Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Kiln Shell Scanner Specification Thermoteknix

Caricato da

vsrikala680 valutazioniIl 0% ha trovato utile questo documento (0 voti)

302 visualizzazioni3 pagineSpecial instrument

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoSpecial instrument

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

302 visualizzazioni3 pagineKiln Shell Scanner Specification Thermoteknix

Caricato da

vsrikala68Special instrument

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 3

Product: Kiln Shell Temperature Scanning System

Supplier Thermoteknix Systems Limited, England

Model: Centurion TK 30 with WinCem Graphic

Sensor

1.1 Scanning speed 20 Hz.

20 Hz is data collection speed.

Motor can have rotation speed

up to 100 Hz

1.2 Calculated no of lines of data per rev

(assuming 4 RPM kiln speed)

300 line of data per rev for kiln

speed of 4 rpm

1.3 Data Collected Per Scan

a) Number of Samples

b) Number of Measurement Spot used

2240

1120

1.4 A. Temperature measurement spot size.

90% Modulation

B. Spot Detection size. 50% Modulation

< 1 mili radians

< 2 mili radians

1.5 Scan Angle 100 deg (configurable)

1.6 Scanning motor Brushless

1.7 Scanner controls Fully Digital. Scanner access

software provided

1.8 Internal checking 2 internal references

100 & 250 C

1.9 Scanning Optics All Reflective Mirror Assembly. No

Lens in the system

1.10 IR detector wavelength 3.3 - 4.2 micrometers

1.11 Temperature detection accuracy 4 deg C at 100 - 250 C.

<1% at 250 700 C

1.12 Temperature detection repeatability <1C

5C (one calibration per year)

1.13 Thermal Sensitivity <8C @ 100C

1.14 Temperature measurement range 100 deg C to 700 deg C

1.15 Scanner location We shall recommend scanner

location on receipt of site drawings

1.16 Scanner environmental protection IP 62

1.17 Ambient operating temperatures -5C to +50C

1.18 Ambient operating Relative humidity 93% RH @ 40C

KILN SHELL SCANNER

1.19 Supplier recommended protection Canopy to protect from direct rain

and sun

1.20 Is air conditioning required? NO

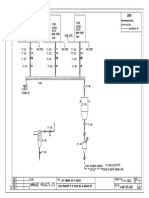

1.21 Communications with CCR RS 485 / RS 422

1.22 Cooling/viewing window cleaning Using dedicated blower supplied

with system

1.23 Is compressed air required? NO

1.24 Recommended re-calibration period Annual

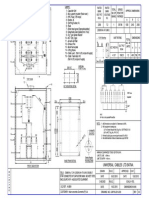

1.25 Size width x height x depth 260 x 336 x 340

1.26 Weight 35 kgs

1.27 Scanner power consumption 50 watts

1.28 Ancilliary power consumption (cooling etc) 0.75 kW max

Item Description Requirement

2.1 Operating System Windows XP / Windows Vista

2.2 Client/server system Fully Client Server System.

Remote viewing on clients & data

storage on remote storage system

2.3 Networking Yes

2.4 Connectivity to kiln control system & Shell

Cooling Fan Control

Digital/4 - 20 mA/OPC.

2.5 Data Display in 1, 2 or 4 user defined windows:

2.5.a Live Profile with live scan. Not just

Max, Min and Avg

2.5.b Envelope comprising live profile and

last revolution max/min for every

point measured along the kiln

2.5.c Map of all points displayed

2.5.d Subtraction

2.5.e Trend on Temperature spot/area

tool

2.5.f Trend on Alarm

2.5.g Prediction of future temperature

2.5.h Real 3D (NOT relief)

2.5.j 2D Coating at any point along the

kiln

2.5.k History recall. Can be recalled while

viewing live data

2.5.l Data Magnification

2.5.m Campaign high temperatures (user

defined) for re-bricking planning

2.5.n Bricking chart display

2.5.o 10 colour pallettes

2.6 Analysis tools Unlimited spots

Kiln shell temperature scanning system software

Unlimited Areas

Trend on spot/area with prediction.

