Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Casting Simulation For Sand Casting of Flywheel

Caricato da

Editor-in-Chief IJRATTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Casting Simulation For Sand Casting of Flywheel

Caricato da

Editor-in-Chief IJRATCopyright:

Formati disponibili

International Journal of Research in Advent Technology, Vol.2, No.

8, August 2014

E-ISSN: 2321-9637

82

Casting Simulation for Sand Casting of Flywheel

Naveen Hebsur

1

, Sunil Mangshetty

2

1. Post graduate student, Department of Mechanical Engineering, PDA College of Engineering, Gulbarga,

Karnataka, India. Email:naveen_b6@yahoo.com.

2. Associate Professor, Department of Mechanical Engineering, PDA College of Engineering, Gulbarga,

Karnataka, India Email:mangshetty@rediffmail.com

Abstract- Sand casting technologies have now emerged as practical and commercial ways of manufacturing

high integrity near net shape castings. A variety of castings have found their way into general engineering

applications. Castings that serve these specific applications have to achieve the quality requirements of superior

mechanical properties and zero-porosity. To achieve these objectives within a limited time frame in a product

development process, CAD technologies combined with process simulation tools are increasingly used to

optimize form filling and solidification of the cast parts. This project describes the newly developed simulation

of flywheel component that was prototyped via sand casting route. Results of casting trials showed a high level

of confidence in the simulation tools.

Index Terms- Flywheel, Casting simulation, Greensand, Solidification, Fluid flow, Shrinkage.

1. INTRODUCTION

The formation of various casting defects is

directly related to fluid flow phenomena during the

mold filling stage and in the cast metal [1]. The rate of

solidification greatly affects the mechanical properties

such as strength, hardness, machinability etc [2]. One

of the critical elements that has to be considered for

producing a high quality sand casting product is the

gating system design and risering system design [3-4].

Any improper designing of gating system and risering

system results in cold shut and shrinkage porosities.

Therefore adequate care is necessary in designing

gating and risering systems for improved yield of

defect free castings

Casting simulation essentially replaces or

minimises shopfloor trials to achieve the desired

internal quality at the highest possible yield. A

number of casting simulation programs are available

today, such as ADSTEFAN, CastCAE, MAGMA,

Novacast, ProCAST, and SolidCAST. Most of them

use Finite Element Method to discretise the domain

and solve the heat transfer and/or fluid flow equations

[5]. The main inputs include the geometry of the

mould cavity (including the part cavity, feeders, and

gating channels), thermo-physical properties (density,

specific heat, and thermal conductivity of the cast

metal as well as the mould material, as a function of

temperature), boundary conditions (such as the metal-

mould heat transfer coefficient, for normal mould as

well as feed-aids including chills, insulation and

exothermic materials), and process parameters ((such

as pouring rate, time and temperature). The results of

solidification simulation include color-coded freezing

contours at different instants of time starting from

beginning to end of solidification. This provides a

much better insight into the phenomenon compared to

shop-floor trials (real moulds being opaque). The user

can verify if the location and size of feeders are

adequate, and carry out iterations of design

modification and simulation until satisfactory results

are obtained. Sometimes, it is not possible to achieve

the desired quality by changes to method (mainly

feeding and gating) alone. In such an event, it may

become necessary to modify the part design.

For example, the wall thickness of the part

can be increased (referred to as padding) at locations

that choke the flow of feed metal. Another typical

modification is adding or increasing taper to promote

directional solidification. These modifications

however, imply additional machining cost. If

feedability analysis is carried out at the product design

stage itself in a systematic manner, it can potentially

lead to superior product-process compatibility. This

implies foundry-friendly castings, making it easier to

achieve the desired quality with high yield [6].

Shamasunder [7] discussed the steps involved,

possible sources of errors and care to be taken during

the casting process simulation. According to him the

designer needs to have full confidence in the casting

simulation tool. This can come only by experience

and usage of the tool to mimic effect of various

process parameters. With the advances in technology

and proper care in modeling, it is possible to simulate

the defects generated during casting before the casting

is practically produced. They presented different case

studies using ADSTEFAN software

The location and size of the feeders and

ingates is an important input for solidification

simulation. This decision requires considerable

methoding experience from the user. Further, the

engineer has to create or modify the solid model of

the feeder, attach it to the casting model using a CAD

program, and import it into the casting simulation

program for each iteration. These tasks require

computer skills. The accuracy of results (such as

International Journal of Research in Advent Technology, Vol.2, No.8, August 2014

E-ISSN: 2321-9637

83

solidification time and location of shrinkage defects)

is influenced by metallurgical models and availability

of temperature dependent material property database.

