Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Microsoft PowerPoint - LECTURE7 PDF

Caricato da

Saurabh ChoudhariTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Microsoft PowerPoint - LECTURE7 PDF

Caricato da

Saurabh ChoudhariCopyright:

Formati disponibili

1

MANUFACTURING

MANUFACTURING

PROCESSES

PROCESSES

- - AMEM 201 AMEM 201

Lecture 7 Lecture 7: : Machining Processes Machining Processes

DR. SOTIRIS L. OMIROU

Shaping Shaping Drilling Drilling Broaching Broaching

2 2

Shaping Shaping Shaping Shaping Shaping Shaping Shaping Shaping

Shaping uses a single Shaping uses a single- -point tool that is moved point tool that is moved

horizontally in a reciprocating motion along a slide. It horizontally in a reciprocating motion along a slide. It

is used to create a planar surface, usually to prepare is used to create a planar surface, usually to prepare

rectangular blocks that can later be used as rectangular blocks that can later be used as

workpieces workpieces for machining on a milling machine etc. for machining on a milling machine etc.

2

3 3

Shaping Shaping Shaping Shaping Shaping Shaping Shaping Shaping

4 4

Broaching is the process of removing metal with a Broaching is the process of removing metal with a

tool which has teeth arranged in a row. Each tool which has teeth arranged in a row. Each

tooth is successively higher than the previous tooth is successively higher than the previous

tooth and removes more material. tooth and removes more material.

Thus the first few sets of teeth remove most of Thus the first few sets of teeth remove most of

the material, while the last few provide a finishing the material, while the last few provide a finishing

cut with very small amount of material removal. cut with very small amount of material removal.

The geometric shape of the last set of teeth is The geometric shape of the last set of teeth is

identical to the required geometry of the designed identical to the required geometry of the designed

part. part.

In broaching, one stroke or cycle of the machine In broaching, one stroke or cycle of the machine

produces a finished part. Broaching is used to produces a finished part. Broaching is used to

produce both internal and external features. produce both internal and external features.

Production rates are high and tolerances of Production rates are high and tolerances of

+/ +/- - 0.01 mm are possible. 0.01 mm are possible.

Broaching Broaching Broaching Broaching Broaching Broaching Broaching Broaching

3

5 5

Broaching Broaching Broaching Broaching Broaching Broaching Broaching Broaching Tools Tools Tools Tools Tools Tools Tools Tools

6 6

Broaching Broaching Broaching Broaching Broaching Broaching Broaching Broaching Tools Tools Tools Tools Tools Tools Tools Tools

Broaching cutter details Broaching cutter details

4

7 7

Design and construction considerations Design and construction considerations

Material to be broached Material to be broached

Size and shape of cut Size and shape of cut

Quality of surface finish Quality of surface finish

Part tolerance Part tolerance

Productions rates Productions rates

Type of machine Type of machine

Workholding Workholding method method

Strength of the Strength of the workpiece workpiece

Broaching Broaching Broaching Broaching Broaching Broaching Broaching Broaching Tools Tools Tools Tools Tools Tools Tools Tools

8 8

Tool Feed Direction

Gullet

Workpiece

Depth of

cut per tooth

Tool

Broaching Broaching Broaching Broaching Broaching Broaching Broaching Broaching mechanism mechanism mechanism mechanism mechanism mechanism mechanism mechanism

5

9 9

Broaching Broaching Broaching Broaching Broaching Broaching Broaching Broaching - -- - - -- - Advantages Advantages Advantages Advantages Advantages Advantages Advantages Advantages

Rough to finish in one pass Rough to finish in one pass

Cutting time is quick Cutting time is quick

Rapid load and unload of parts Rapid load and unload of parts

External and internal features External and internal features

Any form that can be produced on a Any form that can be produced on a

broaching tool can be produced broaching tool can be produced

Production tolerances are excellent Production tolerances are excellent

Surface finishes are equal to milling Surface finishes are equal to milling

Operator skill is low Operator skill is low

Production rates are highs Production rates are highs

10 10

Tooling cost can be high Tooling cost can be high

Broaching Broaching Broaching Broaching Broaching Broaching Broaching Broaching - -- - - -- - Disadvantages Disadvantages Disadvantages Disadvantages Disadvantages Disadvantages Disadvantages Disadvantages

