Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

AL-KOmatic AL-KOmatic Service Handbook

Caricato da

vali_monroe100%(1)Il 100% ha trovato utile questo documento (1 voto)

951 visualizzazioni72 pagineThis document appears to be a service manual or handbook for AL-KOmatic caravan/trailer chassis. It contains warnings and cautions about safely operating, maintaining and servicing the chassis. The document provides descriptions of the chassis components and their operation. It also outlines recommended maintenance and service procedures, including inspecting wheels and brakes, lubricating parts, and storing the caravan/trailer. Spare parts ordering information and troubleshooting guides are included as well.

Descrizione originale:

AL-KO Automatic Reversing System Operation Manual

Titolo originale

AL-KO Automatic Reversing System Operation Manual

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document appears to be a service manual or handbook for AL-KOmatic caravan/trailer chassis. It contains warnings and cautions about safely operating, maintaining and servicing the chassis. The document provides descriptions of the chassis components and their operation. It also outlines recommended maintenance and service procedures, including inspecting wheels and brakes, lubricating parts, and storing the caravan/trailer. Spare parts ordering information and troubleshooting guides are included as well.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

951 visualizzazioni72 pagineAL-KOmatic AL-KOmatic Service Handbook

Caricato da

vali_monroeThis document appears to be a service manual or handbook for AL-KOmatic caravan/trailer chassis. It contains warnings and cautions about safely operating, maintaining and servicing the chassis. The document provides descriptions of the chassis components and their operation. It also outlines recommended maintenance and service procedures, including inspecting wheels and brakes, lubricating parts, and storing the caravan/trailer. Spare parts ordering information and troubleshooting guides are included as well.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 72

AL-KOmatic AL-KOmatic

AL-KOmatic AL-KOmatic AL-KOmatic

Handbookincluding

ServiceInstructionsandSparePartslist

AL-KOchassisfittedwiththeautomaticreversingsystem

Part No. Part No. Part No. Part No. Part No.

NOTE: Do to the age of this hand- NOTE: Do to the age of this hand- NOTE: Do to the age of this hand- NOTE: Do to the age of this hand- NOTE: Do to the age of this hand-

book, it may not be complete; there book, it may not be complete; there book, it may not be complete; there book, it may not be complete; there book, it may not be complete; there

are several drawings missing and are several drawings missing and are several drawings missing and are several drawings missing and are several drawings missing and

some may have hand-written marks. some may have hand-written marks. some may have hand-written marks. some may have hand-written marks. some may have hand-written marks.

Please use as a reference guide only. Please use as a reference guide only. Please use as a reference guide only. Please use as a reference guide only. Please use as a reference guide only.

AL-KOWARRANTY AL-KOWARRANTY AL-KOWARRANTY AL-KOWARRANTY AL-KOWARRANTY

WARRANTY WARRANTY WARRANTY WARRANTY WARRANTY

The Company's products are supplied with a 12-month warranty against faulty materials or workmanship which is operative from

thedatetheproductwasdeliveredtotheuser.Anyrequestforserviceunderthiswarrantymustbeaddressedtothesupplierfrom

whom the product was purchased.

CONDITIONS CONDITIONS CONDITIONS CONDITIONS CONDITIONS

(a) Thewarrantyappliestotheoriginalpurchaseroftheproductandisnottransferable.

(b) TheliabilityofAL-KOKoberLtdislimitedtothecostofrepairorreplacementattheCompany'sdiscretionofthefaultyitem

withinthewarrantyperiod.Repairsorreplacementunderthewarrantydonotextendtheperiodofvalidity.

(c) Ifanyproductisreturnedunderwarrantyandfoundtocomplywiththerelevantspecificationorstandard,thenthecostofany

testingandcarriagetoandfromtheCompanywillbebornebytheCustomer.

(d) This warranty does not cover fair wear and tear, accident, misuse, overloading, incorrect installation or storage, unauthorised

repair or adjustment. Where recommended routine servicing, as set out in the Company's handbook, applies to the product

withinthewarrantyperiod,failuretoundertakesuchservicingwillinvalidatethewarranty.

(e) All warranties will be invalidated if unauthorised repairs are made to the product.

(f) Reasonable evidence of date of purchase must be produced whenever service under this warranty is requested. In the case

of caravans and trailer chassis, serial numbers and axle details are required.

(g) Nosupplier,dealerorservicecentrehasanyauthoritytovarythetermsofthisguarantee.

(h) Thiswarrantydoesnotaffectthepurchaser'sstatutoryrights.

LISTOFCONTENTS LISTOFCONTENTS LISTOFCONTENTS LISTOFCONTENTS LISTOFCONTENTS

1 11 11

Page

2.5 Inspecting/changing the

wheels 31

2.6 Examine and lubricate the

coupling head 33

2.7 Examine and lubricate the

overrun assembly 33

2.8 Lubricatethejockeywheel 34

2.9 Lubricate the brake linkage 34

2.10 Lubricate the corner

steadies 34

2.11 Servicethebattery 34

2.12 Measure the towing ball 35

2.13 Servicingafteruse 35

2.14 Check the brake linings and

pull-off springs for wear or

fatigue 36

2.15 Visualaxlecheck 36

2.16 Sub section content 37

2.17 Change an overrun damper

ontypes161S/251S 37

2.18 Change an overrun damper

ontypes60S-2/90S-3 39

2.19 Storingyourcaravan/trailer 40

Page

SECTION3 SECTION3 SECTION3 SECTION3 SECTION3

ORDERINGSPARES ORDERINGSPARES ORDERINGSPARES ORDERINGSPARES ORDERINGSPARES 41

SECTION4 SECTION4 SECTION4 SECTION4 SECTION4

ILLUSTRATEDPARTSLIST ILLUSTRATEDPARTSLIST ILLUSTRATEDPARTSLIST ILLUSTRATEDPARTSLIST ILLUSTRATEDPARTSLIST 49

SECTION5 SECTION5 SECTION5 SECTION5 SECTION5

FAULTFINDING FAULTFINDING FAULTFINDING FAULTFINDING FAULTFINDING 63

SECTION6 SECTION6 SECTION6 SECTION6 SECTION6

INDEX INDEX INDEX INDEX INDEX 67

LISTOFCONTENTS LISTOFCONTENTS LISTOFCONTENTS LISTOFCONTENTS LISTOFCONTENTS

Page

WARNINGSANDCAUTIONS WARNINGSANDCAUTIONS WARNINGSANDCAUTIONS WARNINGSANDCAUTIONS WARNINGSANDCAUTIONS 2

INTRODUCTION INTRODUCTION INTRODUCTION INTRODUCTION INTRODUCTION 5

SECTION1 SECTION1 SECTION1 SECTION1 SECTION1

DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION

1.1 The chassis 7

1.2 Handling 8

1.3 Coupling head 10

1.4 Axle 13

1.5 Braking system 14

1.6 Wheels and tyres 21

1.7 Accessories 23

SECTION2 SECTION2 SECTION2 SECTION2 SECTION2

SERVICE&MAINTENANCE SERVICE&MAINTENANCE SERVICE&MAINTENANCE SERVICE&MAINTENANCE SERVICE&MAINTENANCE

2.1 Servicing philosophy 26

2.2 Servicing schedule 26

2.3 Jackingupthecaravan/

trailer 27

2.4 Check and adjust brake

shoes and brake linkage 28

Towing ball Towing ball Towing ball Towing ball Towing ball

A worn ball should be renewed without

delay.

Do not grease the tow ball when using

the AKS 2000 stabiliser.

Wheels and tyres Wheels and tyres Wheels and tyres Wheels and tyres Wheels and tyres

Itisverydangeroustoneglecttyre

damage.Atyreshouldberenewedifa

blister,ruptureorcutexposingthe

casingisdetected.Ifthetyrehas

sufferedimpact(eg.againstakerb),it

should be examined by a specialist as

soon as possible.

Damaged or distorted wheels must be

renewed immediately.

Alwaysusethecorrectboltstosecure

the wheels.

The wheel bolt torque settings should

berecheckedafterthefirst20milesof

use,andevery3000milesthereafter.

Torque settings:

M12Wheelbolts,88Nm(65lb/ft)

M10Wheelbolts,49Nm(36lb/ft)

Caravan/trailer handling Caravan/trailer handling Caravan/trailer handling Caravan/trailer handling Caravan/trailer handling

Maximum gross weight, as advised by

the caravan/trailer manufacturer or

stamped on the axle data plate, must

notbeexceeded.

Thepermittedtrailernoseweightsofthe

coupling ball, towing ball coupling and

overrun assembly must never exceed

thatvaluestatedonthecouplinghead.A

low,negativeorexcessivecaravan/trailer

noseweightwilladverselyaffectthe

handlingoftheunit.

Incorrect loading is a major cause of

instability.

Coupling head Coupling head Coupling head Coupling head Coupling head

Couplingheadsshouldneverbedrilled.

Serious damage will occur unless the

lockingcatchisliftedfirstandthe

handle lifted forward before the

caravan/trailer is lifted manually. This

prevents the nose weight being

transmitted through the locking catch.