The simulation of intricate castings may involve more

time and cost than shop-floor trials, and any error in

program inputs implies further delay and expenses.

Casting simulation programs can be used by

foundry engineers for quality assurance and yield

optimization without shop-floor trials, as well as by

product engineers for analysing and optimising the

feedability of a casting during design phase itself. For

widespread application, the simulation programs

should require little domain experience, and they

should be fast, reliable, easy-to-use, and economical.

These goals can be achieved by automating some of

the tasks involved: identifying the location of a

feeder, calculating its minimum size, creating its solid

model, attaching the feeder model to the casting,

carrying out solidification simulation, predicting

quality and estimating the yield. The sand Casting

(Green Sand) molding process utilizes a cope ( top

half ) and drag ( bottom half ) flask of sand, ( usually

silica ), clay and water. When the water is added it

develops the bonding characteristics of the clay,

which binds the sand grains together. When applying

pressure to the mold material it can be compacted

around a pattern, which is either made of metal or

wood, to produce a mold having sufficient rigidity to

enable metal to be poured into it to produce a casting.

The process also uses coring to create cavities inside

the casting. After the casting is poured and has cooled

the core is removed. The material costs for the process

are low and the sand casting process is exceptionally

flexible.

In this work simulation is carried out for

manufacturing of STEEL flywheel and the results

were presented

.

2. CASTING SIMULATION

This includes mould filling, solidification,

grain structure, stresses and distortion. It requires

solid models of product and tooling (parting, cores,

mould layout, feeders, feedaids and gates),

temperature-dependent properties of part and mould

materials, and process parameters (pouring

temperature, rate, etc.). The simulation results can be

interpreted to predict casting defects such as

shrinkage porosity, hard spots, blowholes, cold shuts,

cracks and distortion. The inputs however, require

considerable expertise and may not be easily available

to product designers. One solution is to involve

tooling and foundry engineers in the product design

stage, and evolve the product, tooling and process

designs simultaneously, ensuring their mutual

compatibility with each other. This approach is

referred to as concurrent engineering.

3. Equationsmaterial and methodology

Flywheels are typically made of steel and

rotate on conventional bearings; these are generally

limited to a revolution rate of a few thousand RPM.

Chemical analysis of steel material is as shown below.

Element Wt %

C 0.25

Si 0.60

Mn 1.50

P 0.040

S 0.035

Cr 0.35

Ni 0.40

Mo 0.15

Cu 0.40

V 0.05

Table I: Chemical Properties of STEEL

Figure shows drawing of a typical flywheel. The

flywheel casting model with essential elements of the

gating system like In-gate, runner, sprue and risering

system were generated in CATIA V5 CAD modeling

software. Four ingates are provided at the first model

(fig 1), after the completion of first iteration the

shrinkage defect is occurred. In order to obtain sound

cast the model has to be modified in such a way that

two ingates are provided at the thicker section of inner

rib of flywheel and on which the risers are provided to

achieve the directional solidification (fig 2).

Fig: 1 Top & bottom view of f Flywheel

Fig: 2 Top & bottom view of f Flywheel

(modified model)

Simulation Process

ADSTEFAN is casting simulation software

developed by Hitachi Corporation Ltd, Japan. This

was used to simulate fluid flow and solidification of

International Journal of Research in Advent Technology, Vol.2, No.8, August 2014

E-ISSN: 2321-9637

84

sand casting of flywheel. Casting simulation and

result analysis was done to predict the molten metal

solidification behavior inside the mold. The casting

component with gating system was imported in STL

(Stereo lithography) format to the ADSTEFAN

software and meshing of the model was done in the

pre-processor mesh generator module. The mesh size

of the casting was taken 5 and the structural boundary

conditions are automatically taken care by the

software.

Assignment of material properties, fluid flow and

solidification parameters: The meshed model was

taken into the precast environment of the software,

where the number of materials, type of mold used,

density of cast material, liquidus and solidus

temperatures of STEEL and other input parameters of

fluid flow and solidification conditions like pouring

time, pouring type, direction of gravity etc. were

assigned. Table & 5 show the material properties,

fluid flow & solidification parameters. After the

assignment of material properties and simulation

conditions, prediction of air entrapment, temperature

distribution and shrinkage porosity are carried out.

