Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

16 MM Grade 60-70 p1g1 To p2g2

Caricato da

John EvansTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

16 MM Grade 60-70 p1g1 To p2g2

Caricato da

John EvansCopyright:

Formati disponibili

/

G'

COMTECH METALS PVT LTD.

QW-482 WELDING PROCEDURE SPECIFICATION (WPS)

(AS per QW-200.2 Section IX ASME Boiler and Pressure Vessel Code)

Company Name:

COMTECH METALS PVT LTD

WPS No.

CMPLIWPS/12/12-13

Rev. no. :- 0

IDate:- 9/8/2012

PQR No.

CMPLI PQR/12/12-13

Rev. No. :- 0

IDate:- 9/8/2012

Welding Process

GTAW+SMAW

Type

11;:i:i1';;if,<

Manual

'ii/lt:.>'>;>:

';'j.;'i.i.<?ii[(r01,;r;

'1ii;:12\\:!Yl':e"Pt~TS(QW~(j~ "~l~~;:~;t \~ ,',~';;'

.,iiY""?:",i;I!:>

fil

Specific Joint Details

As per Drawing

Joint Design

Yes

Backing

For GTAW - NIL & SMAW - Weld metal

Backing Material

AS PER DRAWING

Retainers

No

Retainer Material

NA

BAse~ETAL (Q~-40~)

."i}'\

.;';0(,\U;!i

"'ii~,r' i t

'?~;\~'i ;';ii~~~'j.!'

iX5iii/,i ;'i\iiiI'i}'iikl!i>.,.. . ,.:"ii';:I'. .j\{W:;~1

..'i;ii;hi

Material Spec. I P no. I

Group no.

From P No. 1 Group 1 to P no. 1 Group No.2 OR P No. 1 Group 1 to P no. 1 Group No. 1 OR P

No.1 Group 2 to P no. 1 Group No.2

Thickness of Test Coupon

16 MM

Thickness Range

Groove

t pass> 13 mm

iiii ;..... 3.'1111

16 to 32 mm

Fillet

All

NO, t pass < 13 mm

. :;g

'"

',,;l~\j'

!!";\\~It,lI;i~;tiIIETill:l,f;Nlib~.i_

'i'

~.ll;J;'Vii(.

Welding Process

GTAW

SMAW

F No.

ANo.

11

11

Diameter

2.4 MM DIA

2.5 MM DIA & 3.15 MM DIA

SFA No.

5.28

5.5

With or Without Filler

With filler only

NA

Filler metal product form

Solid

NA

Supplemental Filler Metal

NA

NA

Alloy Elements

NA

NA

Flux Design

NA

NA

Deposit of Weld Metal

Thickness

Upto 8 mm

Upto 24 mm

Classification

ER-80SD2

E-8018 G

Brand Name

D&H,ESAB,GEE,HONAVER,ADOR

D&H

iii

0",

#~ "0

( ~')(~fi,~; '

'--f\~~

"..",

COMTECH METALS PVT LTD.

QW 482 (Back)

WPS No.

CMPL!WPS/12/12-13 Rev. no. :- 0 Dated 09.08.12

POSITION QW-405

Position of Groove

.,,\

All

3G uphill

Welding Progression

Position of fillet

All

:).:'0};f",:,f"~;~~,\:},,fii\01;s>::1,~f;;j/' ,t;t~"T:f~8~-407)J~!:

Temp. :

NA

Time Range:

NA

Holding Time (Min)

PREHEAT (QW-406),,\,:,\;I~;lf!)i/1]i;~4:!;;~\!:{;;;jf

Preheat Temp. (min)

16 C

Interpass Temp.

250' C

Preheat Maintenance:

Others

,\

Flow Rate

Shielding

ARGON

SINGLE

10-12 mm

NA

Trailing

NA

NA

NA

Nil

Backing

NA

NA

NA

Polarity

<;i"\,,.JECHNICtf.ft;;/(QW-41 0"

i"<'.