Historical, Live and Prediction

Trend

Trend on tyre slip with prediction

2.7 Alarms High/Low alarms on all temperature

tools

2.8 Live ring migration (Tyre slip) Yes.

2.9 Histories Automatic configurable History

Storage

2.10 Scanner/kiln alignment via software Yes

2.11 Digital communication with scanner for

trouble shooting

Yes.

2.12 Daily printouts A worst case over the last 24

hours

The history map for the last hour

The current live map

2.13 Auto Rotation control Software monitors the rotation input

and changes over to manual without

user intervention if the kiln speed

drops below a user-configurable

threshold. When the rate increases

again it reverts to switch control.

2.14 Shadow elimination Can be suggested if needed.

Potrebbero piacerti anche

- Microcontroller-Based Temperature Monitoring and ControlDa EverandMicrocontroller-Based Temperature Monitoring and ControlValutazione: 3.5 su 5 stelle3.5/5 (2)

- The IT System That Couldn't Deliver SummaryDocumento3 pagineThe IT System That Couldn't Deliver SummaryWnsyuhada Ismail100% (1)

- Brochure - Loading Spout - Pubc-0499-AulDocumento2 pagineBrochure - Loading Spout - Pubc-0499-Aulm_verma21Nessuna valutazione finora

- Arunachala Aksharamanamalai - TamilDocumento10 pagineArunachala Aksharamanamalai - Tamildeepaksubsmani@yahoo.com95% (19)

- Symfony Reference 2.5Documento336 pagineSymfony Reference 2.5niurkamNessuna valutazione finora

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionDa EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionValutazione: 4.5 su 5 stelle4.5/5 (3)

- Position Sensing: Angle and Distance Measurement for EngineersDa EverandPosition Sensing: Angle and Distance Measurement for EngineersNessuna valutazione finora

- Amesim English s01Documento20 pagineAmesim English s01Chetan P BhatNessuna valutazione finora

- Clmd4a Ictg6Documento25 pagineClmd4a Ictg6Rose RamosNessuna valutazione finora

- Decision Support SystemDocumento6 pagineDecision Support SystemNaveenNessuna valutazione finora

- Climatronic - 1 - Passat VWDocumento8 pagineClimatronic - 1 - Passat VWMiguel FerreiraNessuna valutazione finora

- 002 - Gas ChromatographDocumento52 pagine002 - Gas Chromatographtubagus syariefNessuna valutazione finora

- Webinar PowerpointDocumento62 pagineWebinar Powerpointraghukk1988Nessuna valutazione finora

- CCTV Specification BCASDocumento8 pagineCCTV Specification BCASPraveen MohanNessuna valutazione finora

- Project ReportDocumento61 pagineProject Reportlove goyal100% (2)

- Extech 407780Documento1 paginaExtech 407780TedosNessuna valutazione finora

- Case 06 RPA WALT Robotic Process AutomationDocumento13 pagineCase 06 RPA WALT Robotic Process AutomationPragya JoshiNessuna valutazione finora

- DL 172 Portable Datalogger Temp+HumDocumento3 pagineDL 172 Portable Datalogger Temp+HumMasthan GMNessuna valutazione finora

- Elcometer 319 - Dewpoint MeterDocumento5 pagineElcometer 319 - Dewpoint MeterArya KamiNessuna valutazione finora

- DS Manual HiWEIGHDocumento24 pagineDS Manual HiWEIGHDaniel Alejandro Rodríguez PérezNessuna valutazione finora

- Onesense Sun - THDocumento7 pagineOnesense Sun - THBeanAirNessuna valutazione finora

- Item Reference Description Qty.: Air Conditioning Automobile Module (10 Cai + Cal) Ref: 0933/10SDocumento3 pagineItem Reference Description Qty.: Air Conditioning Automobile Module (10 Cai + Cal) Ref: 0933/10SA94leo14hsetmaNessuna valutazione finora