Casting simulation program provides output files in

the form of graphical images and video files which

are analyzed to predict defects after the successful

execution.

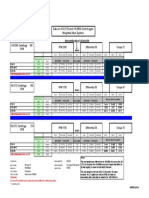

Table II: Input material properties and conditions

Parameter Type of

Mould

Conditions

Material Green Sand STEEL(IS

1030)

Density 1.5 gm/cm^3 7.6 gm/cm^3

Initial

Temperature

20C 1580

Liquidus

temperature

-- 1505

Solidus

temperature

-- 1450

Table III: Input fluid flow and solidification

parameters

4. RESULTS AND DISCUSSION

4.1 Fluid flow

Figure 3(a) (b) shows metal filling in mould cavity,

that ensure the smooth flow of Liquid metal and the

cold metal is not entering in the mould cavity. The

pouring temperature for steel is 1580C to 1600C.

The estimated pouring time for complete filling of

mould cavity is 38 seconds. From the iteration 1&2

we can easily predict that the cavity is filling

smoothly, uniformly without any turbulence and

temperature differences we can see. The Yellow color

highlights the temperature drop due to chill provided.

But this temperature drop is in safer side there are no

possibilities of cold metal or cold shut. In any of the

iteration there is no defect associated with fluid flow,

in casting component and gating system.

Fig: 3(a): Fluid flow in the casting component.

Parameter Input condition

Velocity of fluid flow 19.8 cm/s

Fill time 38 sec

Critical solid fraction 0.8 (maximum 1)

Pouring type Gravity Pouring

Output files

1) Fluid flow

2) Solidification pattern

3)Shrinkage and

porosity

Riser type Open

International Journal of Research in Advent Technology, Vol.2, No.8, August 2014

E-ISSN: 2321-9637

85

Fig: 3(b): Fluid flow in the casting component.

4.2 Solidifaction

It is necessary to provide the directional solidification

in order to achieve the sound casting .The directional

solidification starts from thinnest section to thickest

section and which ends at riser. The actual

solidification of metal begins at liquidus temperature

of 1505C. The solidification of metal ends at solidus

temperature 1450C.

Defect affected zone

Fig: 4(a) Solidification of the casting component.

Fig: 4(b) Solidification of the casting component.

In figure 4(a) 1

st

iteration the inner rib of the flywheel

section is also chilled but the section thickness is

small at ingate area, so the hot spot is increased at

ingate area so isolation is formed in that section so

that isolation prone to defective area. Thus in orders

to eliminate these defective areas, the ingates are

provided at the thicker section of the inner rib of

flywheel component and simulation is carried out. In

2

nd

iteration only two ingates are provided on which

the risers are provided to achieve the directional

solidification and fig 4(b) shows the directional

solidification of the casting component.

4.3 Shrinkage Porosity

Figure 5 shows shrinkage porosity in the casting

component for first iteration of simulation. It is

observed that in first iteration gating system

simulation showed shrinkage porosities at four

different locations.

Fig: 5(a): Shrinkage porosity in the casting

component.

Fig: 5(b) Shrinkage porosity in the casting

component.

But in the 2

nd

iteration fig 5(b) these

shrinkage porosity are at the different locations of the

component are eliminated by providing ingates at the

proper location, and also the diameter of ingate are

International Journal of Research in Advent Technology, Vol.2, No.8, August 2014

E-ISSN: 2321-9637

86

increased from 50 to 60mm and on which the risers

are provided. Thus shrinkage porosity decreased

significantly by 98%. These studies thus helped in

arriving at an optimum gating system.

5. CONCLUSION

In the present work a 3D component model was

developed using casting simulation software

ADSTEFAN to evaluate possible casting defects for

sand casting of flywheel. Notable conclusions from

this study are:

By adopting the pressurized gating system, the

fluid flow was smooth and air was expelled

without any entrapment inside the mould cavity.

Simulation showed that the molten metal was

able to fill the mould within the desired time.

Therefore fluid heat distribution was good and no

cold shut was observed.

In first iteration improper location of ingates led

to formation of shrinkage porosities where in the

second iteration only two ingates are located at

the thicker section of the inner rib of the

flywheel, on which risers are located in order to

achieve directional solidification.

