Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Selection of Induction Motors For Industrial Applications Part 1

Caricato da

shadi22Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Selection of Induction Motors For Industrial Applications Part 1

Caricato da

shadi22Copyright:

Formati disponibili

elect rical-engineering-port al.

com

http://electrical-engineering-portal.com/selection-of-induction-motors-for-industrial-applications-part-1

Sel ecti on of Inducti on Motors for Industri al Appl i cati ons (photo by http://www.i ecee.org)

Ashok Parikh

Selection of Induction Motors for Industrial Applications (part

1)

Introduction

All types of industries are invariably required to install dif f erent types of electric motors as prime mover f or

driving process equipment participating in their respective production line up. The continuous process of

technical development has resulted into availability of highly diversif ied types of electric motors.

Hence, an utmost care should be exercised in selection of most appropriate type of motor considering

number of technical factors for each application, so that the motor would provide desired and optimum

performance.

The characteristics of motors vary widely with the nature of their application and the type of duty they are

expected to perf orm. For example, the applications like constant speed, constant torque, variable speed,

continuous/intermittent duty, steep/sudden starts, f requent start/stops, etc. should be taken into

consideration caref ully when deciding f or the type of a motor f or that specif ic application.

Moreover, the motors are required to perform quite often under abnormal conditions during their total

service lif e.

Stator and Rotor Damages

In view of above, an incorrect selection of motor always lands the industrial buyer into all sorts of

problems, including premature failure of the motor, causing severe production curtailments.

Like one mentioned above, a number of other f actors and design f eatures like weather conditions,

stringent system conditions, abnormal surroundings, hazardous area, duty cycle, motor efficiency,

etc. should be considered while deciding the rating and subsequently drawing out the technical

specif ications of the motor.

Abnormal

condit ions and

ef f ect s

The usual abnormal

conditions

encountered by the

motors are given

below.

1. Abnormal Syst em

Condit ions

1. Voltage

1. Undervoltage

2. Overvoltage

3. Unbalance in 3-phase

4. Single phasing

5. Voltage surges

2. Frequency

1. Low f requency

2. High f requency

2. Abnormal Operat ing condit ions

1. Locked rotor or stalled rotor

2. Reswitching/Frequent start-stops

3. Momentary interruption/Bus transf er

4. Overloading

5. Improper cable sizing

3. Environment al condit ions

1. High/low ambienttemperature

2. High altitude

3. High humidity

4. Corrosive atmosphere

5. Hazardous atmosphere/surroundings

6. Exposure to steam/salt-laden air/oil vapour

4. Mechanical problems

1. Seized bearings

2. Incorrect alignment/f oundation levelling

3. Incorrect f ixing of coupling

4. High vibration mounting

5. External shock due to load

5. Condit ion at locat ion

1. Poor ventilation

2. Dirt accumulation

3. Exposure to direct sunlight

Though, above mentioned abnormalities may prevail f or short or long duration or may be transient in

nature, major impact of the listed abnormal conditions is overheating of the motor along with one or

several of the other ef f ects as f ollows.

Change in the motor perf ormance characteristics like drawl of more power and consequent deterioration in

motor ef f iciency, etc.

Increase in mechanical stresses leading to:

1. Shearing of shaf ts

2. Damage to winding overhang

3. Bearing f ailures

4. Insulation f ailures

Increase in stator and rotor winding temperature leading to:

1. Premature f ailure of stator or rotor insulation (For wound rotor motor)

2. Increased f ire hazard

3. Breakage of rotor bar and/or end ring (For squirrel cage motors)

All the motors encounter few or several of these abnormalities during the course of their service lives.

Consideration of listed abnormal conditions at design stage greatly helps to minimise the effects of

abnormal conditions to maintain a consistent perf ormance.

Design Considerations

Following are the most important design factors required to be considered when selecting a motor f or any

of the diversif ied industrial applications.

Out put in kW/HP

There are two principle limitations for selecting the motor output:

1. Mechanical limit at ion

The breakdown torque, which is the maximum torque that the motor can produce when operating without

stalling. This is a critical design f actor in motor applications, particularly for the motors subjected to

occasional extreme load conditions.

Another critical f actor is the locked-rotor torque, which is the maximum torque that the motor can produce

during startup f rom steady-state condition, a critical design f eature f or conveyor drives.

2. Elect rical limit at ion due t o insulat ion provided on t he mot or windings

The electrical load on the motor can be imposed till the winding insulation is able to withstand the

prescribed temperature rise over an ambient f or that particular class of insulation. Lif e of the motor greatly

depends on the temperature rise of the windings.

