Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ti - e - Protegol 32-99 Nov 07

Caricato da

A MahmoodTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ti - e - Protegol 32-99 Nov 07

Caricato da

A MahmoodCopyright:

Formati disponibili

Corrosion Protection Systems

P R O T E G O L

EP - Coating 32-99

Solvent-free, airless-sprayable two-component epoxy coating

1-K / 2-K Airless hot-spray system application

Date of issue 11/2007

TIB Chemicals AG | Muelheimer Strasse 16 -22 | 68219 Mannheim | P. O. Box 81 02 20 | 68202 Mannheim

Phone +49 621 8901-812 | Fax +49 621 8901-902 | info.protegol@tib-chemicals.com | www.tib-chemicals.com

This information is given to the best of our knowledge but without obligation. We are not liable for any wrong advice or any advice we may have failed to give.

This data sheet becomes invalid as soon as a new edition has been published. Please contact us for latest.

1/3

Description

Solvent-free two-component epoxy coating approved

for units in contact with potable water such as

containers and fittings. The Test Report meeting the

UBA Recommendations for epoxy coatings in

contact with potable water (January 31, 2003)

established by Hygienic Institute Gelsenkirchen

corresponds to the microbiological requirements as

laid down in DVGW Arbeitsblatt W 270.

The product is applied by two component airless

hotspray equipment.

Furthermore it fulfills french potable water

requirements.

Bending of the pipes after applying the coating is not

intended.

Uses

Internal coating of iron and cast iron for

fittings

valves

containers / tanks

Benefits

test meets recommendations UBA for containers,

fittings and pipes > DN300

solvent-free

fast curing

corresponds to the microbiological requirements

(W 270)

coating thickness till 0,9 mm per operation

fulfills french potable water requirements

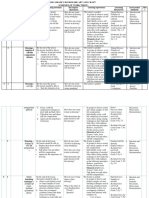

Product Data

The following data were obtained at +20 C unless

otherwise stated:

Type two-component material

Base epoxy

Solvents none

Volume solids 100 %

Viscosity

Comp. A

Comp. B

Liquid (4.000 mPas approx.)

Liquid (4.000 mPas approx.)

Density

Comp. A approx. 1,43 g/cm

Comp. B approx. 1,66 g/cm

Comp. A + B approx. 1,50 g/cm

Mixing ratio

Comp. A : B 60 : 40 parts by weight

1,75 : 1 parts by volume * approx.

Application method 2-Comp. airless hot-spray system

Minimum coating thickness 400-900 m

Application thickness Approx. 900m per operation on

vertical surfaces

Sag resistance 900 m

Application temp. Substrate > 10 C

Comp. A 30 C - 50 C

Comp. B 30 C - 50 C

Processing time 100 g -batch (A + B)

at 20C - 50 min

at 60C - approx. 9 min

Application method 1Comp. Airless Spray

Equipment high efficient airless pump with a

delivery rate of about 10 l/min and a

possible pressure ratio of about

66:1

hose diameter 3/8 inch

Spray tip nozzle orifice: 0.021- 0,026

Nozzle pressure: 200 240 bar typically

Waiting periods between

applications

approx. 4 hours

Tack free

(0,5 mm coating)

after approx. 5 hours

Hard dry depending on temperature

12 to 18 hours

Corrosion Protection Systems

P R O T E G O L

EP - Coating 32-99

Solvent-free, airless-sprayable two-component epoxy coating

1-K / 2-K Airless hot-spray system application

Date of issue 11/2007

TIB Chemicals AG | Muelheimer Strasse 16 -22 | 68219 Mannheim | P. O. Box 81 02 20 | 68202 Mannheim

Phone +49 621 8901-812 | Fax +49 621 8901-902 | info.protegol@tib-chemicals.com | www.tib-chemicals.com

This information is given to the best of our knowledge but without obligation. We are not liable for any wrong advice or any advice we may have failed to give.

This data sheet becomes invalid as soon as a new edition has been published. Please contact us for latest.

