Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Write Up On Waste Water Treatment From Gelatin Industry

Caricato da

Deepak100%(2)Il 100% ha trovato utile questo documento (2 voti)

721 visualizzazioni2 pagineThe document discusses the gelatine manufacturing industry and its effluents. It notes that gelatine production involves extracting collagen from animal tissues, generating large amounts of wastewater. These effluents contain high levels of biological oxygen demand and pollutants. Conventionally, effluents are treated using activated sludge methods, but this produces sludge requiring disposal. Some states now mandate zero liquid discharge from these plants. SSP PVT Limited provides zero liquid discharge treatment solutions using evaporation and drying technology. The process concentrates effluents into a calcium chloride powder via multiple effect evaporation and spray drying, allowing water recycling and achieving zero liquid discharge.

Descrizione originale:

waste water from gelatin production and ways to tackle the effluent so generated

Titolo originale

Write Up on Waste Water Treatment From Gelatin Industry

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThe document discusses the gelatine manufacturing industry and its effluents. It notes that gelatine production involves extracting collagen from animal tissues, generating large amounts of wastewater. These effluents contain high levels of biological oxygen demand and pollutants. Conventionally, effluents are treated using activated sludge methods, but this produces sludge requiring disposal. Some states now mandate zero liquid discharge from these plants. SSP PVT Limited provides zero liquid discharge treatment solutions using evaporation and drying technology. The process concentrates effluents into a calcium chloride powder via multiple effect evaporation and spray drying, allowing water recycling and achieving zero liquid discharge.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

100%(2)Il 100% ha trovato utile questo documento (2 voti)

721 visualizzazioni2 pagineWrite Up On Waste Water Treatment From Gelatin Industry

Caricato da

DeepakThe document discusses the gelatine manufacturing industry and its effluents. It notes that gelatine production involves extracting collagen from animal tissues, generating large amounts of wastewater. These effluents contain high levels of biological oxygen demand and pollutants. Conventionally, effluents are treated using activated sludge methods, but this produces sludge requiring disposal. Some states now mandate zero liquid discharge from these plants. SSP PVT Limited provides zero liquid discharge treatment solutions using evaporation and drying technology. The process concentrates effluents into a calcium chloride powder via multiple effect evaporation and spray drying, allowing water recycling and achieving zero liquid discharge.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

Page 1 of 2

IMPORTANCE OF THE GELATINE MANUFACTURING INDUSTRY

Gelatine, a heterogeneous mixture of water soluble proteins derived from the

collagen of animal hide or bone is composed of various essential amino acids required for

human nutrition. It has a diversity of uses in food science and industry, including wine

fining, confectionary etc. Therefore, the gelatine industry is of great importance to society.

CHARACTERISTICS OF GELATINE INDUSTRY EFFLUENTS

The gelatin manufacturing process primarily involves selective hydrolysis and

extraction of collagen from the connective tissues of animals. In India, the conventional

raw materials used in gelatine manufacture are bovine bones.

The major consideration during the manufacture of all forms of gelatine is the generation of

large amounts of process waste effluents.

These waste effluents contain mineral components and lipid material, which create a high

biological oxygen demand (BOD).

The effluents of a gelatine manufacturing unit are in pH, COD and calcium content, which

constitute a major source of pollution.

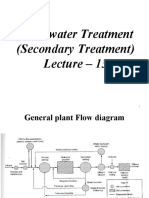

Conventionally, these effluents are treated in ETPs using the activated sludge method.

Later, the active sludge is dehydrated to form a sludge cake, which is subsequently

disposed. However, the disposal of organically rich sludge generated from conventional

ETPs requires a large dump yard. Furthermore, it may potentially cause environmental

pollution by leaching or harbouring pathogens. Discharge of effluents without suitable

treatment can cause environmental damage.

In India, Pollution Control Boards in some states have imposed additional conditions, which

read concerned Industry shall utilize the whole quantity of treated effluent within their

premises for plantation and horticulture etc. Effluent shall not be discharged outside the

factory premises in any circumstances. Zero discharge conditions shall be maintained.

