Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

IR HL Heatless Dryer

Caricato da

Ying Kei ChanCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

IR HL Heatless Dryer

Caricato da

Ying Kei ChanCopyright:

Formati disponibili

Prices Subject to Change Without Notice

656

(314) 427-0600 www.jhf.com (FAX) 314-427-3502

pneumatic and hydraulic equipment 800-444-0522

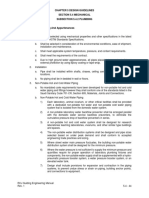

DESICCANT AIR DRYER

Operation

The heatless dryer works by passing

compressed air through a tower filled with

desiccant. Moisture from the airstream is

adsorbed onto the desiccant thereby produc-

ing extremely dry outlet air. While one tower

is on-line performing the drying function, the

second tower is off-line being regenerated by

a portion (approx. 15%) of the discharge dry

air flow.

This operation is controlled by valves (V1 &

V2) which divert the flow of air to the on-line

tower and away from the regenerating tower.

At the same time, a purge valve (V3 or V4) al-

lows the regenerating air flow entering the

off-line tower to escape and thereby purge

the moisture adsorbed from the desiccant to

the atmosphere. On a 40F dewpoint dryer,

this process lasts for four minutes and thirty

seconds, at which time repressurization of

the off-line (regenerating) tower begins to

prevent desiccant bed fluidization. The purge

valve (V3 or V4) will close so that the off-line

tower is allowed to repressurize.

After repressurization is complete, the flow

valves (V1 & V2) will divert the drying air flow

to the previously off-line tower.

Simultaneously, a purge valve (V3 or V4) will

open allowing the previously on-line dryer

tower to depressurize and begin

regeneration. This will last for four minutes

and thirty seconds at which point the process

will again be reversed. The total cycle time is

ten minutes.

-40F pressure dewpoint. Performance to CAGI Standard 200

ADF 200.

Basic twin tower heatless dryer with drying in one tower and

regeneration in the other.

Low profile design places key maintenance points at operator

level for faster servicing.

Upflow drying for long desiccant life.

ASME coded pressure vessels with pressure relief valves

Activated alumina desiccant filled in towers from factory

(approx. 35 year life).

Desiccant fill and drain ports for easy maintenance

Tower cycle operation switched via electronic controller which

also monitors dryer operations and is MODBUS capable for

network connection.

150 PSIG maximum working pressure

Purge air exhausted through exhaust mufflers to reduce noise

levels.

Vessel pressure gauges installed on each tower.

Mounted on floor stand.

Dryer on/off switch and power on light.

115/160 NEMA 1 Electrics

High efficiency pre-filter and particulate afterfilter included and

mounted (except 15001800 cfm models shipped loose).

Optional EMS Energy Management System moisture load

control energy saver matches purge air rate to actual moisture

load during reduced or fluctuating air demand periods.

-100F pressure dewpoint option

Capacity ratings are based on 100 psig inlet air pressure, 100F inlet air temperature, 100% relative

humidity, and 100F ambient air temperature.

SCFM Dimensions

@ 40F In / Out Width Depth Height Weight

Model Dewpoint Connect (in. ) (in. ) (in. ) (in. ) (lbs. )

HL120 120 1.0 NPT 40.5 30 63 563

HL160 160 1.5 NPT 44.5 33 66 707

HL200 200 1.5 NPT 44.5 33 66 731

HL250 250 1.5 NPT 48.5 33 67 869

HL300 300 2.0 NPT 48.5 34 67 924

HL400 400 2.0 NPT 52.5 36 68 1115

HL500 500 2.0 NPT 56.5 40 82 1564

HL600 600 2.0 NPT 56.5 40 82 1664

HL800 800 3.0 NPT 64 52 88 2017

HL1000 1000 3.0 NPT 64 52 88 2237

HL1200 1200 3.0 NPT 64 52 88 2424

HL1500 1500 4.0 FLG 78.5 55 81 2974

HL1800 1800 4.0 FLG 84 61 94 3905

Ingersoll-Rand HL Series Heatless Dual Tower Desiccant Air Dryer

BACK FORWARD

INDEX

BACK

FORWARD

H

O

M

E

Potrebbero piacerti anche

- Chemical Reactor Design, Optimization, and ScaleupDa EverandChemical Reactor Design, Optimization, and ScaleupNessuna valutazione finora

- High Pressure Phase Behaviour of Multicomponent Fluid MixturesDa EverandHigh Pressure Phase Behaviour of Multicomponent Fluid MixturesNessuna valutazione finora

