Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

3 Phase Separators ( Separators') - Ascom Separation

Caricato da

naveenbaskaran1989Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

3 Phase Separators ( Separators') - Ascom Separation

Caricato da

naveenbaskaran1989Copyright:

Formati disponibili

3 Phase Separators (Separators) | Ascom Separation http://www.ascomseparation.com/technology-and-products/classic-separa...

1 of 5 8/19/2014 11:55 AM

3 Phase Separators (Separators)

ASCOM designed separators guarantee a very high performance because of:

Application of state-of-the-art design rules based on in-house expertise using CFD and

empirically verified by testing.

1.

Use of the proprietary range of high performance ASCOM HiPer internals. 2.

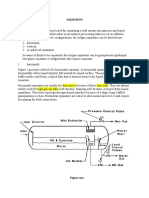

Design philosophy: 4 sections of a separator

Generally, in horizontal orientated gas/liquid separators, the incoming multiphase mixture

flows into the vessel through an inlet device.

The inlet section (1) ensures preliminary gas/liquid(s) separation and a good flow

distribution across the vessel. The design of separators generally includes a gas/liquid

gravity separation section (2), that ensures the creation and fall out of large liquid

droplets. The gravity separation section can include a coalescer stage (either a mesh type

or vane type coalescer). After the fall out of the bulk liquids, the demisting section (3)

ensures the removal of finer mist particles. In the liquid separation section (4) liquids are

degassed and the light and heavy liquid phases are separated. Designed based on the

fluid properties and liquid-liquid separation requirements, this section is large enough to

provide sufficient residence time for gas bubbles to escape from the liquids and oil and

water droplets to reach the oil-water interface.

For separators located on FPSOs or moving facilities it is essential to be thoroughly

evaluated by Computational Fluid Dynamics and where necessary by finite element analysis

strength calculations. ASCOM has these capabilities and this will ensure the end user of a

robust design under a wide range of operating conditions.

Inlet section

In horizontal three phase gas/liquid separators (separators), the incoming multiphase

mixture flows into the vessel through an inlet device. In the processing industry many

types of inlet devices are used ranging from inlet baffles, half open pipes to more

elaborate vane type and cyclonic inlet devices. Irrespective of the service, only vane type

inlet devices and properly designed cyclonic inlet devices will handle the fluids at the inlet

nozzle adequately and will maximise the separation performance. All other inlet devices will

result in a very poor gas distribution AND in an increase of the liquid content entrained in

the gas due to the high shear forces exerted by these devices.

A poorly designed or wrongly chosen inlet device can result in a poor gas and liquid

distribution, increase the liquid content entrained in the gas and create smaller water in oil

and oil in water droplets due to the high shear forces exerted by these devices. This will

result in a poor liquid-liquid separation performance and potentially to liquid control issues.

With ASCOM HiPer internals these problems will be avoided!

Gravity separation of liquids entrained in the gas phase

Downstream of the inlet device the gas section of the separator ensures the pre-separation

3 Phase Separators (Separators) | Ascom Separation http://www.ascomseparation.com/technology-and-products/classic-separa...

2 of 5 8/19/2014 11:55 AM

of entrained liquids. The gravity separation section of the separator is basically an open

volume in which larger liquid droplets will fall out by gravity. This effect will be stronger

when the gas is well distributed over de cross section of the vessel. The gas distribution

can be improved by the application of well-designed distribution baffles.

In this case the fluids are introduced into the vessel by means of a battery of HiPer Inlet

Cyclones whereby the bulk of the liquid is introduced through the bottom of the cyclone

tubes and the gas will enter the vessel through the top. As the gas jets from the cyclones

it will need to be evenly distributed as to maximise the liquid drop out in the gravity

separation section (2) from the perforated distributor plates to the mist eliminating

equipment (3).

Coalescence aids in the gravity separation section

In clean services, i.e. no presence of wax or fouling tendencies, a HiPer Mesh Coalescer

can be used to increase the liquid handling capacity of the gravity separation section. The

wire mesh structure is designed to coalesce small liquid droplets into larger ones. The

specific arrangement of the HiPer Mesh Coalescer ensures very good drainage of the liquid

accumulated within the mesh. This device will increase the turndown properties of the

scrubber as the mode of operation changes from a flooded mode to a demisting mode once

the gas velocity is reduced to below the transition point. In situations where the fluids do

have a fouling tendency, alternatively a HiPer Vane Coalescer can be considered.