Anticipated lif e-span of the motor can be achieved provided it is operated at its rated output without

overloading and the prescribed preventive maintenance practices are religiously f ollowed.

Speed of t he Mot or

Most of the motors are directly coupled with the driven equipment where in the speed of the motor and

the driven equipment will be same.

In order to meet the speed of the driven equipment, the devices like gearbox, chains or belts are

introduced between motor and driven equipment. In this case, it may be necessary to provide the rotor

shaft suitable f or its attachment with the speed decreasing or increasing device and hence the

specif ication should include such specif ic requirement.

In case a variable speed drive is to be used f or the speed variation, the motor should be compatible f or this

specif ic application. The standard motor may not provide desired perf ormance when operated via variable

speed drive.

Cant see this video? Click here to watch it on Youtube.

Power Supply Volt age and Frequency Variat ions

Variations in the power supply parameters, i.e. voltage and f requency signif icantly af f ect overall

perf ormance of the motor. As provided in IS:325-1996, the permissible voltage variation is 5 to 10%,

permissible frequency is 50Hz 3%, and permissible combined variation is 6 %.

The effect of undervoltage is more serious than that of overvoltage.

The higher torque, resulting f rom overvoltage, can handle a little overload without undue heating of the

winding, but only f or a short duration. Continuous operation with undervoltage condition increases the

current at the rate of about 20% f or every 5% reduction in the supply voltage, increasing the rated copper

loss.

This results into heating and prolonged temperature rise, and f inally the burning of winding. During a

motor start-up, the torque reduces by 10% f or each 5% reduction in the supply voltage, causing more

starting current and consequently more rapid heating of the

winding.

Large burned out i nducti on motor

The

motor

offers

reduced efficiency at either overvoltage or undervoltage. Power f actor drops sharply with higher voltage

and improves with lower voltage. Even when motor is lightly loaded, over-voltage cause rise in current and

temperature thus reducing the lif e of motor. The variation in f requency by +5 % decreases the torque by

about 10% and vice-versa at 5% f requency, the torque increases by about 10%.

It is, theref ore, of utmost importance to consider the combined ef f ect of variation in voltage and f requency

both when purchasing the motor.

Unbalance in the supply voltage results into a current unbalance of 6 to 10 times the percentage

voltage unbalance. This in turn results into generation of negative sequence currents in the rotor causing

its overheating and premature f ailure.

It is theref ore vital to specif y the permissible limits of variations in the power supply parameters f or the

motor in accordance with the requirement of the driven equipment. However, the permissible limits should

never be more than provided in the applicable Indian Standard IS:325-1996 (Reaf f irmed in 2002).

Will be continued very soon

Potrebbero piacerti anche

- Selection of Induction MotorsDocumento5 pagineSelection of Induction MotorsadauNessuna valutazione finora

- Selection of MotorsDocumento16 pagineSelection of Motorsmithun46Nessuna valutazione finora

- Selection of Motors ARPDocumento7 pagineSelection of Motors ARPashokparikhNessuna valutazione finora

- ManualDocumento385 pagineManualSayak BoseNessuna valutazione finora

- Basics of 3phase Induction Motor Part 4Documento47 pagineBasics of 3phase Induction Motor Part 4sanjay sharmaNessuna valutazione finora

- Vemat-Slip Ring MotorsDocumento16 pagineVemat-Slip Ring MotorszoelfiantaNessuna valutazione finora

- JETIR2107059Documento8 pagineJETIR2107059Gebrerufael GebrelibanosNessuna valutazione finora

- Week 101Documento48 pagineWeek 101Raphael SebucNessuna valutazione finora

- MotorDocumento15 pagineMotorersanjeeb_456Nessuna valutazione finora

- Training Manual On Motor MaintenanceDocumento107 pagineTraining Manual On Motor MaintenancePhanindra Kumar J100% (1)

- 3 Phase Induction Motor Speed Control Using PIC PDFDocumento18 pagine3 Phase Induction Motor Speed Control Using PIC PDFAmmar Al-Kindy100% (2)

- Paradeep Phosphates Limited: Motor MaintenanceDocumento39 pagineParadeep Phosphates Limited: Motor MaintenanceSushanta kumar pandaNessuna valutazione finora

- Basics of 3phase Induction Motor Part 4Documento5 pagineBasics of 3phase Induction Motor Part 4TigrilloNessuna valutazione finora