- GoyalDocumento3 pagineGoyalVan LeNessuna valutazione finora

- Liquid Monopropellant CombustionDocumento4 pagineLiquid Monopropellant Combustionherdi sutanto adigunaNessuna valutazione finora

- Steam Tracing AppendixDocumento13 pagineSteam Tracing AppendixAmin BagheriNessuna valutazione finora

- Manual Flare Sim ExproDocumento69 pagineManual Flare Sim ExproJuan Pablo AlonsoNessuna valutazione finora

- 1a.calibration of OrificemeterDocumento7 pagine1a.calibration of OrificemeterArjun P PNessuna valutazione finora

- Float Board Level GaugeDocumento6 pagineFloat Board Level GaugeanaismariaNessuna valutazione finora

- CFD Modeling Analysis of A Vertical Gas Liquid SeparatorDocumento9 pagineCFD Modeling Analysis of A Vertical Gas Liquid SeparatorTanweer HussainNessuna valutazione finora

- 10 1016@j Jngse 2016 01 016Documento37 pagine10 1016@j Jngse 2016 01 016saiful bahriNessuna valutazione finora

- Compressed Air Dryer: Industrial Ammonia SystemsDocumento8 pagineCompressed Air Dryer: Industrial Ammonia Systemsfernando_tkm_65065Nessuna valutazione finora

- SP 1125Documento12 pagineSP 1125Venkat RanganNessuna valutazione finora

- E 106Documento1 paginaE 106Bith SMGNessuna valutazione finora

- Minimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunityDocumento7 pagineMinimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunitySHINessuna valutazione finora

- C:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchDocumento1 paginaC:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchFadhila Ahmad AnindriaNessuna valutazione finora

- Fire Relief Dynamic StudyDocumento2 pagineFire Relief Dynamic StudylguardiaNessuna valutazione finora

- UFC-85 Plants For Urea Fertilizer Projects: Recommended DosageDocumento8 pagineUFC-85 Plants For Urea Fertilizer Projects: Recommended Dosagevaratharajan g rNessuna valutazione finora

- Safety Valve Technical DetailsDocumento5 pagineSafety Valve Technical DetailsvineethvskkdNessuna valutazione finora

- Thermowell Calculation Guide V1.3Documento19 pagineThermowell Calculation Guide V1.3AymanelorbanyNessuna valutazione finora

- E07 QDocumento20 pagineE07 QSoledad Fernández SantosNessuna valutazione finora

- Compressor Calculations: Polytropic CalculationDocumento1 paginaCompressor Calculations: Polytropic CalculationChirag DarjiNessuna valutazione finora

- Smith Et al-1958-AIChE Journal PDFDocumento3 pagineSmith Et al-1958-AIChE Journal PDFAlastairNessuna valutazione finora

- Design Practices - SVsDocumento12 pagineDesign Practices - SVsagarwalashwin32Nessuna valutazione finora

- CRP Sampling Literature PDFDocumento8 pagineCRP Sampling Literature PDFgullenariNessuna valutazione finora

- CMPAPPP Separator Vessel and Filter Design GuideDocumento18 pagineCMPAPPP Separator Vessel and Filter Design GuideJWilson73Nessuna valutazione finora

- About Jockey PumpsDocumento4 pagineAbout Jockey PumpsChemical.AliNessuna valutazione finora

- Level Gauges Definition Types Measuring Range Ordering InformationDocumento3 pagineLevel Gauges Definition Types Measuring Range Ordering Informationkamala 123Nessuna valutazione finora

- Side Mounted HandwheelDocumento20 pagineSide Mounted HandwheelaaaNessuna valutazione finora

- Liquid Valve CV CalcDocumento4 pagineLiquid Valve CV Calcamit_kt1973Nessuna valutazione finora

- Summer Internship Project Report MAY - JUNE 2018: "Energy Balance of Distillation Column"Documento14 pagineSummer Internship Project Report MAY - JUNE 2018: "Energy Balance of Distillation Column"krishan palNessuna valutazione finora

- Desplazamiento Positivo PDFDocumento20 pagineDesplazamiento Positivo PDFMelina SbhNessuna valutazione finora

- Tube Rupture (Two Phase-Omega Method) PDFDocumento1 paginaTube Rupture (Two Phase-Omega Method) PDFAmin RoisNessuna valutazione finora

- Chien1995 PDFDocumento6 pagineChien1995 PDFFelipeMorenoNessuna valutazione finora

- Calculation of Pressure Loss: DetailsDocumento2 pagineCalculation of Pressure Loss: DetailsLigru_RazvanNessuna valutazione finora