Mist elimination

After the gas has travelled through the gravity separation section, it will only contain fine

mist droplets. The third section is the mist eliminating section (3) which ensures the

separation of these fine mist particles. Essentially, the overall gas-liquid separation

efficiency of a separator depends on the fraction of liquid entrained as mist in the gas, the

droplet size distribution, the volumetric amount of the liquid in mist form and the

efficiency of the mist eliminating equipment under those conditions.

Again the gas distribution is of significant importance to maximise the gas-liquid separation

efficiency. In particular mist eliminating equipment with a low pressure drop (e.g. mesh or

vane mist eliminator) is prone to mal-performance as the result of gas mal-distribution on

the face of the equipment. Therefore the orientation in the gas flow is a critical design

parameter. Mist eliminating cyclones typically having a slightly higher pressure drop

positively contribute to an overall improved gas distribution in the entire vessel.

Oil / water separation

The liquid introduced into the vessel by either a HiPer Vane Diffuser or HiPer Inlet

Cyclones is very turbulent in the inlet section. Maximising the liquid/liquid separation

efficiency, the flow of liquids needs to be evenly distributed over the entire cross-sectional

area of the vessels liquid section. For this reason, perforated baffles need to be installed

in three-phase separators.

In order to further enhance the liquid/liquid separation, a HiPer Plate Coalescer can be

considered. This can either reduce the vessel size required in a new built situation, or

3 Phase Separators (Separators) | Ascom Separation http://www.ascomseparation.com/technology-and-products/classic-separa...

3 of 5 8/19/2014 11:55 AM

increase the throughput or improve the oil in water or water in oil outlet performance in

retrofit situations. Between each of the flat parallel plates oil-water interfaces are being

established which significantly reduce the distance oil or water droplets need to travel to

their respective continuous phase. This directly impacts the time and distance required for

liquid/liquid separation to occur, which therewith improves the minimum Tan/Tan length

requirement of the separator.

When applied during the initial design stages of a new built facility, the space, weight and

overall cost savings can be quite substantial due to the knock-on effects on the overall

facility.

Sand removal

Fields where a large amount of sand is produced, sand will accumulate in process

equipment. Horizontal and vertical separators can be equipped with a HiPer Sand Fluidising

System. This will allow solid particles that have settled in the separator to temporarily

being fluidised by the injection water and the slurry simultaneously being drained off to

the sand handling / produced water system for physical removal from the process. This can

be done both whilst the separator is offline as well as online.

Separators on floating installations

Separators that are installed on moving facilities such as FPSOs deserve special attention

for separation as well as mechanical reasons. The movement of the facility as a result of

the local weather conditions / waves induces the liquid in the separator to move backward

and forward, eventually leading to sloshing under the more severe weather/motion

conditions. In case liquid sloshing is not adequately suppressed by wave suppression

baffles, the separation process in the separator will be affected.

Effect as result of motion vs Operational consequence(s)

Inlet device to become submerged Obliteration of liquid, overloading of mist

elimination equipment

1.

Bottom of inlet cyclones to become exposed , Obliteration of liquid, overloading of

mist elimination equipment, liquid level control difficulties, oil water interface

disruption

2.

Mist elimination overloaded with liquid Leading to excessive liquid carryover 3.

Mist elimination equipment to become submerged Leading to excessive liquid

carryover

4.

Oil exiting water outlet nozzle Leading to excessive OIW carryover 5.

Water sloshing over weir Leading to excessive WIO carryover 6.

Liquid level & interface control difficulties Leading to level trips and consequential

shut-down

7.

Reducing mechanical loads on distribution baffles Leading to excessive forces and

potential mechanical failure

8.

During the entire design process, ASCOM takes effects and their operational consequences

into consideration. This applies to both the process and the mechanical aspects. To verify

the robustness of the design, the separator is subjected to a Computational Fluid Dynamics

3 Phase Separators (Separators) | Ascom Separation http://www.ascomseparation.com/technology-and-products/classic-separa...

4 of 5 8/19/2014 11:55 AM

(CFD) study. The movement of the liquid will be visualised and the mechanical forces on

the wave mitigation baffles will be calculated. This information is used to properly design

baffles and their welded supports in the vessel and to ensure that the design and material

thicknesses are adequate to handle the loads. Finite element analysis will be performed if

necessary.

