Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

F Komatsu

Caricato da

neelgalaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

F Komatsu

Caricato da

neelgalaCopyright:

Formati disponibili

KOMATSU LIMITED

1

January 1985, and Chairman Ryoichi Kawai of Komatsu Limited, the worlds second largest

earth-moving equipment (EME) company, was happy at the losses reported in the quarterly

financial results of Caterpillar Tractor Co. (Cat), its arch-rival. Kawai was not too sure if a

prolonged industrial dispute that had led to a bitter 204 day strike had something to do with

it. He was aware that Cat had cited a labor cost differential of 45% and a steel input cost

differential of 25% with its Japanese competition as the reason to contain costs.

The market for Earth Moving Equipment [EME] is a singular market. Demand depends

mainly on the general level of construction and mining activities, and both industries had

undergone considerable change during the 1970s. [There are also two distinct market

segments, the bidding market and the commercial market. The former relates mainly to

government expenditure in the developing countries and the latter to more sophisticated

demand]. For one, the future markets lay in the developing countries. And in these countries,

financing considerations played a significant part in buying decisions for all capital

equipment. Further, the state sector was often a significant buyer, and for EME, the buying

behavior typically stressed up-front bidding procedures that regularly included not only

machines but also spare parts for a period of two years or more.

In 1983 Komatsu Limited, the Osaka-based Japanese company with its headquarters in

Tokyo, had consolidated net sales of $3.2 billion, with 81% of the sales emanating from the

EME sector and the balance from a diversified base of manufactures, such as diesel engines,

presses, machine tools, industrial robots, solar batteries, and steel castings. Yet, only two

decades earlier, Komatsu had been just one of many small local equipment manufacturers

living in the shadow of Cat.

Komatsu was established in 1921 as a specialized producer of mining equipment. The

companys basic philosophy since its earliest days emphasized the need to export. The

founder of the company, Mr. Takeuchi, had stressed in his management goals statement as

early as 1921 the requirement for management to have two important perspectives-an

overseas orientation and a user orientation. A year later Komatsu acquired an electric

furnace and started producing steel castings. In 1931 the company successfully produced a

two-ton crawler type of agricultural tractor, the first in Japan. During the Second World War

Komatsu became an important producer of bulldozers, tanks, howitzers, and so forth.

In the postwar years the company reoriented itself toward industrial EME. The companys

bulldozer was much in demand in the late 1950s as Japans postwar reconstruction started in

earnest. Due to policy restrictions there was little competitive pressure on Komatsu either to

augment its product line or to improve the quality of products. Thus, despite the booming

demand and the tariff-sheltered market, by 1963, Komatsu remained a puny, $168 million

manufacturer of a limited line of EME, lacking technical know-how to produce sophisticated

machines.

The turning point came in 1963, when the Japanese Ministry of International Trade and

Investment (MITI) decided to open the EME industry to foreign capital investment. Cat

decided to take advantage of the opportunity, and Komatsu was suddenly faced with a

formidable competitor in its own backyard. Komatsu opposed the proposed Mitsubishi-Cat

joint venture, but MITI was only willing to delay the project for two years.

The 1960s : In his single-minded drive for survival, Kawai set two goals; the acquisition of

the necessary advanced technology from abroad and the improvement of product quality

within the company. The company entered licensing arrangements with two major EME

manufacturers in the United States - International Harvester and Bycyrus-Erie. The former

1

Condensed from an HBS case 9-385-277 by Christopher A Bartlett and U Srinivasa Ragavan. This case has been prepared for

class discussion rather than to illustrate either effective or ineffective handling of an administrative situation.

2

was well known for its wheel-loader technology, and the latter was a world leader in

excavator technology. Komatsu also concluded a licensing and technology collaboration

agreement with Cummins Engine in the United States, which led the world in diesel engine

development. Komatsu paid a substantial price for this technological access, not only in

financial payments but also in restrictions on exports that it had to agree to as part of the

arrangements. Recognizing that its dependence on these licensees lift it vulnerable, the

company established its first R&D laboratory in 1966 to focus on the application of electrical

engineering developments.

