Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Lab Report

Caricato da

dudescape0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

107 visualizzazioni4 pagineLab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoLab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

107 visualizzazioni4 pagineLab Report

Caricato da

dudescapeLab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report Lab Report

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 4

OBJECTIVES

At the end of the experiment,student should be able to :

1. To observe the saturation pressure of steam for distilled water at different

temperature.

2. To plot the saturation line of water on P-T diagram.

3. To state differences between absolute and gauge pressure.

EQUIPMENTS

1. Vapor pressure Power Apparatus

2. Data Acquisition Software for LS-17123 Pressure Power Apparatus

3. 4L Tap Water and 4L Distilled Water

SAFETY PRECAUTIONS

1) Keep all the body parts away from the boiler and system piping when in operation

to avoid injury.

2) Always use personal proctective equipment (heat resistant gloves and protection

glasses ) when operating this system .

3) Always ensure that the boiler vessel is filled with water until half full before

operating to prevent heater burnout.

4) Ensure that the boiler valves are kept closed when the system is in operating .

5) Keep all body parts and objects away from the relief valve blowdown line.The

safetyrelief valve will automatically discharge steam through the blowdown line

in the event of boiler over pressure.

6) Keep all the body parts and objects away from the moving mechanical parts of the

turbine and generator.

PROCEDURES

1) The water inlet port at the bottom of the boiler is connected to a water supply.

2) The outlet port at the top of the boiler is connected to a relief valve blowdown line and

the discharge port to adrain.

3) The lower valve are opened and the throttling valve.The boiler vessel is filled with tap

water until half full.The heater cartridge is completely submerged in water.

4) Both the valve are closed.

5) The main switch is switched on.

6) The temperature is set at 160C and switch on heater.

7) When the temperature reaches 90C ,the upper valve is slowly opened.Air deposit in the

boiler is removed.The upper valve is fully closed when steam flow out from the outlet.

8) The Data Acquistion Software is runned and data logging is started.

9) Once the bolier reaches at pressure 3.7 BAR ,the throttling valve is slowly opened .The

throttling reaches the pressure 3 BAR and closed.

10) The turbine valve is slowly opened. The turbine speed was allowed to gradually pick up

speed.

11) The turbine valve was fully opened.

12) The lamps was switched on one by one until all the four lamps are switched on.

Between switchingon each lamp, the turbine was allowed to run for 5 to 10 seconds so

that a set of reading can be captured by the software.

13) The procedure was repeated using distilled water.

14) All the lamps are switched off.

15) The heater and the main switch are switched off.

Potrebbero piacerti anche

- Exercise 1Documento2 pagineExercise 1dudescapeNessuna valutazione finora

- BDA 31203 Binding Report FormatDocumento7 pagineBDA 31203 Binding Report FormatdudescapeNessuna valutazione finora

- Project Fatigue PDFDocumento219 pagineProject Fatigue PDFdudescapeNessuna valutazione finora

- Level and Flow SystemDocumento47 pagineLevel and Flow SystemdudescapeNessuna valutazione finora

- Level and Flow SystemDocumento2 pagineLevel and Flow SystemdudescapeNessuna valutazione finora

- Report On Robbery IncidentDocumento1 paginaReport On Robbery IncidentdudescapeNessuna valutazione finora

- Problem Statement: - Poor Reading Comprehension - Poor Word Recognition - Poor Speech - Poor DecodingDocumento7 pagineProblem Statement: - Poor Reading Comprehension - Poor Word Recognition - Poor Speech - Poor DecodingdudescapeNessuna valutazione finora

- Chapter 3 Work and Energy MethodDocumento23 pagineChapter 3 Work and Energy Methoddudescape100% (1)

- 4 2 CastiglianoDocumento3 pagine4 2 CastiglianodudescapeNessuna valutazione finora

- FileDocumento1 paginaFiledudescapeNessuna valutazione finora

- Assignment MomDocumento4 pagineAssignment Momdudescape0% (3)

- Chapter 1 Kinematics of A ParticleDocumento52 pagineChapter 1 Kinematics of A ParticledudescapeNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Practical Boiler Operation EngineeringDocumento55 paginePractical Boiler Operation EngineeringDaniel GómezNessuna valutazione finora