WARNINGSANDCAUTIONS WARNINGSANDCAUTIONS WARNINGSANDCAUTIONS WARNINGSANDCAUTIONS WARNINGSANDCAUTIONS

All Warnings, Cautions and Notes

usedinthishandbookaresetin BOLD BOLD BOLD BOLD BOLD

typeandmaybeupperorlowercase.

Warranty Warranty Warranty Warranty Warranty

AL-KO recommends that all servicing

andrepairsbecarriedoutbya

recognised dealer throughout the

periodcoveredbythewarranty.

Damage to the chassis caused by an

incorrectlymountedbodyorbythe

body itself will negate the terms of the

warranty. Unauthorised or poorly

executedworkcarriedoutonthe

chassiswillalsorenderthetermsofthe

warrantynullandvoid.

Unauthorised holes must not be drilled

intothechassisasthiswillinvalidatethe

warranty.

No unauthorised parts to be welded or

bolted to the chassis.

If damaged, chassis members must be

replaced not repaired or welded.

WARNINGSANDCAUTIONS WARNINGSANDCAUTIONS WARNINGSANDCAUTIONS WARNINGSANDCAUTIONS WARNINGSANDCAUTIONS

2 22 22

Brakes Brakes Brakes Brakes Brakes

Always chock the wheels when

parking the caravan/trailer on sloping,

loose or slippery surfaces.

Whenparkingthecaravan/trailerthe

handbrake must be fully applied to the

lasttooth(i.e.vertical).Ifitisnotand

thecaravan/trailerisparkedona

reverse slope the brakes will not hold

andthecaravan/trailerwillrunaway.

Itisabsolutelyvitalthataslight

backwards push of the caravan/trailer

is applied before it is uncoupled from

thetowingunit.

Itisalsoimportanttocheckthatthe

brakehasinfactoperatedcorrectlyas

soon as the caravan/trailer has been

uncoupled.

Always ensure that the handbrake

leverisinthefullyverticalposition.

When the handbrake has been

applied, it is possible for the caravan/

trailer to roll back as much as 25cm

beforethefullforceofthebraketakes

effect.

Brake adjustment Brake adjustment Brake adjustment Brake adjustment Brake adjustment

The brake hub must be adjusted first

andthenifnecessarythebrake

linkage.

During wheel brake adjustment, the

drummustonlybeturnedinthe

directionofforwardrotation.

Do not use excessive force during

adjustment.

Reversingwillbedifficultifeitherthe

brake shoes or the brake linkage is

over-adjusted.

Jacking up the trailer Jacking up the trailer Jacking up the trailer Jacking up the trailer Jacking up the trailer

The corner steadies should never be

usedtojackupthetrailer.Theycanbe

loweredtotouchthegroundonlyasa

safety measure.

Never use the AL-KO chassis

members as jacking points.

Lubrication Lubrication Lubrication Lubrication Lubrication

ThefrictionpadsoftheAKS2000

stabiliser must not be contaminated

with grease during lubrication.

Spares Spares Spares Spares Spares

Allcomponentsofboththeoverrun

assembly and the wheel brakes must

bethosemanufacturedbyAL-KOas

the braking and reversing systems

must be matched to ensure optimum

braking performance.

Combining parts manufactured by

AL-KOwiththoseproducedbyother

suppliers may invalidate any guaran-

teeenteredintobyAL-KO.

WARNINGSANDCAUTIONS WARNINGSANDCAUTIONS WARNINGSANDCAUTIONS WARNINGSANDCAUTIONS WARNINGSANDCAUTIONS

3 33 33

4 44 44

INTRODUCTION INTRODUCTION INTRODUCTION INTRODUCTION INTRODUCTION

This handbook is designed to help

caravan/trailer users of the chassis to

towtheunitsafely.Thehandbookalso

supplies information to enable the

usertogiveallthecareandattention

necessary to maintain the reliability of

the chassis.

Thefirstsectionofthebookdetailsthe

correctprocedureforconnectingthe

chassis to the towing unit, loading the

towed unit, handling the combined

vehicle and applying the handbrake.

The second section outlines the

servicing philosophy and presents

detailed instructions for servicing

routines together with their

recommended interval.

Servicing should be carried out by an Servicing should be carried out by an Servicing should be carried out by an Servicing should be carried out by an Servicing should be carried out by an

authorised dealer throughout the authorised dealer throughout the authorised dealer throughout the authorised dealer throughout the authorised dealer throughout the

period covered by the chassis period covered by the chassis period covered by the chassis period covered by the chassis period covered by the chassis

warranty. warranty. warranty. warranty. warranty.

The second section also contains

sufficientinformationtocarryoutminor

repairs.

Thesecanbecarriedoutbythe

enthusiastic owner, providing he has

thecorrecttools,oryourdealerwill

undertaketheworkforyou.

All repairs should be carried out by All repairs should be carried out by All repairs should be carried out by All repairs should be carried out by All repairs should be carried out by

an authorised dealer throughout the an authorised dealer throughout the an authorised dealer throughout the an authorised dealer throughout the an authorised dealer throughout the

period covered by the chassis period covered by the chassis period covered by the chassis period covered by the chassis period covered by the chassis

warranty. warranty. warranty. warranty. warranty.

Thethirdandforthsectionsfacilitate

the identification and ordering of spare

parts.

Thefifthsectionofthehandbook

comprises a fault finding table which

details the fault, the possible cause

and remedial action.

The owner should carefully read this

handbook before attempting to

operate or maintain the vehicle and

shouldkeepithandyforreferenceas

required.

Chassis specifications may vary

according to market requirements

AL-KO'spolicyofcontinuously

improvingtheirproductmayinvolve

major or minor changes to the chas-

sis or its accessories. The manufac-

turerreservestherighttoalter

specifications, with or without prior

notice,atanytime.

Whilsteveryefforthasbeenmadeto

ensuretheaccuracyoftheinformation

contained within this handbook, no

liabilitycanbeacceptedbythe

manufacturer for incorrect use or

interpretation of this information.

Damage to the AL-KO chassis Damage to the AL-KO chassis Damage to the AL-KO chassis Damage to the AL-KO chassis Damage to the AL-KO chassis

caused by an incorrectly mounted caused by an incorrectly mounted caused by an incorrectly mounted caused by an incorrectly mounted caused by an incorrectly mounted

body or by the body itself will negate body or by the body itself will negate body or by the body itself will negate body or by the body itself will negate body or by the body itself will negate

the terms of the warranty. the terms of the warranty. the terms of the warranty. the terms of the warranty. the terms of the warranty.

Unauthorised or poorly executed Unauthorised or poorly executed Unauthorised or poorly executed Unauthorised or poorly executed Unauthorised or poorly executed

work carried out on the chassis will work carried out on the chassis will work carried out on the chassis will work carried out on the chassis will work carried out on the chassis will

also render the terms of the also render the terms of the also render the terms of the also render the terms of the also render the terms of the

warranty null and void. warranty null and void. warranty null and void. warranty null and void. warranty null and void.

5 55 55

INTRODUCTION INTRODUCTION INTRODUCTION INTRODUCTION INTRODUCTION

DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION

6 66 66

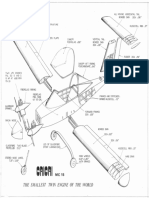

FIG.1CHASSIS FIG.1CHASSIS FIG.1CHASSIS FIG.1CHASSIS FIG.1CHASSIS

7 77 77

Manufacturedfromhighqualitysteel,

the chassis has extra deep sections

toprovidestrengthatpointsofmaxi-

mum stress. Chassis members are

hot dip galvanised for added protec-

tion.

Large elongated holes are located in

both main longitudinal and 'A' frame

members to reduce weight to a

minimum. Each hole incorporates a

return flange to maintain the required

SECTION1 SECTION1 SECTION1 SECTION1 SECTION1

DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION

1.1TheChassis(Fig.1) 1.1TheChassis(Fig.1) 1.1TheChassis(Fig.1) 1.1TheChassis(Fig.1) 1.1TheChassis(Fig.1)

General Information General Information General Information General Information General Information

The AL-KO lightweight chassis has

beenperfectedbymanyyearsof

research and development, supported

byanexhaustivetestprogramme.

strengthandtoproviderigidity.

Unauthorised holes must not be Unauthorised holes must not be Unauthorised holes must not be Unauthorised holes must not be Unauthorised holes must not be

drilled into the chassis as this will drilled into the chassis as this will drilled into the chassis as this will drilled into the chassis as this will drilled into the chassis as this will

invalidate the warranty. invalidate the warranty. invalidate the warranty. invalidate the warranty. invalidate the warranty.

Each AL-KO caravan/trailer chassis

hasasetofpunchedholesrearofthe

axletoenablefittingofanAL-KO

telescopic spare wheel carrier.

From1992eachAL-KOcaravan/trailer

chassis has a set of holes punched

behindtheaxletoenablethecaravan/

trailermanufacturertofittheAL-KO

side mounted caravan/trailer jack

outriggers.

DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION

1.2Handling 1.2Handling 1.2Handling 1.2Handling 1.2Handling

Strictattentionmustbepaidtothe

operating limitations when handling

thecaravan/trailer.Theseconcernthe

caravan/trailerjockeywheel,thenose

weight and loading.

