Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Prae J 1435 F Output

Caricato da

mano_gce0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

21 visualizzazioni14 pagineTitolo originale

Prae j 1435 f Output

Copyright

© © All Rights Reserved

Formati disponibili

XLS, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLS, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

21 visualizzazioni14 paginePrae J 1435 F Output

Caricato da

mano_gceCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato XLS, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 14

Description Value Unit

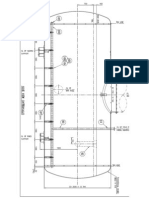

Component Name DIFFUSER PIPE -

Location HHP STEAM VENT SILENCER -

TAG PRAE-J-1435-F -

Design Pressure 10.689 MPa

Design Temperature 540

o

C

550 NPS x 95 THK. -

559 x 95 OD x Nominal thickness

Material SA387 Gr.22 CL.2 -

Ligament efficiency 51 %

Corrosion allowance 2 mm

Mill tolerance 0 %

Allowable stress 52.66 MPa

Available thickness 93.00 mm

Condition 1 PASS -

Condition 2 FAILED APPENDIX 1, 1-2 APPLICABLE

Condition 3 PASS -

Required thickness based on circumferential stress 91.77 mm

Required thickness based on longitudinal stress 43.11 mm

Conclusion

DIFFUSER PIPE CALCULATION

According to ASME Section VIII Division I Edition 2010 Addenda 2011a -UG 27

Size

SAFE

Description Value Unit

Component Name PIPE CAP -

Location HHP STEAM VENT SILENCER -

TAG PRAE-J-1435-F -

Design Pressure 10.689 MPa

Design Temperature 540

o

C

550 NPS x 60 THK. Formed - 2:1 SEMI ELLIPSOIDAL

559 x 60 OD x Nominal thickness

Material SA387 Gr.22 CL.2 -

Joint efficiency 100 %

Corrosion allowance 2 mm

Mill tolerance 0 %

Thinning allowance 15 %

Allowable stress 52.66 MPa

Crown radius 395.10 mm

Knuckle radius 74.63 mm

Available thickness 49.00 mm

Condition PASS -

Required thickness 45.48 mm

Conclusion SAFE

PIPE CAP CALCULATION

According to ASME Section VIII Division I Edition 2010 Addenda 2011a -UG 32

Size

Description Value Unit

Component Name SILENCER SHELL -

Location HHP STEAM VENT SILENCER -

TAG PRAE-J-1435-F -

Design Pressure 0.147 MPa

Design Temperature 540

o

C

Size 3600 x 10 THK OD x Nominal thickness

Material SA387 Gr.22 CL.2 -

Joint efficiency 85 %

Corrosion allowance 2 mm

Mill tolerance 0 %

Allowable stress 52.66 MPa

Available thickness 8.00 mm

Condition 1 PASS -

Condition 2 PASS -

Condition 3 PASS -

Required thickness based on circumferential stress 5.89 mm

Required thickness based on longitudinal stress 2.94 mm

Conclusion

SILENCER SHELL CALCULATION

According to ASME Section VIII Division I Edition 2010 Addenda 2011a - UG 27

SAFE

Description Value Unit

Component Name SILENCER DISHED HEAD -

Location HHP STEAM VENT SILENCER -

TAG PRAE-J-1435-F -

Design Pressure 0.147 MPa

Design Temperature 540

o

C

Size 3600 x 12 THK OD x Nominal thickness

Material SA387 Gr.22 CL.2 -

Joint efficiency 100 %

Corrosion allowance 2 mm

Mill tolerance 0 %

Thinning allowance 15 %

Allowable stress 52.66 MPa

Crown radius 3218.40 mm

Knuckle radius 607.92 mm

Available thickness 8.20 mm

Condition PASS -

Required thickness 4.99 mm

Conclusion

Nozzle size 559 x 95 OD x Nominal thickness

Required thickness of nozzle 91.77 mm

Allowable stress of nozzle 52.66 MPa

Nozzle inside projection 500 mm

Pad plate provision YES -

Pad plate thickness 12 -

Pad plate width 200 -

Compensation area required 1842.26 mm

2

compensation area available 5820.34 mm

2

Conclusion SAFE

SILENCER DISHED HEAD CALCULATION

According to ASME Section VIII Division I Edition 2010 Addenda 2011a - UG 32 & UG 37

