Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Cat Diesel Engines - Basic

Caricato da

JESSDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Cat Diesel Engines - Basic

Caricato da

JESSCopyright:

Formati disponibili

Service Training

MALAGA

CAT Diesel Engines

Thorben

November 1997

CHAPTER : Introduction

CAT DIESEL ENGINES

2 Page:

Caterpillar produces engines for various applications:

EPG

MARINE

INDUSTRIAL

CAPTIVE

The engines are divided in three categories:

Small engines (3000 - 3300)

Medium engines (3400 - 3500)

Large engines (3600 - MAK)

CHAPTER : Introduction

CAT DIESEL ENGINES

3 Page:

Caterpillar engines can be divided in two types:

IN-LINE ENGINES

V

E

E

-

E

N

G

I

N

E

S

Those two types of engines are running on two different

types of fuel:

GAS DIESEL

CHAPTER : Introduction

CAT DIESEL ENGINES

4 Page:

If you know one, you know them all !

The difference from one engine to another is the fuel

system.

All other systems (cooling , lubrication , air) are fitted to

the different fuel systems.

The fuel system is the heart of an engine. It gives the

engine its power.

CHAPTER : Engine systems

CAT DIESEL ENGINES

5 Page:

OIL

AIR INTAKE & EXHAUST

LUBRICATION

COOLING

FUEL

CAT DIESEL ENGINES

6 Page:

Air intake & exhaust

CHAPTER : Air intake systems

CAT DIESEL ENGINES

7 Page:

Natural Aspirated Turbocharged

Turbocharged Turbocharged Aftercooled

JWAC

CHAPTER : T & TA

CAT DIESEL ENGINES

8 Page:

CHAPTER : NA & ATAAC

CAT DIESEL ENGINES

9 Page:

CHAPTER : JWAC & SCAC

CAT DIESEL ENGINES

10 Page:

CHAPTER : Air intake & exhaus

CAT DIESEL ENGINES

11 Page:

The use of a turbocharger is to get more power out of an

engine.

More air in the cylinder...

More fuel can be burned...

More horsepower output !

Aftercooling is an addition to turbocharging - this

increases the horsepower again !!

CHAPTER : 4-stroke system

CAT DIESEL ENGINES

12 Page:

CAT DIESEL ENGINES

13 Page:

OIL

Lubrication system

CHAPTER : Lub. system functions

CAT DIESEL ENGINES

14 Page:

An engine oil serves 5 vital functions in a modern diesel

engine:

1. Lubricates friction surfaces by forming a fluid film

2. Cools internal engine parts by absorbing heat.

3. Cleans the engine by flushing away dirt and wear

particles

4. Supprts the crankshaft and bearing

5. Protects the engine from harmfull acids, rust and

deposits

CHAPTER : Lubrication

CAT DIESEL ENGINES

15 Page:

Viscosity

Internal resistance felt as one layer of liquid moves relative

to another layer - ie: internal liquid friction.

SAE 20 weight 20 at 100C (212F)

SAE 20W weight 20 at -18C (0F)

SAE 20W - 30 weight 20 at -18C (0F)

&

weight 30 at 100C (212F)

CHAPTER : External & internal comp.

CAT DIESEL ENGINES

16 Page:

CHAPTER : Cross drillings & camshaft lub.

CAT DIESEL ENGINES

17 Page:

CHAPTER : Oil flow 3406 engine

CAT DIESEL ENGINES

18 Page:

CHAPTER : Oil pressure relief valve

CAT DIESEL ENGINES

19 Page:

CAT DIESEL ENGINES

20 Page:

Cooling system

CHAPTER : Heat transfer

CAT DIESEL ENGINES

21 Page:

Fuel burning temperature can reach 1927C (3500F).