- Item Reference Description Qty.: Air Conditioning Automobile Module (5 Cai + Cal) Ref: 0933/5SDocumento3 pagineItem Reference Description Qty.: Air Conditioning Automobile Module (5 Cai + Cal) Ref: 0933/5SA94leo14hsetmaNessuna valutazione finora

- Extech Ea20 SpecDocumento1 paginaExtech Ea20 Specalem733Nessuna valutazione finora

- Meteo Dataloggers & Sensors: Automatic Measuring StationsDocumento12 pagineMeteo Dataloggers & Sensors: Automatic Measuring StationsMilton Damián Cornejo ReyesNessuna valutazione finora

- HDT VicatDocumento4 pagineHDT Vicatanon-609453Nessuna valutazione finora

- Item Reference Description Qty.: Air Conditioning Automobile Module Ref: 0933Documento3 pagineItem Reference Description Qty.: Air Conditioning Automobile Module Ref: 0933A94leo14hsetmaNessuna valutazione finora

- MMY170 ADocumento1 paginaMMY170 AthotalnNessuna valutazione finora

- VDM 300 ThermoDocumento4 pagineVDM 300 ThermoAmr KonswaNessuna valutazione finora

- Honeywell Humidicon™ Digital Humidity/Temperature Sensors: Hih6130/6131 and Hih6120/6121 SeriesDocumento11 pagineHoneywell Humidicon™ Digital Humidity/Temperature Sensors: Hih6130/6131 and Hih6120/6121 SeriesSevenUp2014Nessuna valutazione finora

- Sensor: Wireless Light & IR Temperature SensorDocumento8 pagineSensor: Wireless Light & IR Temperature SensorBeanAirNessuna valutazione finora

- Video-Based Thermography For Combustion ProcessesDocumento4 pagineVideo-Based Thermography For Combustion ProcessesHeri SetyantoNessuna valutazione finora

- OneSense SUN - TDocumento8 pagineOneSense SUN - TBeanAirNessuna valutazione finora

- Item Reference Description Qty.: Air Conditioning - Basic Module Ref: 0930Documento4 pagineItem Reference Description Qty.: Air Conditioning - Basic Module Ref: 0930A94leo14hsetmaNessuna valutazione finora

- TOKO Alghifarisurvey Jual Beli, Sewa, Servis Kalibrasi Total Station Sokkia Set-62 Series.Documento2 pagineTOKO Alghifarisurvey Jual Beli, Sewa, Servis Kalibrasi Total Station Sokkia Set-62 Series.agusNessuna valutazione finora

- Autoclave With Fully-Automated Process For Easy & Quick ControlDocumento13 pagineAutoclave With Fully-Automated Process For Easy & Quick ControlAthar Ali Khan SuperintendentNessuna valutazione finora

- MTS6Documento4 pagineMTS6CHARLES MATHEWNessuna valutazione finora

- Fluke Tis Building Diagnostic Thermal Imaging Scanner: Technical DataDocumento3 pagineFluke Tis Building Diagnostic Thermal Imaging Scanner: Technical DataVasile SilionNessuna valutazione finora

- Edibon SCADADocumento37 pagineEdibon SCADAMusa MohammadNessuna valutazione finora

- Stock DTG: Digital Reference Temperature GaugeDocumento2 pagineStock DTG: Digital Reference Temperature GaugeNathan SnappNessuna valutazione finora

- Item Reference Description Qty.: Refrigeration. Medium Module (5 Cai + Cal) Ref: 0911/5SDocumento6 pagineItem Reference Description Qty.: Refrigeration. Medium Module (5 Cai + Cal) Ref: 0911/5SA94leo14hsetmaNessuna valutazione finora

- Leica ScanStation P30-P40Documento3 pagineLeica ScanStation P30-P40bbutros_317684077Nessuna valutazione finora

- HIH9000 SeriesDocumento13 pagineHIH9000 SeriesDan LeNessuna valutazione finora

- E-Series Folder PMDocumento4 pagineE-Series Folder PMqxyzNessuna valutazione finora