SAFE

Description Value Unit

Component Name CONNECTING PIPE -

Location HHP STEAM VENT SILENCER -

TAG PRAE-J-1435-F -

Design Pressure 10.689 MPa

Design Temperature 540

o

C

450 NPS x 53 THK. -

457 x 53 OD x Nominal thickness

Material SA387 Gr.22 CL.2 -

Joint efficiency 85 %

Corrosion allowance 2 mm

Mill tolerance 0 %

Allowable stress 52.66 MPa

Available thickness 51.00 mm

Condition 1 PASS -

Condition 2 PASS -

Condition 3 PASS -

Required thickness based on circumferential stress 48.92 mm

Required thickness based on longitudinal stress 20.00 mm

Conclusion

CONNECTING PIPE-I CALCULATION

SAFE

According to ASME Section VIII Division I Edition 2010 Addenda 2011a -UG 27

Size

FLANGE SA182 F22 MATERIAL 2500# IS REQUIRED.

Description Value Unit

Component Name CONNECTING PIPE -

Location HHP STEAM VENT SILENCER -

TAG PRAE-J-1435-F -

Design Pressure 10.689 MPa

Design Temperature 540

o

C

500 NPS x 60 THK. -

508 x 60 OD x Nominal thickness

Material SA387 Gr.22 CL.2 -

Joint efficiency 85 %

Corrosion allowance 2 mm

Mill tolerance 0 %

Allowable stress 52.66 MPa

Available thickness 58.00 mm

Condition 1 PASS -

Condition 2 PASS -

Condition 3 PASS -

Required thickness based on circumferential stress 54.08 mm

Required thickness based on longitudinal stress 22.11 mm

Conclusion

CONNECTING PIPE-II CALCULATION

According to ASME Section VIII Division I Edition 2010 Addenda 2011a -UG 27

Size

SAFE

Description Value Unit

Component Name DIFFUSER PIPE -

Location HHP STEAM VENT SILENCER -

TAG PRAE-J-1435-F -

Design Pressure 10.689 MPa

Design Temperature 540

o

C

550 NPS x 53 THK. -

559 x 53 OD x Nominal thickness

Material SA387 Gr.91 CL.2 -

Ligament efficiency 51 %

Corrosion allowance 2 mm

Mill tolerance 0 %

Allowable stress 111 MPa

Available thickness 51.00 mm

Condition 1 PASS -

Condition 2 PASS -

Condition 3 PASS -

Required thickness based on circumferential stress 48.23 mm

Required thickness based on longitudinal stress 20.61 mm

Conclusion

DIFFUSER PIPE CALCULATION

According to ASME Section VIII Division I Edition 2010 Addenda 2011a -UG 27

Size

SAFE

Description Value Unit

Component Name PIPE CAP -

Location HHP STEAM VENT SILENCER -

TAG PRAE-J-1435-F -

Design Pressure 10.689 MPa

Design Temperature 540

o

C

550 NPS x 32 THK. Formed - 2:1 SEMI ELLIPSOIDAL

559 x 32 OD x Nominal thickness

Material SA387 Gr.91 CL.2 -

Joint efficiency 100 %

Corrosion allowance 2 mm

Mill tolerance 0 %

Thinning allowance 15 %

Allowable stress 111 MPa

Crown radius 445.50 mm

Knuckle radius 84.15 mm

Available thickness 25.20 mm

Condition PASS -

Required thickness 24.07 mm

Conclusion

Size

SAFE

PIPE CAP CALCULATION

According to ASME Section VIII Division I Edition 2010 Addenda 2011a -UG 32

Description Value Unit

Component Name SILENCER SHELL -

Location HHP STEAM VENT SILENCER -

TAG PRAE-J-1435-F -

Design Pressure 0.147 MPa

Design Temperature 540

o

C

Size 3600 x 6 THK OD x Nominal thickness

Material SA387 Gr.91 CL.2 -

Joint efficiency 85 %

Corrosion allowance 2 mm

Mill tolerance 0 %

Allowable stress 111 MPa

Available thickness 4.00 mm

Condition 1 PASS -

Condition 2 PASS -

Condition 3 PASS -

Required thickness based on circumferential stress 2.80 mm

Required thickness based on longitudinal stress 1.40 mm

Conclusion

SILENCER SHELL CALCULATION

According to ASME Section VIII Division I Edition 2010 Addenda 2011a - UG 27

SAFE

Description Value Unit

Component Name SILENCER DISHED HEAD -

Location HHP STEAM VENT SILENCER -

TAG PRAE-J-1435-F -