2/3

Exposure to mech. and

chemical load

after 5 days

Shore D** 80 + 3

Cleaning material Solvent D or Solvent G

* The volumetric mixing ratio was determined

on processing conditions

** After the coating has fully reacted and cured

Colours

Ivory

Coverage

Approx. 0,15 kg/0,1 per mm dft / m

(theoretical,value)

Packaging

Comp. A and Comp. B in 200 ltr. non-returnable

drums

Comp. A = 250 kg, net

Comp. B = 250 kg, net

(Drums with PE inlay upon request)

Storage

Store in a cool and dry place, shelf life is approx. 12

months in tightly closed original packs.

Comp.A can become solid due to crystallisation. It

can be melt by heating (for example in water

quench,in furnace at 50C)

Storage and Transport Data

Flash point RID / ADR ICAO / IATA-DGR

PROTEGOL

32-99

Comp. A > 100 C -

Cl. 9, UN 3082 / II

Comp. B > 100 C -

Cl. 8, UN 2289 / II

Solvent D 25 C A II Cl. 3, UN 1263 /III

Solvent G appr. 7 C A I Cl. 3, UN 1263

Application

Substrate

The steel surfaces to be coated must be dry, clean,

free from dust, have a good profile and be free from

all matter acting as release agents (e.g. oil, grease,

old paint etc.). In order to obtain the necessary

conditions, suitable substrate preparation methods

such as blasting must be used.

Steel surfaces must be abrasive blast cleaned to

near white (degree of cleanliness according

to DIN EN ISO 12944-4 degree of cleanliness at

least

Sa 2 ). The first coating must be applied

immediately after blast cleaning.

The surface profile should be between 50 m and 70

m. The blasting material shall be angled-shot.

2-Comp. Application

Ensure that the temperature of the substrate is at

least 3C above the dew point to avoid condensation

of the substrate to be coated due to humidity.

PROTEGOL

EP 32-99 is applied using a two-

component airless hot-spray system only. Dosing for

each component must be very precise with a

tolerance of 3 %.

Relative humidity during application and curing of the

coating must be < 80 %.

Depending on the field of use, small quantities can

be mixed manually and applied by brush.

Both components should be stored at room

temperature which will make application easier at

lower temperatures whereas at high summer

temperatures the drums shall be stored in a cool

place, by no means expose them to direct sunlight.

Corrosion Protection Systems

P R O T E G O L

EP - Coating 32-99

Solvent-free, airless-sprayable two-component epoxy coating

1-K / 2-K Airless hot-spray system application

Date of issue 11/2007

TIB Chemicals AG | Muelheimer Strasse 16 -22 | 68219 Mannheim | P. O. Box 81 02 20 | 68202 Mannheim

Phone +49 621 8901-812 | Fax +49 621 8901-902 | info.protegol@tib-chemicals.com | www.tib-chemicals.com

This information is given to the best of our knowledge but without obligation. We are not liable for any wrong advice or any advice we may have failed to give.

This data sheet becomes invalid as soon as a new edition has been published. Please contact us for latest.

3/3

1 Comp- Application

Mixing

Both components should be stored at room

temperature which will make application easier. At

lower temperatures whereas at high summer

temperature the drums shall be stores in a cool

place.

Optimum material temperatures for a good spray

result are 20-25C.

Thoroughly mix the 2 Components with a slow speed

mechanical stirrer (e.g. drill fitted with a stirring

paddle running at about 400 rpm). Take care not to

stir in any air. Component B shall be added to

Component A while stirring. Then put the whole

content into another new and clean container, strip

any adhering residues with a spatula and add to the

new container while still stirring until the material has

been mixed homogeneously.

Application

To ensure a good spray result the material

temperature in the spray gun have to be 25C

minimum, this is the reason why we recommend the

usage of a flow heater on the high pressure side of

the airless pump.

Put the pump immediately after mixing direct in the

mixing vessel and start spray application.

Take care that after every 15 to 20 min. this vessel

have to be changed to avoid that reacted material

flow into the pump.

After every interruption of the pump, the hose and

the spraygun have to be cleaned with Solvent.

Depending on the field of use small quantities can be

mixed manually and applied by brush.

Maintenance of tools

Immediately after use all instruments should be

cleaned with Solvent D or G.