- Item Reference Description Qty.: Heating Module Ref: 0940Documento3 pagineItem Reference Description Qty.: Heating Module Ref: 0940A94leo14hsetmaNessuna valutazione finora

- FLIR A325sc DatasheetDocumento2 pagineFLIR A325sc Datasheetlegato13Nessuna valutazione finora

- Perkin Elmer 44-135800SPC June 11 GSP Instrument SpecificationsDocumento4 paginePerkin Elmer 44-135800SPC June 11 GSP Instrument SpecificationsKhorana100% (1)

- Condumax II Transportable 97149 US Datasheet-V1Documento4 pagineCondumax II Transportable 97149 US Datasheet-V1MuhammadUmairNessuna valutazione finora

- Item Reference Description Qty.: Refrigeration. Medium Module (20 Cai + Cal) Ref: 0911/20SDocumento6 pagineItem Reference Description Qty.: Refrigeration. Medium Module (20 Cai + Cal) Ref: 0911/20SA94leo14hsetmaNessuna valutazione finora

- MCS Tailor-Made Chambers (E)Documento4 pagineMCS Tailor-Made Chambers (E)bravistNessuna valutazione finora

- Video and Thermography Analyzing System For Cement PlantsDocumento4 pagineVideo and Thermography Analyzing System For Cement PlantshamidkatebiNessuna valutazione finora

- Ficha Tecnica de Termometro - ExtechDocumento1 paginaFicha Tecnica de Termometro - ExtechRubi SotoNessuna valutazione finora

- HDT 3-6 Vicat GB-AP911-06Documento6 pagineHDT 3-6 Vicat GB-AP911-06Diego Fernado AvendañoNessuna valutazione finora

- Testo DetaloggerDocumento30 pagineTesto DetaloggerMostafa EghdamtalabNessuna valutazione finora

- Salt SparyDocumento4 pagineSalt SparyganeshkhaviNessuna valutazione finora

- Miyawaki Advanced Steam Trap Management System DR Trap PM301Documento2 pagineMiyawaki Advanced Steam Trap Management System DR Trap PM301iran1362Nessuna valutazione finora

- Hydrostatic Recorder Hydro001Documento1 paginaHydrostatic Recorder Hydro001Raju VrajuNessuna valutazione finora

- Memmert CO2-incubator ICO105 ENDocumento4 pagineMemmert CO2-incubator ICO105 ENMoh. andi sulaimanNessuna valutazione finora

- FT Kistock KH210 RFDocumento4 pagineFT Kistock KH210 RFHassan HoudoudNessuna valutazione finora

- Data Sheet G2301 CRDS Analyzer For CO2 CH4 H2O in Air PDFDocumento2 pagineData Sheet G2301 CRDS Analyzer For CO2 CH4 H2O in Air PDFFlorianisNessuna valutazione finora

- Sensirion Humidity SHTC1 Datasheet V3Documento14 pagineSensirion Humidity SHTC1 Datasheet V3Marian NiculaeNessuna valutazione finora

- Protem d404pdf Rele Temperatura de TrafosDocumento16 pagineProtem d404pdf Rele Temperatura de TrafosIvan FrancoNessuna valutazione finora

- 8388 Mmy170Documento56 pagine8388 Mmy170thotalnNessuna valutazione finora

- Doprimo IIDocumento4 pagineDoprimo IIddzako9140Nessuna valutazione finora

- Pixelfly DatasheetDocumento6 paginePixelfly DatasheetanugunarsiNessuna valutazione finora

- Temperature and Humidity Data Logger: No. of Items 3Documento7 pagineTemperature and Humidity Data Logger: No. of Items 3Omwesigo Gw'entumwaNessuna valutazione finora

- Memmert Environmental Test Chambers CTC256.enDocumento5 pagineMemmert Environmental Test Chambers CTC256.enanil nsNessuna valutazione finora