CHAPTER : Heat sources

CAT DIESEL ENGINES

22 Page:

Other heat gernerating sources:

- transmission oil coolers

- hydraulic oil coolers

- aftercoolers

- water-cooled exhaust manifolds

- water-cooled turbocharger shields and

housings

- marine gear oil coolers

- torque converter / retarder coolers

CHAPTER : Systems & components

CAT DIESEL ENGINES

23 Page:

Cooling systems:

- radiator

- keel cooler

- shunt cooling

- heat exchanger cooling

Basic components:

- radiator

- fan

- coolant

- water pump

- engine oil cooler

- water temperature regulator

- pressure cap

CHAPTER : Keel/shunt/heat ex. system

CAT DIESEL ENGINES

24 Page:

CHAPTER : Coolant flow

CAT DIESEL ENGINES

25 Page:

Coolant flow:

water pump

oil cooler

cylinder block

cylinder head

(radiator)

water pump

CHAPTER : Pressure cap

CAT DIESEL ENGINES

26 Page:

CHAPTER : Altitude compensation

CAT DIESEL ENGINES

27 Page:

CAT DIESEL ENGINES

28 Page:

Fuel system

CHAPTER : CAT fuel systems

CAT DIESEL ENGINES

Pump & lines - Mul ti pl e pl unger pump

- Hi gh pressure fuel l i nes

- I nj ect i on nozzl es

- Li mi t ed i nj ect i on pressure (18. 000 PSI )*

- Li mi t ed i nj ect i on t i mi ng

- Li mi t ed i nj ect i on rat e capabi l i t i es

MUI - Mai nl y used on l arge engi nes to el i mi nate the need

for l ong hi gh pressure l i nes and the rel ated probl ems

i nherent wi th control l i ng pressure i n these l i nes.

- Requi res an addi ti onal cam l obe, l i fter, push rod

and rocker arm for each cyl i nder.

*Current engi ne emi ssi ons and perf ormance requi rement s demand i nj ect i on

pressure i n excess of 20.000 PSI and greater ti mi ng fl exi bi l i ty.

PEEC (Programmabl e El ectroni c Engi ne Control )

- ECM takes over of the functi ons of the mechani cal

governor.

- Fuel pump i s sti l l used.

- Throt t l e l i nkage repl aced by el ect roni c t hrot t l e.

- Ai r f uel rat i o cont rol el ect roni cal l y cont rol l ed.

- Engi ne i s equi pped wi t h vari ous sensors f or moni t ori ng.

EUI / MEUI (Mechani cal El ectroni c Uni t Inj ectors)

- Fuel i s metered el ectroni cal l y by means of a sol enoi d

operated poppet val ve.

- System sti l l requi res a mechani cal val ve trai n to

actuate the pl unger.

(Mechani cal l y act uat ed , el ect roni cal l y cont rol l ed)

- Fuel transfer pump repl aces the "pump & l i nes".

HEUI (Hydraul i c El ect roni c Uni t Inj ectors)

- Pl unger movement i s not l i mi ted to speed or durati on

of a cam l obe.

- Pl unger speed i s a functi on of actuati on pressure

versus fuel pumpi ng resi stance.

(Hydraul i cal l y act uat ed , el ect roni cal l y cont rol l ed)

- Inj ecti on pressure i s +20.000 PSI

CHAPTER : Fuel pumps (pump & lines)

CAT DIESEL ENGINES

30 Page:

CHAPTER : System components

CAT DIESEL ENGINES

31 Page:

C

H

A

P

T

E

R

:

P

u

m

p

&

l

i

n

e

s

f

u

e

l

s

y

s

t

e

m

C

A

T

D

I

E

S

E

L

E

N

G

I

N

E

S

3

2

P

a

g

e

:

TRANSFER PUMP

FUEL FILTER

WATER

SEPARATOR

LIFT PUMP

PRESSURE

REGULATOR

INJECTOR

ROTOR

DELIVERY

VALVE

PLUNGERS

METERING

VALVE

AUTOMATIC

ADVANCE

GOVERNOR

GOVERNOR

SPRING

RETURN

CHECK

VALVE

HOUSING LUBE

FUEL TANK

ORIFICE

CHECK VALVE

VENT

WIRE

HEAD

PASSAGE

CHAPTER : Lift pump

CAT DIESEL ENGINES

33 Page:

CHAPTER : Lift pump operation

CAT DIESEL ENGINES

34 Page:

C

H

A

P

T

E

R

:

S

t

a

n

d

a

d

y

n

e

f

u

e

l

p

u

m

p

C

A

T

D

I

E

S

E

L

E

N

G

I

N

E

S

3

5

P

a

g

e

:

CAM

FUEL RETURN

CHECK VALVE

METERING VALVE

FUEL OUTLET

PRESSURE

REGULATOR

TRANSFER

PUMP

DELIVERY

VALVE

ROTOR

ORIFICE CHECK

VALVE

SHOE

AUTOMATIC ADVANCE

MECHANISM

GOVERNOR

WEIGHTS

PISTON

ROLLER

GOVERNOR

SPRING

CHAPTER : Internal tranfer pump

CAT DIESEL ENGINES

36 Page:

CHAPTER : Metering valve

CAT DIESEL ENGINES

37 Page:

CHAPTER : Charging passages

CAT DIESEL ENGINES

38 Page:

CHAPTER : Pumping chambers

CAT DIESEL ENGINES

39 Page:

CHAPTER : Pumping chambers

CAT DIESEL ENGINES

40 Page:

CHAPTER : Fuel delivery to injectors

CAT DIESEL ENGINES

41 Page:

CHAPTER : Delivery valve

CAT DIESEL ENGINES

42 Page:

CHAPTER : Injection cycle review

CAT DIESEL ENGINES

43 Page:

CHAPTER : Timing advance

CAT DIESEL ENGINES

44 Page:

CHAPTER : Governor principle

CAT DIESEL ENGINES

45 Page:

CHAPTER : Plunger operation

CAT DIESEL ENGINES

46 Page:

CHAPTER : Standadyne governor

CAT DIESEL ENGINES

47 Page:

CHAPTER : Throttle lever operation

CAT DIESEL ENGINES

48 Page:

CHAPTER : Fuel Ratio Control (FRC)

CAT DIESEL ENGINES

49 Page:

CHAPTER : Shut off solenoid

CAT DIESEL ENGINES

50 Page:

Shut off solenoidCHAPTER :

CAT DIESEL ENGINES

51 Page:

CHAPTER : MUI fuel system

CAT DIESEL ENGINES

52 Page:

Filter

change

valve

Relief valve

Hand

priming

pump

Check

valve

Unit

injector

Pressure

relief

valve

Secondary

fuel filter

elements

Secondary

fuel filter

elements

Main

fuel

pump

Main

fuel tank

Primary

Fuel filters

Check

valve

Check

valve

Check

valve

Check

valve

CHAPTER : Mechanical Unit Injector

CAT DIESEL ENGINES

53 Page:

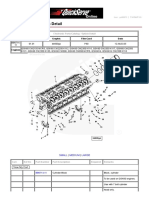

CHAPTER : MUI cylinder head

CAT DIESEL ENGINES

54 Page:

CHAPTER : Electronic engines

CAT DIESEL ENGINES

55 Page:

Input

Circuit

Power

Circuit

Output

Circuit

- From Battery

( 8vdc Minimum )

- To Rack And Lamps

- To Sensors

- Signals From Sensor

- Filter Electrical Noise

- Protect Voltage Levels

CHAPTER : System components (PEEC)

CAT DIESEL ENGINES

56 Page:

Eng Speed Sensor

Shutoff Solenoid

Rack Position Sensor

Rack BTM

Atmospheric Pressure

Sensor

Boost Pressure

Sensor

Oil Pressure

Sensor

Coolant Temp

Sensor

Coolant

Level

Sensor

Customer

Connector

Eng Data Link

Connector

E C M

P7 J7

P15 J15

P8 J8

P9 J9

P12 J12

P17

P14 J14

J13

C

H

A

P

T

E

R

:

P

E

E

C

f

u

e

l

s

y

s

t

e

m

C

A

T

D

I

E

S

E

L

E

N

G

I

N

E

S

5

7

P

a

g

e

:

BTM

FSOS

RPS

PRIMING

PUMP

ECM

TRANSFER PUMP

INJECTOR

TANK

PRIMARY

FILTER

CHECK

VALVE

SECONDARY

FILTER

CHAPTER : PEEC fuel rack

CAT DIESEL ENGINES

58 Page:

SHUTOFF SOLEINOID

B T M

FUEL RACK

SERVO

FUEL ON

PWM

RACK POSITION SENSOR

C

H

A

P

T

E

R

:

C

o

n

t

r

o

l

l

o

g

i

c

(

P

E

E

C

)

C

A

T

D

I

E

S

E

L

E

N

G

I

N

E

S

5

9

P

a

g

e

:

ELECTRONIC

GOVERNOR

RACK POSITION SENSOR

RACK

CONTROL

TORQUE

MAPS

FRC

MAPS

RACK

BTM

SPEED SENSOR

BOOST PRESS. SENSOR

DESIRED SPEED

ACTUAL SPEED

RATED

RACK

LIMIT

FRC

RACK

LIMIT

ACTUAL RACK POSITION

RACK POSITION SENSOR

THROTTLE

POSITION

SENSOR

C

H

A

P

T

E

R

:

E

U

I

s

y

s

t

e

m

c

o

m

p

o

n

e

n

t

s

C

A

T

D

I

E

S

E

L

E

N

G

I

N

E

S

6

0

P

a

g

e

:

ELECTRONIC UNIT

INJECTOR

12V

TIMING CALIBRATION SENSOR

ELECTRONIC

CONTROL MODULE

(ECM)

ENGINE

HARNESS

SPEED/TIMING SENSOR

COOLANT TEMPERATURE SENSOR

TURBO OUTLET PRESSURE SENSOR

ATMOSPHERIC PRESSURE SENSOR

FUEL TEMPERATURE SENSOR

MACHINE

HARNESS

GROUND

STUD

MAIN

POWER RELAY

KEY

SWITCH

15 AMP

BREAKER

DATA LINK

CONNECTOR

ET/ECAP

DATA LINK

THROTTLE POSITION SENSOR

CHECK ENGINE LAMP

LAMP FLASH SWITCH

TRANSMISSION PRESSURE SWITCHES

ADEM II

CONTROL

3176B EUI COMPONENT DIAGRAM

CHALLENGER 75C/85C

J1 P1

CONNECTOR

J2 P2

CHAPTER : Fuel system (EUI)

CAT DIESEL ENGINES

61 Page:

MECHANICALY ACTUATED ELECTRONICAL CONTROLED

Electronic

Unit

Injector

FILTER

E C M

PUMP

FUEL

TANK

RELIEF

VALVE

CHAPTER : Fuel injection

CAT DIESEL ENGINES

62 Page:

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

11

12

1. Solenoid Connection

2. Solenoid Valve Assem

3. Spring

4. Valve

5. Plunger

6. Barrel

7. Seal

8. Seal

9. Spring

10. Spacer

11. Body

12. Check

C

H

A

P

T

E

R

:

H

E

U

I

f

u

e

l

s

y

s

t

e

m

C

A

T

D

I

E

S

E

L

E

N

G

I

N

E

S

6

3

P

a

g

e

:

High Pressure

Oil Pump

HIGH PRESSURE OIL MANIFOLD

Fuel Return Line

ECM

Fuel

Filter

Fuel

Trans

Pump

Fuel Tank

Oil

Pump

Oi

lS

u

m

p

Oil

Cooler

Oil

Filter

Vehicle

System

Engine System

Regulator

Pressure

Control

Valve

40 to 210 BAR

LOW PRESSURE 3 BAR

CHAPTER : HEUI fuel system

CAT DIESEL ENGINES

64 Page:

T

O

L

U

B

E

S

Y

S

T

E

M

F

U

E

L

T

R

A

N

S

F

E

R

P

U

M

P

P

U

M

P

C

O

N

T

R

O

L

V

A

L

V

E

O

I

L

F

I

L

T

E

R

O

I

L

C

O

O

L

E

R

H

E

U

I

H

E

U

I

O

I

L

S

U

M

P

H

Y

D

R

A

U

L

I

C

P

R

E

S

S

U

R

E

S

E

N

S

O

R

H

Y

D

R

A

U

L

I

C

T

E

M

P

E

R

A

T

U

R

E

S

E

N

S

O

R

O

I

L

P

R

E

S

S

U

R

E

S

E

N

S

O

R

H

Y

D

R

A

U

L

I

C

S

U

P

P

L

Y

P

U

M

P

G

R

O

U

P

C

O

O

L

D

O

W

N

C

I

R

C

U

I

T

F

U

E

L

T

E

M

P

E

R

A

T

U

R

E

S

E

N

S

O

R

E

C

M

F

U

E

L

T

A

N

K

P

R

E

S

S

U

R

E

R

E

G

U

L

A

T

I

N

G

V

A

L

V

E

S

E

C

O

N

D

A

R

Y

F

U

E

L

F

I

L

T

E

R

P

R

I

M

A

R

Y

F

U

E

L

F

I

L

T

E

R

W

A

T

E

R

S

E

P

A

R

A

T

O

R

L

U

B

E

O

I

L

P

U

M

P

C

O

L

D

S

T

A

R

T

O

I

L

R

E

S

E

R

V

O

I

R

F

L

U

I

D

M

A

N

I

F

O

L

D

H

Y

D

R

A

U

L

I

C

P

A

S

S

A

G

E

F

L

U

I

D

M

A

N

I

F

O

L

D

H

Y

D

R

A

U

L

I

C

P

A

S

S

A

G

E

CHAPTER : HEUI injector

CAT DIESEL ENGINES

65 Page:

BARREL

PISTON

VALVE

FUEL INLET

CHECK VALVE

PIN

SPACER

SLEEVE

VALVE BODY

CHECK

SHIM

ADAPTER

SPACER

ARMATURE

SOLENOID

WASHER

PLUNGER

SLEEVE

LOWER FUEL SEAL

UPPER FUEL SEAL

NOZZLE

CHAPTER : Injection

CAT DIESEL ENGINES

66 Page:

CHAPTER : Poppet valve open

CAT DIESEL ENGINES

67 Page:

ARMATURE

SCREW

POPPET

SPRING

CHAPTER : Drain

CAT DIESEL ENGINES

68 Page:

CHAPTER : Poppet valve closed

CAT DIESEL ENGINES

69 Page:

INLET

VALVE SEAT

SOLENOID

POPPET VALVE

ARMATURE

EXHAUST

VALVE SEAT

CHAPTER : Nozzle group

CAT DIESEL ENGINES

70 Page:

FUEL

ATOMIZATION

NOZZLE GROUP

CHECK VALVE

REVERSE FLOW

CHECK VALVE

CHAPTER : Injection cycle

CAT DIESEL ENGINES

71 Page:

CROSS SECTION

OF PLUNGER

START OF INJECTION PRESSURE DROP

INJECTION

RATE

START OF

INJECTION

DURATION

FINAL

PRESSURE INCREASE

TIME (MILLISECONDS)

END OF

INJECTION

C

H

A

P

T

E

R

:

V

a

r

i

a

b

l

e

d

i

s

p

l

a

c

e

m

e

n

t

p

u

m

p

C

A

T

D

I

E

S

E

L

E

N

G

I

N

E

S

7

2

P

a

g

e

:

PRIMING PORT

ORIFICE

RESERVOIR

SWASHPLATE

TRANSFER PUMP

COMPENSATOR

VALVE

VALVE BASE

DRAIN PASSAGE

CHAPTER : Injection pressure

CAT DIESEL ENGINES

73 Page:

IDLE

I

N

J

E

C

T

I

O

N

P

R

E

S

S

U

R

E

MECHANICALLY ACTUATED

FUEL SYSTEM

H E U I

ENGINE SPEED

Potrebbero piacerti anche

- 3500bepg MotorDocumento46 pagine3500bepg Motorkom376376100% (2)

- CAT-ENGINES Presentation 1Documento107 pagineCAT-ENGINES Presentation 1Mohamed Saied100% (2)

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorDa EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNessuna valutazione finora

- Caterpillar Service TrainingDocumento694 pagineCaterpillar Service TrainingQuangvu Hoang95% (44)

- CAT Diesel Engines BasicsDocumento73 pagineCAT Diesel Engines Basicsjetdede100% (2)

- Basic EngineDocumento151 pagineBasic EngineJean Marco Cordova Velasquez100% (4)

- 12V24V Electrical SystemsDocumento26 pagine12V24V Electrical SystemsAllan Lariosa100% (17)

- Diagnostico y TroubleshootingDocumento40 pagineDiagnostico y Troubleshootinggabriel pacovilca arhuataNessuna valutazione finora

- Elect Sect01Documento113 pagineElect Sect01Luis Eduardo Corzo Enriquez100% (4)

- 3516 Engines ClassDocumento75 pagine3516 Engines ClassMohamed Bakheet89% (19)

- 3512 Engine OverhaulDocumento7 pagine3512 Engine OverhaulDarkman P and B50% (2)

- Caterpillar Common RailDocumento6 pagineCaterpillar Common Rail08088338100% (2)

- Acert Technology For Off-Highway C15, C18, C27 and C32 EnginesDocumento81 pagineAcert Technology For Off-Highway C15, C18, C27 and C32 EnginesManuel Ruiz Cayun100% (2)

- Cat Basic EngineDocumento104 pagineCat Basic EngineMahmmod Mohammed100% (3)