In some cases In some cases-- --not suited for low not suited for low

production rates production rates

Parts to be broached must be strong Parts to be broached must be strong

enough to withstand the forces of the enough to withstand the forces of the

process process

Surface to be broached must be accessible Surface to be broached must be accessible

6

11 11

Pull broaching Pull broaching - - broach is pulled broach is pulled

through or across stationary work through or across stationary work

Push broaching Push broaching - - broach is pushed broach is pushed

through or across work through or across work

Surface broaching Surface broaching - - either the work or either the work or

the broach moves across the other the broach moves across the other

Broaching Broaching Broaching Broaching Broaching Broaching Broaching Broaching - -- - - -- - Methods of Operation Methods of Operation Methods of Operation Methods of Operation Methods of Operation Methods of Operation Methods of Operation Methods of Operation

12 12

Broaching Broaching Broaching Broaching Broaching Broaching Broaching Broaching Machines Machines Machines Machines Machines Machines Machines Machines

7

13 13

Complex hole shapes cut by broaching Complex hole shapes cut by broaching

Broaching Broaching Broaching Broaching Broaching Broaching Broaching Broaching products products products products products products products products

14 14

Drilling is one of the most common machining process.

A large amount of all metal-cutting material removed

comes from drilling operations.

Drilling is one of the most common machining process.

A large amount of all metal-cutting material removed

comes from drilling operations.

Drilling Drilling Drilling Drilling Drilling Drilling Drilling Drilling

By drilling are creating holes that are right circular

cylinders. This operation is accomplished most common

by using twisted drills (that is the tool).

By drilling are creating holes that are right circular

cylinders. This operation is accomplished most common

by using twisted drills (that is the tool).

In order to perform the drilling operation the tool has to

have o rotation motion, that is the cutting motion and

the tool or work part will achieve the feeding motion,

which is a translation one, on the same direction with

rotation axis.

In order to perform the drilling operation the tool has to

have o rotation motion, that is the cutting motion and

the tool or work part will achieve the feeding motion,

which is a translation one, on the same direction with

rotation axis.

8

15 15

Feeding

motion

Cutting

motion

Work

Part

Twisted

Drill

Drilling Drilling Drilling Drilling Drilling Drilling Drilling Drilling

16 16

Some features of drilling set it apart from other metal cutting

operations. Among these are:

Characteristics of Drilling Characteristics of Drilling Characteristics of Drilling Characteristics of Drilling Characteristics of Drilling Characteristics of Drilling Characteristics of Drilling Characteristics of Drilling

* The chips must exit out of the hole created by the

cutting tool, so the friction and as a consequence the

temperature is very high.

* The chip exit can cause problems when chips are large

and/or continuous.

* The drill can wander when the holes are deep

* For very deep holes the coolant may need to be

delivered through the drill shaft to the cutting front

area

9

17 17

Drilling, Drilling, Drilling, Drilling, Drilling, Drilling, Drilling, Drilling, Reaming, Boring, Tapping Reaming, Boring, Tapping Reaming, Boring, Tapping Reaming, Boring, Tapping Reaming, Boring, Tapping Reaming, Boring, Tapping Reaming, Boring, Tapping Reaming, Boring, Tapping

All four methods produce holes of different types.

Drilling produces round holes of different types.

Reaming is used to improve the dimensional

tolerance on a drilled hole.

Boring uses a special machine operating like a

lathe, to cut high precision holes.

Tapping creates screw-threads in drilled holes.

For drilling in brick, stone,

concrete, slate, plaster

and other masonry materials

For drilling cast iron

or non-ferrous material.

For drilling cast iron, plastic

or non-ferrous materials

These heavy duty drills feature

a regular helix and polished flutes

for rapid chip removal. Ideal for

drilling steel, cast iron, and non-

ferrous materials.