The second iteration resulted in reducing the

shrinkages by 98% and the defect associated with the

cast is eliminated and the sound cast is achieved

Acknowledgments

The authors wishes to thank research paper review

committee, department of mechanical engineering.

Hod and Principal of PDA college of Engineering,

Gulbarga for their suggestions, encouragement and

support in undertaking the present work.

REFERENCES

[1]. Mohd Rizuan Mohammed Shafiee, "Effects of

gating design on the mechanical strength of thin

section castings", ELSEVIER: Journal of

Materials Processing Technology, Vol-105, Pg.

128-133, 2009.

[2]. T.Nandi, "Optimization of Riser size of

Aluminium alloy (LM6) castings by using

conventional method and computer simulation

technique", International Journal of Scientific &

Engineering Research, Vol-2, 2011, ISSN 2229-

5518. 2011

[3]. Lee, P.D, Chirazi, A and see, D (2001).

Modelling micro porosity in aluminium -silicon

alloys: a review. Journal of light metals. Vol.1

Pg 15-30

[4]. Katzarov, I.H (2003). Finite element modelling

of the porosity formation in casting.

International Journal of Heat and Mass Transfer.

Vol 46. Pg. 1545-1552.

[5]. . Ravi, Metal Casting: Computer-Aided Design

and Analysis, Prentice-Hall India, New Delhi,

2005.

[6]. B. Ravi, R.C. Creese and D. Ramesh, Design

for Casting A New Paradigm to Prevent

Potential Problems, Transactions of the AFS,

107, 1999.

[7]. Shamasunder S., To believe or not to believe

results of casting simulation software,

ALUCAST, pp. 62-67, 2012.

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Investigation of Adsorption Based Air-Condition System Committed For Colling of Truck CompartmentDocumento4 pagineInvestigation of Adsorption Based Air-Condition System Committed For Colling of Truck CompartmentEditor-in-Chief IJRATNessuna valutazione finora

- Paper ID-612201814Documento4 paginePaper ID-612201814Editor-in-Chief IJRATNessuna valutazione finora

- Value Engineering Study of Various Gantry Girder ProfileDocumento7 pagineValue Engineering Study of Various Gantry Girder ProfileEditor-in-Chief IJRATNessuna valutazione finora

- First Ply Failure Behaviour of Laminated Composite Skew Plate Under Concentrated LoadDocumento6 pagineFirst Ply Failure Behaviour of Laminated Composite Skew Plate Under Concentrated LoadEditor-in-Chief IJRATNessuna valutazione finora

- Paper ID-612201808Documento7 paginePaper ID-612201808Editor-in-Chief IJRATNessuna valutazione finora

- Studies On Removal of Rhodamine-B Dye by Using Bark of Vachellia Nilotica TreeDocumento4 pagineStudies On Removal of Rhodamine-B Dye by Using Bark of Vachellia Nilotica TreeEditor-in-Chief IJRATNessuna valutazione finora

- Design and Analysis of Crankshaft of Single Cylinder Four Stroke Engine Using ANSYS SoftwareDocumento8 pagineDesign and Analysis of Crankshaft of Single Cylinder Four Stroke Engine Using ANSYS SoftwareEditor-in-Chief IJRATNessuna valutazione finora

- Effect of Intercriticle Annealing On Impact Energy and Hardness of AISI 1026steelDocumento4 pagineEffect of Intercriticle Annealing On Impact Energy and Hardness of AISI 1026steelEditor-in-Chief IJRATNessuna valutazione finora

- Effect of Intercriticle Annealing On Impact Energy and Hardness of AISI 1026steelDocumento4 pagineEffect of Intercriticle Annealing On Impact Energy and Hardness of AISI 1026steelEditor-in-Chief IJRATNessuna valutazione finora

- Developing Blockchain Authentication For Hadoop Using HDFS ClientDocumento7 pagineDeveloping Blockchain Authentication For Hadoop Using HDFS ClientEditor-in-Chief IJRATNessuna valutazione finora

- Activity Based Student S Performance Measure Using Moodle Log FilesDocumento3 pagineActivity Based Student S Performance Measure Using Moodle Log FilesEditor-in-Chief IJRATNessuna valutazione finora

- Secure Voice Over Internet Protocol (Voip) Network With Biometric KeyDocumento6 pagineSecure Voice Over Internet Protocol (Voip) Network With Biometric KeyEditor-in-Chief IJRATNessuna valutazione finora