.,!

Stringer I Weave (Weaving shall not be greater

.

.

than 3 times of the electrode diameter)

Orrifice Cup Size

10 mm

G'nn d'mg I W'Ire brus h'mg I Ch'Ippmg

.

Grinding, if applicable

Methode of Back Gouging:

Amp.

NA

2.4 mm dia.& Osciliation:

o'

2 Vo thonated

Contact Tube to Work Distance:

NA

Mode of Metal Transfer

NA

Multiple or Single Pass(Per side)

Multiple

Heat Input Maximum

aII owa bl e

3.5 J/mm

.

MaXlmum

Multiple or Single Electrode:

T

I S pee d

rave

Single

Referbei ow tabl e

Other

QW-410.11 & QW-41 0.64 - Not applicable

FILLER METALS

WELD LAYER

CURRENT

PROCESS

AWS CLASS

DIA MM

POLARITY

AMPS

VOLTS

TRAVEL

SPEED IN

MM 1MIN

ROOT

GTAW

ER-80SD2

2.4

DCEN

90 to 110

16 TO 22 60 TO 90

HOT PASS

GTAW

ER-80SD2

2.4

DCEN

95 to 120

16 TO 22 60 TO 90

FILL UP

SMAW

E-8018G

3.15

DCEP

85 to 125

22T030 60T090

FINAL

SMAW

E-8018G

2.5

DCEP

85 to 125

22 TO 30 60 TO 90

PREPARED BY

NAME:

~~~(Q,o..!Q~~)~

~.V\;S \, \).

SIGNATURE'

..

)'.

DATE: 09/08/2012

REVIEWED BY

,. Al.$A

\~

~v~

.~,

... /~

~AI~>\?J;:

-

APPROVED BY

~~'i)~,t:~'

NAME:X'>~I\i'~ ~~h~~i.~~

SIGNATURE:

DATE:

. F' ,

, ...... )

,0

..

)~w~. :U-'

OC1.() ~\1.9l'

NAME:

-III

.r::" 11

O,-)--..____ .-:;.(\"V-)

'~~fH~ ~

")"""'1

.

W

N d

Stnng or eave ea:

Methode

. of initial and interpass

See Table CI

eamng:

Tungsten Electrode

(qW~(j8)jf' ';1:';

Percentage Compositions

DC

V oItage

Ct.

NA

Gases

ElE;CTRICA'C!tlATA (QW-409)

Current AC I DC

. 1!!'9AS

;YilfY,,>,iit,lliV'\!\'i

SIGNATURE:

....._-...

UV~V(~O

. ~~.;;-. . .;'V <5>%

lie ~1Q: _.

q\~(~:f

DATE:.

~~\f\

~~\ /

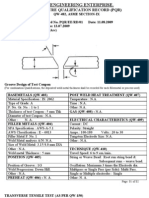

COMTECH METALS PVT LTO.

QW-483, Procedure Qualification Record

(AS per QW-200.2 Section IX ASME Boiler and Pressure Vessel Code)

CMPLI PQR/12/12-13

REV:O

Prepared By

Mr. Santsharan Parmar

CMPLlWPS/12/12-13

REV:O

Welder Name

Mr. Bapi Ruidas

Location

CMPL

GTAW+SMAW

75 5deg.

16mm

2 0.5 mm

21mm

None

Material Spec.

SA 516 GR 60 TO SA516 GR 70

NA

NA

HAET No.

P no. 1 Group No.2

NA

5.28

5.5

Type

Gas (es)

Mixures

Flow Rate

ER 80 S 02

E-8018 G

Shielding

ARGON

SINGLE

10-12 MM

Trailing

NA

NA

NA

11

11

Backing

NA

NA

NA

Size of filler Metal

2.4 MM OIA

2.5 MM & 3.15 MM OIA

Weld Metal Thickness

8mm

24 mm

Trade Name

GEE

O&H

Metal Analysis A No.

ing Progression

Interpass Temprature(Max)

Others

Up Hill

Polarity

None.

Amps

250 C

Refer Annexure 01

Grinding & Wire brush

Multipass

No Peening

COMTECH METALS PVT LTD.

QW-483 ( Back)

PQRNo.

Date:- 09/08/2012

CMPLI PQRl12/12-13 Rev-O

T-1

15.6

20.8

I 324.48

190000

585.5

Parent Metal

T-2

15.55

20.9

192000

590.7

Parent Metal

325

SB-1

SIDE BEND

180

38mm

Satisfactory

SB-2

SIDE BEND

180

38mm

Satisfactory

SB-3

SIDE BEND

180

38mm