Komatsu also launched a quality upgrading program in its factories. The program, on the first

to reflect the Total Quality control (TQC) concept, was an adaptation and extension of the

well-known Japanese Quality-Control-circles system in manufacturing operations. Komatsu

management was proud of receiving the highly coveted 1964 Deming Prize for quality control

within three years of launching TQC.

In 1964 the company also began Project A. The project aimed to upgrade the quality of the

small and medium-sized bulldozers, Komatsus primary domestic market product. A top

manager recalled, The president commanded the staff to ignore the costs and produce

world-standard products. The first batch of upgraded products reached the market in 1966

and produced spectacular results.

At this stage the company launched the second phase of Project A as cost reductions took

precedence. Every aspect of design, production facilities, parts assembly, assembly-line

systems, and the operation processes was subjected to thorough scrutiny, and costs were

pared down. Between 1965 and 1970 the company increased its domestic market share from

50% to 65% despite the advent of the Mitsubishi-Caterpillar joint venture in Japan.

The Early 1970s: By the early 1970s Komatsus management sensed the need for

aggressive expansion abroad. The company had achieved dominance within Japan. With

domestic construction activity leveling off, however, it appeared as if the EME market was

reaching maturity with little prospect of substantial growth. Meanwhile, management was

aware of the rise of natural resources activities throughout the world, and particularly the

construction boom in the Middle East in the post-1974 period.

In the mid-1960s the company turned its attention to Western Europe. Large-scale

shipments to Italy were followed by exports to other countries. In 1967 Komatsu Europe was

established as a European marketing subsidiary to achieve better sales and service

coordination. In the same year the first Komatsu machines were exported to the United

States. In 1970 Komatsu America was established to develop business in the huge North

American market. In most of these markets Komatsu concentrated on selling a limited

product line, typically crawler-tractors and crawler-loaders, which were the most common

equipment on construction sites. By pricing 30% to 40% below similar Cat equipment, the

company soon established a foothold in most target markets. Again to ensure good service,

Komatsu maintained extensive parts inventories in each country - a deliberate overkill,

according to one dealer.

In 1972 Komatsu launched a new project called Project B. This time the focus was on the

exports. The large bulldozer, the companys main export item, was chosen for improvement.

The aim was similar to Project As : to upgrade the quality and reliability of its large bulldozer

models and bring them up to world standards, then work on cost reductions. Once these

aims were realized, the company planned to launch similar efforts for the other lines of

export products such as power shovel. Although Project Bs main objective was to develop

the companys overseas markets, the new machines were also offered in Japan and further

reinforced Komatsus domestic position.

The mid-1970s also saw the beginnings of efforts to penetrate the markets of LDCs, and in

particular the fast-growing industrializing countries in Asia and Latin America. In 1974 the

company established a new presale service department that provided assistance from the

3

earliest stage of planned development projects in LDCs. The services that the department

made available to LDCs free of cost included advice on issues such as site investigation,

feasibility studies, planning of projects, selections of machines, training of operators, and so

on. Dealer network, never a strong point with Komatsu, was strengthened. With all these

efforts, Komatsus ratio of exports to total sales grew from 20% in 1973 to 41% in 1974 and

to 55% in 1975.

During the early 1970s the companys R&D efforts continued apace with some attention to

basic research as well as product development. The efforts, however focused on the needs of

the domestic market since the licensing arrangements constrained exports efforts in some

important new product areas. New excavator models were brought onto the market in this

period, as were completely new products such as pipe layers, large dump trucks, and hydro

shift vehicles.

The Late 1970s : By 1976 the Japanese market was highly concentrated, with Komatsu

taking a 60% share and the Mitsubishi-Cat joint venture left with slightly over 30%.

However, there was no indication of much market growth in the near future, since worldwide

demand for construction equipment was slowing. Komatsu management decided to focus on

improving the competitiveness of its products.

A four-part cost-reduction plan was initiated the first part being dubbed the V-10

campaign. The V-10 goal was to reduce the cost by 10% while maintaining or improving

product quality. The second part of the overall plan called for reducing the number of parts

by over 20%. The third, was aimed at value engineering, specifically focusing on redesigning

the products to gain economies in materials/ manufacturing. The fourth, was a rationalization

of the manufacturing system. By the end of the decade Komatsu was well on its way to

achieving all these goals.