Summary

ASCOM posseses expertise and CFD capabilities as well as the possibilitiy to test equipment

under model and real life conditions which results in ASCOM having a very powerful design

expertise. In combination with the range of proprietary HiPer separator internals, this

guarantees that ASCOM separators and scrubbers will provide:

Maximum liquid droplet coalescence and separation from gas

Maximum oil from water and water from oil separation efficiency

Excellent turndown characteristics

Insensitivity to sand presence

Insensitivity to wave induced motion

Low pressure drop

Insensitivity to fouling service

No maintenance requirements due to robust design

Removable through Man Way

No welding requirements for installation

Easily replaces existing older internals

3 Phase Separators (Separators) | Ascom Separation http://www.ascomseparation.com/technology-and-products/classic-separa...

5 of 5 8/19/2014 11:55 AM

Potrebbero piacerti anche

- Separator & Production FacilitiesDocumento11 pagineSeparator & Production FacilitiestumiNessuna valutazione finora

- Natural Gas Quality Enhancement: Training Report ONDocumento20 pagineNatural Gas Quality Enhancement: Training Report ONRajkishan GuptaNessuna valutazione finora

- Oil and Gas SeparatorsDocumento23 pagineOil and Gas SeparatorsSofea Hanom NordinNessuna valutazione finora

- Separator Vessel: Ms. Shreya SahajpalDocumento6 pagineSeparator Vessel: Ms. Shreya SahajpalShreya Sahajpal KaushalNessuna valutazione finora

- Chap3 - Seperators and Seperation TechniquesDocumento37 pagineChap3 - Seperators and Seperation Techniquesghgh140Nessuna valutazione finora

- Separators: Figure OneDocumento8 pagineSeparators: Figure OneMohamed Moder100% (1)

- There Phase Oil Water Gas SeparatorsDocumento6 pagineThere Phase Oil Water Gas SeparatorsHAMZA GUERFI100% (1)

- Three Phase Separator DesignDocumento5 pagineThree Phase Separator DesignAymen KhlifiNessuna valutazione finora

- Introduction For Test Separator: CNPCIC Field ProductionDocumento18 pagineIntroduction For Test Separator: CNPCIC Field Productionsalahadine maideNessuna valutazione finora

- 3-Phase Test Separators VVFDocumento2 pagine3-Phase Test Separators VVFPetroFisicNessuna valutazione finora

- Upstream Oil ProcessingDocumento6 pagineUpstream Oil Processinge_buljubasicNessuna valutazione finora

- VGS Vane Separators Are Recommended ForDocumento1 paginaVGS Vane Separators Are Recommended ForSanthu PeelaNessuna valutazione finora

- Design of 3 Phase Production SeparatorDocumento8 pagineDesign of 3 Phase Production Separatormyself_riteshNessuna valutazione finora

- What Are Oil and Gas SeparatorsDocumento15 pagineWhat Are Oil and Gas SeparatorsFriday IjokgwungNessuna valutazione finora

- Finger Type Slug CatcherDocumento41 pagineFinger Type Slug CatcherIrfaan Taufiiqul Rayadi100% (1)

- 2nd Stage Separator: For Production Conditions / The Process Can Be AchievedDocumento5 pagine2nd Stage Separator: For Production Conditions / The Process Can Be AchievedihsansepalmaNessuna valutazione finora

- Conventional SeparatorsDocumento27 pagineConventional SeparatorsMax Singh100% (1)

- of 3-Phase-Separator PDFDocumento25 pagineof 3-Phase-Separator PDFD K SNessuna valutazione finora

- Separator SizingDocumento3 pagineSeparator SizingMaryJane Ayisha Sado-ObahNessuna valutazione finora

- Cpi O&m ManualDocumento36 pagineCpi O&m Manualprasad336Nessuna valutazione finora

- H07127 ThreePhaseHorzSepDocumento2 pagineH07127 ThreePhaseHorzSepGuillermo Manuel SchödlNessuna valutazione finora

- Surface Facilities 2 STDocumento155 pagineSurface Facilities 2 STI Made Wahyu WiratmajaNessuna valutazione finora

- Knockout DrumDocumento9 pagineKnockout Drumgautam_96948069Nessuna valutazione finora

- Api Oil Water Separator Discussion PDFDocumento4 pagineApi Oil Water Separator Discussion PDFAhmed Moustafa100% (1)

- Three Phase SeparatorDocumento433 pagineThree Phase SeparatorAbdur Rehman100% (1)

- Three Phase SeparatorsDocumento6 pagineThree Phase SeparatorsJatin RamboNessuna valutazione finora

