Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

5 Steps To Choose Best Motor For Your Application

Caricato da

at35Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

5 Steps To Choose Best Motor For Your Application

Caricato da

at35Copyright:

Formati disponibili

electrical-engineering-portal.com http://electrical-engineering-portal.

com/5-steps-to-choose-best-motor-for-your-application

by Edvard

5 Steps To Choose Best Motor For Your Application

Few steps you should know before choosing best motor for your application

Step 1: Know the load characteristics

For line-operated motors, loads fall into three general categories: constant torque, torque that changes abruptly,

and torque that change gradually over time. Bulk material conveyors, extruders, positive displacement pumps, and

compressors without air unloaders run at relatively steady levels of torque.

Sizing a motor for these applications is simple once the torque (or horsepower) for the application is known. Load

demands by elevators, compactors, punch presses, saws, and batch conveyors change abruptly from low to high

in a short time, often in a fraction of a second.

The most critical consideration for selecting a motor in these cases is to choose one whose speed-torque curve

exceeds the load torque curve.

Loads from centrifugal pumps, fans, blowers, compressors with unloaders, and similar equipment tend to be

variable over time. In choosing a motor for these conditions, consider the highest continuous load point, which

typically occurs at the highest speed.

Step 2: Get a handle on horsepower

The rule of thumb for motor horsepower is: Select only what you need, and avoid the temptation to oversize or

undersize. Calculate the required horsepower from this formula:

Horsepower = Torque x Speed / 5250

Where torque is in lb-ft and speed is in rpm.

Step 3: Getting started

Another consideration is inertia, particularly during startup. Every load represents some value of inertia, but punch

presses, ball mills, crushers, gearboxes that drive large rolls, and certain types of pumps require high starting

torques due to the huge mass of the rotating elements.

Motors for these applications need to have special ratings so that the temperature rise at startup does not exceed

the allowable temperature limit. A properly sized motor must be able to turn the load from a dead stop (locked-rotor

torque), pull it up to operating speed (pull-up torque), and then maintain the operating speed.

Motors are rated as one of four design types for their ability to endure the heat of that starting and pull up.

In ascending order of their ability to start inertial loads, NEMA designates these as design type A, B, C, and D.

Type B is the industry standard and is a good choice for most commercial and industrial applications.

Step 4: Adjust for duty cycle

Duty cycle is the load that a motor must handle over the period when it starts, runs, and stops.

Continuous duty

Continuous duty is by far the simplest and most efficient application. The duty cycle begins with startup, then long

periods of steady operation where the heat in the motor can stabilize as it runs.

A motor in continuous duty can be operated safely at or near its rated capacity because the temperature has a

chance to stabilize.

Intermittent duty

Intermittent duty is more complicated. The life of commercial airplanes is measured by their number of landings; in

the same way, the life of a motor is proportional to the number of starts it makes. Frequent starts shorten life

because inrush current at startup heats the conductor rapidly.

Because of this heat, motors have a limited number of starts and stops that they can make in an hour.

Step 5: The last consideration, motor hypoxia

If your motor is going to operate at altitudes that are substantially above sea level, then it will be unable to operate

at its full service factor because, at altitude, air is less dense and does not cool as well. Thus, for the motor to stay

within safe limits of temperature rise, it must be derated on a sliding scale.

Up to an altitude of 3,300 ft, SF = 1.15; at 9000 ft, it declines to 1.00.

This is an important consideration for mining elevators, conveyors, blowers, and other equipment that operates at

high altitudes.

Should You Buy New or To Rewind?

Cant see this video? Click here to watch it on Youtube.

When you have a motor failure youll need to decide if you should buy a new motor or fix the old one. A common

cause of motor failure is problems with the motor windings, and the solution often is to rewind the old motor.

Because it is economical in terms of initial cost, rewinding of motors is very common particularly for motors of

more than 10 horsepower.

However, the motor rewinding process often results in a loss of motor efficiency.

It is generally cost-effective to replace motors under 10 horsepower with new high-efficiency motors rather than

rewind them. When deciding whether to buy a new motor or rewind the old one, consider the cost difference

between the rewind and a new high-efficiency motor, and the potential increase in energy costs of a rewound

motor that is less efficient than the original.

The quality of the rewind has a big impact on operating cost.

A poorly rewound motor may lose up to 3% in efficiency. A 100 HP motor may use several hundred dollars more in

electricity each year due to this drop in efficiency, compared to its original efficiency. The operating cost may be

even more compared to a new high efficiency motor.

References

[1] www.wikipedia.org

[2] www.seedt.ntua.gr

[3] www.designworldonline.com

[4] www.energy.gov

[5] www.energyasia.com

[6] www.powerdivision.gov.bd

[7] www.bpdb.gov.bd

[8] www.reb.gov.bd

[9] www.pgcb.org.bd

Edvard - Electrical engineer, programmer and founder of EEP. Highly specialized for design of LV

high power busbar trunking (<6300A) in power substations, buildings and industry fascilities.