- Emergency ShutingdownDocumento11 pagineEmergency ShutingdownOsama OmayerNessuna valutazione finora

- 25nb y StrainerDocumento1 pagina25nb y StrainerKailas NimbalkarNessuna valutazione finora

- MC-001-DS-M-002-120 DS For Condensate Separator Rev ADocumento4 pagineMC-001-DS-M-002-120 DS For Condensate Separator Rev AHeldiyan RamdhanNessuna valutazione finora

- Vapor Liquid Equilibrium of Water + Ethanol + GlycerolDocumento8 pagineVapor Liquid Equilibrium of Water + Ethanol + GlycerolcsandrasNessuna valutazione finora

- Long Weld Necks 300 PDFDocumento1 paginaLong Weld Necks 300 PDFPedro Montes MarinNessuna valutazione finora

- 16 PR Paper158175Documento5 pagine16 PR Paper158175Jomer J SimpsonNessuna valutazione finora

- Cast - Basket Strainers - 2nd EditionDocumento27 pagineCast - Basket Strainers - 2nd EditionmartinnovelNessuna valutazione finora

- Orifice Plate Sizing Calculation Using A New Labview TechniqueDocumento6 pagineOrifice Plate Sizing Calculation Using A New Labview TechniquesyamsulNessuna valutazione finora

- BS 470 Entry PVDocumento8 pagineBS 470 Entry PVbonnicoNessuna valutazione finora

- Condensate Line SizingDocumento23 pagineCondensate Line SizingNirnay Patil100% (2)

- InstruCalc Relief Device SizingDocumento1 paginaInstruCalc Relief Device SizinggeorgD2010Nessuna valutazione finora

- Acfm vs. SCFM vs. Icfm: Series of Technical White Papers From Squire-CogswellDocumento9 pagineAcfm vs. SCFM vs. Icfm: Series of Technical White Papers From Squire-Cogswellegsg50100% (1)

- DD Katalog PDFDocumento110 pagineDD Katalog PDFAnand GuptaNessuna valutazione finora

- Orifice Plate BrochureDocumento39 pagineOrifice Plate Brochureronzies100% (1)

- PRV 2 Size Quick Start GuideDocumento36 paginePRV 2 Size Quick Start GuideAlcides Llanque ChoqueNessuna valutazione finora

- Abu Orf M.M. Centrate Viscosity For Continuous Monitoring of Polymer Feed in Dew Ate Ring Applications 2003Documento8 pagineAbu Orf M.M. Centrate Viscosity For Continuous Monitoring of Polymer Feed in Dew Ate Ring Applications 2003fermortaraNessuna valutazione finora

- Danfoss SFVLDocumento8 pagineDanfoss SFVLTorres Ivan100% (1)

- X ViberDocumento4 pagineX ViberHenry CruzNessuna valutazione finora

- Steam Separator and Steam Trap Are Almost Same in FunctionDocumento7 pagineSteam Separator and Steam Trap Are Almost Same in FunctionTHEOPHILUS ATO FLETCHERNessuna valutazione finora

- 750-326 Blowdown Separator 11 2015Documento10 pagine750-326 Blowdown Separator 11 2015osamaNessuna valutazione finora

- Summary of ASME BPVC Section VIII Div 1 (Part 2) - Welding & NDTDocumento14 pagineSummary of ASME BPVC Section VIII Div 1 (Part 2) - Welding & NDTTin Aung KyiNessuna valutazione finora

- Chen 3009 - Tutorial 2-2021 RevisedDocumento43 pagineChen 3009 - Tutorial 2-2021 RevisedRosario QFNessuna valutazione finora

- 7.2.24 - Breather ValvesDocumento28 pagine7.2.24 - Breather Valvessav33Nessuna valutazione finora

- CN5191 - L2 - A1-Centrifugal Pump Process Data SheetDocumento1 paginaCN5191 - L2 - A1-Centrifugal Pump Process Data SheetMochi CumilinaNessuna valutazione finora

- Actuador XRPDocumento16 pagineActuador XRPNicolas AndradeNessuna valutazione finora

- ABO Ball ValveDocumento6 pagineABO Ball ValveSunil BajpaiNessuna valutazione finora

- 1 Rath Filtration Presentation For Hungarian Silicate Industrial Society 20190507Documento19 pagine1 Rath Filtration Presentation For Hungarian Silicate Industrial Society 20190507Ying Kei ChanNessuna valutazione finora

- Short Test of Strength For Production WasteDocumento12 pagineShort Test of Strength For Production WasteYing Kei ChanNessuna valutazione finora

- 2017 Glass BrochureDocumento6 pagine2017 Glass BrochureYing Kei ChanNessuna valutazione finora