- Horizontal Three Phase SeparatorDocumento1 paginaHorizontal Three Phase SeparatorsandeepNessuna valutazione finora

- Water Handling and TreatmentDocumento18 pagineWater Handling and Treatmentxion_mew2Nessuna valutazione finora

- Scrubber NATCODocumento22 pagineScrubber NATCOkalikamalaNessuna valutazione finora

- Hydrocyclone SeparatorDocumento2 pagineHydrocyclone Separatorgautam_96948069100% (1)

- Desalter EfficiencyDocumento3 pagineDesalter Efficiencykronos39zeusNessuna valutazione finora

- General Separator 1636422026Documento55 pagineGeneral Separator 1636422026mohamed abdelazizNessuna valutazione finora

- Features/Benefits: Production Testing Solutions Three-Phase Test SeparatorDocumento1 paginaFeatures/Benefits: Production Testing Solutions Three-Phase Test SeparatorJayesh SanganiNessuna valutazione finora

- Flare SystemDocumento60 pagineFlare Systemmmairaja100% (1)

- PWS2014 Rawlins DesanderStudyRDocumento10 paginePWS2014 Rawlins DesanderStudyRJhon Henry Segundo LlaguentoNessuna valutazione finora

- New Method To Estimate Surface-Separator Optimum Operating PressuresDocumento12 pagineNew Method To Estimate Surface-Separator Optimum Operating PressuresIkramullohNessuna valutazione finora

- Equipment Catalogue API Oil SeparatorDocumento2 pagineEquipment Catalogue API Oil Separatorbesant vargheesNessuna valutazione finora

- Separators 2Documento55 pagineSeparators 2Wael BadriNessuna valutazione finora

- Application of Multiphase Desander Technology To Oil and Gas ProductionDocumento19 pagineApplication of Multiphase Desander Technology To Oil and Gas ProductionJose Rodrigo Salguero DuranNessuna valutazione finora

- APEX Deoiler HydrocycloneDocumento9 pagineAPEX Deoiler HydrocycloneChem.EnggNessuna valutazione finora

- Principles of Separation: Production and Test SeparatorsDocumento28 paginePrinciples of Separation: Production and Test SeparatorsهانيزايدNessuna valutazione finora

- Bucket and Weir Type SeparatorDocumento3 pagineBucket and Weir Type SeparatorAdewunmi OlufemiNessuna valutazione finora

- Chapter 3-Two-Phase Oil and Gas SeparationDocumento56 pagineChapter 3-Two-Phase Oil and Gas SeparationIvan Zvonar75% (4)

- Vane Separator (Brochure PEERLESSMFG)Documento6 pagineVane Separator (Brochure PEERLESSMFG)Julio OrtegaNessuna valutazione finora

- Presentationlu 180126221936 PDFDocumento20 paginePresentationlu 180126221936 PDFhaptoorNessuna valutazione finora

- FlareDocumento39 pagineFlareMuhammad Tahir RazaNessuna valutazione finora

- Design Procedure For Two Phase SeparatorsDocumento6 pagineDesign Procedure For Two Phase Separatorsmadx222222Nessuna valutazione finora

- Case 1. Gas Lift System DesignDocumento10 pagineCase 1. Gas Lift System DesignDaniel ChiriacNessuna valutazione finora

- Design 2P Separators in Rigth LimitsDocumento8 pagineDesign 2P Separators in Rigth Limitsedgardiaz5519Nessuna valutazione finora

- 2 Phase Seperator PDFDocumento66 pagine2 Phase Seperator PDFKanthan DevanNessuna valutazione finora

- VEL2162 0814 MANUAL Filter Separator Vessel WebDocumento40 pagineVEL2162 0814 MANUAL Filter Separator Vessel WebfajaraminwahyullahNessuna valutazione finora

- Module 2 - Oil and Gas Separation - LectDocumento62 pagineModule 2 - Oil and Gas Separation - LectmahmoudNessuna valutazione finora

- How Is Nitrogen Used in Oil and Gas FieldsDocumento4 pagineHow Is Nitrogen Used in Oil and Gas FieldsrajasekharboNessuna valutazione finora

- Savvy Separator: The Ghosts of Separators Past, Present, and FutureDocumento7 pagineSavvy Separator: The Ghosts of Separators Past, Present, and FutureDeepblue09100% (1)

- Open Drain Separator SizingDocumento23 pagineOpen Drain Separator SizingSuchart TarasapNessuna valutazione finora