- C32 Project GuideDocumento32 pagineC32 Project GuideAnonymous Kr13NEB100% (4)

- 3600 Engines - BasicDocumento57 pagine3600 Engines - Basicmizahur100% (1)

- c9 Machine Acert 2Documento56 paginec9 Machine Acert 2Gustavo Portos100% (4)

- C9 Electronic Control SystemDocumento26 pagineC9 Electronic Control Systemnilton ac100% (2)

- Instruct Motor BasicoDocumento57 pagineInstruct Motor Basicokom376376Nessuna valutazione finora

- Over The Road Engine Service TrainingDocumento318 pagineOver The Road Engine Service Trainingibrahem100% (3)

- Caterpillar Engine Oil SpecificationsDocumento10 pagineCaterpillar Engine Oil SpecificationsKikemol Lv O0% (1)

- Cat Electronic Control ModuleDocumento2 pagineCat Electronic Control ModuleAndresan50767% (6)

- Caterpillar Speed Sensor Principles and OperationDocumento31 pagineCaterpillar Speed Sensor Principles and OperationCharles HornNessuna valutazione finora

- SIS News 3500 SeriesDocumento56 pagineSIS News 3500 SeriesЕвгений АбрамовNessuna valutazione finora

- 3500 Engine Controls - Electronic Unit Injection (Slides) PDFDocumento101 pagine3500 Engine Controls - Electronic Unit Injection (Slides) PDFSaul Leonidas Astocaza Antonio100% (12)

- Cat 3406 Intervalos Mantenimientos PDFDocumento61 pagineCat 3406 Intervalos Mantenimientos PDFdqsclNessuna valutazione finora

- FUEL SYSTEM OF C18 and C6.6Documento135 pagineFUEL SYSTEM OF C18 and C6.6Sahr, Cyprian Fillie100% (2)

- 135 3500-3500B MotoresDocumento131 pagine135 3500-3500B MotoresMARCOS100% (3)

- Global Service Learning: 777F (JRP) Off-Highway TrucksDocumento79 pagineGlobal Service Learning: 777F (JRP) Off-Highway TrucksManuel Pompa Flores100% (3)

- Caterpillar EMCPDocumento40 pagineCaterpillar EMCPrealwild93% (59)

- Troubleshooting and Repairing Diesel Engines, 5th EditionDa EverandTroubleshooting and Repairing Diesel Engines, 5th EditionValutazione: 2.5 su 5 stelle2.5/5 (2)

- Systems Operation: Cerrar SISDocumento138 pagineSystems Operation: Cerrar SISCar GarciaNessuna valutazione finora

- Curso Cat 3054-56E Mot Electronicos Bosch VP30Documento62 pagineCurso Cat 3054-56E Mot Electronicos Bosch VP30marcosluna68100% (11)

- Heui Fuel System c9 EngineDocumento25 pagineHeui Fuel System c9 Enginebabaisandip91% (53)

- Paxman SpecsDocumento9 paginePaxman Specsbastech100% (2)

- Diesel Engine CatDocumento73 pagineDiesel Engine CatMorales Quijada A100% (1)

- Systems Operation: Shutdown SIS Previous ScreenDocumento304 pagineSystems Operation: Shutdown SIS Previous Screenm yani0% (1)

- Motor C6.6Documento15 pagineMotor C6.6Fernando Ortiz100% (3)

- Serv1852 02 TXT8Documento52 pagineServ1852 02 TXT8ابو احمد100% (8)

- Oporeation Cammon RailDocumento14 pagineOporeation Cammon Railimam nahrowiNessuna valutazione finora

- Service Training MALAGA CAT Diesel EnginDocumento73 pagineService Training MALAGA CAT Diesel Enginahmed elsheikhNessuna valutazione finora

- Fuel SystemDocumento26 pagineFuel SystemjuankielecNessuna valutazione finora

- 1-Method of OperationDocumento77 pagine1-Method of OperationAHMADNessuna valutazione finora

- X9 Training SupportDocumento33 pagineX9 Training Supportpassero202Nessuna valutazione finora

- C5-12D - A320 Capabilities - April2014 PDFDocumento8 pagineC5-12D - A320 Capabilities - April2014 PDFMohammad AzamNessuna valutazione finora

- Funcionamiento Del Sistema Heui 938GIIDocumento23 pagineFuncionamiento Del Sistema Heui 938GIIchristian vergaray gonzalesNessuna valutazione finora