As Komatsu planned this ambitious cost-reduction plan, an unexpected development

occurred that required immediate management attention. In the fall of 1977 the Japanese

yen began appreciating rapidly against most major currencies. For example, the yen/dollar

exchange rate went from 293 at the end of 1976 to 240 a year later. Management responded

by adopting a policy of using a pessimistic internal yen/dollar exchange rate of 180 for

planning purposes. Manufacturing was responsible for achieving a cost structure that could

be profitable even at this worst-scenario rate. After trading at a high of Y179 to the dollar

in mid-1978, the yen weakened considerably against the dollar and most other currencies in

1979.

During the late 1970s Komatsu also accelerated its product development program. Between

1976 and 1981 the number of models offered in the five basic categories of EME (bulldozers,

excavators, dump trucks, loaders, and graders) increased from 46 to 77. When Komatsu

introduced its off-highway dump trucks and hydraulic excavators earlier than Cat,

management proudly hailed the companys new leadership in technical development and

innovation. We are not content to produce the same type of equipment year after year, said

one technical manager, but are always looking at the latest technical developments and are

trying to see how we can adapt them to our products. An example of this approach was the

application of electronic technology to all types of machinery. Komatsu had the distinction of

introducing the worlds first radio-controlled bulldozer, amphibious bulldozer, and remote-

controlled underwater bulldozer, for special uses such as toxic dump sites and underwater

mining.

The 1980s : Until 1980 Komatsu was impeded by the narrow product line it offered abroad.

Any company that aspired to become a global competitor needed to gain a strong foothold in

the commercial market. and to do so, it was almost a competitive necessity to be a full-line

manufacturer with an extensive sales and service network.

The decision to become a full-line supplier, however, meant that Komatsu had to reevaluate

its licensing relationships with technology suppliers. The original agreement had been

4

restrictive, not allowing Komatsu to enter into distinctly specified market segments, and the

licensees were not willing to sell the contract. Komatsu appealed to Japans fair trade

commission. After appropriate deliberations, the government agency agreed with Komatsu

that it was a restrictive business practice that impaired competition. This finding allowed

Komatsu to buy its way out of the contract, paying Bucyrus $13.6 million to get the data it

wanted and another $6 million for royalties on the balance of the contract in May 1981. In

early 1982 Komatsu had an opportunity to buy out of its obligations to International

Harvester. When financially strapped Harvester was looking for cash, Komatsu bought back

IHs half interest in its loader business for $52 million. Freed of the constraints of the

licensing agreements, Komatsu could sell hydraulic excavators and wheel loaders to world

markets. The company emerged as a full-line competitor.

Komatsu celebrated its sixtieth anniversary in 1981. That year it launched a new project

called EPOCHS, which stood for Efficient Production-Oriented Choice Specifications. The

projects theme was reconciliation of two contradictory demands. The aim was to improve

production efficiency without reducing the number of product specifications required by the

market. The overseas expansion in the 1970s taught management that customer

requirements varied widely by market and by application. For example, in Australia prospects

were excellent in coal and iron-ore mining, but the tough operating requirements surpassed

the capabilities of machines designed for Japanese construction applications. Komatsu

responded by designing bulldozers, power shovels, and dump trucks adapted to mining

conditions in Australia. To better its competition, it sent field engineers to survey Australian

miners and elicited their comments and complaints about the equipment which were then

incorporated into its products.

As its export market increased, the company faced demands to adapt its products to suit the

user requirements in different countries and diverse applications. These requirements varied

with each countrys environmental conditions and legal requirements. Such adaptations,

however, were costly in terms of production efficiency, parts inventory, and field service

management. The purpose of the EPOCHS projects was to allow the company to respond to

the diverse market needs without compromising its cost position.