Caravan/Trailer Jockey Wheel Caravan/Trailer Jockey Wheel Caravan/Trailer Jockey Wheel Caravan/Trailer Jockey Wheel Caravan/Trailer Jockey Wheel

(Fig.2,3,4) (Fig.2,3,4) (Fig.2,3,4) (Fig.2,3,4) (Fig.2,3,4)

Each chassis is provided with an

adjustable jockey wheel.

This can be clamped outboard or

inboardtoonememberofthe'A'frame

closetoitsapexordirectlytothe

overrun assembly respectively. The

jockey wheel provides stabilisation

andcanbefittedwithapneumaticor

solidtyre.

Before commencing a journey, the

caravan/trailer jockey wheel must be

cranked fully home to its stowage

stop,thenliftedclearoftheground

and secured with the clamp provided.

Caravan/Trailer Nose Weight Caravan/Trailer Nose Weight Caravan/Trailer Nose Weight Caravan/Trailer Nose Weight Caravan/Trailer Nose Weight

The caravan/trailer nose weight must

becheckedpriortothestartofany

journey.

The permitted nose weights of the The permitted nose weights of the The permitted nose weights of the The permitted nose weights of the The permitted nose weights of the

towbar coupling ball, towing ball towbar coupling ball, towing ball towbar coupling ball, towing ball towbar coupling ball, towing ball towbar coupling ball, towing ball

coupling and overrun assembly must coupling and overrun assembly must coupling and overrun assembly must coupling and overrun assembly must coupling and overrun assembly must

never exceed the lesser of these never exceed the lesser of these never exceed the lesser of these never exceed the lesser of these never exceed the lesser of these

nose weights. A low, negative or nose weights. A low, negative or nose weights. A low, negative or nose weights. A low, negative or nose weights. A low, negative or

excessive caravan/trailer nose excessive caravan/trailer nose excessive caravan/trailer nose excessive caravan/trailer nose excessive caravan/trailer nose

weight will adversely affect the weight will adversely affect the weight will adversely affect the weight will adversely affect the weight will adversely affect the

handling of the unit. handling of the unit. handling of the unit. handling of the unit. handling of the unit.

DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION

FIG.3 FIG.3 FIG.3 FIG.3 FIG.3 FIG.4 FIG.4 FIG.4 FIG.4 FIG.4 FIG.2 FIG.2 FIG.2 FIG.2 FIG.2

8 88 88

LoadOverAxle(Fig.7) LoadOverAxle(Fig.7) LoadOverAxle(Fig.7) LoadOverAxle(Fig.7) LoadOverAxle(Fig.7)

Optimum roadholding together with

maximum braking effect. Exceptionally

heavyloadsshouldbepackeddirectly

overtheaxle.

Attention should be paid to the legal Attention should be paid to the legal Attention should be paid to the legal Attention should be paid to the legal Attention should be paid to the legal

regulations regarding the permitted regulations regarding the permitted regulations regarding the permitted regulations regarding the permitted regulations regarding the permitted

pressure exerted by the towbar on pressure exerted by the towbar on pressure exerted by the towbar on pressure exerted by the towbar on pressure exerted by the towbar on

the towed unit. the towed unit. the towed unit. the towed unit. the towed unit.

Incorrect loading is a major cause of Incorrect loading is a major cause of Incorrect loading is a major cause of Incorrect loading is a major cause of Incorrect loading is a major cause of

instability. instability. instability. instability. instability.

FIG.6 FIG.6 FIG.6 FIG.6 FIG.6

FIG.5 FIG.5 FIG.5 FIG.5 FIG.5

FIG.7 FIG.7 FIG.7 FIG.7 FIG.7

DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION

9 99 99

Loading Loading Loading Loading Loading

Maximum gross weight, as advised Maximum gross weight, as advised Maximum gross weight, as advised Maximum gross weight, as advised Maximum gross weight, as advised

by the caravan/trailer manufacturer by the caravan/trailer manufacturer by the caravan/trailer manufacturer by the caravan/trailer manufacturer by the caravan/trailer manufacturer

or stamped on the axle plate, must or stamped on the axle plate, must or stamped on the axle plate, must or stamped on the axle plate, must or stamped on the axle plate, must

not be exceeded (see page 41). not be exceeded (see page 41). not be exceeded (see page 41). not be exceeded (see page 41). not be exceeded (see page 41).

LoadTooFarForward(Fig.5) LoadTooFarForward(Fig.5) LoadTooFarForward(Fig.5) LoadTooFarForward(Fig.5) LoadTooFarForward(Fig.5)

Steering and braking ability reduced.

Increased loading on the rear axle

and chassis of the towing vehicle

.LoadTooFarBack(Fig.6) LoadTooFarBack(Fig.6) LoadTooFarBack(Fig.6) LoadTooFarBack(Fig.6) LoadTooFarBack(Fig.6)

High skid risk together with poor

braking effect and poor handling.

1.3CouplingHead 1.3CouplingHead 1.3CouplingHead 1.3CouplingHead 1.3CouplingHead

Description Description Description Description Description

The coupling head is designed to

engage automatically with the

international 50mm towing ball

recommended by the following:

British Standards Institution

National Caravan Council

SocietyofMotorManufacturersand

Traders.

ISO

AL-KO coupling heads incorporate a

correct attachment indicator.

Coupling heads should never be Coupling heads should never be Coupling heads should never be Coupling heads should never be Coupling heads should never be

drilled. drilled. drilled. drilled. drilled.

AL-KOproduceseveraltypesof

coupling head each having provision

forananti-theftdeviceasanoptional

extrawhichconsistsofakeyoperated

brass insert. The anti-theft device

comes complete with two keys. Secur-

ing the coupling head inhibits move-

DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION

10 10 10 10 10

mentofthelockingcatchFig.8(7),

making it possible to lock the coupling

whetherornotthetowingballis

connected.

Operation Operation Operation Operation Operation

All coupling head types are designed

for one hand operation.

Coupling up-all types Coupling up-all types Coupling up-all types Coupling up-all types Coupling up-all types

Reversethecartothecaravan/trailer

ormovethecaravan/trailerforwardto

the coupling point.

AK10/2(Fig.8) AK10/2(Fig.8) AK10/2(Fig.8) AK10/2(Fig.8) AK10/2(Fig.8)

Liftthelockingcatch(7)onthelever

mechanism and lift the handle (5)

upwards and forward.

Place the unlocked coupling head

ontothetowingballandapplyslight

downward pressure. The head will

automaticallylockontotheball.

DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION

Ensurethatthelockingcatch(7)has

returned to its free position before

attemptingtotow.

The correct attachment indicator

should show green.

11 11 11 11 11

FIG.8 FIG.8 FIG.8 FIG.8 FIG.8

Connect the breakaway cable and

lightingplugtothetowingvehicle.

Raise the jockey wheel to its stowed

position.

Uncoupling - all types Uncoupling - all types Uncoupling - all types Uncoupling - all types Uncoupling - all types

Ensure the handbrake is fully applied.

Lowerthejockeywheeltotheground.

Disconnect the breakaway cable and

lighting plug.

Operatethehandleandlockingcatch,

then manually lift the coupling head

clearofthetowingballorraisethe

telescopicjockeywheeltoachievethe

same effect.

Serious damage will occur unless Serious damage will occur unless Serious damage will occur unless Serious damage will occur unless Serious damage will occur unless

the locking catch is operated first the locking catch is operated first the locking catch is operated first the locking catch is operated first the locking catch is operated first

and the handle raised forward before and the handle raised forward before and the handle raised forward before and the handle raised forward before and the handle raised forward before

the caravan/trailer is lifted manually the caravan/trailer is lifted manually the caravan/trailer is lifted manually the caravan/trailer is lifted manually the caravan/trailer is lifted manually.

This prevents the nose weight being This prevents the nose weight being This prevents the nose weight being This prevents the nose weight being This prevents the nose weight being

transmitted through the locking transmitted through the locking transmitted through the locking transmitted through the locking transmitted through the locking

catch. catch. catch. catch. catch.

The head coupling on the chassis The head coupling on the chassis The head coupling on the chassis The head coupling on the chassis The head coupling on the chassis

has been type tested; the maximum has been type tested; the maximum has been type tested; the maximum has been type tested; the maximum has been type tested; the maximum

support load at the coupling point support load at the coupling point support load at the coupling point support load at the coupling point support load at the coupling point

must not be exceeded. must not be exceeded. must not be exceeded. must not be exceeded. must not be exceeded.

DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION

12 12 12 12 12

1.4TheAxle(Fig.9) 1.4TheAxle(Fig.9) 1.4TheAxle(Fig.9) 1.4TheAxle(Fig.9) 1.4TheAxle(Fig.9)

The AL-KO rubber suspension axle

has been designed for new standards

of spring comfort and is maintenance

free.

Three rubber elements are contained

withinanhexagonalaxletube.These

provide suspension and have inherent

damping characteristics. Octagon

shock absorbers are available as a

retro-fitkitfortheAL-KOEuro-Axle.