Health and Safety

Although PROTEGOL

EP 32-99 is solvent-free, it

may, if processed at elevated temperatures, develop

vapours which may cause irritation to the skin. It

must be ensured by suitable measures, such as

continuous ventilation, mechanical extraction or

respiratory protection that such vapours and any mist

eventually forming during the spraying process are

not inhaled. Therefore we recommend to wear filter

or fresh air masks.

When using PROTEGOL

EP Coating 32-99, all

safety precautions applicable to handling epoxy

resins and their hardeners must be observed. They

are listed in the Merkblatt fr die Verarbeitung von

Polyester- und Epoxidharzen (Application advice for

polyester and epoxy resins) published by the

German liability insurance association of the

chemical industry (order number M 023, Jedermann-

Verlag, Heidelberg).

Notes on dangers and safety advice on the

containers must be strictly observed!

In addition, the health and safety precautions being

effective in the respective country should be

observed.

Contact with the unprotected skin should be avoided.

Any material accidentally splashed onto the skin

should immediately be removed using warm, soapy

water or preferably with warm non-alkaline detergent.

(such as Lutrol E 400, BASF) Afterwards wash again

thoroughly with soap and water.

It is recommended to protect the skin with a silicone-

free barrier cream before starting work (such as

Stokolan, producer: Stockhausen, Krefeld or

Sansibal, producer: Basotherm, Biberach/Riss)

Any further information can be taken from the

material safety data sheets.

Potrebbero piacerti anche

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryDa EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Ti e Protegol 132 HT Jan 08Documento3 pagineTi e Protegol 132 HT Jan 08A MahmoodNessuna valutazione finora

- Ti - e - Protegol 32-97 Jan 08Documento3 pagineTi - e - Protegol 32-97 Jan 08A MahmoodNessuna valutazione finora

- Ti e Protegol 32-55 TD Jan 08Documento4 pagineTi e Protegol 32-55 TD Jan 08A MahmoodNessuna valutazione finora

- Ti e Protegol 32-47 R Jan 08Documento3 pagineTi e Protegol 32-47 R Jan 08A MahmoodNessuna valutazione finora

- Ti e Protegol 32-55 H Nov 07Documento3 pagineTi e Protegol 32-55 H Nov 07A MahmoodNessuna valutazione finora

- Ti e Protegol 130 HT Nov 07Documento3 pagineTi e Protegol 130 HT Nov 07A MahmoodNessuna valutazione finora

- Ti e Protegol 32-60 Apr08Documento3 pagineTi e Protegol 32-60 Apr08A Mahmood100% (1)

- Ti e Protegol 32-55 R Nov 07Documento4 pagineTi e Protegol 32-55 R Nov 07A MahmoodNessuna valutazione finora

- Ti e Protegol 32-55 RRM Nov 07Documento4 pagineTi e Protegol 32-55 RRM Nov 07A MahmoodNessuna valutazione finora

- Ti - e - Protegol 130 HT L - Jan 08Documento3 pagineTi - e - Protegol 130 HT L - Jan 08A MahmoodNessuna valutazione finora

- Ti e Protegol 32-55 RRG Jan 08Documento3 pagineTi e Protegol 32-55 RRG Jan 08A MahmoodNessuna valutazione finora

- Ti e Protegol 32-55 M Jul 08Documento4 pagineTi e Protegol 32-55 M Jul 08A MahmoodNessuna valutazione finora

- Ti e Protegol 32-45 Jan 12Documento3 pagineTi e Protegol 32-45 Jan 12ruben quedo salazarNessuna valutazione finora

- PC 0261 Is 2339 Aluminium PaintDocumento3 paginePC 0261 Is 2339 Aluminium PaintEr Aftab ShaikhNessuna valutazione finora

- Coal Tar Epoxy 83 - English (Uk) - Issued.06.12.2007Documento3 pagineCoal Tar Epoxy 83 - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Rust O Cap PDFDocumento1 paginaRust O Cap PDFBharat Tailor100% (2)