Komatsu meanwhile continued on its investments in R&D. The culmination of its successes

came when at a International Fair [ Conexpo81 ] Komatsu displayed its 1,000 hp bulldozer

bigger than Cats top-of-the-line 700 hp machine. According to Komatsu managers, the most

interested observers at their exhibit were Cat technicians. On Komatsu manager reportedly

photographed four Cat managers examining and measuring the companys equipment at the

exposition. Ten years ago, he smiled, we would have been the ones caught doing that.

Nonetheless, concern persisted about the depressed state of the construction industry

worldwide, and Komatsu managers began talking increasingly about other business

opportunities. In 1979 top management launched a companywide project called F and F.

The abbreviation stood for Future and Frontiers, and its objective was to develop new

products and new businesses. The project encouraged suggestions from all employees,

asking them to consider both the needs of society and the technical know-how of the

company. Some of the 3,500 suggestions included diverse new products as arc-welding

robots, heat pumps, an excavating system for deep sea sand, and amorphous silicon

materials for efficient exploitation of solar energy.

By 1984 Komatsus managers had good reason to be proud of their companys record of

previous two decades It still held a 60% market share in Japan, helped in part by sales to its

fully owned construction and real estate subsidiaries. The companys domestic sales & service

network was acknowledged to be the most extensive and efficient in Japan.

Exports expanded so that they represented well over half of Komatsus total sales in 1983.

The company continued to strengthen its relationships with the Eastern bloc and had a

backlog of orders for equipment for the Siberian natural resource project. The Reagan

administrations embargo in December 1981 on the sale of Cat pipe-laying equipment to

5

Russia handed the total contract to the Japanese company. Komatsu also signed a contract

with the Soviets to develop a scraper based on a Russian design, using Japanese

components, and was collaborating with the Russians on a big crawler-dozer and dump

truck. Komatsus sales to the Soviet Union were soon expected to overtake Cats.

Despite competitors suggestions to the contrary, Komatsu dealers generally denied that they

were still competing mainly on price. A U.S. dealer commented: When you are selling

against number one, you need some price advantage. But we tell contractors we can give

them 10% more machine for 10% less money. Thats not selling price in my book

Pondering the Future : It was quite in character for Ryoichi Kawai, the chairman of

Komatsu, to ponder the future direction for the company that he had headed since 1964,

succeeding his father, Yashinari Kawai. Kawai greatly admired Cat and often spoke of

modeling his company after it. This spirit of competition with Cat pervaded the entire

company. Komatsus in-house slogan was Maru-C, which roughly translated meant

Encircle Caterpillar. Reportedly, the company continuously monitored events in Peoria, and

one of the main jobs of Komatsus executives in the United States was to keep tabs on any

and all relevant press reports. Cats monthly in-house letter to its employees, which featured

new product introductions and other company-related news, was required reading for all

Komatsu executives, and copies were sent by express mail to Tokyo for analysis at the

corporate headquarters.

As Kawai continued to think about the possible changes in Komatsus competitive strategy,

he kept reminding himself that complacency is one vice his company had to guard against.

Eternal vigilance is not the price of liberty alone. It is also the price of prosperity.

Questions :

[1] Evaluate Komatsus strategy of Internationalization, [2] How much of this success can be

traced to formulation or implementation of strategy, [3] What is Komatsus basis of

Sustainable Competitive Advantage.

6

Strategy/ Additional Data on Komatsu

Table A : Cost Structure of a large Bulldozer

[ equl. to Cat D-6 ]

Component Percent of cost

Labor 35%

Components and subassemblies 12.4

Overhead 18.4

Assembly 4.6

Purchased material and components 49.6

Overheads 15.4

Source B C G

Table B : Steel Price Comparison

Product US J apan J apan/ US

HR coil 494 359 73%

HR Steel Plate 635 445 70%

Source B C G : assumed at $1 = Yen 220

Table C : Market Share for Major EME Producers

Producer 1971 1980 1984

Cat 55 53 43

Komatsu 10 15 25

J J Case 7 10 10

Fiat-Allias 4 6 4

Deere 6 7 7

Int. Harvester 11 5 3

Clark 6 4 4

Total 100 100 100

Source : Form 20F reports

Table D : Komatsus sales by Geographic Region

Region 1977 1980 1983

Japan 58 56 46

Asia & Oceania 11 18 30

America, north &

south

18 12 7

Europe, Middle east

and Africa

12 13 16

Total 100 100 100

Source : Form 20F reports

Potrebbero piacerti anche

- Cat CS66B: Smooth Drum Vibratory Soil CompactorDocumento4 pagineCat CS66B: Smooth Drum Vibratory Soil CompactorhendrynNessuna valutazione finora