Satisfactory

SB-4

SIDE BEND

180

38mm

Satisfactory

---1

Ductile Fracture

Ductile Fracture

90-RQ/2012 DTD:-19/7/12

Mark

I HAZ(GR-60) r

1OX1 0

-46'C

20

32

20

10X10

10X10

-46'C

-46'C

22

38

30

42

34

30

VISUAL TEST

Type of Test (Other)

28.67

36.67

376

Refer report no.

R/2012 Dt: 20.07.12

: Found Satisfactory

RADIOGRAPHIC TEST:- Fount satisfactory. REPORT No-NRS-REP/1124/12-13 DTD:9n112

HARDNESS TEST

:NA

CORROSION TEST

: NA

PWHT TEST

vvr:::Lur:::r;o NAME:

Mr. Bapi Ruidas

CONDUCTED BY:

Met Heat Engineers Pvt. Ltd.

: NA

CLOCK NO.

STAMP NO. w-19

LABORATORY TEST NO.: 90-RQ/2012 DTD:-19/7/12

CERTIFY THAT THE STATEMENT IN THIS RECORD ARE CORRECT AND THAT THE TEST WELDS WERE PREPARED

VVt:LUt:U

AND TESTED IN ACCORDANCE WITH THE REQUIREMENT OF SECTION IX OF THE ASME CODE.

~~.

NAME:

SIGN:

DATE:

.rr.----------------------------------

COMTECH METALS PVT LTD.

PQR No.

CMPLI PQR/12/12-13 REV-O DATED 09.08.12

WPS No.

CMPLIWPS/12/12-13 REV-O DATED 09.08.12

ANNEXURE -1

FILLER METALS

WELD LAYER

CURRENT

JTRAVEL SPEED

I PROCESS

liN MM 1 MINUTE

AWSCLASS

DIAMM

POLARITY

AMPS

VOLTS

ROOT

GTAW

ER-80SD2

2.4

DCEN

90 TO 105

20 TO 22

60 TO 90

HOT PASS

GTAW

ER-80SD2

2.4

DCEN

95 TO 113

20 TO 24

60 TO 90

FILL UP &

SUB-SEQUENT

RUNS

SMAW

IE-8018G

13. 15

IDCEP

187T0115

123 TO 31

160 TO 90

FINAL

SMAW

IE-8018G

12.5

IDCEP

185 TO 111

125 TO 30

160 TO 90

PREPARED BY

REVIEWED BY

OVEDBY

NAME:I

SIGNATURE:

SIGNATURE:

DATE: 09/08/2012

DATE:

,"

(.

(~)

r!imay Raiio9f'aphic Sef'vice:1

O~

(fonne(y Iqwwn as CBaroaa lnaustrialX-ray Services)

Radiographic & Other NOT Testing of Welds, Casting & Piping

43/8, G.I.D.C., Makarpura, VADODARA - 390010.

Ph. : (0265) 2632808, 2642456 Fax: (0265) 3042854 e-mail: nimay-rs@hotmail.com

Mis

Report No' NRS-Repl 1124 f12-13

Comtech Metals Pvt . Ltd

Plot No-111, Near Gujarat Engg.Co.

Jarod - Samlaya Road,

Vadodara

Date: 9-Jul-12

RADIOGRAPHIC INSPECTION REPORT

Source:

Iridium 192

Source Size:

2.95 mm

Strength:

14.00 Ci

IQI hole type: ASTMwire type: ASTM - 1 B 11

Total No of Exposures:

. Acceptance Crieteria: ASME Sec IX

SeNo.

,SOD:

OFO from SSO:

,E~posure Type:

Viewing:

Exposure Time:

Material: SA 516

Film:

AGFA - 0 7

Lead front:

0.1 mm

Screen back:

0.1 mm

Weldi~g Tech.:

Film per

cassette:

490.00 mm

18 mm

sin~le wall

single image

"'

9 min

,nil

In'

uln

Identification Marks

Film Size

Observation

CMPL PQR-1iV\119 XR-1 SAP] RUIOAs

15" x 3"

NSD

Remarks

mlJ

..

I)

'"

~.

It)

It I

I'

.'

YNY

_Ny

,,,,',,y

Note: Films Marked as C.S(gheck SurfacEl) must be viewed cmd these films will be

('

I2L

Inspection Agency

accept~d

accordingy

Page_of_

......

'

.,

--------~--

MET:t~ENGINEERS PVT. LTD.

IMHEPLH/F-wt7]

857/2, G.I.D.C.

INDUSTRIAL ESTATE, MAKARPURA,