- Naviguard ME - English (Uk) - Issued.06.12.2007Documento3 pagineNaviguard ME - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- 3 - PC 7049 - Apcodur MioDocumento3 pagine3 - PC 7049 - Apcodur Miosujay AvatiNessuna valutazione finora

- TDS - Muki Z 2008 - English (Uk) - Issued.26.11.2010Documento4 pagineTDS - Muki Z 2008 - English (Uk) - Issued.26.11.2010Keith ChooNessuna valutazione finora

- Sikafloor - 2530 W: 2-Part Water Based Epoxy CoatingDocumento5 pagineSikafloor - 2530 W: 2-Part Water Based Epoxy Coatingthe pilotNessuna valutazione finora

- PC 1752 - Asian Bituminous CoatingsDocumento3 paginePC 1752 - Asian Bituminous CoatingsRamesh BabuNessuna valutazione finora

- Penguard Stayer - English (Uk) - Issued.06.12.2007Documento3 paginePenguard Stayer - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Penguard Primer PDFDocumento4 paginePenguard Primer PDFheri_prasetyadi7715Nessuna valutazione finora

- Asian Apcodur Epoxy Mio PaintDocumento3 pagineAsian Apcodur Epoxy Mio PaintPrinceRaghavNessuna valutazione finora

- HEAT RESISTANT SILICONE ALUMINIUM PAINTDocumento3 pagineHEAT RESISTANT SILICONE ALUMINIUM PAINTrumi_2kNessuna valutazione finora

- Baltoflake S2000 Technical Data SheetDocumento4 pagineBaltoflake S2000 Technical Data Sheetrezza182Nessuna valutazione finora

- PC 7298 - Apcodur 804Documento3 paginePC 7298 - Apcodur 8048mzpdsjzsdNessuna valutazione finora

- Penguard HBDocumento4 paginePenguard HBhedisanjayaNessuna valutazione finora

- Baltoflake - English (Uk) - Issued.25.03.2010Documento4 pagineBaltoflake - English (Uk) - Issued.25.03.2010Mohamed FaragNessuna valutazione finora

- PC 2569 Apcomin Industrial Rozc PrimerDocumento3 paginePC 2569 Apcomin Industrial Rozc PrimerAshishKumar RavalNessuna valutazione finora

- Alkyd Primer Technical DataDocumento4 pagineAlkyd Primer Technical Datawey5316Nessuna valutazione finora

- Ti e Protegol 32-55 PN Juni 08Documento4 pagineTi e Protegol 32-55 PN Juni 08A Mahmood100% (1)

- BASF MasterSeal M 800Documento4 pagineBASF MasterSeal M 800Mohiuddin Muhin100% (2)

- Dura Mastic DatasheetDocumento4 pagineDura Mastic DatasheetBhisamS SallehNessuna valutazione finora

- Two-Pack Epoxy Primer Technical DataDocumento4 pagineTwo-Pack Epoxy Primer Technical Datawey5316Nessuna valutazione finora

- High Build Epoxy CoatingDocumento4 pagineHigh Build Epoxy Coatingwey5316Nessuna valutazione finora

- Apcoglass Mastic 2000Documento3 pagineApcoglass Mastic 2000replyrajanNessuna valutazione finora

- Rust o Cap LX Pc2761Documento1 paginaRust o Cap LX Pc2761Power PowerNessuna valutazione finora

- Penguard FC - English (Uk) - Issued.06.12.2007Documento4 paginePenguard FC - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Copon - Hycote 162 HBDocumento2 pagineCopon - Hycote 162 HBSherif AbdelhameedNessuna valutazione finora

- Rust O Cap: Surface Tolerant EpoxyDocumento3 pagineRust O Cap: Surface Tolerant EpoxySanthana SaravanaNessuna valutazione finora

- Alkydprimer - English (Uk) - Issued.06.12.2007Documento3 pagineAlkydprimer - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- FT Forbo 233 EUROSOLDocumento3 pagineFT Forbo 233 EUROSOLAndreiNessuna valutazione finora

- Apcothane 676 AlDocumento3 pagineApcothane 676 AlJOSEPH GRAHAMSENGGNessuna valutazione finora