- Komatsu LogotypeDocumento40 pagineKomatsu Logotypeconnect100% (1)

- Plant 27 StepsDocumento120 paginePlant 27 StepsHebert SozinyuNessuna valutazione finora

- Patent Infringement Damages - A Brief Summary - Articles - FinneganDocumento14 paginePatent Infringement Damages - A Brief Summary - Articles - FinneganneelgalaNessuna valutazione finora

- HBO Jieliang Home PhoneDocumento6 pagineHBO Jieliang Home PhoneAshish BhalotiaNessuna valutazione finora

- DepreciationDocumento35 pagineDepreciationAlexie Gonzales60% (5)

- Damac Inventorydetail Clone PDFDocumento4 pagineDamac Inventorydetail Clone PDFAnonymous 2rYmgRNessuna valutazione finora

- Case SummaryDocumento3 pagineCase SummaryWilliam WeilieNessuna valutazione finora

- CircuiTree - 07 JUL 2009Documento44 pagineCircuiTree - 07 JUL 2009jumanleeNessuna valutazione finora

- Komatsu LimitedDocumento5 pagineKomatsu LimitedRoberto Ortega MicalizziNessuna valutazione finora

- Technical Description Hydraulic Excavator: LitronicDocumento10 pagineTechnical Description Hydraulic Excavator: Litronicwalk01Nessuna valutazione finora

- May Catalogue pg1-44Documento44 pagineMay Catalogue pg1-44Aten HarisNessuna valutazione finora

- Om PC50MR-2 Weam006705Documento238 pagineOm PC50MR-2 Weam006705Дмитро ФедоровNessuna valutazione finora

- KomatsuDocumento2 pagineKomatsuYudi BaayNessuna valutazione finora

- Hydraulic Oil: Komatsu GenuineDocumento4 pagineHydraulic Oil: Komatsu GenuineKattie ValerioNessuna valutazione finora

- Hw300 AssembleDocumento111 pagineHw300 AssembleAndreiNessuna valutazione finora

- Horsepower Gross: 266 KW 357 HP at 1900 RPM Net: 263 KW 353 HP at 1900 RPM Bucket Capacity 4.3-5.6 MDocumento12 pagineHorsepower Gross: 266 KW 357 HP at 1900 RPM Net: 263 KW 353 HP at 1900 RPM Bucket Capacity 4.3-5.6 MANDRANessuna valutazione finora

- Sơ Đồ Bơm ,Van Và Các Ký HiệuDocumento87 pagineSơ Đồ Bơm ,Van Và Các Ký HiệuPhan Dung100% (1)

- Tvis p15Documento66 pagineTvis p15Mihir007123456Nessuna valutazione finora

- Hour Meter: Component Tracking - Lac Des Iles Mines LTDDocumento7 pagineHour Meter: Component Tracking - Lac Des Iles Mines LTDgrtyyNessuna valutazione finora

- Course Komatsu pc4000 2023Documento72 pagineCourse Komatsu pc4000 2023José Alberto Huaman ChipanaNessuna valutazione finora

- Section F: Publication NoDocumento16 pagineSection F: Publication NoLuis BertaoNessuna valutazione finora

- Om 830e Serie A30733 Up Cead015001 PDFDocumento154 pagineOm 830e Serie A30733 Up Cead015001 PDFFernando AloNsoNessuna valutazione finora

- Spare Parts HB 3600Documento36 pagineSpare Parts HB 3600П' АпиэNessuna valutazione finora

- HD785-5 Axle Assy Reman ManualDocumento181 pagineHD785-5 Axle Assy Reman ManualJack PranNessuna valutazione finora

- Komatsu Maintenance and Repair Programs Brochure English AESB351 02Documento20 pagineKomatsu Maintenance and Repair Programs Brochure English AESB351 02maximeNessuna valutazione finora