VADODARA - 390 010.

TELEFAX: 0265-2632374, 2643655, 2648026,

6548715,6548716

E-mail: info@metheat.com

Website : www.metheat.com

METALLURGICAL LABORATORY

ON APPROVED LIST OF VARIOUS GOVT. DEPART~ENTS

& PUBLIC SECTOR UNDERTAKINGS

'

(SINCE 1975)

TEST REPORT (PHYSICAL)

Ie of The Customer

wo:e7/734SrHo.l PI/

COMTECH METALS PVT LTD

PLOT NO:111~

NR.GUJARAT ENGG. CO.

VILLAGE-VADADALA

PTR No.

Date

3&-Cr-Hol'

90-RQ/2012

19/07/2012

Date of Receipt: 13/07/2012

omer's Reference N0'i REF: CMPL/CMO-58/MET-HEAT /21

!rial Specification

SA-516 GRADE-60:2010 TO SA-516 GRADE-70:2010

...

Identification

Description

of Material

Dia-Width

mm

Thick

mm

Cross

Sectional

Area

mm 2

Yield

Strength

Yieid

Load

Required

Minimum

Welded Test

PIl:CE 16M'! nil(

PLATE

stamped ...

29.80

is. fill

324.46

'TWO

Of TW..H(R)

Gauge

Length

mm

Required

Minimum

'. 1'F'a

f.

41S

Elong

ation %

Final

Length

mm

Required

Minimum

l'F'a

"

I

Tensile

Strength

Ultimate

Load

1'ii1IIIIHCt.

lSSS.,s i3t'0keR -ParMt MiKal

Fr a.c::tI.lre-Ouctil.

,

(SA-S16 ClR-filI)

--

ID: CK"L/CI'Il-SSI

PCFVl2/12-13

\IPS. NO : OPl/llPSl

12/2912-13

NO:OPL/PI'.V

12/2012-13

T-l

do

29.',;0

do T-2

lS.SS

192H11iS9C1 .,

32S._

Fr acture;-DuctU.

(SAi-S16 OR-tA)

38._ . . Ar'I<ill. Of 'BIr!d' 1ar1.II'

do

do

SEI-l

SIDE BEHO rtsT SaUaf.ctory

MilndrU Oia

do

do 00-2

SIDE BEND TEST Satiafactory

Kandril Oia

38.011 . . I!n'iIle Of fland lfl111 ,

do

do 00-3

SIDE BEND TEST Sa.tiafactory

Mandril Oia

:sa.

111M

AAgl. Of ElllndlE111

do

doSB-4

SIDE eEHO TEST Satisfactory

Mandril Oia

:sa."

I11III

An<ille Of 8end U'0.0

':~.

. _ - - - _ _ _........ _ _ ........ _ _ _ _ _ _ _ _ ... _ _ _ _ ... _ _ -

tettlCld Of Testing

- - _ _._ ... - ....... _ ... _' .... -

...... _ - _ _ _ _ _

..,._~

...... - - - _ _ _ _ _ _ _ -

- - - - - - _ _ _ ... _ - - ... - - - - - , - - ..... -

... - . - - - - - - -

~.

-~

abow reaulta are naeting lIIit..!'l physical requirllll'lEl'lta of ASME SECTIQoIIX lIIithrespaet of test carried

'" --... - ... -._- - _... -- ........ - -----_.

-- , ............. _... -.- ------- ................ _. - _.......... _............ --- - .... - ... .... .... .,. --- -.- - ........ _.... _....

-_

- --

-- -

_ .... _ ......<00: - - - - - - - - - - - _ _

ASME SEC-IX.:: 2910

._..... ____ ... _._. ___ ...... _...... _________ -. ...... _______ ...... _______.___,_-___.______... __.___________________ ----- ________ ... - - - -- . .

I

-_ - _

--

... -----i.. . . . _-- ...;;;..----'

Cll.It~

_--- -------- -- --- --

....

'1JI1~.

Authorised Signatory . /

rvJ;S;;1

..,

C,~~T ENGINEERS PVT. LTD.

[r~HEPUFMt18J

857/2, G.LD.C,

INDUSTRIAL ESTATE, MAKARPURA,

VADODARA - 390 010,

TELEFAX: 0265-2632374, 2643655, 2648026

E-mail: info@methea!.com

Website .www.metheat.com

METALLURGICAL LABORATORY