Page 2 of 2

ZERO LIQUID DISCHARGE EFFLUENT TREATMENT PLANT

SSP PVT LIMITED has been providing Zero Liquid Discharge Effluent Treatment

Solutions to the Gelatine Industry based on Evaporation & Drying Technology.

SSPs core competence lies in evaporation and drying technology. SSP has made its

presence increasingly felt over the last two decades and is accredited with the supply of

more than 600 evaporation and drying installations across the globe.

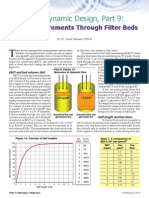

The Zero Liquid Discharge effluent treatment system is based on the principle of

concentrating the effluent using Multiple Effect Evaporator and subsequently Spray Drying

of the concentrate to convert into Free Flowing Powder (Calcium Chloride) which can be

marketed.

Effluent from Gelatine Industry (Calcium Chloride) is fed to the vacuum evaporator to

concentrate it up to 40 50% total solids. The total process is under vacuum and the

vapors generated in the system are re-used to economize steam consumption through

thermal vapor recompression system. The condensate water obtained from evaporation

plant can be reused within the plant premises.

The concentrated effluent at the outlet of the evaporator will be fed to Spray Dryer where

the rest of the water is evaporated and we get final product as free flowing Spray Dried

Powder. This technology helps achieve Zero Liquid Discharge as all the liquid effluent is

converted into solid (powder) and the recovered water (condensate) can be reused.

Potrebbero piacerti anche

- Sugar IndustryDocumento27 pagineSugar IndustryChali HaineNessuna valutazione finora

- Performance Evaluation of Effluent Treatment Plant of Dairy Industry PDFDocumento6 paginePerformance Evaluation of Effluent Treatment Plant of Dairy Industry PDFMortezaNessuna valutazione finora

- Sustainable Production: Effluent Treatment PlantDocumento12 pagineSustainable Production: Effluent Treatment PlantKush SharmaNessuna valutazione finora

- Waste Water TreatmentDocumento4 pagineWaste Water TreatmentIbrar ZahidNessuna valutazione finora

- Mini Project ReportDocumento5 pagineMini Project ReportSaj BhaiNessuna valutazione finora

- Water Maze Delta-3000a 1Documento2 pagineWater Maze Delta-3000a 1Marcelita AraujoNessuna valutazione finora

- Reverse Osmosis System FaridDocumento30 pagineReverse Osmosis System FaridAchFaridWadjdiNessuna valutazione finora

- Aerobic Biodegrdtn of PhenolDocumento41 pagineAerobic Biodegrdtn of PhenolMeetika GuptaNessuna valutazione finora

- Inclined Plate ClarifierDocumento2 pagineInclined Plate ClarifierKelvin SiewNessuna valutazione finora

- Slide ElectrocoagulationDocumento15 pagineSlide ElectrocoagulationUmmi SurayaNessuna valutazione finora

- Managing and Monitoring Effluent Treatment PlantsDocumento36 pagineManaging and Monitoring Effluent Treatment PlantsNandhakumarNessuna valutazione finora

- Water Treatment Plant Chemical Safety Presentation Complete Final 1Documento21 pagineWater Treatment Plant Chemical Safety Presentation Complete Final 1api-339319779100% (1)

- Ozone Based Waste Water TreatmentDocumento10 pagineOzone Based Waste Water TreatmentZafar BukhariNessuna valutazione finora

- Removal of Removal of Iron (Fe) and Manganese (MN) : DR Liu YuDocumento20 pagineRemoval of Removal of Iron (Fe) and Manganese (MN) : DR Liu YuChuah Chong YangNessuna valutazione finora

- Fertilizer Industry Wastewater TreatmentDocumento1 paginaFertilizer Industry Wastewater TreatmentAnmol UpadhyayNessuna valutazione finora

- 1R16 - Project StudyDocumento27 pagine1R16 - Project StudyRenzo Cadag MacasilNessuna valutazione finora

- Semiconductor Wastewater Treatment Using Tapioca Starch As A Natural CoagulantDocumento9 pagineSemiconductor Wastewater Treatment Using Tapioca Starch As A Natural Coagulanthuonggiangnguyen3011Nessuna valutazione finora