- Catalouge Bucket Wearplate & AccessoriesDocumento18 pagineCatalouge Bucket Wearplate & Accessoriesaribawayuni16Nessuna valutazione finora

- Sales Manual - Comparison With 3a - Ps-En240 PDFDocumento128 pagineSales Manual - Comparison With 3a - Ps-En240 PDFHalil KaraNessuna valutazione finora

- Komatsu HM400-3M0Documento16 pagineKomatsu HM400-3M0Jorge Reyes AguilarNessuna valutazione finora

- D85EX-15 Operator CabDocumento9 pagineD85EX-15 Operator CabQuy Le Thanh100% (1)

- Field Assembly ManualDocumento40 pagineField Assembly Manualmikhail.glotovNessuna valutazione finora

- SB Hopper Broom 205 Series Cold Planer SpecialDocumento35 pagineSB Hopper Broom 205 Series Cold Planer SpecialLuis JesusNessuna valutazione finora

- Komatsu PC490LC 11Documento24 pagineKomatsu PC490LC 11Dutchie169Nessuna valutazione finora

- ST19-17A How To Download KOMTRAX Plus Data Wirelessly With Laptop Which Does Not Have Software Access Point (SoftAP) FeatureDocumento9 pagineST19-17A How To Download KOMTRAX Plus Data Wirelessly With Laptop Which Does Not Have Software Access Point (SoftAP) FeatureLeonardo RomeroNessuna valutazione finora

- P&H CompDocumento11 pagineP&H CompMileniaNessuna valutazione finora

- Equipment Report Parts For Komatsu HD7Documento6 pagineEquipment Report Parts For Komatsu HD7whmidi73310% (1)

- Caterpillar 740B Articulated Dump Truck Specs & Dimensions - RitchieSpecsDocumento7 pagineCaterpillar 740B Articulated Dump Truck Specs & Dimensions - RitchieSpecsSandipNessuna valutazione finora

- Structure & Function Cooling SystemDocumento13 pagineStructure & Function Cooling SystemVikNessuna valutazione finora

- Rear Axle Support (#90216-)Documento4 pagineRear Axle Support (#90216-)CEVegaONessuna valutazione finora

- HM400 3M0 PDFDocumento20 pagineHM400 3M0 PDFFakhrur RizkyNessuna valutazione finora

- Meeting With Lovol Service TeamDocumento4 pagineMeeting With Lovol Service TeamHughoNessuna valutazione finora

- Airroc T25 / D40 (Roc 203) : Atlas Copco Surface Drill RigsDocumento2 pagineAirroc T25 / D40 (Roc 203) : Atlas Copco Surface Drill RigsjhanetNessuna valutazione finora

- SY Series Multiple Cylinder Hydraulic Cone CrusherDocumento39 pagineSY Series Multiple Cylinder Hydraulic Cone CrusherShanhu GroupNessuna valutazione finora

- Ex1200 7 - Ko 582 00 - Weekly+visualDocumento12 pagineEx1200 7 - Ko 582 00 - Weekly+visualJardel Fernandes de MoraesNessuna valutazione finora

- O&m 730e Series A30597 & Up Ceam022201Documento174 pagineO&m 730e Series A30597 & Up Ceam022201Luis Alberto Ramirez PerezNessuna valutazione finora

- AVTEC Off Highway Brochure - V22 - AVTEC Off Highway Brochure - V22Documento12 pagineAVTEC Off Highway Brochure - V22 - AVTEC Off Highway Brochure - V22Vajid KhanNessuna valutazione finora

- 改 81.Xxx.a1 Basic Work Standard of Machining (Annex)Documento279 pagine改 81.Xxx.a1 Basic Work Standard of Machining (Annex)Nadivi Nursyamsa100% (2)

- WA900-3LC PALA Operacion y Mtto.Documento296 pagineWA900-3LC PALA Operacion y Mtto.Juan Jose Delgado RiveraNessuna valutazione finora

- 02 GD825 Overview PDFDocumento21 pagine02 GD825 Overview PDFDaniel MacielNessuna valutazione finora