Design Pressure 0.147 MPa

Design Temperature 540

o

C

Size 3600 x 10 THK OD x Nominal thickness

Material SA387 Gr.91 CL.2 -

Joint efficiency 100 %

Corrosion allowance 2 mm

Mill tolerance 0 %

Thinning allowance 15 %

Allowable stress 111 MPa

Crown radius 3222.00 mm

Knuckle radius 608.6 mm

Available thickness 6.50 mm

Condition PASS -

Required thickness 2.37 mm

Conclusion

Nozzle size 559 x 53 OD x Nominal thickness

Required thickness of nozzle 48.23 mm

Allowable stress of nozzle 111 MPa

Nozzle inside projection 500 mm

Pad plate provision YES -

Pad plate thickness 10 -

Pad plate width 200 -

Compensation area required 1074.00 mm

2

compensation area available 4185.67 mm

2

Conclusion

SILENCER DISHED HEAD CALCULATION

According to ASME Section VIII Division I Edition 2010 Addenda 2011a - UG 32 & UG 37

SAFE

SAFE

Description Value Unit

Component Name CONNECTING PIPE -

Location HHP STEAM VENT SILENCER -

TAG PRAE-J-1435-F -

Design Pressure 10.689 MPa

Design Temperature 540

o

C

450 NPS x 28 THK. -

457 x 28 OD x Nominal thickness

Material SA387 Gr.91 CL.2 -

Joint efficiency 85 %

Corrosion allowance 2 mm

Mill tolerance 0 %

Allowable stress 111 MPa

Available thickness 26.00 mm

Condition 1 PASS -

Condition 2 PASS -

Condition 3 PASS -

Required thickness based on circumferential stress 24.37 mm

Required thickness based on longitudinal stress 11.11 mm

Conclusion SAFE

CONNECTING PIPE-I CALCULATION

According to ASME Section VIII Division I Edition 2010 Addenda 2011a -UG 27

Size

FLANGE SA182 F91 MATERIAL 1500# IS REQUIRED.

Description Value Unit

Component Name CONNECTING PIPE -

Location HHP STEAM VENT SILENCER -

TAG PRAE-J-1435-F -

Design Pressure 10.689 MPa

Design Temperature 540

o

C

500 NPS x 30 THK. -

508 x 30 OD x Nominal thickness

Material SA387 Gr.91 CL.2 -

Joint efficiency 85 %

Corrosion allowance 2 mm

Mill tolerance 0 %

Allowable stress 111 MPa

Available thickness 28.00 mm

Condition 1 PASS -

Condition 2 PASS -

Condition 3 PASS -

Required thickness based on circumferential stress 27.23 mm

Required thickness based on longitudinal stress 12.41 mm

Conclusion

According to ASME Section VIII Division I Edition 2010 Addenda 2011a -UG 27

Size

SAFE

CONNECTING PIPE-II CALCULATION

Potrebbero piacerti anche

- Ga CurveDocumento3 pagineGa Curvemano_gceNessuna valutazione finora

- Cethar Vessels LTD.,: Wind Pressure Calculations (As Per Is - 875 1983)Documento2 pagineCethar Vessels LTD.,: Wind Pressure Calculations (As Per Is - 875 1983)mano_gceNessuna valutazione finora

- Chennai - KolkataDocumento2 pagineChennai - Kolkatamano_gceNessuna valutazione finora

- Lifting Lug Design CalculationDocumento8 pagineLifting Lug Design Calculationmano_gceNessuna valutazione finora

- Ansaldo Caldaie S.P.A.: Shell Thickness Calculation According To Indian Boiler Regulation 270Documento3 pagineAnsaldo Caldaie S.P.A.: Shell Thickness Calculation According To Indian Boiler Regulation 270mano_gceNessuna valutazione finora

- Diffuser Pipe CalculationDocumento15 pagineDiffuser Pipe Calculationmano_gceNessuna valutazione finora

- Prae J 1435 F Output Rev00Documento12 paginePrae J 1435 F Output Rev00mano_gceNessuna valutazione finora

- Droit Consulting Engineers: 1. Address SealDocumento2 pagineDroit Consulting Engineers: 1. Address Sealmano_gceNessuna valutazione finora

- Suresh V PalisettiDocumento1 paginaSuresh V Palisettimano_gceNessuna valutazione finora

- Storage Tank With Steam Sparger PipeDocumento1 paginaStorage Tank With Steam Sparger Pipemano_gceNessuna valutazione finora