- 3M Liqui-Cel Membrane Contactors Beverage Brochure UK Ire 2018Documento8 pagine3M Liqui-Cel Membrane Contactors Beverage Brochure UK Ire 2018Ying Kei ChanNessuna valutazione finora

- Rpbid: Serial SolutionDocumento5 pagineRpbid: Serial SolutionYing Kei ChanNessuna valutazione finora

- EGE Inductive SensorsDocumento72 pagineEGE Inductive SensorsYing Kei ChanNessuna valutazione finora

- Operation Manual: Mist CollectorDocumento40 pagineOperation Manual: Mist CollectorYing Kei ChanNessuna valutazione finora

- EGE Pressure SensorsDocumento8 pagineEGE Pressure SensorsYing Kei ChanNessuna valutazione finora

- EGE Infrared DetectorsDocumento12 pagineEGE Infrared DetectorsYing Kei ChanNessuna valutazione finora

- 3M High Flow Filter System Brochure 2019Documento12 pagine3M High Flow Filter System Brochure 2019Ying Kei ChanNessuna valutazione finora

- EGE Metal DetectorsDocumento8 pagineEGE Metal DetectorsYing Kei ChanNessuna valutazione finora

- EGE Level SensorsDocumento40 pagineEGE Level SensorsYing Kei ChanNessuna valutazione finora

- American Ultraviolet Packaged Equipment Kit (PEK) SeriesDocumento2 pagineAmerican Ultraviolet Packaged Equipment Kit (PEK) SeriesYing Kei ChanNessuna valutazione finora

- Pentair Mecair Threaded Pulse Jet ValvesDocumento5 paginePentair Mecair Threaded Pulse Jet ValvesYing Kei ChanNessuna valutazione finora

- M12 Connector: Cable Plug Housing Pin-AssignmentDocumento10 pagineM12 Connector: Cable Plug Housing Pin-AssignmentYing Kei ChanNessuna valutazione finora

- EGE Opto SensorsDocumento16 pagineEGE Opto SensorsYing Kei ChanNessuna valutazione finora

- Solar Cells: By: Omar Ahmed Syed To: Assıst .Prof. Dr. Ayşe DuldaDocumento40 pagineSolar Cells: By: Omar Ahmed Syed To: Assıst .Prof. Dr. Ayşe DuldaYing Kei ChanNessuna valutazione finora

- Paper Joggers CatalogDocumento20 paginePaper Joggers CatalogYing Kei ChanNessuna valutazione finora

- PMA Material Separators: Type: Cardboard/Paper (PMA/-U) Foil (PMA-F)Documento8 paginePMA Material Separators: Type: Cardboard/Paper (PMA/-U) Foil (PMA-F)Ying Kei ChanNessuna valutazione finora

- Protect Public Spaces From Pathogens With UV Solutions From American UltravioletDocumento6 pagineProtect Public Spaces From Pathogens With UV Solutions From American UltravioletYing Kei ChanNessuna valutazione finora

- CAMFILL HEPA Ispe ArticleDocumento12 pagineCAMFILL HEPA Ispe ArticleYing Kei ChanNessuna valutazione finora

- ASCO Fluid Control-ChapH-2 - 2-Dust Collector Valves-CAT-gbDocumento6 pagineASCO Fluid Control-ChapH-2 - 2-Dust Collector Valves-CAT-gbYing Kei ChanNessuna valutazione finora

- Flameless Vent - FLEX ProDocumento2 pagineFlameless Vent - FLEX ProYing Kei ChanNessuna valutazione finora

- Explosion Proof "Mini" Drum KitDocumento2 pagineExplosion Proof "Mini" Drum KitYing Kei ChanNessuna valutazione finora

- Isolation Valve RSK: A Passive Device For Isolating Dust Explosions. Certification According To 94/9/ECDocumento3 pagineIsolation Valve RSK: A Passive Device For Isolating Dust Explosions. Certification According To 94/9/ECYing Kei ChanNessuna valutazione finora

- XP Drum Kit: Installation, Operation, and Maintenance Manual Patent Pending - Utility 35 Usc 111 (A)Documento16 pagineXP Drum Kit: Installation, Operation, and Maintenance Manual Patent Pending - Utility 35 Usc 111 (A)Ying Kei ChanNessuna valutazione finora

- Nicks Four Roses Family Restaurant - PrintInspectionDocumento3 pagineNicks Four Roses Family Restaurant - PrintInspectionLiz ShepardNessuna valutazione finora