- Tribo Losses in TransmissionDocumento29 pagineTribo Losses in Transmissionjamesv52_743942786100% (1)

- 730E (AC) Spec Sheet PDFDocumento16 pagine730E (AC) Spec Sheet PDFsoufiane OkNessuna valutazione finora

- PC5500 SN 15032 Operation and Maintenance ManualDocumento527 paginePC5500 SN 15032 Operation and Maintenance ManualFernando Pérez Sarria100% (1)

- CR KomatsuDocumento22 pagineCR KomatsuSuratmanNessuna valutazione finora

- Customer Service Department: Komatsu Utility Europe Pag. 1 Di 5 WETT001304Documento5 pagineCustomer Service Department: Komatsu Utility Europe Pag. 1 Di 5 WETT001304juanito100% (1)

- Article On 'Backhoe Loader Industry in India' by Chaitanya Raj GoyalDocumento10 pagineArticle On 'Backhoe Loader Industry in India' by Chaitanya Raj GoyalChaitanya Raj GoyalNessuna valutazione finora

- V Ec140b Ec460b 21f4351187 2004 09 PDFDocumento12 pagineV Ec140b Ec460b 21f4351187 2004 09 PDFDadang dadanhNessuna valutazione finora

- 345BL II InglésDocumento30 pagine345BL II InglésAlvaro HSNessuna valutazione finora

- Kunci Sukses Ternak Ayam Jawa SuperDocumento50 pagineKunci Sukses Ternak Ayam Jawa SuperEste HeruNessuna valutazione finora

- I-140 Hydraulics Rev - 00Documento75 pagineI-140 Hydraulics Rev - 00Parangueo training CapacitacionNessuna valutazione finora

- Komatsu Information Guide 2017Documento17 pagineKomatsu Information Guide 2017phankhoa83-1100% (1)

- With Tier 2 Engine: 638 KW 856 HP at 2050 RPMDocumento12 pagineWith Tier 2 Engine: 638 KW 856 HP at 2050 RPMSoegeng Iingin Slalu BelajarNessuna valutazione finora

- 01 - 03 Chapter 2 - TermsDocumento45 pagine01 - 03 Chapter 2 - TermsЕвгений АбрамовNessuna valutazione finora

- KomatsuDocumento285 pagineKomatsuStelian CrisanNessuna valutazione finora

- 油缸配件1catalogDocumento9 pagine油缸配件1catalogXiangzhendongNessuna valutazione finora

- Komatsu International BusinessDocumento19 pagineKomatsu International BusinessPravin Dhas50% (2)

- Case 3 KomatsuDocumento3 pagineCase 3 Komatsugiadcunha0% (1)

- Dropbox Instructions: (STEP 1) Sign Up For Free Web File Storage at DropboxDocumento2 pagineDropbox Instructions: (STEP 1) Sign Up For Free Web File Storage at DropboxneelgalaNessuna valutazione finora

- 9.. Hospital Nutrition PROBLEMDocumento2 pagine9.. Hospital Nutrition PROBLEMneelgalaNessuna valutazione finora

- Cleco CorporationDocumento8 pagineCleco CorporationneelgalaNessuna valutazione finora

- 1.. Servers - pg113 Productn PROBLEMDocumento3 pagine1.. Servers - pg113 Productn PROBLEMneelgalaNessuna valutazione finora

- 0.. Start.. Pencil ProblemDocumento1 pagina0.. Start.. Pencil ProblemneelgalaNessuna valutazione finora

- CM Team Divide The Data Based On Dosage Divide Each Dosage Data Based On Site Analyze The DataDocumento1 paginaCM Team Divide The Data Based On Dosage Divide Each Dosage Data Based On Site Analyze The DataneelgalaNessuna valutazione finora

- Robbins Eob11 Tif Ch12Documento38 pagineRobbins Eob11 Tif Ch12neelgala100% (2)

- First ProblemDocumento1 paginaFirst ProblemneelgalaNessuna valutazione finora

- SAP Journey in BPCLDocumento5 pagineSAP Journey in BPCLneelgalaNessuna valutazione finora