- Amavasya TharpanamDocumento5 pagineAmavasya TharpanamK KwaranNessuna valutazione finora

- 2356KVAr, 7.2KV - 12 UNIT (DRG. NO.10-203)Documento1 pagina2356KVAr, 7.2KV - 12 UNIT (DRG. NO.10-203)vsrikala68Nessuna valutazione finora

- Elac030003 1 1Documento1 paginaElac030003 1 1vsrikala68Nessuna valutazione finora

- Zero Speed Switch Data Sheet NO:ELAC020002: Application DetailsDocumento1 paginaZero Speed Switch Data Sheet NO:ELAC020002: Application Detailsvsrikala68Nessuna valutazione finora

- Diff. Pressure Switch Data Sheet NO. ELAC010001: Application DetailsDocumento1 paginaDiff. Pressure Switch Data Sheet NO. ELAC010001: Application Detailsvsrikala68Nessuna valutazione finora

- M/S Asian Concretes & Cement PVT - LTD.: 1.5 Mtpa Grinding Unit-Ii at Solan (As Built - Electrical)Documento1 paginaM/S Asian Concretes & Cement PVT - LTD.: 1.5 Mtpa Grinding Unit-Ii at Solan (As Built - Electrical)vsrikala68Nessuna valutazione finora

- Pressure Switch Data Sheet NO:ELAC000001: Application DetailsDocumento1 paginaPressure Switch Data Sheet NO:ELAC000001: Application Detailsvsrikala68Nessuna valutazione finora

- Diff. Pressure Switch Data Sheet NO. ELAC010001: Application DetailsDocumento1 paginaDiff. Pressure Switch Data Sheet NO. ELAC010001: Application Detailsvsrikala68Nessuna valutazione finora

- Flyash Storage & Transport - SheetDocumento2 pagineFlyash Storage & Transport - Sheetvsrikala68Nessuna valutazione finora

- Flow Sheet - Cement SiloDocumento1 paginaFlow Sheet - Cement Silovsrikala68Nessuna valutazione finora

- PR-131 (C) Q-U36-2010-256 (Item-1)Documento1 paginaPR-131 (C) Q-U36-2010-256 (Item-1)vsrikala68Nessuna valutazione finora

- Cover Sheet PDFDocumento1 paginaCover Sheet PDFvsrikala68Nessuna valutazione finora

- Flow SheetDocumento4 pagineFlow Sheetvsrikala68Nessuna valutazione finora

- Flow Sheet - Packing PlantDocumento1 paginaFlow Sheet - Packing Plantvsrikala68Nessuna valutazione finora

- Vasa Mari Yat Hamal ArgalDocumento60 pagineVasa Mari Yat Hamal ArgalArockiaruby RubyNessuna valutazione finora

- Corrig1 Eng 3889 TPT 828Documento37 pagineCorrig1 Eng 3889 TPT 828vsrikala68Nessuna valutazione finora

- ACL - EP - GU - Part VI B1 Design Criteria and Technical Specification For Control & InstrumentationDocumento101 pagineACL - EP - GU - Part VI B1 Design Criteria and Technical Specification For Control & Instrumentationvsrikala68Nessuna valutazione finora

- ACL - EP - GU - Part VI B2 Laboratory Equipments Technical SpecificationDocumento8 pagineACL - EP - GU - Part VI B2 Laboratory Equipments Technical Specificationvsrikala68Nessuna valutazione finora

- ACL - EP - GU - Part VI B4 Design Criteria ForTechnical Specification For C& I CableDocumento6 pagineACL - EP - GU - Part VI B4 Design Criteria ForTechnical Specification For C& I Cablevsrikala68Nessuna valutazione finora

- Satya TamilDocumento64 pagineSatya Tamilsrinivas3usNessuna valutazione finora

- Ameritrade 1099 2010Documento3 pagineAmeritrade 1099 2010vsrikala68Nessuna valutazione finora

- Siemens PTDocumento71 pagineSiemens PTvsrikala68Nessuna valutazione finora

- Star Sai SiteDocumento37 pagineStar Sai Sitevsrikala68Nessuna valutazione finora

