Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Validation of Mixer Double Cone Blender

Caricato da

Syed Rizvi0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

161 visualizzazioni6 pagine- to prepare validation protocol of a mixer and perform its validation of mixing performance wit respect to low dose dr!g"

Descrizione originale:

Titolo originale

124483723 Validation of Mixer Double Cone Blender

Copyright

© © All Rights Reserved

Formati disponibili

DOC, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documento- to prepare validation protocol of a mixer and perform its validation of mixing performance wit respect to low dose dr!g"

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

161 visualizzazioni6 pagineValidation of Mixer Double Cone Blender

Caricato da

Syed Rizvi- to prepare validation protocol of a mixer and perform its validation of mixing performance wit respect to low dose dr!g"

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 6

PRACTICAL PROTOCOL

Roll no- 23 Pages -

Aim :- To prepare validation protocol of a mixer and perform its validation of mixing

performance wit respect to low dose dr!g"

P!rpose :-

#$ Red!ction of %!alit& cost"

2$ Process validation"

3$ Ass!rance of %!alit& and safet&"

References :-

#$ Lac'man" L ( Li)erman *Te teor& and practice of ind!strial parmac& (+

,argese p!)lication page no" #-2-"

2$ Potdar A". *Parmace!tical /!alit& Ass!rance (+ 2--0 1irali p!)lication

page no" 2"32"

3$ 4aider 5"I *,alidation standard operating proced!re (+second edition page no

363-366"

Re%!irements :-

#$ Cemicals-

5r" 1o 1ame of Cemical /!antit& Ta'en

# Calci!m car)onate 7CaCo3$ #--gm

2 Potassi!m paramagnet 78m1o3$ #gm

3 Cr&stal violet

2$ 9lasswares -

5r " 1o 1ame Of 9lassware Capacit& /!antit&

# ,ials #- ml #-

2 5tirrer ----- -#

3 :ea'er #--ml -2

3 ,ol!metric flas' #--ml -#

6 ,ol!metric flas' #-ml -6

3$ Instr!ments ;

5r" 1o 1ame of Instr!ment .odel .a'e

# Colo!rimeter Potocal -<62 =%!ip-tronics

2 >o!)le cone )lender

Teor& :-

,alidation :-

A doc!mented programmed wic provides a ig degree of ass!rance tat specific

processes will consistenc& prod!ce a prod!ct meeting its predetermined specification

and %!alit& attri)!tes"

Importance of validation

#$ Red!ction of %!alit& cost"

2$ Process validation"

3$ Ass!rance of %!alit& and safet&"

.ixing :-

A process tat tends to res!lt in a randomi?ation of dissimilar particles ( witin a

s&stem or to p!t togeter in one mass or assem)lage wit more or less tro!g

diff!sion of te constit!ent elements among one anoter"

.ecanisms of mixing

#$ >iff!sion :- random action of individ!al particles in te mixer"

2$ Convection :- transfer of ad@acent particles gro!ps in te mixt!re "

3$ 5ear :- config!ration cange tro!g slip planes"

A$ =%!ipments !sed for mixing :- 7powder$

T!m)ler mixer

>o!)le cone )lender

Agitated powder mixer

Air mixer

:$ =%!ipments !sed for mixing :- 7li%!ids$

Propeller mixer

T!r)ine mixer

Paddle mixer

C$ =%!ipments !sed for mixing :- 7semisolid$

Triple roller mill

Agitator mixer

Planetar& mixer

>o!)le cone )lender :-

It is developed in an attempt to overcome some of te sortcoming of rotating

mixer" Te mixing of powder in do!)le cone )lender is d!e to t!m)ling and

searing action wit )lade " Te efficienc& of )lender depends mainl& on speed of

rotation "

Te rate of rotation so!ld )e optim!m wic depends !pon te si?e and sape of

t!m)ler as well as nat!re of material" Te common range is 3--#-- rpm"

Te material to )e )lended is loaded approximatel& 6--<-A of te total capacit&

of )lender " As te )lender rotates te material !ndergoes t!m)ling motion and mixes

te material"

Te do!)le cone )lender is an efficient design for mixing powder of difference

densities and is !sed mainl& for small %!antit& of powder"