- AS4041 ASME B31 - 3 Pipe Wall ThicknessDocumento8 pagineAS4041 ASME B31 - 3 Pipe Wall Thicknesscutefrenzy100% (1)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Faculty of Engineering and Technology Semester End Examination Question Paper - M. TechDocumento3 pagineFaculty of Engineering and Technology Semester End Examination Question Paper - M. TechBRIAN LOPEZNessuna valutazione finora

- PresentationDocumento25 paginePresentationShreya GhoshNessuna valutazione finora

- Microwave ExperimentDocumento18 pagineMicrowave ExperimentChris RaymondNessuna valutazione finora

- Retail Analysis With Walmart DataDocumento2 pagineRetail Analysis With Walmart DataSriram100% (9)

- 3102354-EN R015 VS Series Compatibility ListDocumento20 pagine3102354-EN R015 VS Series Compatibility ListFrancisco CanoNessuna valutazione finora

- Detector Balance Induccion.Documento11 pagineDetector Balance Induccion.Jesus OrtizNessuna valutazione finora

- Orange HRM ReportDocumento7 pagineOrange HRM ReportarunvinodhNessuna valutazione finora

- Engine Crankshaft Deflection MeasurementDocumento9 pagineEngine Crankshaft Deflection MeasurementVannex MensidorNessuna valutazione finora

- Bellus Minni Book GuideDocumento9 pagineBellus Minni Book GuideMikkjel ThonNessuna valutazione finora

- TSE S.R.O. Karpatské Námestie 10A 831 06 Bratislava SlovakiaDocumento2 pagineTSE S.R.O. Karpatské Námestie 10A 831 06 Bratislava SlovakiaIronko Pepe100% (1)

- An5200 Eogas AbatorDocumento3 pagineAn5200 Eogas AbatorDinhtrung TruongNessuna valutazione finora

- FTTX GPONDocumento25 pagineFTTX GPONAlirezaNessuna valutazione finora

- Brosur All New Innova MUVs 16393Documento7 pagineBrosur All New Innova MUVs 16393Roni SetyawanNessuna valutazione finora

- Lesson Plan 2 Like TermsDocumento8 pagineLesson Plan 2 Like Termsapi-245950665Nessuna valutazione finora

- Panel Simplex 2008Documento86 paginePanel Simplex 2008JhonyLazoNessuna valutazione finora

- RG Cabble Losses ChartDocumento7 pagineRG Cabble Losses Chartsyr_rif11Nessuna valutazione finora

- PS1800 Centrifugal Pumping Systems: General Data and Sizing TablesDocumento12 paginePS1800 Centrifugal Pumping Systems: General Data and Sizing TablesSINES FranceNessuna valutazione finora

- User Manual Asset AccountingDocumento47 pagineUser Manual Asset AccountinginasapNessuna valutazione finora

- Domyancic State OfficialDocumento1 paginaDomyancic State Officialapi-300790110Nessuna valutazione finora

- Introduction To ERPDocumento3 pagineIntroduction To ERPmaheshNessuna valutazione finora

- Template - OQ - 0001 - 01 - Operational Qualification TemplateDocumento9 pagineTemplate - OQ - 0001 - 01 - Operational Qualification TemplateSoon Kooi0% (1)

- 1 Historical AntecedentsDocumento12 pagine1 Historical AntecedentshithereNessuna valutazione finora

- Manufacturing of Milk PowderDocumento4 pagineManufacturing of Milk PowderShikha SinghNessuna valutazione finora

- DUROFLEX2020 LimpiadorDocumento8 pagineDUROFLEX2020 LimpiadorSolid works ArgentinaNessuna valutazione finora

- Lesson Plan 4 Multiplication As Repeated Addition - Clinical 429Documento6 pagineLesson Plan 4 Multiplication As Repeated Addition - Clinical 429api-176688637100% (1)

- Clel083e138 MVSWG Exe WDG 601Documento40 pagineClel083e138 MVSWG Exe WDG 601arielaparicioNessuna valutazione finora

- Data Modelling Using ERD With Crow Foot NotationDocumento15 pagineData Modelling Using ERD With Crow Foot NotationDonald HeathNessuna valutazione finora

- 132KV Transfer Buscoupler...............Documento13 pagine132KV Transfer Buscoupler...............apsNessuna valutazione finora

- References PDFDocumento7 pagineReferences PDFresigjeflinNessuna valutazione finora

- Science PracticeDocumento7 pagineScience PracticeAndi CentenoNessuna valutazione finora