- Vibration Monitoring For Fault Motors Diagnosis PDFDocumento8 pagineVibration Monitoring For Fault Motors Diagnosis PDFuuur35100% (1)

- IE3-IE4 Motors - Selecting The Right Control and Protection Components - EE PublishersDocumento8 pagineIE3-IE4 Motors - Selecting The Right Control and Protection Components - EE PublishersTruong HungNessuna valutazione finora

- Maintenance of Motors and GeneratorsDocumento116 pagineMaintenance of Motors and GeneratorsAtiqur RahmanNessuna valutazione finora

- Part I Protection Philosophy of Electrical EquipmentsDocumento25 paginePart I Protection Philosophy of Electrical EquipmentsNaresh RajuNessuna valutazione finora

- Electric MotorsDocumento13 pagineElectric MotorsCholan PillaiNessuna valutazione finora

- Basics For Practical Operation - Motor ProtectionDocumento68 pagineBasics For Practical Operation - Motor ProtectionSumit VermaNessuna valutazione finora

- How To Specify Motor VoltageDocumento4 pagineHow To Specify Motor VoltageCyrix.OneNessuna valutazione finora

- IM Protection Using PSCADDocumento8 pagineIM Protection Using PSCADRavishankar KankaleNessuna valutazione finora

- AC Generator Reverse KVAr IssueDocumento14 pagineAC Generator Reverse KVAr IssueMURALINessuna valutazione finora

- AC Generator Reverse KVAr IssueDocumento14 pagineAC Generator Reverse KVAr IssueMURALINessuna valutazione finora

- Electric Motors: Syllabus Electric Motors: Types, Losses in Induction Motors, Motor Efficiency, Factors AffectingDocumento12 pagineElectric Motors: Syllabus Electric Motors: Types, Losses in Induction Motors, Motor Efficiency, Factors AffectingAjay kunwar singhNessuna valutazione finora

- Induction Motors For Farm ApplicationsDocumento9 pagineInduction Motors For Farm ApplicationsramfalNessuna valutazione finora

- K AssmamawDocumento15 pagineK AssmamawagegnehukassahuagegnehuNessuna valutazione finora

- Chirag Sem 8 NewDocumento26 pagineChirag Sem 8 Newchiragarunkar2511Nessuna valutazione finora

- Ge VFD MotorsDocumento33 pagineGe VFD Motorssanjay.gawadeNessuna valutazione finora

- Electric Motor TestingDocumento5 pagineElectric Motor Testings_r_manoNessuna valutazione finora

- Nema MG 11-2001 - Energy Mangement Guide For Selection and Use of Single-Phase MotorsDocumento8 pagineNema MG 11-2001 - Energy Mangement Guide For Selection and Use of Single-Phase MotorsjamescarvalhoaraujoNessuna valutazione finora

- Lab Rep 2qweqretetDocumento7 pagineLab Rep 2qweqretetKent Orriele FadriquelNessuna valutazione finora

- YKK Series of High-Voltage Three-Phase Induction Motors Products CatalogDocumento17 pagineYKK Series of High-Voltage Three-Phase Induction Motors Products CatalogAgustinus Bayu Dewanto100% (1)

- Motor Protection Relay Setting GuideDocumento175 pagineMotor Protection Relay Setting GuideThanigaivelan Govindhasamy100% (19)

- Unit-3: (This Unit Covers Criteria P4, P5, P7, D2) Motor StartersDocumento15 pagineUnit-3: (This Unit Covers Criteria P4, P5, P7, D2) Motor StartersMuhja AljaserNessuna valutazione finora

- Lecture 12 (EPSP)Documento28 pagineLecture 12 (EPSP)JaleesNessuna valutazione finora

- Selection of Induction Motors Part 3Documento6 pagineSelection of Induction Motors Part 3adau100% (1)

- Allen Bradley F-SERIES MOTORDocumento12 pagineAllen Bradley F-SERIES MOTORFamilia Pereztagle BandaNessuna valutazione finora

- SE Large Motor Starting 101Documento3 pagineSE Large Motor Starting 101YepremNessuna valutazione finora

- Denso Report FileDocumento32 pagineDenso Report FileRahul Pandey75% (4)

- Rotork PDFDocumento4 pagineRotork PDFgoomiNessuna valutazione finora

- Care and Maintenance of Induction MotorDocumento106 pagineCare and Maintenance of Induction Motorhprabowo100% (2)