Proced!re:- 7 Cali)ration c!rve of cr&stal violet $

#$ >issolve #-mg of cr&stal violet in # . 425O3 to prod!ce #--ml " 4eat te

sol!tion for 6-#-min 7!ntil )oil$"

2$ Cool te )ea'er sol!tion at room temp" and filter wit te elp of cotton pl!g

in f!nnel"

3$ Prepare dil!tion from te a)ove stoc' sol!tion #--mgBml to prod!ce conc"

#- CgBml and also prepare te 2(3(<(2(#- CgBml !sing #. 425O3"

3$ .eas!re te a)sor)ance on colorimeter"

O)servation Ta)le:-

Concentration A)sor)ance

2

3

<

2

#-

Proced!re :-

#$ Deig #--gm of CaCo3 and #gm of cr&stal violet and pass tem tro!g

sieve no <-"

2$ Load tose powder in do!)le cone )lender and note down te rpm of do!)le

cone )lender"

3$ Ta'e te samples from top( middle( and )ottom" >issolve tem in #-ml #.

425O3 in vials"

3$ Eilter it and meas!re te a)sor)ance !sing colorimeter"

6$ >etermine te conc" Fsing cali)ration c!rve and calc!late te std" deviation

of eac five interval( predict te optim!m time of mixing"

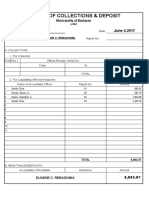

O)servation ta)le 7 I $ :-

5r" no Time Top .iddle :ottom

# 6

2 #-

3 #6

3 2-

6 26

< 3-

O)servation ta)le 7 II $ :-

5r" no Time Conc" Erom grap G dil" Eactor 7#--$ 5tandard

deviation Top .iddle :ottom mean

# 6

2 #-

3 #6

3 2-

6 26

< 3-

Res!lt :-

.ixing of cr&stal violet wit CaCO3 was carried o!t and validation parameter of

mixing were as )elow

5r" no Parameter .ixing metod 7 do!)le

cone )lender$

# i) CaCO3 #--gm

ii$ Cr&stal violet #gm

2 Optim!m mixing time

3 Conc" of optim!m time

5OP 1O -#23 =ffective date- ddBmmB&&

Approved )&- .r"a)c

Title - :lender 7 do!)le cone $

A!tor - 1ame B title B department

5ign date

Cec'ed )& - 1ame B title B department

5ign date

Approved )& - 1ame B title B department

5ign date

Revisions :-

5r" no 5ection Pages Initials B date

5OP 1O -#23 =ffective date- ddBmmB&&

Approved )&- .r"a)c

5!)@ect :- :lender 7 do!)le cone $

P!rpose:-

To descri)e te proced!re for validation of )lender to ens!re tat it meets installation(

operational( and performance %!alification re%!irements"

Responsi)ilit& :-

It is te responsi)ilit& of te prod!ction manager and tecnical services manager to

follow te proced!re" Te %!alit& ass!rance manager is responsi)le for 5OP

compliance"

Proced!re :-

#" ,erif& approved p!rcase order

2" ,erif& invoice

3" Cec' man!fact!rer and s!pplier

3" ,erif& model n!m)er and serial n!m)er

6" Cec' for an& p&sical damage

<" Confirm location and installation re%!irements per recommendation of

man!fact!rer"

0" ,erif& tat te re%!ired !tilities are availa)le

2" Installation sall )e cond!cted per instr!ction provided in te man!al"

H" =ns!re tat all relevant doc!mentation is received

i$ Fser man!al

ii$ .aintenance man!al

iii$ List of cange parts

iv$ =lectrical drawing

v$ .ecanical drawing

Potrebbero piacerti anche

- Multifuge X3R Centrifuge - User ManualDocumento59 pagineMultifuge X3R Centrifuge - User ManualIndika PitonoNessuna valutazione finora

- Limites Microbianos Por PoissonDocumento10 pagineLimites Microbianos Por PoissonJavier GalvanNessuna valutazione finora

