Manager ESDocumento20 pagineHow To Implement A Distributed CommonJ Work Manager ESAbmel Salim LopessierNessuna valutazione finora

- 17.alekhya Research ArticleDocumento8 pagine17.alekhya Research ArticleBaru Chandrasekhar RaoNessuna valutazione finora

- Jimma Institute of Technology Faculty of Mechanical EngineeringDocumento38 pagineJimma Institute of Technology Faculty of Mechanical EngineeringIsmail Ibn BehailuNessuna valutazione finora

- Dawood University of Engineering & Technology Karachi Department of Basic Sciences & HumanitiesDocumento4 pagineDawood University of Engineering & Technology Karachi Department of Basic Sciences & HumanitiessamadNessuna valutazione finora

- Quality Control Tests For Emulsions, Syrups, Tinctures, Elixirs, Ointments and OthersDocumento11 pagineQuality Control Tests For Emulsions, Syrups, Tinctures, Elixirs, Ointments and OthersMuhammad Masoom Akhtar100% (2)

- Comba ODV-065R15E18J-GDocumento1 paginaComba ODV-065R15E18J-GGaga ChubinidzeNessuna valutazione finora

- DistilationDocumento29 pagineDistilationkindenewNessuna valutazione finora

- For Bookbind Final April 2019 PDFDocumento151 pagineFor Bookbind Final April 2019 PDFNeo VeloriaNessuna valutazione finora

- 5000 KW Gearbox High Pinion Bearing Temperatures 1644227029Documento7 pagine5000 KW Gearbox High Pinion Bearing Temperatures 1644227029MC ANessuna valutazione finora

- Calculations of The EFG Tensor in DTN Using GIPAW With CASTEP and QE SoftwareDocumento12 pagineCalculations of The EFG Tensor in DTN Using GIPAW With CASTEP and QE SoftwareAllen MNessuna valutazione finora

- Training - Manual - Diagnostic - and - Troublesh CPC 202GDocumento186 pagineTraining - Manual - Diagnostic - and - Troublesh CPC 202GGA AnnerNessuna valutazione finora

- Wos 2 Pajek 07Documento36 pagineWos 2 Pajek 07Omar SitoNessuna valutazione finora

- StepperDocumento7 pagineStepperahmad_syafrudin_1Nessuna valutazione finora

- Phenol: Carboxylation of Phenol: Kolb-Schmitt ReactionDocumento9 paginePhenol: Carboxylation of Phenol: Kolb-Schmitt ReactionAkhilaNessuna valutazione finora

- M2-Exam 2Documento13 pagineM2-Exam 2youngturtlevibesNessuna valutazione finora

- ReportDocumento1 paginaReportDrew DacanayNessuna valutazione finora

- Answer Key - CK-12 Chapter 01 Basic Geometry Concepts PDFDocumento16 pagineAnswer Key - CK-12 Chapter 01 Basic Geometry Concepts PDFValery Liz0% (1)

- How Torque Converters Work - HowStuffWorksDocumento7 pagineHow Torque Converters Work - HowStuffWorksKrishanu ModakNessuna valutazione finora

- Product Data Sheet: Control Unit Micrologic 5.0 A, For Masterpact NT/ NW, LSI ProtectionsDocumento3 pagineProduct Data Sheet: Control Unit Micrologic 5.0 A, For Masterpact NT/ NW, LSI ProtectionsEvandro PavesiNessuna valutazione finora

- MATHSDocumento221 pagineMATHSAbdulai FornahNessuna valutazione finora

- Sam W Hoke Torch PatentDocumento5 pagineSam W Hoke Torch PatentRichard.nlNessuna valutazione finora

- Test For CarbohydratesDocumento15 pagineTest For CarbohydratesKevin SangNessuna valutazione finora

- Heat and Thermodynamics According To KPK Textbook & Sindh TextbookDocumento15 pagineHeat and Thermodynamics According To KPK Textbook & Sindh Textbookswatmiandam44Nessuna valutazione finora

- Ic Assignment 2Documento1 paginaIc Assignment 2Nilven GastardoNessuna valutazione finora

- 3013 Thule Atlantis 780Documento2 pagine3013 Thule Atlantis 780Duarte MartinsNessuna valutazione finora

- Plcforum - Uz.ua: (LINK) : Eplan P8 2.0.5.4602 + CrackDocumento26 paginePlcforum - Uz.ua: (LINK) : Eplan P8 2.0.5.4602 + Crackphth411100% (1)

- Physics SS2 Term 2 Dec 2022Documento71 paginePhysics SS2 Term 2 Dec 2022TahmidNessuna valutazione finora

- User ManualDocumento91 pagineUser ManualJorge Luis SoriaNessuna valutazione finora