Designing of LV/MV switchgears. Professional in AutoCAD programming and web-design.

Present on Google+.

RSS Feed for Comments

8 Comments

RSS Feed for Comments

Leave a Comment

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- CBSE Class-12 Mathematics NCERT Solution Chapter - 7 Integrals - Exercise 7.3Documento21 pagineCBSE Class-12 Mathematics NCERT Solution Chapter - 7 Integrals - Exercise 7.3at35Nessuna valutazione finora

- Sample Question Paper Class XII (2019-20) BiologyDocumento7 pagineSample Question Paper Class XII (2019-20) BiologyVashu GargNessuna valutazione finora

- Biology MS PDFDocumento6 pagineBiology MS PDFJxjbNessuna valutazione finora

- CBSE Class-12 Mathematics NCERT Solution Chapter - 7 Integrals - Exercise 7.4Documento31 pagineCBSE Class-12 Mathematics NCERT Solution Chapter - 7 Integrals - Exercise 7.4at35Nessuna valutazione finora

- Physics SQPDocumento7 paginePhysics SQPGopa DeyNessuna valutazione finora

- Technical Specification For Pressure Relief ValvesDocumento7 pagineTechnical Specification For Pressure Relief Valvesat35100% (1)

- Important Reactions For Conversions Class 12 Organic ChemistryDocumento4 pagineImportant Reactions For Conversions Class 12 Organic Chemistryyoyo2669679% (115)

- 55 (B) (Physics) PDFDocumento16 pagine55 (B) (Physics) PDFat35Nessuna valutazione finora

- Technical Specification For Pressure Relief ValvesDocumento6 pagineTechnical Specification For Pressure Relief Valvesat35Nessuna valutazione finora

- Reaction Learning Checklist: ShallowDocumento3 pagineReaction Learning Checklist: ShallowmanuuNessuna valutazione finora

- AC Motors Protection Against Short CircuitsDocumento4 pagineAC Motors Protection Against Short Circuitsat35Nessuna valutazione finora

- SN1 Vs SN2 2019 PDFDocumento1 paginaSN1 Vs SN2 2019 PDFKrishna Kumar kunduNessuna valutazione finora

- Technical Specification For Pressure Relief Valves PDFDocumento7 pagineTechnical Specification For Pressure Relief Valves PDFat35100% (1)

- Quantamanual NewDocumento19 pagineQuantamanual Newat35Nessuna valutazione finora

- Biology Merit 1516Documento90 pagineBiology Merit 1516at35Nessuna valutazione finora

- Technical Specification For Level GaugesDocumento6 pagineTechnical Specification For Level Gaugesat35100% (1)

- Aipmt Counselling ProcedureDocumento19 pagineAipmt Counselling ProcedureFirdosh KhanNessuna valutazione finora

- Btech Merit 1516Documento103 pagineBtech Merit 1516at35Nessuna valutazione finora

- Allot List p4Documento42 pagineAllot List p4at35Nessuna valutazione finora

- Sizing The DOL Motor Starter PartsDocumento4 pagineSizing The DOL Motor Starter Partsat35Nessuna valutazione finora

- Sources and Contributors To Short Circuit CurrentDocumento2 pagineSources and Contributors To Short Circuit Currentat35Nessuna valutazione finora

- R - Monthly-09-2014 PDFDocumento17 pagineR - Monthly-09-2014 PDFat35Nessuna valutazione finora

- Admitted List 17-7-2015Documento35 pagineAdmitted List 17-7-2015BhojNessuna valutazione finora

- Maintenance Management of Electrical Equipment Condition Monitoring Based Part 3Documento4 pagineMaintenance Management of Electrical Equipment Condition Monitoring Based Part 3at35Nessuna valutazione finora

- Site Selection Considerations For The Future Power SubstationDocumento2 pagineSite Selection Considerations For The Future Power Substationat35Nessuna valutazione finora

- 6 Simple Rules To Ensure Substation SafetyDocumento3 pagine6 Simple Rules To Ensure Substation Safetyat35Nessuna valutazione finora

- Working Principle of Thermal Motor Protection RelayDocumento2 pagineWorking Principle of Thermal Motor Protection Relayat35Nessuna valutazione finora

- 6 Simple Rules To Ensure Substation SafetyDocumento3 pagine6 Simple Rules To Ensure Substation Safetyat35Nessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Smart House PDFDocumento19 pagineSmart House PDFPPPPRIYANKNessuna valutazione finora

- Generac Spec Sheet 9kw and 11kwDocumento6 pagineGenerac Spec Sheet 9kw and 11kwRichard WiksNessuna valutazione finora