- Curtain Airbag Design For Robust DeploymentDocumento6 pagineCurtain Airbag Design For Robust DeploymentEditor-in-Chief IJRATNessuna valutazione finora

- Comparative Study On Analysis and Design of Flat Slabs With Conventional SlabsDocumento7 pagineComparative Study On Analysis and Design of Flat Slabs With Conventional SlabsEditor-in-Chief IJRATNessuna valutazione finora

- Paper ID-612201848Documento4 paginePaper ID-612201848Editor-in-Chief IJRATNessuna valutazione finora

- Paper ID-612201841Documento10 paginePaper ID-612201841Editor-in-Chief IJRATNessuna valutazione finora

- A Study On Various Routing Algorithms in Mobile Ad-Hoc Networks (Manets)Documento3 pagineA Study On Various Routing Algorithms in Mobile Ad-Hoc Networks (Manets)Editor-in-Chief IJRATNessuna valutazione finora

- Design Metrics Behavior On Object Oriented SoftwareDocumento4 pagineDesign Metrics Behavior On Object Oriented SoftwareEditor-in-Chief IJRATNessuna valutazione finora

- Security in Data Transmission Using Big Data Technique and OBFDocumento3 pagineSecurity in Data Transmission Using Big Data Technique and OBFEditor-in-Chief IJRATNessuna valutazione finora

- Building Detection Using Enhanced HOG - LBP Features and Region Reinement Processes Using SVMDocumento15 pagineBuilding Detection Using Enhanced HOG - LBP Features and Region Reinement Processes Using SVMEditor-in-Chief IJRATNessuna valutazione finora

- Cloud Security Systems: A Comparison Study On DSA and AES AlgorithmsDocumento4 pagineCloud Security Systems: A Comparison Study On DSA and AES AlgorithmsEditor-in-Chief IJRATNessuna valutazione finora

- Retinal Disease Detection Using LBP TechniqueDocumento7 pagineRetinal Disease Detection Using LBP TechniqueEditor-in-Chief IJRATNessuna valutazione finora

- Optimization of Biomethanation Process For High TDS Spent W Ash From DistilleriesDocumento4 pagineOptimization of Biomethanation Process For High TDS Spent W Ash From DistilleriesEditor-in-Chief IJRATNessuna valutazione finora

- Efficient Real Time Traffic Signal Control Using Machine LearningDocumento4 pagineEfficient Real Time Traffic Signal Control Using Machine LearningEditor-in-Chief IJRATNessuna valutazione finora

- A Study On Floristic Diversity Using Geo-Spatial Technologies in The Paderu Mandal of Andhra Pradesh, IndiaDocumento9 pagineA Study On Floristic Diversity Using Geo-Spatial Technologies in The Paderu Mandal of Andhra Pradesh, IndiaEditor-in-Chief IJRATNessuna valutazione finora

- Geodetic Polynomial and Detour Geodetic Polynomial of Bistar GraphsDocumento4 pagineGeodetic Polynomial and Detour Geodetic Polynomial of Bistar GraphsEditor-in-Chief IJRAT0% (1)

- Floristic Diversity and Phytosociological Analysis of Erinjiyan Keezhil Kavu, Kannur District, KeralaDocumento8 pagineFloristic Diversity and Phytosociological Analysis of Erinjiyan Keezhil Kavu, Kannur District, KeralaEditor-in-Chief IJRATNessuna valutazione finora

- Totally and Slightly Nano Gδ-Continuous FunctionsDocumento5 pagineTotally and Slightly Nano Gδ-Continuous FunctionsEditor-in-Chief IJRATNessuna valutazione finora

- Development of Hybrid Model Using Fuse Image TechniquesDocumento8 pagineDevelopment of Hybrid Model Using Fuse Image TechniquesEditor-in-Chief IJRATNessuna valutazione finora

- Paper ID-6122018111Documento12 paginePaper ID-6122018111Editor-in-Chief IJRATNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 60 GHZDocumento9 pagine60 GHZjackofmanytradesNessuna valutazione finora

- CV1000 CV2000 CV3000 Ice Cube Machines SpecsDocumento12 pagineCV1000 CV2000 CV3000 Ice Cube Machines SpecsAriel Godoy100% (1)

- HS-2172 Vs HS-5500 Test ComparisonDocumento1 paginaHS-2172 Vs HS-5500 Test ComparisonRicardo VillarNessuna valutazione finora

- Ub40 LyricsDocumento76 pagineUb40 LyricsJose Lucio Flores SantosNessuna valutazione finora