On Delta axles dampers are fitted, to On Delta axles dampers are fitted, to On Delta axles dampers are fitted, to On Delta axles dampers are fitted, to On Delta axles dampers are fitted, to

damp out excessive oscillations due damp out excessive oscillations due damp out excessive oscillations due damp out excessive oscillations due damp out excessive oscillations due

to a greater wheel travel arc. to a greater wheel travel arc. to a greater wheel travel arc. to a greater wheel travel arc. to a greater wheel travel arc.

DESCRIPTION AND OPERATION DESCRIPTION AND OPERATION DESCRIPTION AND OPERATION DESCRIPTION AND OPERATION DESCRIPTION AND OPERATION

Figures9(a),(b)and(c)showthe

deformation of the rubber elements at

the extremes of suspension move-

ment.

The axle is designed to ride with the The axle is designed to ride with the The axle is designed to ride with the The axle is designed to ride with the The axle is designed to ride with the

suspension drop arm at, or slightly suspension drop arm at, or slightly suspension drop arm at, or slightly suspension drop arm at, or slightly suspension drop arm at, or slightly

below, the horizontal position. below, the horizontal position. below, the horizontal position. below, the horizontal position. below, the horizontal position.

13 13 13 13 13

FIG.9b FIG.9b FIG.9b FIG.9b FIG.9b

FIG.9a FIG.9a FIG.9a FIG.9a FIG.9a

FIG.9c FIG.9c FIG.9c FIG.9c FIG.9c

1.5BrakingSystem(Fig.10) 1.5BrakingSystem(Fig.10) 1.5BrakingSystem(Fig.10) 1.5BrakingSystem(Fig.10) 1.5BrakingSystem(Fig.10)

TheAL-KOautomaticreversingwheel

brake system comprises twin brake

shoes acting against a drum. The

shoesareactuatedbyafullyfloating

expanding clutch. which when oper-

atedforcestheshoesintocontactwith

the drum. The system also contains

an adjuster housing to arrest direc-

tionalmotionoftheexpandingclutch

and shoes when the brake is en-

gaged, and

a spring-loaded reverse lever which

collapses when reverse braking is

applied.

DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION

14 14 14 14 14

FIG.10 FIG.10 FIG.10 FIG.10 FIG.10

DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION

15 15 15 15 15

FIG.11 FIG.11 FIG.11 FIG.11 FIG.11

27

29

33

1

32

26

25

2

5

19

21

20

18

16

15

10

14 13

8

4 3 31 6

7

This sub-assembly forms the

spring-loaded auto-reverse

mechanism. Its various functions are

entirely dependent upon the position

ofthefulcruminrelationtotheexpand-

ing clutch and brake shoes.

The brake shoes (6) and (16),

(handed on 1637 brake units, not

handed on 2051 and 2361 brake

units), joined together by a tensioned

pulloffspring(7),aresecuredtothe

backplate using tension springs (20)

heldinplacebycoverplates(26).

Description (Fig. 11) Description (Fig. 11) Description (Fig. 11) Description (Fig. 11) Description (Fig. 11)

The wheel brake unit comprises a

brakebackplate(1),handedleftor

right, assembled to a stub axle (31).

The backplate accepts various items

ofthebrakeunit.Ahandedreverse

lever(5)isattachedtothestarwheel

adjuster housing (21) by a bearing bolt

(18)securedbyasplitpin(19).The

functionofthereverselever(bearing

bolt) is set to work against a tensioned

spring(4)attachedtothebackplate.

An adjusting nut, commonly called the

starwheel, slots into the other end of

the adjuster housing (21) and is held

in place by an adjusting screw.

The expanding clutch (8) is inserted

between the trailing edges of the

shoes and is floating.The attachment

ontheendoftheBowdencablefits

into the expanded clutch mechanism.

Aflangedhubnut(13)locatedunder

thedustcap(14)usedtokeepthe

brake drum, complete with bearing

and circlip (10) insitu is a one-shot nut

(iemustonlybeusedonce).Ifre-

moveditmustbereplacedwithanew

flanged hub nut.

No attempt should be made to No attempt should be made to No attempt should be made to No attempt should be made to No attempt should be made to

remove the bearing as the brake remove the bearing as the brake remove the bearing as the brake remove the bearing as the brake remove the bearing as the brake

drum is a sealed for life, drum is a sealed for life, drum is a sealed for life, drum is a sealed for life, drum is a sealed for life,

maintenance free unit, available only maintenance free unit, available only maintenance free unit, available only maintenance free unit, available only maintenance free unit, available only

as a complete unit. as a complete unit. as a complete unit. as a complete unit. as a complete unit.

Therearstubnut(32)islocatedunder

therearstubnutcap(33).

The rear stub nut must not be The rear stub nut must not be The rear stub nut must not be The rear stub nut must not be The rear stub nut must not be

disturbed under any circumstances disturbed under any circumstances disturbed under any circumstances disturbed under any circumstances disturbed under any circumstances

as this will invalidate all warranties. as this will invalidate all warranties. as this will invalidate all warranties. as this will invalidate all warranties. as this will invalidate all warranties.

Operation(Fig.12and13) Operation(Fig.12and13) Operation(Fig.12and13) Operation(Fig.12and13) Operation(Fig.12and13)

Forward Braking Forward Braking Forward Braking Forward Braking Forward Braking

Inthefreeposition,withthehandbrake

fullyforwardintheOFFposition,the

drawshaft of the overrun assembly is

fullyextendedandtheshoesareclear

ofthedrum.

Asthetowingvehiclebrakes,the

weightofthecaravan/trailerunit

compresses the overrun assembly

against the fixed drawshaft.

Reversing Reversing Reversing Reversing Reversing

Whenthetowingvehiclereverses,the

overrun assembly is again com-

pressed by the drawshaft. This

movement is transmitted in the normal

mannertotheexpandingclutchinthe

brake unit.

The clutch forces both brake shoes

intocontactwiththebrakedrum.Initial

friction between these creates a

tendency for the shoes and expanding

clutchtomoveinthedirectionofwheel

rotationi.e.reverse.

This movement is tranmitted via the

overrunlever,brakerodandBowden

cabletotheexpandingclutch.This

mechanism forces the leading brake

shoeand,byreaction,thetrailingshoe

outwardsintocontactwiththedrum.

Friction between the brake shoes and

thedrumcreatesatendencyforboth

shoes and the expanding clutch to

moveinthedirectionofforward

rotationuntiltheyabutagainstthe

adjuster housing. This ensures that

both shoes remain in the braking

position.

DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION

16 16 16 16 16

Parking Parking Parking Parking Parking

TheAL-KOparkingbrakesystem

incorporates a patented device for

addedsafetywhenparkingona

reverse-sloping site or steep hill.

TheAL-KOparkingbrakesystem

comprises a handbrake lever

mechanism actuating firstly a brake

rodthen2or4Bowdencableswhich

operate the brake unit assembly

contained within the wheel hub.

This movement puts pressure on the

spring-loaded auto-reverse lever,

causing it to collapse. This releases

the shoes from the drum allowing the

caravan/trailertoreverse.

Slightforwardmovementofthe

chassis will allow the spring to

reassert itself, enabling the reverse

levertorecovertoitsnormalposition.

Normal braking is then immediately

available.

AL-KO's unique parking brake system

requiresasourceofstoredenergyto

apply the wheel brakes should the

caravan/trailerstartmoveafterithas

been uncoupled from the towing unit.

AL-KOprovidetwoalternativeparking

brakesystemstoprovidethesourceof

storedenergy.Bothtypeshavethe

same Bowden cable and wheel hub

brake unit.

The difference between the systems is

the handbrake mechanism used to

actuate the Bowden cable.

DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION

17 17 17 17 17

FIG.12 FIG.12 FIG.12 FIG.12 FIG.12 FIG.13 FIG.13 FIG.13 FIG.13 FIG.13

Thisenergysourceisprovidedby

eitheraspringcylinderchargedby

handoragasstrutonthehandbrake

acting as an accumulator.

Each system requires a slightly

different method of operation when

parkingthecaravan/trailer,thoughthey

both operate in the same manner

when forward or reverse braking is

applied.

SpringCylinderType(Fig.14) SpringCylinderType(Fig.14) SpringCylinderType(Fig.14) SpringCylinderType(Fig.14) SpringCylinderType(Fig.14)

Description Description Description Description Description

T TT TThe spring cylinder is located on the he spring cylinder is located on the he spring cylinder is located on the he spring cylinder is located on the he spring cylinder is located on the

brake rod between the handbrake brake rod between the handbrake brake rod between the handbrake brake rod between the handbrake brake rod between the handbrake

tension lever and the yoke end. Full tension lever and the yoke end. Full tension lever and the yoke end. Full tension lever and the yoke end. Full tension lever and the yoke end. Full

application of the handbrake lever application of the handbrake lever application of the handbrake lever application of the handbrake lever application of the handbrake lever

(such that the lever is vertical) to the (such that the lever is vertical) to the (such that the lever is vertical) to the (such that the lever is vertical) to the (such that the lever is vertical) to the

last tooth of the ratchet compresses last tooth of the ratchet compresses last tooth of the ratchet compresses last tooth of the ratchet compresses last tooth of the ratchet compresses

a spring inside the cylinder and a spring inside the cylinder and a spring inside the cylinder and a spring inside the cylinder and a spring inside the cylinder and

energy is stored energy is stored energy is stored energy is stored energy is stored.