- Innovations in Fire Fighting EquipmentDocumento6 pagineInnovations in Fire Fighting EquipmentIklil AjaoNessuna valutazione finora

- Chanel ConnectivityDocumento15 pagineChanel ConnectivityAlfian AminNessuna valutazione finora

- Answer Key Reading Qs P 60-65Documento2 pagineAnswer Key Reading Qs P 60-65Boundless MindNessuna valutazione finora

- The Soul BrochureDocumento24 pagineThe Soul Brochureavinandan sahaNessuna valutazione finora

- Lumina 17 A2 User GBDocumento69 pagineLumina 17 A2 User GBAndrewNessuna valutazione finora

- Power Production Based On Osmotic Pressure.: Øystein S. Skråmestø, Stein Erik Skilhagen, Werner Kofod NielsenDocumento10 paginePower Production Based On Osmotic Pressure.: Øystein S. Skråmestø, Stein Erik Skilhagen, Werner Kofod NielsenShrishti ChaurasiaNessuna valutazione finora

- Onion Drying Using Catalytic Infrared Dryer PDFDocumento45 pagineOnion Drying Using Catalytic Infrared Dryer PDFSteve DennisNessuna valutazione finora

- Chapter 5 Design Guidelines Section 5.4 Mechanical Subsection 5.4.2 PlumbingDocumento4 pagineChapter 5 Design Guidelines Section 5.4 Mechanical Subsection 5.4.2 PlumbingkapsarcNessuna valutazione finora

- Reject Water Management Techniques: Navin Kumar, Vidushi Bharadwaj, Shikha Mitra, Debajyoti BoseDocumento10 pagineReject Water Management Techniques: Navin Kumar, Vidushi Bharadwaj, Shikha Mitra, Debajyoti BoseG NaveenNessuna valutazione finora

- Tank ManualDocumento399 pagineTank ManualFikret YenenNessuna valutazione finora

- Hydropower Slide 2Documento46 pagineHydropower Slide 2Shankar ShaudNessuna valutazione finora

- Catálogo de Flujometros Industriales Spirax SarcoDocumento152 pagineCatálogo de Flujometros Industriales Spirax SarcosaconaconacaNessuna valutazione finora

- Final Guidance On Producing A Flood Emergency Plan Nov 2011Documento22 pagineFinal Guidance On Producing A Flood Emergency Plan Nov 2011Dijana Vukovic-AleksicNessuna valutazione finora

- Dowclene Msds 1601Documento10 pagineDowclene Msds 1601Justformedia JustformediaNessuna valutazione finora

- CO2 Well ConstructionDocumento12 pagineCO2 Well ConstructionSakshi SinghNessuna valutazione finora

- Loss ProtDocumento109 pagineLoss ProtcrNessuna valutazione finora

- Fly Fishing in BosniaDocumento20 pagineFly Fishing in BosniampodrugNessuna valutazione finora

- 3 3 2 A Plumbing Optional 1Documento2 pagine3 3 2 A Plumbing Optional 1api-300375532100% (1)

- Narrative Report World Toilet DayDocumento2 pagineNarrative Report World Toilet DayBithao Daisy84% (19)

- Roman Baths OriginDocumento25 pagineRoman Baths OriginNitescu DorinNessuna valutazione finora

- Abhishek Roy SSPDocumento65 pagineAbhishek Roy SSPNavneet Kumar SinghNessuna valutazione finora

- APA Technical Note - Condensation Causes and ControlDocumento4 pagineAPA Technical Note - Condensation Causes and ControlLJD211Nessuna valutazione finora

- Umpp Greener Future121015 PDFDocumento68 pagineUmpp Greener Future121015 PDFMohan KrishnaNessuna valutazione finora

- ElepahatShield BrocureDocumento11 pagineElepahatShield BrocureBinoy KaladiNessuna valutazione finora

- Iqra's Vocabulary Register: Word Dictionary Meaning Synonyms Antonyms Sample SentenceDocumento4 pagineIqra's Vocabulary Register: Word Dictionary Meaning Synonyms Antonyms Sample SentenceiqraNessuna valutazione finora

- Gas ProcessingDocumento31 pagineGas ProcessingAkbar Yudhanto100% (2)

- Safety Data Sheet FuseDocumento7 pagineSafety Data Sheet Fuse. .Nessuna valutazione finora

- Council Order 11-17Documento3 pagineCouncil Order 11-17Anthony WarrenNessuna valutazione finora

- 1993 Utah Native Plant Society Annual CompliationsDocumento63 pagine1993 Utah Native Plant Society Annual CompliationsFriends of Utah Native Plant SocietyNessuna valutazione finora