- Motor FaultsDocumento9 pagineMotor FaultsMazen MohamedNessuna valutazione finora

- Fadriquel 2208 Laboratory Report 2Documento7 pagineFadriquel 2208 Laboratory Report 2Kent Orriele FadriquelNessuna valutazione finora

- Franklin - Why ESP Motors FailDocumento4 pagineFranklin - Why ESP Motors FailAutumn NunezNessuna valutazione finora

- Guide To Motors and Starting 1998 (Schneider)Documento24 pagineGuide To Motors and Starting 1998 (Schneider)RudanekNessuna valutazione finora

- HandbookDocumento27 pagineHandbookArtur MkrtchyanNessuna valutazione finora

- Gambi CADocumento28 pagineGambi CAishan0588Nessuna valutazione finora

- AC MotorsDocumento52 pagineAC Motorsjennybunnyomg50% (6)

- Motor ProtectionDocumento41 pagineMotor Protectionrjphansalkar100% (3)

- Protection of Large Induction MotorsDocumento8 pagineProtection of Large Induction MotorsAnonymous 13LTklH9my0% (1)

- CSPDocumento8 pagineCSPmeghraj01100% (1)

- Power System ProtectionDocumento12 paginePower System ProtectionAkbarul KausarNessuna valutazione finora

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideDa EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideValutazione: 4.5 su 5 stelle4.5/5 (8)

- Electric Motor Maintenance and Troubleshooting, 2nd EditionDa EverandElectric Motor Maintenance and Troubleshooting, 2nd EditionValutazione: 3 su 5 stelle3/5 (2)

- Project Closure Report: Project Name: Department: Focus Area: Product/ProcessDocumento11 pagineProject Closure Report: Project Name: Department: Focus Area: Product/Processshadi22Nessuna valutazione finora

- Suppliers' Tips: What Kind of Maintenance Will Keep My Feeder Accurate?Documento2 pagineSuppliers' Tips: What Kind of Maintenance Will Keep My Feeder Accurate?shadi22Nessuna valutazione finora

- BigData AnalyIntelligent ManuDocumento1 paginaBigData AnalyIntelligent Manushadi22Nessuna valutazione finora

- Ensuring Resources Are Allocated To Make The Project Successful: Employees Will Be AllocatedDocumento2 pagineEnsuring Resources Are Allocated To Make The Project Successful: Employees Will Be Allocatedshadi22Nessuna valutazione finora

- 63 PDFDocumento4 pagine63 PDFshadi22Nessuna valutazione finora

- BVD 2231 GBDocumento2 pagineBVD 2231 GBshadi22Nessuna valutazione finora

- MULTIDOS WeighfeederDocumento4 pagineMULTIDOS Weighfeedershadi22Nessuna valutazione finora

- DEA 300/600 Weighbelt Feeders: For More Information, Please Contact Us at 1-800-558-0184 or Fax: 262-473-4384Documento2 pagineDEA 300/600 Weighbelt Feeders: For More Information, Please Contact Us at 1-800-558-0184 or Fax: 262-473-4384shadi22Nessuna valutazione finora

- Implementing ISO 9001 ProjectDocumento1 paginaImplementing ISO 9001 Projectshadi22Nessuna valutazione finora

- TocDocumento8 pagineTocshadi22Nessuna valutazione finora

- Programming C Ontrol S Trategies With IEC 61131Documento15 pagineProgramming C Ontrol S Trategies With IEC 61131shadi22Nessuna valutazione finora

- Strain Guage Summing - PLCSDocumento5 pagineStrain Guage Summing - PLCSshadi22Nessuna valutazione finora

- PG PC Connection 6RA70 & SimovertDocumento1 paginaPG PC Connection 6RA70 & Simovertshadi22Nessuna valutazione finora

- Posco: A New Steel Plant in IndiaDocumento2 paginePosco: A New Steel Plant in Indiashadi22Nessuna valutazione finora

- Why Can't I Run Load Cells Directly Into A PLCDocumento8 pagineWhy Can't I Run Load Cells Directly Into A PLCshadi22Nessuna valutazione finora

- Material Control Procedure - TemplateDocumento5 pagineMaterial Control Procedure - TemplateHernandito Rahmat KusumaNessuna valutazione finora

- FutbolistaDocumento18 pagineFutbolistaKaren Osses50% (2)

- Msds EthanolDocumento7 pagineMsds EthanolHeru HarnadiNessuna valutazione finora