ON APPROVED LIST OF VARIOUS GOVT. DEPARTMENTS

& PUBLIC SECTOR UNDERTAKINGS

(SINCE 1975)

WO:07/734 SrNo.l PI/

TEST REPORT

of The Customer

COMTECH METALS PVT LTD

PLOT NO:111.

NR.GUJARAT ENGG. CO.

VILLAGE-VADADALA

30-Cr

Test Report No.

Date

376-R /2012

20/07/2012

Date of Receipt

13/07/2012

lars of Sample Submitted:

Welded Test PIECE 16MM THK PLATE

al Specification

SA-S16 GRADE-60:2010 TO SA-S16 GRADE-70:2010

ication of Sample

Stamped As 'TUY' Of TUY-NORD.ID:CMPL/CMO-58/PQR/12/12-13

WPS.NO:CMPL/WPS/12/2012-13 PQR NO:CMPL/PQR/12/2012-13

f Test Required

mer's Reference No.

','

/0

V Notch Charpy Impact Test at -46 C. By ASTM E-23:2007A

[MINUS FORTY SIX Degree Centigrade ]

REF:CMPL/CMO-S8/MET-HEAT/21

ts

ocation

Size mm

Energy absorbed in Joules

I

II

III

Average

Value

Required

Value

-------------------------/----/----------?--------~----------~-------------

eld

10x10.00

20J

32J

20J

24.00J'

AZ (GR-60)

AZ (GR-70)

10x10.00 .I'

10x10 . 00./

22 :Y

38J ,/

30J . . .

42J ('"

34J/

30J .r

28.67J /'

36.67J ./

-----------------------------------------------------------------------~-----

-----x----

~

.J~

fey

Authorised Sianatorv

Potrebbero piacerti anche

- wps63 PDFDocumento4 paginewps63 PDFErick HoganNessuna valutazione finora

- PQR 014 (Qualified Sa 106 GR BDocumento5 paginePQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- 6GR WPS PQRDocumento15 pagine6GR WPS PQRKiukStaks100% (6)

- Qualification Soudeur PDFDocumento3 pagineQualification Soudeur PDFr_racNessuna valutazione finora

- Weld Joint 1Documento81 pagineWeld Joint 1rajibali27100% (1)

- Welding Procedure Specification SampleDocumento5 pagineWelding Procedure Specification SampleAdiNessuna valutazione finora

- IsometricsDocumento4 pagineIsometricsMuhammedHafisNessuna valutazione finora

- CWB CredentialsDocumento14 pagineCWB Credentialsranjith_022Nessuna valutazione finora

- 6GR WPS PQR PDFDocumento15 pagine6GR WPS PQR PDFerwincalvoNessuna valutazione finora

- 6GR WPS PQRDocumento15 pagine6GR WPS PQRMohammed NazeerNessuna valutazione finora

- MPQT Alishar SPM 3 31.08.2013 To 02.09.2013Documento68 pagineMPQT Alishar SPM 3 31.08.2013 To 02.09.2013mdsajidalamNessuna valutazione finora

- Piping Isometrics CPF Area Cpf2 Process Area - Drawing IndexDocumento12 paginePiping Isometrics CPF Area Cpf2 Process Area - Drawing IndexWnava CrisNessuna valutazione finora

- WPS PQR 12Documento9 pagineWPS PQR 12Ranjan KumarNessuna valutazione finora

- PQR-WPS-WPQR XXX Rev 0Documento6 paginePQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- Ce Const2 220kv CB Siemens 2012Documento18 pagineCe Const2 220kv CB Siemens 2012erkamlakar2234100% (1)

- Dle Oyot RTDocumento23 pagineDle Oyot RTHirobertsNessuna valutazione finora

- WPS PQR-01Documento9 pagineWPS PQR-01Ranjan Kumar0% (1)