- GanasktDocumento30 pagineGanasktvsrikala68Nessuna valutazione finora

- LT XLPE Aerial BunchedDocumento13 pagineLT XLPE Aerial BuncheddthotagamuwaNessuna valutazione finora

- Best of Talacauvery Recommended by Indian TravellersDocumento4 pagineBest of Talacauvery Recommended by Indian Travellersvsrikala68Nessuna valutazione finora

- G InstrumentationDocumento4 pagineG Instrumentationvsrikala68Nessuna valutazione finora

- Tc14.0.0.0 ActiveWorkspace6.2.2 READMEDocumento5 pagineTc14.0.0.0 ActiveWorkspace6.2.2 READMEgyuregabiNessuna valutazione finora

- Essentials of Investments 8th Edition Bodie Test BankDocumento22 pagineEssentials of Investments 8th Edition Bodie Test BankJoanSmithrgqb100% (47)

- Puana Cell Phone Search WarrantDocumento24 paginePuana Cell Phone Search WarrantHNN67% (3)

- Marelli Sra Ecu For Formula Renault 2000Documento8 pagineMarelli Sra Ecu For Formula Renault 2000arielfoxtoolsNessuna valutazione finora

- Using IComparer IComparable For Sorting in WPFDocumento6 pagineUsing IComparer IComparable For Sorting in WPFAbhiNessuna valutazione finora

- Finite State Machine (FSM) : ExampleDocumento22 pagineFinite State Machine (FSM) : Examplehaseeb tNessuna valutazione finora

- SokkiaioDocumento24 pagineSokkiaioUlisesRiveraUrbanoNessuna valutazione finora

- MVC Interview Questions AnswersDocumento12 pagineMVC Interview Questions AnswersKapil SharmaNessuna valutazione finora

- ResumeDocumento1 paginaResumeKevin Shui HuNessuna valutazione finora

- Name Any Three Client Applications To Connect With FTP ServerDocumento5 pagineName Any Three Client Applications To Connect With FTP ServerI2414 Hafiz Muhammad Zeeshan E1Nessuna valutazione finora

- NGSPICE Manual-Devices and Circuits LabDocumento15 pagineNGSPICE Manual-Devices and Circuits LabShreya R HNessuna valutazione finora

- Sample Cu A QuestionsDocumento4 pagineSample Cu A QuestionsIvan Petrov0% (1)

- Edustack Ruff FinDocumento12 pagineEdustack Ruff Finsanjoo1786Nessuna valutazione finora

- ControlMaestro 2010Documento2 pagineControlMaestro 2010lettolimaNessuna valutazione finora

- English Cloze PassageDocumento2 pagineEnglish Cloze PassageKaylee CheungNessuna valutazione finora

- Auto Power ManualDocumento97 pagineAuto Power ManualAngel100% (1)

- SQL DBA ResumeDocumento6 pagineSQL DBA Resumeindhu jayanNessuna valutazione finora

- Financial Accounting Tables Used in Business Planning and Consolidation NW 10.0Documento20 pagineFinancial Accounting Tables Used in Business Planning and Consolidation NW 10.0SarathBabu BandarupalliNessuna valutazione finora

- Micom P40 AgileDocumento386 pagineMicom P40 AgilesanthoshNessuna valutazione finora

- MT6582 Android ScatterDocumento5 pagineMT6582 Android ScatterSharad PandeyNessuna valutazione finora

- Hindalco Aluminium Catalogue PDFDocumento4 pagineHindalco Aluminium Catalogue PDFVansu Saini0% (1)

- Computerized Control Consoles: MCC Classic 50-C8422/CDocumento8 pagineComputerized Control Consoles: MCC Classic 50-C8422/CLaura Ximena Rojas NiñoNessuna valutazione finora

- Gemini AS Operator GuideDocumento149 pagineGemini AS Operator GuideThesa Grace OrnoNessuna valutazione finora