- Ronstan Regatta Watch InstructionsDocumento7 pagineRonstan Regatta Watch InstructionsMatt HartmanNessuna valutazione finora

- Nervous SystemDocumento40 pagineNervous SystemJaneNessuna valutazione finora

- Simple Euler StrutDocumento16 pagineSimple Euler StrutDaniel MabengoNessuna valutazione finora

- Tycho BraheDocumento3 pagineTycho BraheAienna Lacaya MatabalanNessuna valutazione finora

- 6.m.tech-Ece-Vlsi, Vlsi Systems, Vlsi System Design (Vlsi, Vlsis, Vlsisd) r17 Course Structure & SyllabiDocumento35 pagine6.m.tech-Ece-Vlsi, Vlsi Systems, Vlsi System Design (Vlsi, Vlsis, Vlsisd) r17 Course Structure & SyllabiravibabukancharlaNessuna valutazione finora

- Manuel D'utilisation Maison AnglaisDocumento17 pagineManuel D'utilisation Maison AnglaisVanesssNessuna valutazione finora

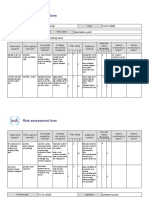

- Risk Assessment Project Iosh - MsDocumento2 pagineRisk Assessment Project Iosh - MsSanjeev Kumar75% (32)

- 100% Chemical-Free Solution For Organic Farming: Where Health Is A HabitDocumento2 pagine100% Chemical-Free Solution For Organic Farming: Where Health Is A Habitamit4118Nessuna valutazione finora

- Mathematics Specialist Unit 3A: VectorsDocumento4 pagineMathematics Specialist Unit 3A: VectorsMahir MahmoodNessuna valutazione finora

- 447.010 Screen Operating Manual v001Documento67 pagine447.010 Screen Operating Manual v001José CarlosNessuna valutazione finora

- DE (Diatomaceous Earth) BenefitsDocumento9 pagineDE (Diatomaceous Earth) BenefitsIlqa116100% (1)

- Lesson Plan 1 - Agriculture in Your LifeDocumento6 pagineLesson Plan 1 - Agriculture in Your Lifeapi-235918896Nessuna valutazione finora

- The Physiology of Potassium in Crop Production PDFDocumento31 pagineThe Physiology of Potassium in Crop Production PDFFelipe R. Parada100% (1)

- Instrumentation & Measurement SystemsDocumento7 pagineInstrumentation & Measurement SystemsAnkit KumarNessuna valutazione finora

- Lesson 5 African LiteratureDocumento3 pagineLesson 5 African LiteratureMiguel CarloNessuna valutazione finora

- MPDFDocumento5 pagineMPDFRoyalAryansNessuna valutazione finora

- D20 25 30 33S-5 D35C-5 (Sb1109e06) PDFDocumento424 pagineD20 25 30 33S-5 D35C-5 (Sb1109e06) PDFGORD100% (8)

- CF1900SS-DF Example Spec - Rev1Documento1 paginaCF1900SS-DF Example Spec - Rev1parsiti unnesNessuna valutazione finora

- Electromagnetic and Thermal AnalysisDocumento5 pagineElectromagnetic and Thermal AnalysishamidrezaNessuna valutazione finora

- Asms 02 0033Documento6 pagineAsms 02 0033Delfia AkiharyNessuna valutazione finora

- C.4. Quiz Conservation of BiodiversityDocumento2 pagineC.4. Quiz Conservation of Biodiversitylaura pongutaNessuna valutazione finora

- IBH Link UA Manual PDFDocumento302 pagineIBH Link UA Manual PDFjavixl1Nessuna valutazione finora

- 120Documento349 pagine120xdyj2005Nessuna valutazione finora

- IoT & WSN - Module 5 - 2018 by Prof - SVDocumento43 pagineIoT & WSN - Module 5 - 2018 by Prof - SVVignesh MJ83% (6)

- Mechanical Smoke Ventilation Calculations For Basement (Car Park)Documento7 pagineMechanical Smoke Ventilation Calculations For Basement (Car Park)Mahmoud Abd El-KaderNessuna valutazione finora

- FEED Deliverable List (Sample) : Project InformationDocumento3 pagineFEED Deliverable List (Sample) : Project Informationamilasri100% (1)

- 02 Unit I Environmental Studies-A Multidisciplinary Subject 14-01-2022Documento69 pagine02 Unit I Environmental Studies-A Multidisciplinary Subject 14-01-2022doramonbhaiyaNessuna valutazione finora