- Penguard Primer Datasheet " Azadjotun"Documento3 paginePenguard Primer Datasheet " Azadjotun"AzadAhmadNessuna valutazione finora

- TDS - Barrier 90 - English (Uk) - Issued.05.10.2011Documento4 pagineTDS - Barrier 90 - English (Uk) - Issued.05.10.2011ansarALLAAHNessuna valutazione finora

- Tds - Penguard Classic ZP - English (Uk) - Issued.19Documento4 pagineTds - Penguard Classic ZP - English (Uk) - Issued.19wey5316Nessuna valutazione finora

- PS 22118Documento2 paginePS 22118omar.moradi3707Nessuna valutazione finora

- PC 7051 - Apcomin Industrial EnamelDocumento3 paginePC 7051 - Apcomin Industrial EnamelHithayathulla KhanNessuna valutazione finora

- TDS - Chemflake Special - English (Uk) - Azad (Jotun Paints Ras Tanutra)Documento4 pagineTDS - Chemflake Special - English (Uk) - Azad (Jotun Paints Ras Tanutra)Robert ClarkNessuna valutazione finora

- Penguard ZP AO - English (Uk) - Issued.06.12.2007Documento3 paginePenguard ZP AO - English (Uk) - Issued.06.12.2007Mohamed FaragNessuna valutazione finora

- Jotun-Penguard Primer - Tech DataDocumento4 pagineJotun-Penguard Primer - Tech Dataanwarali1975Nessuna valutazione finora

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesDa EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesValutazione: 3.5 su 5 stelle3.5/5 (3)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDa EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsValutazione: 5 su 5 stelle5/5 (1)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsDa EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNessuna valutazione finora

- Environmental Scenario in Indian Mining Industry - an OverviewDa EverandEnvironmental Scenario in Indian Mining Industry - an OverviewNessuna valutazione finora

- A 269 - 00 - Qti2os0wma - PDFDocumento5 pagineA 269 - 00 - Qti2os0wma - PDFJose Oliveros ArdilaNessuna valutazione finora

- A 269 - 04 Qti2oqDocumento6 pagineA 269 - 04 Qti2oqfekihassan100% (1)

- A 270 - 01 Qti3mc0wmq - PDFDocumento5 pagineA 270 - 01 Qti3mc0wmq - PDFsingaravelan narayanasamyNessuna valutazione finora

- A 270 - 03 - Qti3mc0wmwDocumento5 pagineA 270 - 03 - Qti3mc0wmwehsanNessuna valutazione finora

- A 254 - 97 R02 Qti1na - PDFDocumento4 pagineA 254 - 97 R02 Qti1na - PDFMan98Nessuna valutazione finora

- A 234 - A 234M - 04 Qtiznc9bmjm0tq - PDFDocumento8 pagineA 234 - A 234M - 04 Qtiznc9bmjm0tq - PDFLuis Daniel ContrerasNessuna valutazione finora

- A 254 - 97Documento4 pagineA 254 - 97Maicol K. Huamán TitoNessuna valutazione finora

- A 53 - A 53m - 00 QtuzltawDocumento7 pagineA 53 - A 53m - 00 QtuzltawPablo CzNessuna valutazione finora

- A 234 - A 234M - 01 Qtiznc0wmq - PDFDocumento8 pagineA 234 - A 234M - 01 Qtiznc0wmq - PDFLuis Daniel ContrerasNessuna valutazione finora

- A 268 - A 268M - 03 Qti2oc0wmw - PDFDocumento6 pagineA 268 - A 268M - 03 Qti2oc0wmw - PDFMan98Nessuna valutazione finora

- Astm A0213 - 1 (En) PDFDocumento13 pagineAstm A0213 - 1 (En) PDFRahul SamalaNessuna valutazione finora

- A 268 - A 268M - 01 Qti2oc0wmq - PDFDocumento6 pagineA 268 - A 268M - 01 Qti2oc0wmq - PDFMan98Nessuna valutazione finora

- A 249 - A 249M - 04 Qti0os9bmjq5tq - PDFDocumento10 pagineA 249 - A 249M - 04 Qti0os9bmjq5tq - PDFMan98Nessuna valutazione finora