- CalibrationDocumento5 pagineCalibrationMonika KshNessuna valutazione finora

- 1 - Fluoroscopy-36063022Documento6 pagine1 - Fluoroscopy-36063022Sinta Dewi P.Nessuna valutazione finora

- Aka GMP Audit FormDocumento8 pagineAka GMP Audit FormAlpian BosixNessuna valutazione finora

- Multifuge 3S CentrifugeDocumento16 pagineMultifuge 3S CentrifugeLEO AROKYA DASS ANessuna valutazione finora

- Hold Time Study Protocol OF Cleaned Manufacturing Equipment Awaiting For UseDocumento11 pagineHold Time Study Protocol OF Cleaned Manufacturing Equipment Awaiting For UseMarwa AhmedNessuna valutazione finora

- Forced DegradationDocumento8 pagineForced DegradationBiyaya San PedroNessuna valutazione finora

- Transport of CellsDocumento20 pagineTransport of CellsshneetsNessuna valutazione finora

- HPLC Verification - Pic Added &shortendDocumento40 pagineHPLC Verification - Pic Added &shortendMD Fahad MiajiNessuna valutazione finora

- ValidationDocumento3 pagineValidationAamerMAhmadNessuna valutazione finora

- IVT Network - Incorporate Domestic and International Regulations For Effective GMP Auditing - 2013-08-20Documento3 pagineIVT Network - Incorporate Domestic and International Regulations For Effective GMP Auditing - 2013-08-20huykhiemNessuna valutazione finora

- Cream & Ointment Process ValidationDocumento3 pagineCream & Ointment Process Validationtajmir haqueNessuna valutazione finora

- Professional SummaryDocumento3 pagineProfessional SummaryVijay LS SolutionsNessuna valutazione finora

- Brexpiprazole - Chem RevDocumento112 pagineBrexpiprazole - Chem RevSam SonNessuna valutazione finora

- Put Your Continued Process VerificationDocumento9 paginePut Your Continued Process VerificationMinh LeNessuna valutazione finora

- Lecture 9 - QAQC PDFDocumento37 pagineLecture 9 - QAQC PDFTMTNessuna valutazione finora

- Chinna Nagamalleswara Reddy Alla: SummaryDocumento5 pagineChinna Nagamalleswara Reddy Alla: SummaryVijay LS SolutionsNessuna valutazione finora

- Documentation Required For Periodic GMP Compliance Inspection Annex 1 JPDocumento5 pagineDocumentation Required For Periodic GMP Compliance Inspection Annex 1 JPspam_discardNessuna valutazione finora

- Canada Health Auth Draft Validation Guide GUI 0029 en For Comment 20 Nov 2018 1Documento34 pagineCanada Health Auth Draft Validation Guide GUI 0029 en For Comment 20 Nov 2018 1atulbsNessuna valutazione finora

- 03 - Revised MOS - AIR BALANCINGDocumento8 pagine03 - Revised MOS - AIR BALANCINGEditor EditorNessuna valutazione finora

- LabX Bro eDocumento12 pagineLabX Bro eWalter BurtonNessuna valutazione finora

- Analytical Method Validation ModuleDocumento60 pagineAnalytical Method Validation ModuleGaoussou TimitéNessuna valutazione finora

- Temperature Mapping Protocol For RM QuarantineDocumento20 pagineTemperature Mapping Protocol For RM Quarantinemehrdarou.qaNessuna valutazione finora

- Scope of Work Qualificatin & ValidationDocumento8 pagineScope of Work Qualificatin & ValidationPerdana Mandiri TekindoNessuna valutazione finora

- FOB2-3 TS - Technical Manual - Section 2 - Installation SpecificationsDocumento10 pagineFOB2-3 TS - Technical Manual - Section 2 - Installation SpecificationsmaghraouiNessuna valutazione finora

- IPQA A Beginner's GuideDocumento170 pagineIPQA A Beginner's GuideGoran MickoNessuna valutazione finora

- URS Contents: Blank TemplateDocumento11 pagineURS Contents: Blank TemplateBREWSKI100% (1)

- Quality by Design For Biotechnology Products-Part 2 - Process Development ForumDocumento7 pagineQuality by Design For Biotechnology Products-Part 2 - Process Development ForumGyro9Nessuna valutazione finora