- Structural Fabrication SpecificationDocumento18 pagineStructural Fabrication Specificationravirawat15Nessuna valutazione finora

- PQR Gmaw3gDocumento4 paginePQR Gmaw3gdevendrasingh2021100% (3)

- EurotrodDocumento76 pagineEurotrodPedro SilvaNessuna valutazione finora

- Equotip 2 User Manual E - 200605Documento35 pagineEquotip 2 User Manual E - 200605mgmqro100% (1)

- 10-01265-015-D-061706180619abc-Qc-Wps PQR001 - Moisture Separator WPS PQR and Weld Map - RD PDFDocumento65 pagine10-01265-015-D-061706180619abc-Qc-Wps PQR001 - Moisture Separator WPS PQR and Weld Map - RD PDFmarghoob100% (1)

- 02 ACSR ZEBRA ConductorDocumento37 pagine02 ACSR ZEBRA Conductorsanjeevchhabra100% (2)

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Documento2 pagineQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNessuna valutazione finora

- MTC of Pipe - SSP MakeDocumento4 pagineMTC of Pipe - SSP Makemubeennavaz100% (1)

- Tornillo 3.4 X 4Documento1 paginaTornillo 3.4 X 4Laura CondizaNessuna valutazione finora

- Concast WPS - REV-01Documento28 pagineConcast WPS - REV-01meena34Nessuna valutazione finora

- 6877-SM-LM-99-00-09052-U1D2 Document Number: Merlin Version 2.2 12-JAN-05 14:08:20 Detailed ReportDocumento6 pagine6877-SM-LM-99-00-09052-U1D2 Document Number: Merlin Version 2.2 12-JAN-05 14:08:20 Detailed ReportSalimNessuna valutazione finora

- WpsDocumento6 pagineWpsabhishek198327Nessuna valutazione finora

- QarDocumento3 pagineQaraboo2uNessuna valutazione finora

- WPS - Smaw - 2Documento6 pagineWPS - Smaw - 2Harkesh RajputNessuna valutazione finora

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Documento2 pagineQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Nessuna valutazione finora

- 16 Electrode QualificationDocumento11 pagine16 Electrode QualificationAkhilesh Kumar67% (3)

- CBT Questions: (2) Peel TestDocumento18 pagineCBT Questions: (2) Peel TestMOHAMEDNessuna valutazione finora

- Form RT Isbl2 EditDocumento5 pagineForm RT Isbl2 EditbudhiNessuna valutazione finora

- Welder Cirt TotalDocumento78 pagineWelder Cirt TotalNguyễn ChâuNessuna valutazione finora

- DSAE0028998 f7nm80Documento17 pagineDSAE0028998 f7nm80Especialista DexterNessuna valutazione finora

- Wps 08-04-2015 - 3Documento6 pagineWps 08-04-2015 - 3Nector MoyanoNessuna valutazione finora

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Documento1 paginaQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNessuna valutazione finora

- DC - Traction Motor 752RS1A-Final Test ReportDocumento5 pagineDC - Traction Motor 752RS1A-Final Test ReportGaurav ChaudharyNessuna valutazione finora

- WpsDocumento2 pagineWpsnaseema1100% (1)

- Line List For Mud Pit Dump System (MD)Documento1 paginaLine List For Mud Pit Dump System (MD)manhngoducNessuna valutazione finora

- WPS PQR-02Documento8 pagineWPS PQR-02Ranjan Kumar100% (1)