Theactionofthebrakeleveroperates

theexpandingclutchinthebrakeunit

viathebrakerodandBowdencable,

this forces both shoes into contact

withthedrum.

Atthisstage,thebrakeunitislatent,

the mechanism waiting to see in

which direction the caravan/trailer will

starttomove.

Ifthecaravan/trailerstartstomove

backwards,thestoredenergyinthe

spring cylinder will be released. The

brake shoes and the expanding clutch

willtendtomoveinthedirectionof

rotation (reverse) and abut against the

stop. Thus the caravan/trailer is

braked.

DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION

FIG.14 FIG.14 FIG.14 FIG.14 FIG.14

18 18 18 18 18

However, if the handbrake is NOT However, if the handbrake is NOT However, if the handbrake is NOT However, if the handbrake is NOT However, if the handbrake is NOT

fully applied to the last tooth (i.e. fully applied to the last tooth (i.e. fully applied to the last tooth (i.e. fully applied to the last tooth (i.e. fully applied to the last tooth (i.e.

vertical) and is set to some lesser vertical) and is set to some lesser vertical) and is set to some lesser vertical) and is set to some lesser vertical) and is set to some lesser

position than the full vertical. The position than the full vertical. The position than the full vertical. The position than the full vertical. The position than the full vertical. The

spring cylinder is not fully com- spring cylinder is not fully com- spring cylinder is not fully com- spring cylinder is not fully com- spring cylinder is not fully com-

pressed and problems will almost pressed and problems will almost pressed and problems will almost pressed and problems will almost pressed and problems will almost

certainly arise after the caravan/ certainly arise after the caravan/ certainly arise after the caravan/ certainly arise after the caravan/ certainly arise after the caravan/

trailer has been uncoupled from the trailer has been uncoupled from the trailer has been uncoupled from the trailer has been uncoupled from the trailer has been uncoupled from the

towing unit. towing unit. towing unit. towing unit. towing unit.

Ifthecaravan/trailerisparkedona

reverse slope or if it is pushed

backwards, the shoes and expanding

clutchwilltendtomovewiththe

directionofrotation(reverse).

This movement puts pressure on the

spring-loaded auto-reverse lever,

causing it to collapse. This releases This releases This releases This releases This releases

the shoes from the drum and the the shoes from the drum and the the shoes from the drum and the the shoes from the drum and the the shoes from the drum and the

caravan/trailer will run away. caravan/trailer will run away. caravan/trailer will run away. caravan/trailer will run away. caravan/trailer will run away.

Operating the Handbrake Operating the Handbrake Operating the Handbrake Operating the Handbrake Operating the Handbrake

Always chock the wheels when Always chock the wheels when Always chock the wheels when Always chock the wheels when Always chock the wheels when

parking the caravan/trailer on sloping parking the caravan/trailer on sloping parking the caravan/trailer on sloping parking the caravan/trailer on sloping parking the caravan/trailer on sloping

sites. sites. sites. sites. sites.

For successful parking on a slope or

steephill,theoperatorneedonlyapply

the handbrake with one hand while

gentlypushingthecaravan/trailera

centimetre or two backwards.

The user must supply this small but

essential backward movement to

ensurethatthefulcrumofthe

transmission lever moves past the

pointofreverse,thuspreventingthe

lever from collapsing as it would

normally do when reversing.

DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION

19 19 19 19 19

GasStrutType(Fig.15) GasStrutType(Fig.15) GasStrutType(Fig.15) GasStrutType(Fig.15) GasStrutType(Fig.15)

Thegasstrutisfittedtothehandbrake

leverandactsasanaccumulatorof

stored energy.

This system is more user friendly, as

thehandbrakeleverneedonlybe

applied until it passes a clearly

detectableovercentrepointforitto

render parking on slopes or steep

hills absolutely safe. It takes minimal

effortfromtheoperatortomovethe

handbrake lever past this point.

Ifthecaravan/trailerstartstomove

when uncoupled from the towing unit,

thentheenergystoredinthegasstrut

is released and the brakes applied in

the normal manner.

Important Points to Remember Important Points to Remember Important Points to Remember Important Points to Remember Important Points to Remember

It is also important to check that the It is also important to check that the It is also important to check that the It is also important to check that the It is also important to check that the

brake has in fact operated correctly brake has in fact operated correctly brake has in fact operated correctly brake has in fact operated correctly brake has in fact operated correctly

as soon as the caravan/trailer has as soon as the caravan/trailer has as soon as the caravan/trailer has as soon as the caravan/trailer has as soon as the caravan/trailer has

been uncoupled been uncoupled been uncoupled been uncoupled been uncoupled

If the caravan/trailer is to be parked If the caravan/trailer is to be parked If the caravan/trailer is to be parked If the caravan/trailer is to be parked If the caravan/trailer is to be parked

on a steep slope or on loose or on a steep slope or on loose or on a steep slope or on loose or on a steep slope or on loose or on a steep slope or on loose or

slippery surfaces, the wheels must slippery surfaces, the wheels must slippery surfaces, the wheels must slippery surfaces, the wheels must slippery surfaces, the wheels must

be chocked. be chocked. be chocked. be chocked. be chocked.

Always ensure that the handbrake Always ensure that the handbrake Always ensure that the handbrake Always ensure that the handbrake Always ensure that the handbrake

lever is in the fully vertical position. lever is in the fully vertical position. lever is in the fully vertical position. lever is in the fully vertical position. lever is in the fully vertical position.

When the handbrake has been When the handbrake has been When the handbrake has been When the handbrake has been When the handbrake has been

applied, it is possible for the applied, it is possible for the applied, it is possible for the applied, it is possible for the applied, it is possible for the

caravan/trailer to roll back as much caravan/trailer to roll back as much caravan/trailer to roll back as much caravan/trailer to roll back as much caravan/trailer to roll back as much

as 25cm before the full force of the as 25cm before the full force of the as 25cm before the full force of the as 25cm before the full force of the as 25cm before the full force of the

brake takes effect. brake takes effect. brake takes effect. brake takes effect. brake takes effect.

DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION

20 20 20 20 20

FIG.15 FIG.15 FIG.15 FIG.15 FIG.15

1.6 Wheels and Tyres 1.6 Wheels and Tyres 1.6 Wheels and Tyres 1.6 Wheels and Tyres 1.6 Wheels and Tyres

Wheels Wheels Wheels Wheels Wheels

The AL-KO chassis is supported on

road wheels fitted with pneumatic

tyres.Thesizeofwheelfittedtothe

chassis is dependent upon the load to

be towed.The wheel should be

positioned as close to the chassis

member as possible to ease loading/

unloading.

Spare Wheel Carrier (Fig. 16) Spare Wheel Carrier (Fig. 16) Spare Wheel Carrier (Fig. 16) Spare Wheel Carrier (Fig. 16) Spare Wheel Carrier (Fig. 16)

Each AL-KO caravan/trailer chassis

has a set of punched holes behind the

axletoenablefittingofanAL-KO

telescopic spare wheel carrier (Fig.

16)

The carrier is of strong, lightweight

constructionandzincplatedforall-

weatherprotection.Itiseasytofitand

accepts all conventional wheel sizes.

The pre-punched holes are on both

sides, therefore enabling the spare

wheelcarriertobefittedtoallow

operationfromeitherleftorrightside

ofthecaravan/trailer.Thisisimportant

when towing abroad.

Jacking System (Fig. 17) Jacking System (Fig. 17) Jacking System (Fig. 17) Jacking System (Fig. 17) Jacking System (Fig. 17)

From1992allAL-KOchassishaveholes

punched behind the axle to enable a

JackingSystemtobefitted.

The fixed jacking system cannot be The fixed jacking system cannot be The fixed jacking system cannot be The fixed jacking system cannot be The fixed jacking system cannot be

fitted to chassis prior to 1992. fitted to chassis prior to 1992. fitted to chassis prior to 1992. fitted to chassis prior to 1992. fitted to chassis prior to 1992.

The system can only be fitted from The system can only be fitted from The system can only be fitted from The system can only be fitted from The system can only be fitted from

1992 if the caravan/trailer has 1992 if the caravan/trailer has 1992 if the caravan/trailer has 1992 if the caravan/trailer has 1992 if the caravan/trailer has

reinforced floors and walls to take reinforced floors and walls to take reinforced floors and walls to take reinforced floors and walls to take reinforced floors and walls to take

advantage of this system. advantage of this system. advantage of this system. advantage of this system. advantage of this system.

Check with the caravan/trailer Check with the caravan/trailer Check with the caravan/trailer Check with the caravan/trailer Check with the caravan/trailer

manufacturer before fitting. manufacturer before fitting. manufacturer before fitting. manufacturer before fitting. manufacturer before fitting.

DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION

21 21 21 21 21

FIG.17 FIG.17 FIG.17 FIG.17 FIG.17 FIG.16 FIG.16 FIG.16 FIG.16 FIG.16

Tyres Tyres Tyres Tyres Tyres

Pressures Pressures Pressures Pressures Pressures

Itisdangeroustodrivewithunder

inflated tyres. The pressures (cold)

recommended by the manufacturers

areincludedaboveasTable1.

Pressure checks, including those on

thesparetyre,shouldbemadewith

thetyrescoldandusinganaccurate

pressure gauge.

The checks should be carried out

beforeeachjourneyandatregular

intervalsduringstorage.Ifajockey

wheelisfittedwithapneumatictyre,

the pressure should be 25 to 30psi

(1.7to2bar).

Tyre Wear and Damage Tyre Wear and Damage Tyre Wear and Damage Tyre Wear and Damage Tyre Wear and Damage

The legal requirements for tread depth

on motor vehicle tyres also applies to

caravan/trailers. Similarly, it is illegal to

mixcross-plyandradialtyresonthe

sameaxle.

Wheels should be balanced and

changed around occasionally to

equalise wear and prolong the life of

thetyres.

It is very dangerous to neglect tyre It is very dangerous to neglect tyre It is very dangerous to neglect tyre It is very dangerous to neglect tyre It is very dangerous to neglect tyre

damage. A tyre should be renewed if damage. A tyre should be renewed if damage. A tyre should be renewed if damage. A tyre should be renewed if damage. A tyre should be renewed if

a blister, rupture or cut exposing the a blister, rupture or cut exposing the a blister, rupture or cut exposing the a blister, rupture or cut exposing the a blister, rupture or cut exposing the

casing is detected. If the tyre has casing is detected. If the tyre has casing is detected. If the tyre has casing is detected. If the tyre has casing is detected. If the tyre has

suffered impact (eg. against a kerb), suffered impact (eg. against a kerb), suffered impact (eg. against a kerb), suffered impact (eg. against a kerb), suffered impact (eg. against a kerb),

it should be examined by a it should be examined by a it should be examined by a it should be examined by a it should be examined by aspecialist specialist specialist specialist specialist

as soon as possible. as soon as possible. as soon as possible. as soon as possible. as soon as possible.

DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION

22 22 22 22 22

1.7 Accessories 1.7 Accessories 1.7 Accessories 1.7 Accessories 1.7 Accessories

AL-KOofferacomprehensiverangeof

accessories for use with all their

caravan/trailers. The list includes

batteries, the AKS 2000 stabiliser

coupling, scissor jacks, a combi brace

and chocks to aid servicing and

maintenance tasks. In addition

octagon shock absorbers are avail-

ableforEuro-Axleasanaidtodamp-

ing.

Batteries (Fig. 18) Batteries (Fig. 18) Batteries (Fig. 18) Batteries (Fig. 18) Batteries (Fig. 18)

AL-KOcansupplyarangeofhigh

energybatteriestopowerthecaravan/

trailer electrical equipment.

Capacities available are 60, 75 and 90

ampere hour.

AL-KO batteries are manufactured

underaBSIapprovedqualityassur-

ancesystemtoprovideasafeand

reliable source of energy.

They are specifically designed to

provide deep cycling characteristics.

Thismeansthatthebatterywill

discharge the power you need when

youneeditandthenrechargewithout

affectingitscapacityorlifespan.

The batteries have strong, moulded

cases complete with carrying handles

forsafeportability.Theyarereliable,

easy to maintain and can be grouped

toprovidethetotalpowerrequirement

forallyourleisureactivities.

60AHCbatteryPartNo376877

75AHCbatteryPartNo376878

90AHCbatteryPartNo376879

(AHC-AmpereHourCapacity)

DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION

23 23 23 23 23

FIG.18 FIG.18 FIG.18 FIG.18 FIG.18

AKS2000Stabiliser(Fig.19) AKS2000Stabiliser(Fig.19) AKS2000Stabiliser(Fig.19) AKS2000Stabiliser(Fig.19) AKS2000Stabiliser(Fig.19)

PartNo.241822.SpareballkitPart PartNo.241822.SpareballkitPart PartNo.241822.SpareballkitPart PartNo.241822.SpareballkitPart PartNo.241822.SpareballkitPart

No. 285 058. Replacement friction No. 285 058. Replacement friction No. 285 058. Replacement friction No. 285 058. Replacement friction No. 285 058. Replacement friction

padkitPartNo.286581 padkitPartNo.286581 padkitPartNo.286581 padkitPartNo.286581 padkitPartNo.286581

An easy to operate stabilising coupling

with unique visual indicator to show

the coupling is fully engaged.

Lowering the stabiliser handle

presses spring loaded friction pads

againstthetowball.Theirhigh

damping force reduces even small

snaking movements - immediately

and automatically.

Scissor Jacks (Fig. 20) Scissor Jacks (Fig. 20) Scissor Jacks (Fig. 20) Scissor Jacks (Fig. 20) Scissor Jacks (Fig. 20)

PartNo.356858(boxed) PartNo.356858(boxed) PartNo.356858(boxed) PartNo.356858(boxed) PartNo.356858(boxed)

Thejack,fittedwithacontouredhead,

willliftcaravan/trailerweighingupto

1500kg to a height of 382mm.

Manufactured with a rugged pressed

steel frame, the jack is supplied with a

heavydutysteelbraceandstowsaway

flat.

FIG.20 FIG.20 FIG.20 FIG.20 FIG.20 FIG.19 FIG.19 FIG.19 FIG.19 FIG.19

DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION

24 24 24 24 24

The fitting of any type of stabiliser The fitting of any type of stabiliser The fitting of any type of stabiliser The fitting of any type of stabiliser The fitting of any type of stabiliser

will act as an aid to towing, but will will act as an aid to towing, but will will act as an aid to towing, but will will act as an aid to towing, but will will act as an aid to towing, but will

not cure an inherently unstable not cure an inherently unstable not cure an inherently unstable not cure an inherently unstable not cure an inherently unstable

combination, car-caravan/trailer. combination, car-caravan/trailer. combination, car-caravan/trailer. combination, car-caravan/trailer. combination, car-caravan/trailer.

NewAKS2000stabiliser(Fig.19a) NewAKS2000stabiliser(Fig.19a) NewAKS2000stabiliser(Fig.19a) NewAKS2000stabiliser(Fig.19a) NewAKS2000stabiliser(Fig.19a)

PartNo.287684,SpareballkitPart PartNo.287684,SpareballkitPart PartNo.287684,SpareballkitPart PartNo.287684,SpareballkitPart PartNo.287684,SpareballkitPart

No. 286 058. Replacement friction No. 286 058. Replacement friction No. 286 058. Replacement friction No. 286 058. Replacement friction No. 286 058. Replacement friction

pad kit Part No. 286581 pad kit Part No. 286581 pad kit Part No. 286581 pad kit Part No. 286581 pad kit Part No. 286581

CombiBrace(Fig.21) CombiBrace(Fig.21) CombiBrace(Fig.21) CombiBrace(Fig.21) CombiBrace(Fig.21)

PartNo.293398 PartNo.293398 PartNo.293398 PartNo.293398 PartNo.293398

A combined corner steady and wheel

brace.Theunitfoldstoprovideextra

leverage and for stowage purposes. It

is of long-lasting construction and has

azincplatedfinish.

WheelChocks(Fig.22) WheelChocks(Fig.22) WheelChocks(Fig.22) WheelChocks(Fig.22) WheelChocks(Fig.22)

Part No. 285 759 (boxed pair) Part No. 285 759 (boxed pair) Part No. 285 759 (boxed pair) Part No. 285 759 (boxed pair) Part No. 285 759 (boxed pair)

Heavydutyplasticchocksforsmall

caravan/trailers supplied complete

withcarrier.Thechockshavearadiito

suit most wheels and are easy to

handle.

Toprotectyourcaravan/traileragainst

theft,anoptionalsecuritylockcanbe

fittedtothecouplinghead.

AK10/2PartNo.203216

AKS2000PartNo.203141

FIG.22 FIG.22 FIG.22 FIG.22 FIG.22

FIG.21 FIG.21 FIG.21 FIG.21 FIG.21

DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION DESCRIPTIONANDOPERATION

25 25 25 25 25

SECTION2 SECTION2 SECTION2 SECTION2 SECTION2

SERVICING SERVICING SERVICING SERVICING SERVICING

2.1 Servicing Philosophy 2.1 Servicing Philosophy 2.1 Servicing Philosophy 2.1 Servicing Philosophy 2.1 Servicing Philosophy

The AL-KO lightweight chassis has

been designed to be maintained at its

optimum performance level with

minimal servicing. Servicing philoso-

phy embraces lubrication, inspections

and adjustments carried out in

accordance with a schedule based on

mileage. However, if the mileage is

not attained, servicing should be

carried out on a periodic basis.

2.2 Servicing Schedule 2.2 Servicing Schedule 2.2 Servicing Schedule 2.2 Servicing Schedule 2.2 Servicing Schedule

After first 20 miles (32 kms) After first 20 miles (32 kms) After first 20 miles (32 kms) After first 20 miles (32 kms) After first 20 miles (32 kms)

- Check wheel bolt torques.