- M&M Case StudyDocumento9 pagineM&M Case Studyneelgala100% (1)

- Compaq Insight Manager XE Device Type Manager Utility: White PaperDocumento43 pagineCompaq Insight Manager XE Device Type Manager Utility: White PaperneelgalaNessuna valutazione finora

- Voip IntroDocumento42 pagineVoip IntroneelgalaNessuna valutazione finora

- Gene Patents KoporcDocumento8 pagineGene Patents KoporcneelgalaNessuna valutazione finora

- Encyclopaedia Britannica vs. NLRCDocumento1 paginaEncyclopaedia Britannica vs. NLRCYsabel PadillaNessuna valutazione finora

- Supernova Muhammad AliDocumento19 pagineSupernova Muhammad AliZafar NawazNessuna valutazione finora

- HIMeeting2 KOM3364Documento28 pagineHIMeeting2 KOM3364Susan ChongNessuna valutazione finora

- ARTA PresentationDocumento45 pagineARTA PresentationRaissa Almojuela Del Valle0% (1)

- 101 Win Themes For All OccasionsDocumento6 pagine101 Win Themes For All OccasionstausarpaoNessuna valutazione finora

- Session 13 - Brand Management PDFDocumento32 pagineSession 13 - Brand Management PDFpeeking monkNessuna valutazione finora

- Literature ReviewDocumento6 pagineLiterature Reviewanon_230550501Nessuna valutazione finora

- Session 7 Organization Size, Life Cycle, and DeclineDocumento45 pagineSession 7 Organization Size, Life Cycle, and DeclineHameer Saghar SaméjoNessuna valutazione finora

- Policy Guidelines On Issuance and Operation of Prepayment Instruments in IndiaDocumento10 paginePolicy Guidelines On Issuance and Operation of Prepayment Instruments in IndiaPreethiNessuna valutazione finora

- EY Capital Markets Innovation and The FinTech Landscape Executive SummaryDocumento9 pagineEY Capital Markets Innovation and The FinTech Landscape Executive SummaryCrowdfundInsider100% (1)

- DBSV - Asian Consumer DigestDocumento119 pagineDBSV - Asian Consumer DigesteasyunittrustNessuna valutazione finora

- Grievance 1Documento10 pagineGrievance 1usham deepika100% (1)

- Audit & Reporting ProvisionsDocumento6 pagineAudit & Reporting Provisionsdmk.murthyNessuna valutazione finora

- OA Frame Work Students GuideDocumento545 pagineOA Frame Work Students GuideutphalrainaNessuna valutazione finora

- Book of Abstracts - 1Documento128 pagineBook of Abstracts - 1Shejal SinhaNessuna valutazione finora

- Naina Arvind MillsDocumento28 pagineNaina Arvind MillsMini Goel100% (1)

- Republic Act No. 11057Documento9 pagineRepublic Act No. 11057FCNessuna valutazione finora

- IP ValuationDocumento4 pagineIP ValuationAbhi RicNessuna valutazione finora

- Hire Purchase and LeasingDocumento30 pagineHire Purchase and LeasingShreyas Khanore100% (1)

- The Demand Curve Facing A Competitive Firm The ...Documento3 pagineThe Demand Curve Facing A Competitive Firm The ...BLESSEDNessuna valutazione finora

- Test of Significance - : 3-Standard Error of DifferenceDocumento4 pagineTest of Significance - : 3-Standard Error of Differenceavinash13071211Nessuna valutazione finora

- ACCT3004Documento8 pagineACCT3004visio2004Nessuna valutazione finora

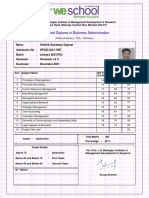

- Advanced Diploma in Business Administration: Hrithik Sandeep GajmalDocumento1 paginaAdvanced Diploma in Business Administration: Hrithik Sandeep GajmalNandanNessuna valutazione finora

- Write UpDocumento5 pagineWrite UpAli Tariq ButtNessuna valutazione finora

- International Business NotesDocumento28 pagineInternational Business NotesLewis McLeodNessuna valutazione finora