- Tr7-8fi ManualDocumento82 pagineTr7-8fi ManualClint CooperNessuna valutazione finora

- Maintenance Instruction Manual Type-Wdg3A Fitted With Dual Brake System 2004-05Documento298 pagineMaintenance Instruction Manual Type-Wdg3A Fitted With Dual Brake System 2004-05Sudeep Prasad0% (1)

- 320A Hydraulic System OperationDocumento135 pagine320A Hydraulic System OperationZawminhtunNessuna valutazione finora

- Tata Bs IV Final CircularDocumento19 pagineTata Bs IV Final CircularD. Nanda KishoreNessuna valutazione finora

- PrattWhitney Book 2Documento393 paginePrattWhitney Book 2luis Minaya100% (7)

- Ata 71 Power PlantDocumento38 pagineAta 71 Power PlantAlejandroNessuna valutazione finora

- Fuel System JTEC ChryslerDocumento56 pagineFuel System JTEC ChryslerkeiwerkasNessuna valutazione finora

- Systems Operation: Shutdown SIS Previous ScreenDocumento163 pagineSystems Operation: Shutdown SIS Previous ScreenAngelica VergaraNessuna valutazione finora

- Techdoc Print Page PDFDocumento5 pagineTechdoc Print Page PDFSuharto ZuhriNessuna valutazione finora

- Cat C 6.4 Fuel SystemDocumento13 pagineCat C 6.4 Fuel Systemali83% (6)

- IT38G Fuel SitemaDocumento24 pagineIT38G Fuel Sitemavitor santosNessuna valutazione finora

- KE Jetronic Mercedes Benz 190 EDocumento3 pagineKE Jetronic Mercedes Benz 190 ERuben Michel100% (4)

- 320, 320 L and 320 N Operation Hydraulic SystemDocumento162 pagine320, 320 L and 320 N Operation Hydraulic SystemF Labio AlexNessuna valutazione finora

- 3 KTA DesignguideDocumento32 pagine3 KTA Designguideodin_auerNessuna valutazione finora

- Conceptos de NOxDocumento48 pagineConceptos de NOxJESS100% (1)

- 04 Monitoring DMSDocumento13 pagine04 Monitoring DMSJESSNessuna valutazione finora

- 998-4529 BD PDFDocumento10 pagine998-4529 BD PDFsabirnaseerNessuna valutazione finora

- Energias RenovablesDocumento20 pagineEnergias RenovablesJESSNessuna valutazione finora

- Energias RenovablesDocumento20 pagineEnergias RenovablesJESSNessuna valutazione finora

- Financiación de Proyectos de Energía Renovable en América LatinaDocumento31 pagineFinanciación de Proyectos de Energía Renovable en América LatinaJESSNessuna valutazione finora

- Regulatory and Commercial Barriers To The Development of Renewable EnergiesDocumento18 pagineRegulatory and Commercial Barriers To The Development of Renewable EnergiesJESSNessuna valutazione finora

- MAVR Excitation ControllerDocumento32 pagineMAVR Excitation ControllerJESSNessuna valutazione finora

- SEPOPE 2012 Synchronous Machine Network Model Full Scope Training SimulatorDocumento11 pagineSEPOPE 2012 Synchronous Machine Network Model Full Scope Training SimulatorJESSNessuna valutazione finora

- Exciter TrainingDocumento111 pagineExciter TrainingJESSNessuna valutazione finora

- ATPDraw v5 PresentationDocumento60 pagineATPDraw v5 Presentation임광식Nessuna valutazione finora

- Motor Stirling 60Documento8 pagineMotor Stirling 60Jhonatan Arley Leon FuentesNessuna valutazione finora

- QSK60 CM500 (33155567) Parts Manual PDFDocumento179 pagineQSK60 CM500 (33155567) Parts Manual PDFP Kumar80% (5)

- Chillers COOLTECH enDocumento2 pagineChillers COOLTECH enGunawanNessuna valutazione finora

- XDI Manual Version 1.4 2007 Electromotive, Inc.: Single Tower Coils Are Used For This ApplicationDocumento36 pagineXDI Manual Version 1.4 2007 Electromotive, Inc.: Single Tower Coils Are Used For This ApplicationDiego FiliceNessuna valutazione finora