D DD D D DD Drilling rilling rilling rilling rilling rilling rilling rilling Tools Tools Tools Tools Tools Tools Tools Tools

10

Straight shank taper

length drills are standard for

general purpose work in drilling

relatively deep holes.

Shanks are of the same diameter

as the drill body

Especially suitable for deep hole

drilling in low tensile

strength materials,

such as aluminum magnesium

and zink alloys

D DD D D DD Drilling rilling rilling rilling rilling rilling rilling rilling Tools Tools Tools Tools Tools Tools Tools Tools

Counterbore drills have

multiple diameters. They make a

chamfered/stepped hole, which is

useful for inserting screws/bolts.

The larger diameter part of the hole

accommodates the screw/bolt head;

For countersinking, chamfering,

and deburring holes. Produces

a smoother finish.

D DD D D DD Drilling rilling rilling rilling rilling rilling rilling rilling Tools Tools Tools Tools Tools Tools Tools Tools

11

D DD D D DD Drilling rilling rilling rilling rilling rilling rilling rilling Tools Tools Tools Tools Tools Tools Tools Tools

Center-drills

It is common to machine a small hole in the material, called a center-hole, before utilizing

the drill. Center-holes are made by special drills called center-drills.

They also provide a good way for the drill bit to get aligned with the location of the hole

center.

22 22

Suitable for general purpose

through hole reaming

For accurate hand reaming of Morse

Taper holes in sockets, sleeves and

spindles

Is especially suited for use in stringy

materials or in through holes where a

slot or keyway is present.

D DD D D DD Drilling rilling rilling rilling rilling rilling rilling rilling Tools Tools Tools Tools Tools Tools Tools Tools

For general reaming in deep holes

requiring precision tolerances.

Reamers

12

Drilling

head

Vertical

Column

Machine table

Base

Vertical guides

Main

spindle

Twisted

drill

The work part that have to be machined

is clamped on the machine table and the

tool (twisted drill) is monted on the main

spindle. The main spindle, with tool, will

perform both the cutting (rotation) and

feeding (translation) motion.

The work part that have to be machined

is clamped on the machine table and the

tool (twisted drill) is monted on the main

spindle. The main spindle, with tool, will

perform both the cutting (rotation) and

feeding (translation) motion.

D DD D D DD Drilling rilling rilling rilling rilling rilling rilling rilling Machine Tools Machine Tools Machine Tools Machine Tools Machine Tools Machine Tools Machine Tools Machine Tools

Column

Radial beam

Radial guides

Work Part

Bed

Drilling head

Tool

Vertical motion

1

Rotation motion

2

Radial motion

3

1,2,3 Auxiliary motions for adjusting the

relative position between the work part and tool

The radial drilling machines are used for machining of large work parts.

Here, it is so difficult to adjust the relative position between the tool

and work part by moving a heavy part. For this reason there are three

auxiliary motions. The cutting and feeding motions are performed by

tool.

The radial drilling machines are used for machining of large work parts.

Here, it is so difficult to adjust the relative position between the tool

and work part by moving a heavy part. For this reason there are three

auxiliary motions. The cutting and feeding motions are performed by

tool.

D DD D D DD Drilling rilling rilling rilling rilling rilling rilling rilling Machine Tools Machine Tools Machine Tools Machine Tools Machine Tools Machine Tools Machine Tools Machine Tools

13

Drilling head

Portal frame

Z

Y

X

Machine

Table

Z Screw

Y Screw

X Screw

Bed

X Guides

Z Guides

Y Guides

D DD D D DD Drilling rilling rilling rilling rilling rilling rilling rilling Machine Tools Machine Tools Machine Tools Machine Tools Machine Tools Machine Tools Machine Tools Machine Tools

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- AP Human Geography Review Unit 2Documento18 pagineAP Human Geography Review Unit 2BaselOsman50% (2)

- Orona Fault CodesDocumento19 pagineOrona Fault CodesDanushka Bandara100% (1)

- 1 2 3 Model For Project SuccessDocumento5 pagine1 2 3 Model For Project SuccessSaurabh ChoudhariNessuna valutazione finora