After first 500 miles (800 kms) After first 500 miles (800 kms) After first 500 miles (800 kms) After first 500 miles (800 kms) After first 500 miles (800 kms)

- Check and adjust the brake

shoes and the brake linkage

Every 500 miles (800 kms) or Every 500 miles (800 kms) or Every 500 miles (800 kms) or Every 500 miles (800 kms) or Every 500 miles (800 kms) or

2-monthly 2-monthly 2-monthly 2-monthly 2-monthly

- Inspect all wheels

- Examine and lubricate the ball

coupling

- Inspectandlubricatetheoverrun

assembly

- Lubricatethejockeywheel

- Lubricate the brake linkage

- Lubricate the corner steadies

- Servicethebattery

Every 1500 miles (2400 kms) or Every 1500 miles (2400 kms) or Every 1500 miles (2400 kms) or Every 1500 miles (2400 kms) or Every 1500 miles (2400 kms) or

6-monthly 6-monthly 6-monthly 6-monthly 6-monthly

(as 500 miles/800 kms) plus:

- Visuallychecktheaxlefor

damage

Every 3000 miles (4800 kms) or Every 3000 miles (4800 kms) or Every 3000 miles (4800 kms) or Every 3000 miles (4800 kms) or Every 3000 miles (4800 kms) or

Annually Annually Annually Annually Annually

(as 1500 miles/2400 kms) plus:

- Measure the towing ball

- Grease the overrun assembly

- Check and adjust the brake

shoes and brake linkage

- Check wheel bolt torques.

Every 6000 miles (9600 kms) or Bi- Every 6000 miles (9600 kms) or Bi- Every 6000 miles (9600 kms) or Bi- Every 6000 miles (9600 kms) or Bi- Every 6000 miles (9600 kms) or Bi-

annually annually annually annually annually

(as 3000 miles/4800 kms) plus:

- Check the brake linings and

brake shoe pull-off springs for

wearorfatigue

- Grease the running nuts on the

brake linkage

After Use Servicing After Use Servicing After Use Servicing After Use Servicing After Use Servicing

Afterjourneysduringwinter,hose

downwithfreshwatertowashoffany

road salt.

Wheel hubs and bearings should not Wheel hubs and bearings should not Wheel hubs and bearings should not Wheel hubs and bearings should not Wheel hubs and bearings should not

be immersed in water. be immersed in water. be immersed in water. be immersed in water. be immersed in water.

For long term storage place the

caravan/trailer on axle stands, ensure

thewheelsareclearoftheground.

SERVICING SERVICING SERVICING SERVICING SERVICING

26 26 26 26 26

Lowering the Caravan/Trailer Lowering the Caravan/Trailer Lowering the Caravan/Trailer Lowering the Caravan/Trailer Lowering the Caravan/Trailer

Raise the corner steadies. Take the

weightofthecaravan/trailerontothe

jackandremovetheaxlestandsor

ramping boards.

Lowerthecaravan/trailertotheground

andremovethejack.

If the side mounted jacking system is

fitted,pushthejackarmintothe

socketasfarasitwillgo.Ensurethe

jack is perpendicular and turn the jack

handle in a clockwise direction to

raise the caravan/trailer.

NEVERUSETHECHASSIS NEVERUSETHECHASSIS NEVERUSETHECHASSIS NEVERUSETHECHASSIS NEVERUSETHECHASSIS

MEMBERSASJACKINGPOINTS. MEMBERSASJACKINGPOINTS. MEMBERSASJACKINGPOINTS. MEMBERSASJACKINGPOINTS. MEMBERSASJACKINGPOINTS.

Place a chock under the grounded

wheelandanaxlestandunderthe

raised wheel.

Recommended Lubricants Recommended Lubricants Recommended Lubricants Recommended Lubricants Recommended Lubricants

Mobilgrease MP is recommended for

all greasing routines. A good all-

purpose oil is recommended for

general use.

2.3 Jacking up the Caravan/Trailer 2.3 Jacking up the Caravan/Trailer 2.3 Jacking up the Caravan/Trailer 2.3 Jacking up the Caravan/Trailer 2.3 Jacking up the Caravan/Trailer

(Fig.23) (Fig.23) (Fig.23) (Fig.23) (Fig.23)

The corner steadies should never be The corner steadies should never be The corner steadies should never be The corner steadies should never be The corner steadies should never be

used to jack up the caravan/trailer. used to jack up the caravan/trailer. used to jack up the caravan/trailer. used to jack up the caravan/trailer. used to jack up the caravan/trailer.

They can be lowered to touch the They can be lowered to touch the They can be lowered to touch the They can be lowered to touch the They can be lowered to touch the

ground only as a safety measure. ground only as a safety measure. ground only as a safety measure. ground only as a safety measure. ground only as a safety measure.

When jacking becomes necessary, use

abottle,screworscissortypejack.(AL-

KO Part No. 356 858 with axle shaped

head is recommended).

Applythehandbrakefullyasfor

parking.

Donotforgettogivethecaravan/trailer

a slight rearwards push to stop the

reversing lever collapsing.

Place the scissor jack under the axle

tube as near as possible to the main

longitudinal member.

SERVICING SERVICING SERVICING SERVICING SERVICING

27 27 27 27 27

FIG.23 FIG.23 FIG.23 FIG.23 FIG.23

2.4 Check and Adjust the Brake 2.4 Check and Adjust the Brake 2.4 Check and Adjust the Brake 2.4 Check and Adjust the Brake 2.4 Check and Adjust the Brake

Shoes and Brake linkage Shoes and Brake linkage Shoes and Brake linkage Shoes and Brake linkage Shoes and Brake linkage

TheAL-KOautomaticreversingbrake

system and its linkage should be

periodically adjusted to compensate

forwearofthebrakeshoeliningand

subsequent stretching of the Bowden

cables.

The caravan/trailer brake will be The caravan/trailer brake will be The caravan/trailer brake will be The caravan/trailer brake will be The caravan/trailer brake will be

subject to greater wear when used subject to greater wear when used subject to greater wear when used subject to greater wear when used subject to greater wear when used

on continuous mountain pass on continuous mountain pass on continuous mountain pass on continuous mountain pass on continuous mountain pass

descents. descents. descents. descents. descents.

Recommended Adjustment Recommended Adjustment Recommended Adjustment Recommended Adjustment Recommended Adjustment

Procedure Procedure Procedure Procedure Procedure

(a) Ensure the drawshaft is fully

extended(inthetowing

position). The handbrake is

OFF(fullyforwardposition).

Confirm that there is some

endfloatintherodandspring

cylinder.

(b) Jackuptheaxle(seepage27)

The brakes must be adjusted first The brakes must be adjusted first The brakes must be adjusted first The brakes must be adjusted first The brakes must be adjusted first

and then if necessary the brake and then if necessary the brake and then if necessary the brake and then if necessary the brake and then if necessary the brake

linkage. linkage. linkage. linkage. linkage.

During wheel brake adjustment, the During wheel brake adjustment, the During wheel brake adjustment, the During wheel brake adjustment, the During wheel brake adjustment, the

drum must only be turned in the drum must only be turned in the drum must only be turned in the drum must only be turned in the drum must only be turned in the

direction of forward rotation. direction of forward rotation. direction of forward rotation. direction of forward rotation. direction of forward rotation.

Do not use excessive force during Do not use excessive force during Do not use excessive force during Do not use excessive force during Do not use excessive force during

adjustment. adjustment. adjustment. adjustment. adjustment.

SERVICING SERVICING SERVICING SERVICING SERVICING

28 28 28 28 28

Wheel Brake Adjustment (Fig.24) Wheel Brake Adjustment (Fig.24) Wheel Brake Adjustment (Fig.24) Wheel Brake Adjustment (Fig.24) Wheel Brake Adjustment (Fig.24)

(c) Remove the plastic bung from

thebrakebackplatetoexpose

the 'starwheel' adjuster.

(d) Adjustthestarwheelinthe

directionofthearrowuntil

there is resistance to wheel

movement.

(e) Slacken until the brake drum

turnsfreelyintheforward

direction.

(f) Checkforcorrectadjustmentat

theendoftheBowdencable

whereitissecuredatthe

abutmentonthecentreofthe

axle.Whenpulled,theinner

cable should extend between 5

and 8mm.

(g) Repeatfortheotherwheelor

wheels.

(h) Applythehandbraketwoor

three times to ensure the brake

shoes are centralised on the

drum. Recheck shoe clearance

atthewheelbrake.

(i) Check for uniform response of

both wheel brakes and the

balance bar is pulled evenly

when the handbrake is operated.

(j) Replace the plastic bung in the

brake backplate.

SERVICING SERVICING SERVICING SERVICING SERVICING

29 29 29 29 29

FIG.24 FIG.24 FIG.24 FIG.24 FIG.24

Brake Linkage Adjustment (Fig. 25) Brake Linkage Adjustment (Fig. 25) Brake Linkage Adjustment (Fig. 25) Brake Linkage Adjustment (Fig. 25) Brake Linkage Adjustment (Fig. 25)

(k) Check the brake rod support

bar,fixedtothecaravan/trailer

floor, is supporting the brake

rodevenlyandnotjustatone

end.