- Mfz-Odv065r15j DS 1-0-0 PDFDocumento1 paginaMfz-Odv065r15j DS 1-0-0 PDFelxsoonNessuna valutazione finora

- Combustion Cat 2008Documento32 pagineCombustion Cat 2008Miguel LinaresNessuna valutazione finora

- Arta Fridei Kahlo A Fost Intotdeauna o ReactieDocumento13 pagineArta Fridei Kahlo A Fost Intotdeauna o ReactieAlta DaianNessuna valutazione finora

- Procedure for safely changing LWCV assembly with torques over 30,000 ft-lbsDocumento2 pagineProcedure for safely changing LWCV assembly with torques over 30,000 ft-lbsnjava1978Nessuna valutazione finora

- Beckman DxI 800 Prolactin Assay Superiority for Monomeric ProlactinDocumento5 pagineBeckman DxI 800 Prolactin Assay Superiority for Monomeric Prolactindoxy20Nessuna valutazione finora

- Edexcel A-Level Biology Experimental Design Marks Scheme (1) (Full Permission)Documento16 pagineEdexcel A-Level Biology Experimental Design Marks Scheme (1) (Full Permission)FardeenKhanNessuna valutazione finora

- IIT2019 RIT-1-CPM Chemistry TestDocumento15 pagineIIT2019 RIT-1-CPM Chemistry TestPRAKHAR GUPTANessuna valutazione finora

- Wirkungen FlechtenstoffeDocumento21 pagineWirkungen FlechtenstoffeLogge UliNessuna valutazione finora

- The Quill Vol. LVIII Issue 1 1-12Documento12 pagineThe Quill Vol. LVIII Issue 1 1-12Yves Lawrence Ivan OardeNessuna valutazione finora

- Guidelines On Dissolution Profile Comparison: Udrun ReitagDocumento10 pagineGuidelines On Dissolution Profile Comparison: Udrun ReitagRaju GawadeNessuna valutazione finora

- DCI-2 Brief Spec-Rev01Documento1 paginaDCI-2 Brief Spec-Rev01jack allenNessuna valutazione finora

- Very Low Altitude Drag-Free Satellites: R D UpdatesDocumento5 pagineVery Low Altitude Drag-Free Satellites: R D Updatesraa2010Nessuna valutazione finora

- Com Statement (HT APFC22 - 02)Documento2 pagineCom Statement (HT APFC22 - 02)SOUMENNessuna valutazione finora

- Myths of Greece and Rome PDFDocumento247 pagineMyths of Greece and Rome PDFratheesh1981Nessuna valutazione finora

- 35.2 - ING - El Puente NewsletterDocumento13 pagine35.2 - ING - El Puente NewsletterIrmali FrancoNessuna valutazione finora

- Celiac DiseaseDocumento14 pagineCeliac Diseaseapi-355698448100% (1)

- IMRAD - G1 PepperDocumento13 pagineIMRAD - G1 PepperRomero, Ken Angelo B.Nessuna valutazione finora

- Plow Moldboard or Disc PlowDocumento7 paginePlow Moldboard or Disc PlowAdewaleNessuna valutazione finora

- Surgical InstrumentsDocumento4 pagineSurgical InstrumentsWafa L. AbdulrahmanNessuna valutazione finora

- Kuffner Final PresentationDocumento16 pagineKuffner Final PresentationSamaa GamalNessuna valutazione finora

- Masturbation It Might Feel Good But ItsDocumento7 pagineMasturbation It Might Feel Good But ItsKshivam KhandelwalNessuna valutazione finora

- Three Bucket Method & Food ServiceDocumento4 pagineThree Bucket Method & Food Servicerose zandrea demasisNessuna valutazione finora

- Bill No. 1 - General Items PreliminariesDocumento24 pagineBill No. 1 - General Items PreliminariesNorazreen NorAzharNessuna valutazione finora

- Standardization Parameters For Production of Tofu Using WSD-Y-1 MachineDocumento6 pagineStandardization Parameters For Production of Tofu Using WSD-Y-1 MachineAdjengIkaWulandariNessuna valutazione finora

- UNIT-2 Design of Spur GearDocumento56 pagineUNIT-2 Design of Spur GearMarthandeNessuna valutazione finora

- Orientation Report PDFDocumento13 pagineOrientation Report PDFRiaz RasoolNessuna valutazione finora