- Wastewater Characterization: Agroindustrial Technology Department University of BrawijayaDocumento39 pagineWastewater Characterization: Agroindustrial Technology Department University of Brawijayadevilturn70100% (1)

- Ammonia StrippingDocumento4 pagineAmmonia StrippingthirumuruganNessuna valutazione finora

- Water Treatment CalculatorDocumento3 pagineWater Treatment CalculatorgrabettyNessuna valutazione finora

- Textile Effluent TreatmentDocumento6 pagineTextile Effluent TreatmentvenkatharunNessuna valutazione finora

- Internship ReportDocumento31 pagineInternship ReportKaran KaushalNessuna valutazione finora

- Today'S Topic "Cooling Water Treatement" "Condenser Leak Detection" "Chlorination Plant" AND "Effluent Treatment"Documento57 pagineToday'S Topic "Cooling Water Treatement" "Condenser Leak Detection" "Chlorination Plant" AND "Effluent Treatment"saravan1891Nessuna valutazione finora

- Multi Effect EvaporatorsDocumento38 pagineMulti Effect EvaporatorsTajuddin ShaikNessuna valutazione finora

- ClarifierDocumento7 pagineClarifiersuleman205Nessuna valutazione finora

- INDION Multigrade Filter PDFDocumento1 paginaINDION Multigrade Filter PDFSandeep K Tiwari100% (1)

- Hospital Waste Water TreatmentDocumento5 pagineHospital Waste Water TreatmentNP100% (1)

- 40 KLD MBR QuoteDocumento15 pagine40 KLD MBR QuoteV Narasimha RajuNessuna valutazione finora

- Coagulation, Flocculation, SedimentationDocumento31 pagineCoagulation, Flocculation, SedimentationLoryl Ira NovenoNessuna valutazione finora

- Waste Water TreatmentDocumento19 pagineWaste Water TreatmentTayaChandranNessuna valutazione finora

- Air Reverse OsmosisDocumento12 pagineAir Reverse Osmosisirdawan100% (2)

- Silt Density IndexDocumento11 pagineSilt Density IndexWilfredo Suarez Torres100% (1)

- Module - 9 Secondary Treatment AS, EAAS, SBRDocumento39 pagineModule - 9 Secondary Treatment AS, EAAS, SBRFaran Masood100% (1)

- 1.1 GeneralDocumento18 pagine1.1 GeneralPravinAlbdusMathewNessuna valutazione finora

- Tertiary and Sludge TreatmentDocumento39 pagineTertiary and Sludge TreatmentmochuzNessuna valutazione finora

- Operation & Maintainence Manual For STPDocumento6 pagineOperation & Maintainence Manual For STPMukesh GautamNessuna valutazione finora

- Atc Ama202Documento1 paginaAtc Ama202Mahmoud BdourNessuna valutazione finora

- Anoxic TankDocumento12 pagineAnoxic TankpragatheeskNessuna valutazione finora

- Design of Ultra Filtration MembraneDocumento3 pagineDesign of Ultra Filtration MembraneMuhammad Zubair SharifNessuna valutazione finora

- Waters Edge STP PPT 2021Documento38 pagineWaters Edge STP PPT 2021lahiruNessuna valutazione finora

- Ammonia Removal From WastewaterDocumento6 pagineAmmonia Removal From WastewaterJunaid AmeerNessuna valutazione finora

- Lubigi Final PDFDocumento36 pagineLubigi Final PDFTakobo JoseNessuna valutazione finora

- Membrane Seperation (10.04.20)Documento57 pagineMembrane Seperation (10.04.20)HARI PRASATHNessuna valutazione finora

- User Manual ETPDocumento26 pagineUser Manual ETPclaoker100% (1)

- Main UASB ReactorDocumento23 pagineMain UASB ReactorsasisNessuna valutazione finora

- Excel Crop Care Limited: "Multi Effect Evaporator Plant"Documento9 pagineExcel Crop Care Limited: "Multi Effect Evaporator Plant"Sparsh ShukalNessuna valutazione finora