- Generac Air-Cooled Gas Gen Ser ManualDocumento210 pagineGenerac Air-Cooled Gas Gen Ser ManualPhillip Ekpo100% (1)

- Mercury Commander Side Mount ControlDocumento18 pagineMercury Commander Side Mount ControlTab Sedgwick100% (1)

- Electronic Measurements Instrumentation U A BakshiDocumento3 pagineElectronic Measurements Instrumentation U A BakshiLawrence Ngari0% (1)

- Mid-Term Examination 2 Semester 1 - Academic Year 2021-2022 Course Name: Electrical MachineDocumento2 pagineMid-Term Examination 2 Semester 1 - Academic Year 2021-2022 Course Name: Electrical MachineTuấn TrầnNessuna valutazione finora

- Sf18P-Lm: 802.3Af/At, 6Kv Lightning, Three Modes, Max 135W Poe PowerDocumento2 pagineSf18P-Lm: 802.3Af/At, 6Kv Lightning, Three Modes, Max 135W Poe PowerRodrigo Olivares hiriartNessuna valutazione finora

- The Peripheral Components of A Computer.: Executed By: Mihai Isac ProfessorDocumento10 pagineThe Peripheral Components of A Computer.: Executed By: Mihai Isac ProfessorMihai IsacNessuna valutazione finora

- 23 CVTDocumento20 pagine23 CVTMatías RebolledoNessuna valutazione finora

- Price Sheet - Alta Construction Equipment Florida, LLCDocumento663 paginePrice Sheet - Alta Construction Equipment Florida, LLCeduardo automotrizcpNessuna valutazione finora

- Name - Atobatele Hameed Olamide Matric Number - CSC/2016/038 Department - Computer Science With Mathematics Course - CPE401Documento11 pagineName - Atobatele Hameed Olamide Matric Number - CSC/2016/038 Department - Computer Science With Mathematics Course - CPE401JIBOLA-SHITTU MoboluwarinNessuna valutazione finora

- h1 O03eg0 ICDocumento131 pagineh1 O03eg0 ICEned ÇelajNessuna valutazione finora

- wt10 enDocumento348 paginewt10 enNguyễn Văn KiênNessuna valutazione finora

- Fischer FH II High Performance AnchorDocumento5 pagineFischer FH II High Performance AnchorJaga NathNessuna valutazione finora

- Microprocessor NotesDocumento44 pagineMicroprocessor NotesMag CreationNessuna valutazione finora

- 1 SMDocumento10 pagine1 SMJoko ParwonoNessuna valutazione finora

- Smart Bias-T AISGDocumento6 pagineSmart Bias-T AISGMariNessuna valutazione finora

- IL SYS INST UM E 6452 en 10Documento190 pagineIL SYS INST UM E 6452 en 10FallNessuna valutazione finora

- Description & OperationDocumento11 pagineDescription & Operationmanoj1945491Nessuna valutazione finora

- SA Z326K Eng V1.14 PDFDocumento53 pagineSA Z326K Eng V1.14 PDFYanira RosasNessuna valutazione finora

- RubricsDocumento2 pagineRubricsMarian Alexis Fernandez67% (3)

- List of Equipments Ec LabDocumento1 paginaList of Equipments Ec LabLester GarciaNessuna valutazione finora

- Chapter 1 (Introduction To Servicing Heavy-Duty Trucks) 1-SignedDocumento16 pagineChapter 1 (Introduction To Servicing Heavy-Duty Trucks) 1-SignedZIBA KHADIBI100% (1)

- Product Manual DCP Trolley Mounted 25-50-75 KGDocumento6 pagineProduct Manual DCP Trolley Mounted 25-50-75 KGm4l4ysiaNessuna valutazione finora

- Indexer Cam Gear Kurvengetriebe HSG BWV - HEINZDocumento20 pagineIndexer Cam Gear Kurvengetriebe HSG BWV - HEINZluiz cláudioNessuna valutazione finora

- Boat Trailer Parts - Rocket TrailersDocumento10 pagineBoat Trailer Parts - Rocket TrailersRocket TrailersNessuna valutazione finora

- FT Sifer 950iDocumento2 pagineFT Sifer 950iAshik M RasheedNessuna valutazione finora

- Computer Architecture Summary 1 Cheat Sheet: by ViaDocumento4 pagineComputer Architecture Summary 1 Cheat Sheet: by ViaKarthiNessuna valutazione finora