- Non Destructive Container Closure Integrity Testing PDFDocumento40 pagineNon Destructive Container Closure Integrity Testing PDFChang Woo JongNessuna valutazione finora

- Cleaning Validation Approach 1Documento19 pagineCleaning Validation Approach 1Dharmesh PatelNessuna valutazione finora

- Handling of Out of Specification Results: International Journal of Pharmaceutical Quality Assurance April 2015Documento8 pagineHandling of Out of Specification Results: International Journal of Pharmaceutical Quality Assurance April 2015Pavana KharwalNessuna valutazione finora

- EMA - Reflection Paper For Laboratories That Perform The Analysis or Evaluation of Clinical Trial SamplesDocumento19 pagineEMA - Reflection Paper For Laboratories That Perform The Analysis or Evaluation of Clinical Trial Samplesrpg1973Nessuna valutazione finora

- An Inside Look at USP71Documento22 pagineAn Inside Look at USP71Dante IulliNessuna valutazione finora

- Cleaning Validation Boot CampDocumento7 pagineCleaning Validation Boot Campramin_47Nessuna valutazione finora

- Generation and Validation of Standard Operating Procedure For Dissolution ApparatusDocumento18 pagineGeneration and Validation of Standard Operating Procedure For Dissolution ApparatusAbhishek JhaNessuna valutazione finora

- ANDADocumento12 pagineANDAManish NangaliaNessuna valutazione finora

- Process Validation From An FDA Perspective - Part 2Documento4 pagineProcess Validation From An FDA Perspective - Part 2Darren Tan100% (1)

- Why The Swab Matters in Cleaning ValidationDocumento3 pagineWhy The Swab Matters in Cleaning ValidationYehuda Rahmanu PuteraNessuna valutazione finora

- 2015-10 - Annex15 Qualification & ValidationDocumento16 pagine2015-10 - Annex15 Qualification & ValidationDarshan PatelNessuna valutazione finora

- Rota 940 - OqDocumento39 pagineRota 940 - Oqsamar elrobyNessuna valutazione finora

- Validation PDFDocumento8 pagineValidation PDFJoanne De JoyaNessuna valutazione finora

- IVT Network - 4 Indispensable Pre-Inspection Actions - 2014-02-27Documento2 pagineIVT Network - 4 Indispensable Pre-Inspection Actions - 2014-02-27Mohammed YousffiNessuna valutazione finora

- Issuance of DocumentsDocumento2 pagineIssuance of DocumentsAshok KumarNessuna valutazione finora

- Lotus: Red Pharmtech Private LimitedDocumento52 pagineLotus: Red Pharmtech Private LimitedprakashNessuna valutazione finora

- ПЕТ Центар- Производство и Контрола На Квалитет- Е. ЈанеевиќDocumento30 pagineПЕТ Центар- Производство и Контрола На Квалитет- Е. ЈанеевиќEmilija Janevik100% (1)

- ANDA Impurities GuidanceDocumento11 pagineANDA Impurities GuidanceFDA Lawyers BlogNessuna valutazione finora

- MHL-VLP-XX Fumigation ValidationDocumento10 pagineMHL-VLP-XX Fumigation ValidationMedicare Hygiene LimitedNessuna valutazione finora

- Pharmaceutical Preformulation and FormulationDocumento10 paginePharmaceutical Preformulation and FormulationPrashansa ShresthaNessuna valutazione finora

- A Final Floor Show For Bugs (Sandle)Documento4 pagineA Final Floor Show For Bugs (Sandle)Tim Sandle100% (1)

- BPOG's ProtocolDocumento11 pagineBPOG's ProtocolRadha Krishna B VNessuna valutazione finora

- Dossier Common Technical Document CTD Index: (Sample Document Will Provide On Request)Documento6 pagineDossier Common Technical Document CTD Index: (Sample Document Will Provide On Request)Karem EladweyNessuna valutazione finora

- Headspace Oxygen Measurement in Vials and AmpoulesDocumento4 pagineHeadspace Oxygen Measurement in Vials and AmpoulesGhanta Ranjith KumarNessuna valutazione finora