- PROBES-75 Guidelines For Developing GreenbeltsDocumento210 paginePROBES-75 Guidelines For Developing Greenbeltsgreymatter2012Nessuna valutazione finora

- 2.principle and Design of Waste MinimizationDocumento27 pagine2.principle and Design of Waste MinimizationFx NiubieNessuna valutazione finora

- Comparison of Dissolved Air Flotation and Sedimentation PDFDocumento5 pagineComparison of Dissolved Air Flotation and Sedimentation PDFPrie TeaNessuna valutazione finora

- DBDocumento25 pagineDBAbhijit MondalNessuna valutazione finora

- What Is Wastewater Treatment?: EnvironmentDocumento9 pagineWhat Is Wastewater Treatment?: EnvironmentAli JawwadNessuna valutazione finora

- UPO-1: Unit Processes and Operations (Physico-Chemical) - Question PapersDocumento20 pagineUPO-1: Unit Processes and Operations (Physico-Chemical) - Question PapersDr. Akepati Sivarami Reddy100% (2)

- Waste Management SIADocumento140 pagineWaste Management SIASaishiva SukkalaNessuna valutazione finora

- Water TreatmentDocumento10 pagineWater TreatmentchristopherNessuna valutazione finora

- 21857, Issue 24 Water Softener Elution STDocumento2 pagine21857, Issue 24 Water Softener Elution STVương Đình NamNessuna valutazione finora

- PROBLEMS - Module 2 - Air Pollution Removal PDFDocumento7 paginePROBLEMS - Module 2 - Air Pollution Removal PDFankursonicivilNessuna valutazione finora

- Treatment of Dye Removal From Textile Wastewater UsingDocumento5 pagineTreatment of Dye Removal From Textile Wastewater UsingkksNessuna valutazione finora

- Lime Softening PDFDocumento16 pagineLime Softening PDFBiljana TausanovicNessuna valutazione finora

- October 2012 Hi Tech MagazineDocumento37 pagineOctober 2012 Hi Tech MagazineeiribooksNessuna valutazione finora

- Iue - 2: Recommendations For Tannery Solid by Product ManagementDocumento6 pagineIue - 2: Recommendations For Tannery Solid by Product ManagementBarkat Ali SolangiNessuna valutazione finora

- Ancient Indian History Notes Guide4Xam PDFDocumento128 pagineAncient Indian History Notes Guide4Xam PDFSakshi Gupta67% (6)

- Screw Press SNP 1-210 - SS Engineering Corporation PDFDocumento6 pagineScrew Press SNP 1-210 - SS Engineering Corporation PDFDeepakNessuna valutazione finora

- DESIGNOFWASTEWATERTREATMENTPLANTFORHOSPITALDocumento7 pagineDESIGNOFWASTEWATERTREATMENTPLANTFORHOSPITALDeepakNessuna valutazione finora

- Chapter 7 Active and Passive PDFDocumento41 pagineChapter 7 Active and Passive PDFphaniNessuna valutazione finora

- Conversion Factors.Documento2 pagineConversion Factors.Stuart GoodswenNessuna valutazione finora

- Active and Passive Voice Exercise: AnswersDocumento11 pagineActive and Passive Voice Exercise: AnswersFxwireless100% (1)

- Hydrodynamic DesignDocumento3 pagineHydrodynamic DesignDeepakNessuna valutazione finora

- Sample Problems StaticsDocumento3 pagineSample Problems StaticsSelina FergusonNessuna valutazione finora

- Sample CV RFPDocumento11 pagineSample CV RFPDeepakNessuna valutazione finora

- Design of Triple Effect Evaporator Developed by A Program in CDocumento5 pagineDesign of Triple Effect Evaporator Developed by A Program in CDeepakNessuna valutazione finora

- Effluent From Dyeing IndustriesDocumento1 paginaEffluent From Dyeing IndustriesDeepakNessuna valutazione finora

- The Sonnets of William Shakespeare: Click Here To Jump To The Table of ContentsDocumento187 pagineThe Sonnets of William Shakespeare: Click Here To Jump To The Table of ContentsIbrahim AbuNessuna valutazione finora