- 6877-SM-LM-99-00-09049-U1A1 Document Number: Merlin Version 2.2 12-JAN-05 14:01:06 Detailed ReportDocumento8 pagine6877-SM-LM-99-00-09049-U1A1 Document Number: Merlin Version 2.2 12-JAN-05 14:01:06 Detailed ReportSalimNessuna valutazione finora

- PQR Al 6xxxDocumento7 paginePQR Al 6xxxAmin ThabetNessuna valutazione finora

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Documento1 paginaQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Nessuna valutazione finora

- SWCC Acceptance Notice For Rel No.29-100inchx20.62mm WTDocumento3 pagineSWCC Acceptance Notice For Rel No.29-100inchx20.62mm WTAlam MD SazidNessuna valutazione finora

- CPWI 4 of 4Documento17 pagineCPWI 4 of 4Jorge SobrevillaNessuna valutazione finora

- NDT Final 2012Documento30 pagineNDT Final 2012wilialexis771Nessuna valutazione finora

- Mce Gulf Contracting Co. Welder Performance QualificationDocumento2 pagineMce Gulf Contracting Co. Welder Performance QualificationhamidjoyiaNessuna valutazione finora

- Ea 682808 001 R05Documento7 pagineEa 682808 001 R05anbarasusivaprakasam100% (1)

- Prestige Engineering L.L.C: Welding Procedure Specification (WPS)Documento24 paginePrestige Engineering L.L.C: Welding Procedure Specification (WPS)Sarathiraja SekarNessuna valutazione finora

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Automation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingDa EverandAutomation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingP D BoydNessuna valutazione finora

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsValutazione: 4.5 su 5 stelle4.5/5 (10)

- Pressuremeter Testing: Methods and InterpretationDa EverandPressuremeter Testing: Methods and InterpretationValutazione: 5 su 5 stelle5/5 (2)

- Procast ManualDocumento471 pagineProcast Manualtudorima100% (4)

- Separation Techniques WorksheetDocumento2 pagineSeparation Techniques WorksheetyuniNessuna valutazione finora

- Bilberry PosterDocumento1 paginaBilberry PosterIrma Puspita DewiNessuna valutazione finora

- Design Optimisation of Space Frame ChassisDocumento40 pagineDesign Optimisation of Space Frame Chassisadj adj100% (1)

- Analysis of Dynamic Load Capacity of The Top Drive of Drilling Rigs.Documento8 pagineAnalysis of Dynamic Load Capacity of The Top Drive of Drilling Rigs.NestorMenesesPintoNessuna valutazione finora

- Filters FPDocumento2 pagineFilters FPMAZENNessuna valutazione finora

- Mechanical Properties of Carbon Fiber Composite MaterialsDocumento2 pagineMechanical Properties of Carbon Fiber Composite MaterialsmehtabpathanNessuna valutazione finora

- 1.8 3 PVDF Hmwpe CableDocumento1 pagina1.8 3 PVDF Hmwpe CableRobert LiraNessuna valutazione finora

- NDocumento7 pagineNIstiak Ahmed PrinceNessuna valutazione finora

- Paper BioDocumento17 paginePaper BioI-hana D'yanaNessuna valutazione finora