(l) On tandem axles ensure there

isabrakerodsupporttube,

screwedontotheendofthe

brake rod and passing through

thecentreholeontheabutment

fixedtothefrontaxleonly.

(m) Adjustthebrakerodsothe

overrunleverbuttsupagainst

theendofthetowingshaft,

leaving no clearance. Secure

all brake rod locking nuts.

Where the spring cylinder overrun Where the spring cylinder overrun Where the spring cylinder overrun Where the spring cylinder overrun Where the spring cylinder overrun

assembly is fitted adjust the locking assembly is fitted adjust the locking assembly is fitted adjust the locking assembly is fitted adjust the locking assembly is fitted adjust the locking

nuts to allow 1mm of clearance only. nuts to allow 1mm of clearance only. nuts to allow 1mm of clearance only. nuts to allow 1mm of clearance only. nuts to allow 1mm of clearance only.

On some caravan/trailers a single On some caravan/trailers a single On some caravan/trailers a single On some caravan/trailers a single On some caravan/trailers a single

nyloc is used instead of two locking nyloc is used instead of two locking nyloc is used instead of two locking nyloc is used instead of two locking nyloc is used instead of two locking

locks. locks. locks. locks. locks.

Reversing will be difficult if either the Reversing will be difficult if either the Reversing will be difficult if either the Reversing will be difficult if either the Reversing will be difficult if either the

brake shoes or the brake linkage is brake shoes or the brake linkage is brake shoes or the brake linkage is brake shoes or the brake linkage is brake shoes or the brake linkage is

over-adjusted. over-adjusted. over-adjusted. over-adjusted. over-adjusted.

SERVICING SERVICING SERVICING SERVICING SERVICING

30 30 30 30 30

FIG.25 FIG.25 FIG.25 FIG.25 FIG.25

2.5 Inspecting/Changing the Wheels 2.5 Inspecting/Changing the Wheels 2.5 Inspecting/Changing the Wheels 2.5 Inspecting/Changing the Wheels 2.5 Inspecting/Changing the Wheels

Inspect all wheels (including the

spare) for damage and distortion,

payingparticularattentiontothe

flanges and wheel dish. Ensure that

the wheel bolt seatings are not

cracked.

Damaged or distorted wheels must Damaged or distorted wheels must Damaged or distorted wheels must Damaged or distorted wheels must Damaged or distorted wheels must

be renewed immediately. be renewed immediately. be renewed immediately. be renewed immediately. be renewed immediately.

SERVICING SERVICING SERVICING SERVICING SERVICING

31 31 31 31 31

FIG.26 FIG.26 FIG.26 FIG.26 FIG.26

Before fitting a new wheel, examine Before fitting a new wheel, examine Before fitting a new wheel, examine Before fitting a new wheel, examine Before fitting a new wheel, examine

it for distortion or other damage. it for distortion or other damage. it for distortion or other damage. it for distortion or other damage. it for distortion or other damage.

Ensure that all mating surfaces are Ensure that all mating surfaces are Ensure that all mating surfaces are Ensure that all mating surfaces are Ensure that all mating surfaces are

clean and dry, including wheel bolt clean and dry, including wheel bolt clean and dry, including wheel bolt clean and dry, including wheel bolt clean and dry, including wheel bolt

seats. seats. seats. seats. seats.

ALWAYSUSETHECORRECT ALWAYSUSETHECORRECT ALWAYSUSETHECORRECT ALWAYSUSETHECORRECT ALWAYSUSETHECORRECT

BOLTSTOSECURETHEWHEEL. BOLTSTOSECURETHEWHEEL. BOLTSTOSECURETHEWHEEL. BOLTSTOSECURETHEWHEEL. BOLTSTOSECURETHEWHEEL.

ChangingaWheel(Fig.26,27,28) ChangingaWheel(Fig.26,27,28) ChangingaWheel(Fig.26,27,28) ChangingaWheel(Fig.26,27,28) ChangingaWheel(Fig.26,27,28)

FIG.27 FIG.27 FIG.27 FIG.27 FIG.27

The torque settings should be The torque settings should be The torque settings should be The torque settings should be The torque settings should be

rechecked after the first 20 miles or rechecked after the first 20 miles or rechecked after the first 20 miles or rechecked after the first 20 miles or rechecked after the first 20 miles or

30 kilometres of use, and every 3000 30 kilometres of use, and every 3000 30 kilometres of use, and every 3000 30 kilometres of use, and every 3000 30 kilometres of use, and every 3000

miles or 4800 kilometres thereafter. miles or 4800 kilometres thereafter. miles or 4800 kilometres thereafter. miles or 4800 kilometres thereafter. miles or 4800 kilometres thereafter.

A corner steady brace is not to be A corner steady brace is not to be A corner steady brace is not to be A corner steady brace is not to be A corner steady brace is not to be

used for the next step. used for the next step. used for the next step. used for the next step. used for the next step.

(?) Fitthenewwheelandrefitthe

wheel bolts.

UsinganAL-KOCombibraceor

suitable socket wrench, tighten the

wheelboltstothecorrecttorque,inthe

sequence North, South, East and

WestasshowninFig.28.

(?) Lowerthecaravan/trailertothe

ground (see page 27).

SERVICING SERVICING SERVICING SERVICING SERVICING

FIG.28 FIG.28 FIG.28 FIG.28 FIG.28

32 32 32 32 32

2.6 Examine and Lubricate the 2.6 Examine and Lubricate the 2.6 Examine and Lubricate the 2.6 Examine and Lubricate the 2.6 Examine and Lubricate the

CouplingHead.(Fig.29) CouplingHead.(Fig.29) CouplingHead.(Fig.29) CouplingHead.(Fig.29) CouplingHead.(Fig.29)

(a) Examine all moving parts and the

lockingfeatureforwearand

correct operation.

(b) Clean off and grease the spheri-

cal seat, bearing points and pivot

pins.

If the AKS 2000 coupling head is If the AKS 2000 coupling head is If the AKS 2000 coupling head is If the AKS 2000 coupling head is If the AKS 2000 coupling head is

fitted do not grease. fitted do not grease. fitted do not grease. fitted do not grease. fitted do not grease.

Torque settings for coupling head

securing bolts:

60S-AK7...............60Nm(44lb/ft)

90S-AK10.............80Nm(59lb/ft)

161S-AK10...........90Nm(66lb/ft)

251S-AK26...........90Nm(66lb/ft)

AKS 2000 Stabiliser

Boltmarked8.8.......86Nm(63lb/ft)

Bolt marked 10.9...120Nm (89lb/ft)

2.7 Examine and Lubricate the 2.7 Examine and Lubricate the 2.7 Examine and Lubricate the 2.7 Examine and Lubricate the 2.7 Examine and Lubricate the

Overrun Assembly. (Fig.30) Overrun Assembly. (Fig.30) Overrun Assembly. (Fig.30) Overrun Assembly. (Fig.30) Overrun Assembly. (Fig.30)

(a) Examineallpivotpinsandlevers

for correct operation and lubricate

withoil.

(b) Checkthehandbrakeratchetfor

correct operation and lubricate

withoil.

(c) Greasethe2nipplesonthetop

oftheoverrunassembly.Onthe

161Sand251Soverrun

assemblies there is a third nipple

underneaththeoverrunlever.

SERVICING SERVICING SERVICING SERVICING SERVICING

33 33 33 33 33

FIG.30 FIG.30 FIG.30 FIG.30 FIG.30 FIG.29 FIG.29 FIG.29 FIG.29 FIG.29

Lubrication (Fig. 31) Lubrication (Fig. 31) Lubrication (Fig. 31) Lubrication (Fig. 31) Lubrication (Fig. 31)

2.8 Lubricate the Jockey Wheel 2.8 Lubricate the Jockey Wheel 2.8 Lubricate the Jockey Wheel 2.8 Lubricate the Jockey Wheel 2.8 Lubricate the Jockey Wheel

Lightlyoilthewheelaxleandscrew

thread.

2.9 Lubricate the Brake Linkage 2.9 Lubricate the Brake Linkage 2.9 Lubricate the Brake Linkage 2.9 Lubricate the Brake Linkage 2.9 Lubricate the Brake Linkage

Lightlyoilallmovingparts

2.10 Lubricate the Corner Steadies 2.10 Lubricate the Corner Steadies 2.10 Lubricate the Corner Steadies 2.10 Lubricate the Corner Steadies 2.10 Lubricate the Corner Steadies

Lightlyoilthescrewandpivotpins.

2.11ServicetheBattery(Fig.31) 2.11ServicetheBattery(Fig.31) 2.11ServicetheBattery(Fig.31) 2.11ServicetheBattery(Fig.31) 2.11ServicetheBattery(Fig.31)

Do not smoke when servicing the Do not smoke when servicing the Do not smoke when servicing the Do not smoke when servicing the Do not smoke when servicing the

battery. battery. battery. battery. battery.

(a) Examinethebatterycasingfor

cracks or damage.

(b) Checkthatthebatteryleads

aresecurelyattachedtothe

terminal posts. Lightly grease

the posts and connectors with

petroleum jelly.

(c) Inspecttheelectrolytelevelin

each cell. Top up as necessary