- Information Brochure Admission To PH.D Full Time and Part Time Programs July 2023 2Documento22 pagineInformation Brochure Admission To PH.D Full Time and Part Time Programs July 2023 2Saurabh ChoudhariNessuna valutazione finora

- Anexas Lean Six Sigma MBB Certification CriteriaDocumento6 pagineAnexas Lean Six Sigma MBB Certification CriteriaSaurabh ChoudhariNessuna valutazione finora

- Toyota-Like Efficiencey To Back Office OperationsDocumento4 pagineToyota-Like Efficiencey To Back Office OperationsSaurabh ChoudhariNessuna valutazione finora

- Lean Quality Circle Problem Solving Methodology & Tools and TechniquesDocumento61 pagineLean Quality Circle Problem Solving Methodology & Tools and TechniquesSaurabh ChoudhariNessuna valutazione finora

- Qcfi Que Set 4 Theory & Questions by JudgesDocumento12 pagineQcfi Que Set 4 Theory & Questions by JudgesSaurabh Choudhari100% (1)

- L QC Case StudiesDocumento30 pagineL QC Case StudiesSaurabh Choudhari100% (1)

- ASTM Standards For Membrane FiltersDocumento2 pagineASTM Standards For Membrane FiltersSaurabh ChoudhariNessuna valutazione finora

- CV Saurabh RaghorteDocumento3 pagineCV Saurabh RaghorteSaurabh ChoudhariNessuna valutazione finora

- Quick Guide To Failure Mode and Effects Analysis: FMEA: The BasicsDocumento29 pagineQuick Guide To Failure Mode and Effects Analysis: FMEA: The BasicsSaurabh ChoudhariNessuna valutazione finora

- Farewell Speech Checklist If Someone Else Is LeavingDocumento2 pagineFarewell Speech Checklist If Someone Else Is LeavingSaurabh ChoudhariNessuna valutazione finora

- Name Designation Cost Code EMP Numbe R Description SG NoDocumento21 pagineName Designation Cost Code EMP Numbe R Description SG NoSaurabh ChoudhariNessuna valutazione finora

- A Competency-Based Educational Model in A Chemical Engineering SchoolDocumento18 pagineA Competency-Based Educational Model in A Chemical Engineering SchoolSaurabh ChoudhariNessuna valutazione finora

- Monthly Stipend Ma323ster FormDocumento1 paginaMonthly Stipend Ma323ster FormSaurabh ChoudhariNessuna valutazione finora

- O RDocumento5 pagineO RSaurabh Choudhari0% (2)

- A Pharmaceutical Company Has 100 KG of A, 180 KG of B and 120 KG of C Available PerDocumento3 pagineA Pharmaceutical Company Has 100 KG of A, 180 KG of B and 120 KG of C Available PerSaurabh Choudhari100% (1)

- E 128 - 99 - RteyoaDocumento3 pagineE 128 - 99 - RteyoaSaurabh ChoudhariNessuna valutazione finora

- Machining Processes Used To Produce Round Shapes: Turning and Hole MakingDocumento40 pagineMachining Processes Used To Produce Round Shapes: Turning and Hole MakingSaurabh ChoudhariNessuna valutazione finora

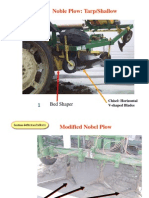

- Noble Plow: Tarp/Shallow: Bed ShaperDocumento18 pagineNoble Plow: Tarp/Shallow: Bed ShaperSaurabh ChoudhariNessuna valutazione finora

- SaurabhDocumento3 pagineSaurabhSaurabh ChoudhariNessuna valutazione finora

- Attacks On Cryptosystems PDFDocumento18 pagineAttacks On Cryptosystems PDFUjjayanta BhaumikNessuna valutazione finora

- Flooding Deagon Flood Flag MapDocumento1 paginaFlooding Deagon Flood Flag MapNgaire TaylorNessuna valutazione finora

- Shi Et Al-2019-Intensive Care MedicineDocumento11 pagineShi Et Al-2019-Intensive Care MedicineJavier BlancNessuna valutazione finora