- EDQM PAT Proceedings, 2004Documento141 pagineEDQM PAT Proceedings, 2004huynhhaichauchauNessuna valutazione finora

- WP Gmp-En AnshDocumento12 pagineWP Gmp-En AnshFelix ShihNessuna valutazione finora

- Monitoring Environmental Parameters of Incubators, Fridge-Freezers QC-05-05 EPADocumento17 pagineMonitoring Environmental Parameters of Incubators, Fridge-Freezers QC-05-05 EPAAna M VrrNessuna valutazione finora

- Cleaning and Cleaning Validation PDFDocumento6 pagineCleaning and Cleaning Validation PDFedgar palominoNessuna valutazione finora

- Data Integrity and Compliance: A Primer for Medical Product ManufacturersDa EverandData Integrity and Compliance: A Primer for Medical Product ManufacturersNessuna valutazione finora

- 3.01 Sugar - ICUMSA ColorDocumento2 pagine3.01 Sugar - ICUMSA ColorSyed RizviNessuna valutazione finora

- 07-1004RD 07-1004RD B B: Scientific Systems IncDocumento1 pagina07-1004RD 07-1004RD B B: Scientific Systems IncSyed RizviNessuna valutazione finora

- Distek 2100CDocumento2 pagineDistek 2100CSyed RizviNessuna valutazione finora

- 07-1005RD 07-1005RD B B: Scientific Systems IncDocumento1 pagina07-1005RD 07-1005RD B B: Scientific Systems IncSyed RizviNessuna valutazione finora

- Openlab Cds Ezchrom Edition A 04 05 Fds 11752Documento38 pagineOpenlab Cds Ezchrom Edition A 04 05 Fds 11752Syed RizviNessuna valutazione finora

- HT-300 - 500 Vesion 1 Calibration ProcedureDocumento4 pagineHT-300 - 500 Vesion 1 Calibration ProcedureSyed RizviNessuna valutazione finora

- Operating Instructions METTLER TOLEDO Karl Fischer Titrator DL35Documento55 pagineOperating Instructions METTLER TOLEDO Karl Fischer Titrator DL35Syed RizviNessuna valutazione finora

- Abbe Mat 200Documento2 pagineAbbe Mat 200Syed RizviNessuna valutazione finora

- Dextran Measurement Spectrophotometric MethodDocumento2 pagineDextran Measurement Spectrophotometric MethodSyed RizviNessuna valutazione finora

- Holding Time Sample ContainersDocumento3 pagineHolding Time Sample ContainersSyed RizviNessuna valutazione finora

- 2005 HPLC BrochureDocumento2 pagine2005 HPLC BrochureSyed RizviNessuna valutazione finora

- UV Detector L-2400 UV-Visible Detector L-2420 Diode Array Detector L-2450Documento4 pagineUV Detector L-2400 UV-Visible Detector L-2420 Diode Array Detector L-2450Syed RizviNessuna valutazione finora

- Fully Automatic Determination of Organic Additives in Electroplating Baths With CVSDocumento4 pagineFully Automatic Determination of Organic Additives in Electroplating Baths With CVSSyed RizviNessuna valutazione finora

- HI2213Documento2 pagineHI2213Syed RizviNessuna valutazione finora

- C D D - 1 0 A: Shimadzu Conductivity Detector For HPLC SystemDocumento2 pagineC D D - 1 0 A: Shimadzu Conductivity Detector For HPLC SystemSyed RizviNessuna valutazione finora

- MSDS Potassium DichromateDocumento8 pagineMSDS Potassium DichromateAyu Lakshemini OkaNessuna valutazione finora

- Mindset For IELTS Level 1 Student's Book PDF English As A Second or Foreign Language International English Language TestinDocumento1 paginaMindset For IELTS Level 1 Student's Book PDF English As A Second or Foreign Language International English Language TestinhiNessuna valutazione finora

- Pit Viper 351Documento6 paginePit Viper 351Sebastian Robles100% (2)

- Dragon Ball Z Project: R1 and R2J Dragon Boxes Merge: AcknowledgementsDocumento11 pagineDragon Ball Z Project: R1 and R2J Dragon Boxes Merge: Acknowledgements8ASergio GamarraNessuna valutazione finora