- Reheat Cycle: Steam Turbines ForDocumento4 pagineReheat Cycle: Steam Turbines Forruben colqueNessuna valutazione finora

- Project Info and Grading - 2021septDocumento3 pagineProject Info and Grading - 2021septMehdi SirajNessuna valutazione finora

- Determination of Certified Relieving CapacitiesDocumento6 pagineDetermination of Certified Relieving CapacitiesGustavo GarciaNessuna valutazione finora

- Gula - 30012014163328Documento20 pagineGula - 30012014163328Nirma Afrisanti KinasihNessuna valutazione finora

- Section I1: Boiler Selection ConsiderationsDocumento28 pagineSection I1: Boiler Selection Considerationsfructora100% (1)

- MRO Product Range From Project Sales Corp, IndiaDocumento43 pagineMRO Product Range From Project Sales Corp, IndiaProject Sales CorpNessuna valutazione finora

- HOVAL BrochureDocumento28 pagineHOVAL Brochurenisuss100% (1)

- Steam TrapDocumento5 pagineSteam TrapDương HoàngNessuna valutazione finora

- Comfort Handbook Alfa LavalDocumento418 pagineComfort Handbook Alfa Lavalsinisamatic100% (4)

- ET101e Simple Compression Refrigeration (Heat Pump)Documento29 pagineET101e Simple Compression Refrigeration (Heat Pump)Rizwan ShadNessuna valutazione finora

- Steam Blowing ProcedureDocumento15 pagineSteam Blowing ProcedureDangol100% (14)

- Warhammer - Steam TanksDocumento14 pagineWarhammer - Steam TanksAndy AknobyNessuna valutazione finora

- Guide To AutoclavingDocumento12 pagineGuide To AutoclavingAndrew TurnerNessuna valutazione finora

- VEIT CasualWear Finish 01-0415Documento15 pagineVEIT CasualWear Finish 01-0415Ciubotaru AdrianNessuna valutazione finora

- Water Cooled Vacuum CondensersDocumento2 pagineWater Cooled Vacuum CondensersRana Mubbashir IqbalNessuna valutazione finora

- Piping Identification and Valve Tagging StandardDocumento6 paginePiping Identification and Valve Tagging Standardmanox007Nessuna valutazione finora

- KKS PltguDocumento1 paginaKKS PltguArief RahmanNessuna valutazione finora

- Sugar CanediffusionDocumento12 pagineSugar Canediffusionjoe_l_1903Nessuna valutazione finora

- Edibls Oil and Fats TechnologyDocumento20 pagineEdibls Oil and Fats TechnologyKhurram Shahzad100% (3)

- Facility Design GuidelinesDocumento440 pagineFacility Design GuidelinesWalid Abou HassanNessuna valutazione finora

- Boiler EmergencyDocumento41 pagineBoiler Emergencysubrata guhaNessuna valutazione finora

- Synloop Waste Heat BoilerDocumento12 pagineSynloop Waste Heat BoilerSimEnzNessuna valutazione finora

- Thermo SolDocumento9 pagineThermo SolLugisaniMushavhanamadiNessuna valutazione finora

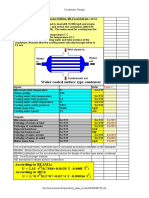

- Condenser DesignDocumento2 pagineCondenser DesignRahul ChandrawarNessuna valutazione finora

- Thermal Engineering IiDocumento1 paginaThermal Engineering IiRAMESHKUMAR BNessuna valutazione finora

- Exhaust Vapour Condenser: High Efficiency Energy Saving SolutionDocumento2 pagineExhaust Vapour Condenser: High Efficiency Energy Saving Solutionmember1000Nessuna valutazione finora

- Operating Instructions: K S G 40/60-2 K S G 50/80-2Documento38 pagineOperating Instructions: K S G 40/60-2 K S G 50/80-2Vlady Lopez CastroNessuna valutazione finora

- Final CondensersDocumento13 pagineFinal Condenserszubi13Nessuna valutazione finora

- 15 Basic Steps in Boiler Design - Meee Services - Mechanical DesignDocumento8 pagine15 Basic Steps in Boiler Design - Meee Services - Mechanical DesignAkiNessuna valutazione finora