- A 249 - A 249M - 01 Qti0os0wmq - PDFDocumento8 pagineA 249 - A 249M - 01 Qti0os0wmq - PDFMan98Nessuna valutazione finora

- A 249 - A 249M - 03 Qti0os9bmjq5ts1sruq - PDFDocumento11 pagineA 249 - A 249M - 03 Qti0os9bmjq5ts1sruq - PDFMan98Nessuna valutazione finora

- A 250 - A 250M - 95 R01 Qti1mc9bmjuwts1sruq - PDFDocumento7 pagineA 250 - A 250M - 95 R01 Qti1mc9bmjuwts1sruq - PDFMan98Nessuna valutazione finora

- A 234 - A 234M - 00 Qtiznc0wma - PDFDocumento8 pagineA 234 - A 234M - 00 Qtiznc0wma - PDFCherie JohnsonNessuna valutazione finora

- A 250 - A 250M - 95 Qti1mc05nq - PDFDocumento4 pagineA 250 - A 250M - 95 Qti1mc05nq - PDFMan98Nessuna valutazione finora

- A 234 - A 234M - 03 Qtiznc9bmjm0ts1sruq - PDFDocumento10 pagineA 234 - A 234M - 03 Qtiznc9bmjm0ts1sruq - PDFLuis Daniel ContrerasNessuna valutazione finora

- A 250 - A 250M - 04 Qti1mc9bmjuwtq - PDFDocumento4 pagineA 250 - A 250M - 04 Qti1mc9bmjuwtq - PDFMan98Nessuna valutazione finora

- A 250 - A 250M - 95 R01 Qti1mc05nviwmq - PDFDocumento4 pagineA 250 - A 250M - 95 R01 Qti1mc05nviwmq - PDFMan98Nessuna valutazione finora

- A 234 - A 234M - 00 Qtiznc0wmee - PDFDocumento8 pagineA 234 - A 234M - 00 Qtiznc0wmee - PDFLuis Daniel ContrerasNessuna valutazione finora

- A 213 - A 213M - 03 Qtixmy0wm0i - PDFDocumento12 pagineA 213 - A 213M - 03 Qtixmy0wm0i - PDFMan98Nessuna valutazione finora

- A 213 - A 213M - 03 Qtixmy0wmw - PDFDocumento10 pagineA 213 - A 213M - 03 Qtixmy0wmw - PDFMan98Nessuna valutazione finora

- A 249 - A 249M - 98 Qti0os05oeux PDFDocumento7 pagineA 249 - A 249M - 98 Qti0os05oeux PDFMan98Nessuna valutazione finora

- A 249 - A 249M - 03 Qti0os0wmw - PDFDocumento9 pagineA 249 - A 249M - 03 Qti0os0wmw - PDFMan98Nessuna valutazione finora

- A 214 - A 214M - 96 Qtixnc05ng - PDFDocumento2 pagineA 214 - A 214M - 96 Qtixnc05ng - PDFMan98Nessuna valutazione finora

- A 213 - A 213M - 01 Qtixmy0wmqDocumento8 pagineA 213 - A 213M - 01 Qtixmy0wmqfadjarNessuna valutazione finora

- A 213 Â " A 213M Â " 03 - QTIXMY0WM0MDocumento13 pagineA 213 Â " A 213M Â " 03 - QTIXMY0WM0MhNessuna valutazione finora

- A 213 - A 213M - 01 Qtixmy0wmue - PDFDocumento9 pagineA 213 - A 213M - 01 Qtixmy0wmue - PDFErolNessuna valutazione finora

- 20 Perfect Water ReflectionsDocumento31 pagine20 Perfect Water ReflectionsPradeep Kumar.rNessuna valutazione finora

- Schwabsky An Art That Eats Its Own HeadDocumento4 pagineSchwabsky An Art That Eats Its Own HeadtobyNessuna valutazione finora

- Relief Prints: (Lesson 1-3 Quarter)Documento16 pagineRelief Prints: (Lesson 1-3 Quarter)Allana PonceNessuna valutazione finora