- Chemical Resistance Chart FRPDocumento36 pagineChemical Resistance Chart FRPHrishikesanNessuna valutazione finora

- Sol-Gel Synthesis and Structure of Cordieritetialite Glass-CeramicsDocumento6 pagineSol-Gel Synthesis and Structure of Cordieritetialite Glass-CeramicsahadsajjadiNessuna valutazione finora

- Product Information Flyer: CIMSTAR® 10-570-HFP With FACT™Documento2 pagineProduct Information Flyer: CIMSTAR® 10-570-HFP With FACT™sobheysaidNessuna valutazione finora

- Dielectric Properties of CoalDocumento11 pagineDielectric Properties of CoalEsther BarrachinaNessuna valutazione finora

- Assignment2 of HMT ME 6003-1Documento2 pagineAssignment2 of HMT ME 6003-1Faraz KhanNessuna valutazione finora

- Gilsonite - Modified Gilsonite - Fluid Loss ControlDocumento3 pagineGilsonite - Modified Gilsonite - Fluid Loss ControlManargudi mannarNessuna valutazione finora

- Ipsita RoyDocumento60 pagineIpsita RoyJohn F ServilleNessuna valutazione finora

- Climaveneta I-Accurate IaxDocumento68 pagineClimaveneta I-Accurate IaxOctavio Farid Rossi YumhaNessuna valutazione finora

- Wood Preservation SecondDocumento239 pagineWood Preservation SecondJuan Antonio Diaz LopezNessuna valutazione finora

- Norne Field Case DescDocumento13 pagineNorne Field Case DescRafin HasanNessuna valutazione finora

- Design Calculation For Oil Skimmer CapacityDocumento4 pagineDesign Calculation For Oil Skimmer CapacityAyon BoseNessuna valutazione finora

- MSDS - Coratex 030700Documento7 pagineMSDS - Coratex 030700shafaykhan78603Nessuna valutazione finora

- Removal of Methyl Orange Dye From Textile Effluent Using Adsorption On Chitosan Hydrogel BeadsDocumento8 pagineRemoval of Methyl Orange Dye From Textile Effluent Using Adsorption On Chitosan Hydrogel BeadsESSENCE - International Journal for Environmental Rehabilitation and ConservaionNessuna valutazione finora

- Production of Liquid Fuel From Plastic Waste Using Integrated Pyrolysis Method With Refinery Distillation Bubble Cap Plate Column-1Documento9 pagineProduction of Liquid Fuel From Plastic Waste Using Integrated Pyrolysis Method With Refinery Distillation Bubble Cap Plate Column-1Bambang Sardi SardiNessuna valutazione finora

- Mechanical Engineering Board Exam SubjectsDocumento4 pagineMechanical Engineering Board Exam Subjectsbenny narrido100% (1)

- Water Budget of Inter-Cropped Maize and Cassava On Bench TerracesDocumento31 pagineWater Budget of Inter-Cropped Maize and Cassava On Bench TerracesSudharsananPRSNessuna valutazione finora

- Flexi Tech 60rg DataDocumento2 pagineFlexi Tech 60rg DatadogankkuNessuna valutazione finora

- Borescope Sample Report PDFDocumento14 pagineBorescope Sample Report PDFWalter TrajadaNessuna valutazione finora

- General Final RevisionDocumento14 pagineGeneral Final RevisionbehejazyNessuna valutazione finora

- Liquid-Liquid ExtractionsDocumento11 pagineLiquid-Liquid ExtractionsSata Ajjam100% (1)