- Triangular Short Crested Weir. Local Geometry ? Discharge CoefficientsDocumento7 pagineTriangular Short Crested Weir. Local Geometry ? Discharge CoefficientsTI Journals PublishingNessuna valutazione finora

- Internal Audit, Compliance& Ethics and Risk Management: Section 1) 1.1)Documento6 pagineInternal Audit, Compliance& Ethics and Risk Management: Section 1) 1.1)Noora Al ShehhiNessuna valutazione finora

- Pipe Support Reference 8-29-14Documento108 paginePipe Support Reference 8-29-14HITESHNessuna valutazione finora

- SolutionsManual NewDocumento123 pagineSolutionsManual NewManoj SinghNessuna valutazione finora

- Subject-Verb AgreementDocumento10 pagineSubject-Verb AgreementLouie Jay Cañada AbarquezNessuna valutazione finora

- RCD - SEF (Liquidating)Documento40 pagineRCD - SEF (Liquidating)Chie NemzNessuna valutazione finora

- Jesoc5 1 PDFDocumento15 pagineJesoc5 1 PDFfaisal3096Nessuna valutazione finora

- D2 1 PDFDocumento148 pagineD2 1 PDFsubas khanalNessuna valutazione finora

- Board Resolution On Assigning Signatories in The Voucher ProgramDocumento2 pagineBoard Resolution On Assigning Signatories in The Voucher ProgramavinmanzanoNessuna valutazione finora

- 02b. POS Learn ModuleDocumento7 pagine02b. POS Learn ModuleKUHINJANessuna valutazione finora

- Air Defence Systems: Export CatalogueDocumento105 pagineAir Defence Systems: Export CatalogueserrorysNessuna valutazione finora

- Phil. Hist. SyllabusDocumento7 paginePhil. Hist. SyllabusCarl Angelo MartinNessuna valutazione finora

- Republic V Mangotara DigestDocumento3 pagineRepublic V Mangotara DigestMickey Ortega100% (1)

- Prishusingh Blogspot Com 2024 03 Digital-Marketing-Course HTMLDocumento12 paginePrishusingh Blogspot Com 2024 03 Digital-Marketing-Course HTMLsudharaj86038Nessuna valutazione finora

- Principles of Public ExpenditureDocumento1 paginaPrinciples of Public ExpenditureNikhil Shenai100% (1)

- Tle7 Ict TD M2 V3Documento28 pagineTle7 Ict TD M2 V3Rowemar Corpuz100% (1)

- Specification For Neoprene Coating On The Riser CasingDocumento17 pagineSpecification For Neoprene Coating On The Riser CasingLambang AsmaraNessuna valutazione finora

- EEE Sofware Lab Experiment 1, PDFDocumento11 pagineEEE Sofware Lab Experiment 1, PDF240 Sadman ShafiNessuna valutazione finora

- The Complete Guide To Installing The 44 Split Defense PDFDocumento171 pagineThe Complete Guide To Installing The 44 Split Defense PDFsaid100% (1)

- Canon JX 500 - 200 - Service ManualDocumento154 pagineCanon JX 500 - 200 - Service ManualFritz BukowskyNessuna valutazione finora

- Resume Of: Name: Kingshuk Saha Address: Mobile: E-MailDocumento2 pagineResume Of: Name: Kingshuk Saha Address: Mobile: E-MailKingshuk Saha PalasNessuna valutazione finora

- Smartpilot s1 s1g Service ManualDocumento30 pagineSmartpilot s1 s1g Service Manualmalte winbaldNessuna valutazione finora

- Pulsating Heat Pipe ReportDocumento65 paginePulsating Heat Pipe ReportIdul Azharul HoqueNessuna valutazione finora

- Case For Overhead and DistributionDocumento2 pagineCase For Overhead and DistributionBhargav D.S.Nessuna valutazione finora

- Particle FilterDocumento16 pagineParticle Filterlevin696Nessuna valutazione finora

- Battle Cry Zulu WarDocumento4 pagineBattle Cry Zulu WarPat RisNessuna valutazione finora