- Red Seal Sample Examination Questions - Red Seal Construction Electrician PDFDocumento2 pagineRed Seal Sample Examination Questions - Red Seal Construction Electrician PDFlouiswang1964Nessuna valutazione finora

- Attom Mission Critical Power System BrochureDocumento20 pagineAttom Mission Critical Power System BrochurejuancanicNessuna valutazione finora

- Jawaban MGT BiayaDocumento9 pagineJawaban MGT BiayaRessa LiniNessuna valutazione finora

- AC-DC LCD TV Poower Architecture and LED Backlight PDFDocumento53 pagineAC-DC LCD TV Poower Architecture and LED Backlight PDFRun Mouth100% (3)

- Assignment SolutionDocumento3 pagineAssignment SolutionSuraj ChaudharyNessuna valutazione finora

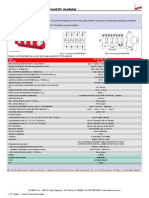

- EasyPact WATSN - NA06304VDocumento2 pagineEasyPact WATSN - NA06304VMulyana YNNessuna valutazione finora

- Wmo - 266 v1 enDocumento198 pagineWmo - 266 v1 enAcademia GustavoNessuna valutazione finora

- Fluence Solar + Storage White PaperDocumento8 pagineFluence Solar + Storage White PaperPovaSNessuna valutazione finora

- Engine Performance Data at 1500 RPM: QSK 1 Cummins IncDocumento4 pagineEngine Performance Data at 1500 RPM: QSK 1 Cummins IncBalariniRetífica100% (1)

- Tidal Power, Ocean Thermal Energy, & Geothermal Energy ConversionDocumento10 pagineTidal Power, Ocean Thermal Energy, & Geothermal Energy ConversionMohammed AnsafNessuna valutazione finora

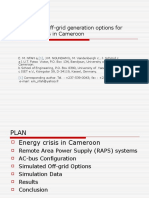

- Off-Grid Generation Options For CameroonDocumento18 pagineOff-Grid Generation Options For CameroonkashifNessuna valutazione finora

- Dehn DV M TNS 255Documento1 paginaDehn DV M TNS 255jaapaap77Nessuna valutazione finora

- Samsung VRF HEAT PUMP - AM100AXVANH - TL - Samsung Business IndiaDocumento4 pagineSamsung VRF HEAT PUMP - AM100AXVANH - TL - Samsung Business Indiachandravadiyaketan1504Nessuna valutazione finora

- FusionDocumento2 pagineFusionNavneet KaliaNessuna valutazione finora

- System Comparison (Presentation 2)Documento25 pagineSystem Comparison (Presentation 2)dreamst4r100% (1)

- Charging System TestingDocumento16 pagineCharging System Testingrodrig15100% (1)

- NH3 New KBR Process For Coal To AmmoniaDocumento13 pagineNH3 New KBR Process For Coal To AmmoniaVăn Đại - BKHN100% (2)

- Hydrogen and Fuel Cells: Opportunities For Growth: A Roadmap For The UKDocumento55 pagineHydrogen and Fuel Cells: Opportunities For Growth: A Roadmap For The UKMeredith GreyNessuna valutazione finora

- Study of Customer Perception Towards Electric VehiclesDocumento46 pagineStudy of Customer Perception Towards Electric Vehiclessistla.suneetha100% (1)

- Deep Sea 5310 Training MaterialDocumento43 pagineDeep Sea 5310 Training MaterialAhmed AbdullahNessuna valutazione finora

- Abb VFD Acs880Documento228 pagineAbb VFD Acs880Raj EngineerNessuna valutazione finora

- Industrial Range Sincro PDFDocumento6 pagineIndustrial Range Sincro PDFHalit YalçınkayaNessuna valutazione finora

- Soal PISA Fisika (2016-2017)Documento14 pagineSoal PISA Fisika (2016-2017)Didik SetyawarnoNessuna valutazione finora

- Auxiliary Boiler Construction Details: BY Mohammed Arif M Mechanical Engineer 41256Documento81 pagineAuxiliary Boiler Construction Details: BY Mohammed Arif M Mechanical Engineer 41256Arif MechanicalNessuna valutazione finora

- Simulatingcombinedcyclegasturbinepowerplantsin Aspen HYSYSDocumento14 pagineSimulatingcombinedcyclegasturbinepowerplantsin Aspen HYSYSJessica Del Carmen Parra MercadoNessuna valutazione finora

- Ec PBL FinalDocumento11 pagineEc PBL FinalAli Shan AhmadNessuna valutazione finora

- Energy Company Balance Scorecard ExampleDocumento13 pagineEnergy Company Balance Scorecard ExampleIan Liu100% (1)