- Correlation of Body Mass Index With Endometrial Histopathology in Abnormal Uterine BleedingDocumento101 pagineCorrelation of Body Mass Index With Endometrial Histopathology in Abnormal Uterine BleedingpritamNessuna valutazione finora

- Photography Techniques (Intermediate)Documento43 paginePhotography Techniques (Intermediate)Truc Nguyen100% (2)

- Facility Systems, Ground Support Systems, and Ground Support EquipmentDocumento97 pagineFacility Systems, Ground Support Systems, and Ground Support EquipmentSree288Nessuna valutazione finora

- Ar ExportsDocumento1 paginaAr ExportsRais AlamNessuna valutazione finora

- Air Cooler With Checking DoorDocumento2 pagineAir Cooler With Checking DoorSuraj KumarNessuna valutazione finora

- Servo Controlled FBW With Power Boost Control, Operations & Maint. ManualDocumento126 pagineServo Controlled FBW With Power Boost Control, Operations & Maint. ManualKota NatarajanNessuna valutazione finora

- List of Irc Publications Referred To in The Specifications: AppendicesDocumento17 pagineList of Irc Publications Referred To in The Specifications: AppendicesPrasad BoniNessuna valutazione finora

- Concrete Saw Core Drilling Swms 10067-8Documento12 pagineConcrete Saw Core Drilling Swms 10067-8JamesNessuna valutazione finora

- Modeling of Conducted EMI (Model Motor Simulink Bun)Documento8 pagineModeling of Conducted EMI (Model Motor Simulink Bun)Ioan ŢileaNessuna valutazione finora

- Travelsinvarious03clar BWDocumento522 pagineTravelsinvarious03clar BWSima Sorin MihailNessuna valutazione finora

- Lexus JTJBT20X740057503 AllSystemDTC 20230702045631Documento2 pagineLexus JTJBT20X740057503 AllSystemDTC 20230702045631Venerable DezzyNessuna valutazione finora

- Local AnesthesiaDocumento55 pagineLocal AnesthesiaAhmed MagdyNessuna valutazione finora

- Research Proposal PHDDocumento19 pagineResearch Proposal PHDSuleiman Mukhtar100% (2)

- HART - Wikipedia, The Free EncyclopediaDocumento3 pagineHART - Wikipedia, The Free EncyclopediakalyanupdownNessuna valutazione finora

- PrionDocumento22 paginePrionAnushkaNessuna valutazione finora

- NTDCDocumento8 pagineNTDCjaved_hanifNessuna valutazione finora

- Safety Data Sheet: Section 1. Identification Jotun Essence Easy CleanDocumento11 pagineSafety Data Sheet: Section 1. Identification Jotun Essence Easy CleanHồng PhongNessuna valutazione finora

- An Adaptive Power Oscillation Damping Controllerby STATCOM With Energy StorageDocumento10 pagineAn Adaptive Power Oscillation Damping Controllerby STATCOM With Energy StorageChristian EmenikeNessuna valutazione finora

- DattadasDocumento4 pagineDattadasJéssica NatáliaNessuna valutazione finora

- Here Is Why Skincare Is ImportantDocumento3 pagineHere Is Why Skincare Is ImportantKevin OkunguNessuna valutazione finora

- DuctBank For Electrical SystemDocumento4 pagineDuctBank For Electrical SystemAnonymous XYAPaxjbYNessuna valutazione finora

- Question Paper - GIAN - 19 - ModifiedDocumento4 pagineQuestion Paper - GIAN - 19 - Modifiedsayan mukherjeeNessuna valutazione finora

- Nav Bharat Nirman: Indispensable Ideas For Green, Clean and Healthy IndiaDocumento4 pagineNav Bharat Nirman: Indispensable Ideas For Green, Clean and Healthy IndiaRishabh KatiyarNessuna valutazione finora

- Cot 3Documento16 pagineCot 3jaycel cynthiaNessuna valutazione finora

- Math Diagnostic ExamDocumento4 pagineMath Diagnostic ExamMananquil JeromeNessuna valutazione finora