- 04 Ro Water ChemistryDocumento8 pagine04 Ro Water ChemistryRajesh Kumar RoshanNessuna valutazione finora

- Spin Flash Dryer General Description: The Wet Product Is Introduced in The Form at Which It Leaves The PrecedingDocumento1 paginaSpin Flash Dryer General Description: The Wet Product Is Introduced in The Form at Which It Leaves The PrecedingDeepakNessuna valutazione finora

- Diet ChartDocumento11 pagineDiet ChartDeepakNessuna valutazione finora

- AlimDocumento1 paginaAlimDeepakNessuna valutazione finora

- CrodaRawMaterialsGuide Personalcare2006Documento62 pagineCrodaRawMaterialsGuide Personalcare2006An BìnhNessuna valutazione finora

- Acid-Induced Gelation of Milk Protein Concentrates With Added Pectin-Effect of Casein Micelle Dissocia 1Documento11 pagineAcid-Induced Gelation of Milk Protein Concentrates With Added Pectin-Effect of Casein Micelle Dissocia 1Ramsan CENessuna valutazione finora

- Types, Manufacture, Formulation of Capsules 1Documento26 pagineTypes, Manufacture, Formulation of Capsules 1chill streamNessuna valutazione finora

- CAPSULES (Dosage Forms)Documento24 pagineCAPSULES (Dosage Forms)Vanessa DLNessuna valutazione finora

- Five Overall Health-Improving Benefits of Royal JellyDocumento2 pagineFive Overall Health-Improving Benefits of Royal JellyHayCurtis38Nessuna valutazione finora

- 4 Hydrogels in Drug DeliveryDocumento15 pagine4 Hydrogels in Drug Deliveryblueflame9505050% (2)

- THE ACTION OF ENZYMES IN LAUNDRY DETERGENTS-Group N6Documento16 pagineTHE ACTION OF ENZYMES IN LAUNDRY DETERGENTS-Group N6Sebastian VillacresNessuna valutazione finora

- Practice Pas Xi EnglishDocumento6 paginePractice Pas Xi EnglishNysa MuktikusumaNessuna valutazione finora

- Control de AguaDocumento309 pagineControl de AguaPedro Felipe AndarciaNessuna valutazione finora

- The Manufacturing Process: Making Hide or Skin GlueDocumento2 pagineThe Manufacturing Process: Making Hide or Skin GlueGlendaB.HononganNessuna valutazione finora

- US6037451Documento3 pagineUS6037451محمد هاني ابوالنورNessuna valutazione finora

- Soft Gels Process BloomDocumento4 pagineSoft Gels Process Bloommailtorubal2573Nessuna valutazione finora

- Cherry Shaped DessertDocumento3 pagineCherry Shaped DessertPetre100% (1)

- Using Gelatin For Moulds and ProstheticsDocumento16 pagineUsing Gelatin For Moulds and Prostheticsrwong1231100% (1)

- Chemical Weekly May03Documento238 pagineChemical Weekly May03devangNessuna valutazione finora

- 0.the Water Vapour Permeability Mechanical Properties and Solubility of Fish Gelatin Chitosan Films Modified With Transglutaminase or 1 Ethyl 3 3 DimethDocumento6 pagine0.the Water Vapour Permeability Mechanical Properties and Solubility of Fish Gelatin Chitosan Films Modified With Transglutaminase or 1 Ethyl 3 3 DimethValentina RoznovNessuna valutazione finora

- John Sundar PaperDocumento29 pagineJohn Sundar PaperarathinamNessuna valutazione finora

- How To Prepare Aqueous SolutionsDocumento16 pagineHow To Prepare Aqueous SolutionsGiovanni OsorioNessuna valutazione finora

- AtulDocumento25 pagineAtulapi-3741769Nessuna valutazione finora

- Formulation and Evaluation of Zolpidem Nasal in SituDocumento12 pagineFormulation and Evaluation of Zolpidem Nasal in SituGopalasatheeskumar KNessuna valutazione finora

- Fenners Complete FormularyDocumento43 pagineFenners Complete FormularyRajesh RaoNessuna valutazione finora

- 6 ENG Шоколадный чизкейкDocumento7 pagine6 ENG Шоколадный чизкейкСофия ДорошенкоNessuna valutazione finora