- MAPEH 9 Arts Q3Documento11 pagineMAPEH 9 Arts Q3ladymaemares.chioNessuna valutazione finora

- American Architects' Biographies - PDocumento9 pagineAmerican Architects' Biographies - PPatricia DillonNessuna valutazione finora

- 12 ML8 Chapter12Documento34 pagine12 ML8 Chapter12yosito VíctorNessuna valutazione finora

- Bow in MapehDocumento46 pagineBow in MapehFay BaysaNessuna valutazione finora

- Thinking With Type A Critical Guide For Designers Writers Editors Students PDFDocumento224 pagineThinking With Type A Critical Guide For Designers Writers Editors Students PDFreioco80% (5)

- OJT Narrative Report for RAPG + Architects ProjectsDocumento9 pagineOJT Narrative Report for RAPG + Architects ProjectsSean Solis DejucosNessuna valutazione finora

- Miracle of The OrdinaryDocumento17 pagineMiracle of The OrdinaryPhiblogsophoNessuna valutazione finora

- The Model of The Genre of Literary PortraitDocumento4 pagineThe Model of The Genre of Literary PortraitInternational Journal of Science and Engineering Investigations100% (1)

- Still Life Drawing TechniquesDocumento8 pagineStill Life Drawing Techniquesabuka.felixNessuna valutazione finora

- Arts and Crafts HandoutsDocumento5 pagineArts and Crafts HandoutsFreyssinet LynNessuna valutazione finora

- Weekly Lesson Plan Cross Curricular Four Years Old Sample Unit 5Documento7 pagineWeekly Lesson Plan Cross Curricular Four Years Old Sample Unit 5Cristina MihuNessuna valutazione finora

- Understanding the ArtsDocumento24 pagineUnderstanding the ArtsИванNessuna valutazione finora

- Animales de Granja Amigurumi PDFDocumento50 pagineAnimales de Granja Amigurumi PDFJoão Ferreira100% (1)

- Mark The Letter A, B, C or D To Indicate The Word Whose Underlined Part Differs From The Other Three in Pronunciation in Each of The Following QuestionsDocumento8 pagineMark The Letter A, B, C or D To Indicate The Word Whose Underlined Part Differs From The Other Three in Pronunciation in Each of The Following QuestionsLe VanNessuna valutazione finora

- Build Up Rate Format - PaintingDocumento2 pagineBuild Up Rate Format - PaintingFaiz Ahmad80% (10)

- Mil DTL 53072CDocumento43 pagineMil DTL 53072CMichael SkrableNessuna valutazione finora

- I Ethiopian Art and Visual Culture UoGDocumento50 pagineI Ethiopian Art and Visual Culture UoGGedi BNessuna valutazione finora

- Fashion IllustrationDocumento20 pagineFashion Illustrationtulika_ajwani100% (3)

- 3 4 Little Architect Free WorksheetsDocumento9 pagine3 4 Little Architect Free WorksheetsJitendra BaviskarNessuna valutazione finora

- The Spell To Re-Integrate The Self: The Significance of The Work of Yayoi Kusama in The New EraDocumento9 pagineThe Spell To Re-Integrate The Self: The Significance of The Work of Yayoi Kusama in The New EramyersalNessuna valutazione finora

- WK9 Lesson PDFDocumento6 pagineWK9 Lesson PDFPaul macaraegNessuna valutazione finora

- Anatomy of A Magazine LayoutDocumento3 pagineAnatomy of A Magazine LayoutBradley WaltonNessuna valutazione finora

- Aluminium Work Method StatementDocumento4 pagineAluminium Work Method StatementChezy629100% (3)

- KAD43P-A Owners ManualDocumento42 pagineKAD43P-A Owners Manualleo100% (3)

- Tessellation ProjectDocumento3 pagineTessellation Projectapi-283599791Nessuna valutazione finora

- Reading: The Story of Street ArtDocumento2 pagineReading: The Story of Street ArtdeboraNessuna valutazione finora

- Learning Plan Mapeh 10 1st QuarterDocumento20 pagineLearning Plan Mapeh 10 1st QuarterMariapaz Colindres Cantilan100% (2)