- Honey Bee (Apis Mellifera) Larval Toxicity Test, Single ExposureDocumento10 pagineHoney Bee (Apis Mellifera) Larval Toxicity Test, Single ExposureLemon DropNessuna valutazione finora

- Research (Stem 4hea)Documento31 pagineResearch (Stem 4hea)charles estradaNessuna valutazione finora

- Chapter IIIDocumento7 pagineChapter IIIRegine Cena CuetoNessuna valutazione finora

- Effect of Temperature in Enzyme ActivityDocumento4 pagineEffect of Temperature in Enzyme ActivityJuan Martín VillazónNessuna valutazione finora

- 1 Extraction of Gelatin From SH Skins by High Pressure TreatmentDocumento6 pagine1 Extraction of Gelatin From SH Skins by High Pressure TreatmentCaroline LidyaNessuna valutazione finora

- Meat & Meat CookeryDocumento34 pagineMeat & Meat CookerySteffi ToringNessuna valutazione finora

- Amway Multi Amw Fact V en Halal Letter of CertificationDocumento13 pagineAmway Multi Amw Fact V en Halal Letter of CertificationGener Resonda100% (1)

- T e XT 1. The Foll o Wing T Ex T Is For Qu e Stions No. 1 - 4Documento6 pagineT e XT 1. The Foll o Wing T Ex T Is For Qu e Stions No. 1 - 4muhamad bgsNessuna valutazione finora

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseDa EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseValutazione: 3.5 su 5 stelle3.5/5 (69)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingDa EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingValutazione: 5 su 5 stelle5/5 (5)

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessDa EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessNessuna valutazione finora

- The Other End of the Leash: Why We Do What We Do Around DogsDa EverandThe Other End of the Leash: Why We Do What We Do Around DogsValutazione: 5 su 5 stelle5/5 (65)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingDa EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingValutazione: 3.5 su 5 stelle3.5/5 (34)

- Fire Season: Field Notes from a Wilderness LookoutDa EverandFire Season: Field Notes from a Wilderness LookoutValutazione: 4 su 5 stelle4/5 (142)

- The Big, Bad Book of Botany: The World's Most Fascinating FloraDa EverandThe Big, Bad Book of Botany: The World's Most Fascinating FloraValutazione: 3 su 5 stelle3/5 (10)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionDa EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionValutazione: 4 su 5 stelle4/5 (811)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsDa EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsValutazione: 4 su 5 stelle4/5 (223)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldDa EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldValutazione: 4.5 su 5 stelle4.5/5 (18)

- Spoiled Rotten America: Outrages of Everyday LifeDa EverandSpoiled Rotten America: Outrages of Everyday LifeValutazione: 3 su 5 stelle3/5 (19)

- The Lives of Bees: The Untold Story of the Honey Bee in the WildDa EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildValutazione: 4.5 su 5 stelle4.5/5 (44)

- Why Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeDa EverandWhy Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeValutazione: 4.5 su 5 stelle4.5/5 (699)

- When You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsDa EverandWhen You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsValutazione: 3.5 su 5 stelle3.5/5 (13)

- The Rise and Fall of the Dinosaurs: A New History of a Lost WorldDa EverandThe Rise and Fall of the Dinosaurs: A New History of a Lost WorldValutazione: 4 su 5 stelle4/5 (595)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorDa EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorValutazione: 4.5 su 5 stelle4.5/5 (137)

- Come Back, Como: Winning the Heart of a Reluctant DogDa EverandCome Back, Como: Winning the Heart of a Reluctant DogValutazione: 3.5 su 5 stelle3.5/5 (10)

- When the Sahara Was Green: How Our Greatest Desert Came to BeDa EverandWhen the Sahara Was Green: How Our Greatest Desert Came to BeValutazione: 4.5 su 5 stelle4.5/5 (6)

- Last Child in the Woods: Saving Our Children From Nature-Deficit DisorderDa EverandLast Child in the Woods: Saving Our Children From Nature-Deficit DisorderValutazione: 4 su 5 stelle4/5 (283)