- 3 Phase Separators ( Separators') : Design Philosophy: 4 Sections of A SeparatorDocumento2 pagine3 Phase Separators ( Separators') : Design Philosophy: 4 Sections of A SeparatorPrie TeaNessuna valutazione finora

- Two-Phase and Three-Phase SeparatorDocumento40 pagineTwo-Phase and Three-Phase Separatormargaretramos100% (1)

- 5.5 Twister Supersonic Separator: Brouwer Et Al., 2004 Okimoto and Brouwer (2002) Brouwer and Epsom (2003)Documento3 pagine5.5 Twister Supersonic Separator: Brouwer Et Al., 2004 Okimoto and Brouwer (2002) Brouwer and Epsom (2003)himanth suggulaNessuna valutazione finora

- Principles of Separation: Incoming Stream Spin Around Reaction Force From The Separator WallDocumento10 paginePrinciples of Separation: Incoming Stream Spin Around Reaction Force From The Separator Wallmohamad alamehNessuna valutazione finora

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingDa EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingValutazione: 5 su 5 stelle5/5 (3)

- Penflex Expansion Joint CatalogDocumento20 paginePenflex Expansion Joint Catalognaveenbaskaran1989Nessuna valutazione finora

- F13 - Carboguard 893-Zn PDS 10-09Documento2 pagineF13 - Carboguard 893-Zn PDS 10-09naveenbaskaran1989Nessuna valutazione finora

- Co2 CorrosionDocumento11 pagineCo2 Corrosionnaveenbaskaran1989Nessuna valutazione finora

- Control Panel Spec.Documento12 pagineControl Panel Spec.naveenbaskaran1989Nessuna valutazione finora

- Swelore Catalogue PDFDocumento6 pagineSwelore Catalogue PDFnaveenbaskaran1989100% (2)

- API-650 Design Procedure ExampleDocumento21 pagineAPI-650 Design Procedure Examplegdwvcd92% (13)

- Structural Steel - S235, S275, S355 Chemical Composition, Mechanical Properties and Common ApplicationsDocumento14 pagineStructural Steel - S235, S275, S355 Chemical Composition, Mechanical Properties and Common Applicationsnaveenbaskaran1989Nessuna valutazione finora

- Use of Type (3) Welds in ASME Pressure Vessel Design - PVEngDocumento4 pagineUse of Type (3) Welds in ASME Pressure Vessel Design - PVEngnaveenbaskaran1989Nessuna valutazione finora

- 3005 (AlMn1Mg0.5, 3.0525, A93005) Aluminum - MakeItFromDocumento5 pagine3005 (AlMn1Mg0.5, 3.0525, A93005) Aluminum - MakeItFromnaveenbaskaran1989Nessuna valutazione finora

- Floating RoofDocumento12 pagineFloating Roofnaveenbaskaran1989Nessuna valutazione finora

- Poncelet MicroencapsulationDocumento30 paginePoncelet MicroencapsulationSduryaNessuna valutazione finora

- Accepted ManuscriptDocumento33 pagineAccepted ManuscriptAbhishek Kumar SinhaNessuna valutazione finora

- Fluvial Hydraulics and River EngineeringDocumento11 pagineFluvial Hydraulics and River EngineeringRenzo E. MedinaNessuna valutazione finora

- CVE 112 (Hydraulics 2) : Lecture 1: Principles of HydrokineticsDocumento13 pagineCVE 112 (Hydraulics 2) : Lecture 1: Principles of HydrokineticsAriel B. LumacadNessuna valutazione finora

- Topic 1 Numerical Simulation of Cavitating Flows Using OpenfoamDocumento7 pagineTopic 1 Numerical Simulation of Cavitating Flows Using OpenfoamKumar ByesNessuna valutazione finora

- Lesson 7. Pressure Forces On Plane Surfaces Hydrostatic Forces On Plane SurfacesDocumento6 pagineLesson 7. Pressure Forces On Plane Surfaces Hydrostatic Forces On Plane SurfacesDaniella Pasilbas SabacNessuna valutazione finora

- Flow in Pipe ManifoldsDocumento4 pagineFlow in Pipe Manifoldskasandra01100% (1)

- Hydrocarbon Reservoir and Well PerformanceDocumento3 pagineHydrocarbon Reservoir and Well PerformanceSHUBHAM SINGH0% (1)

- Chap 10P Mechanical Properties of Fluid ArvindDocumento91 pagineChap 10P Mechanical Properties of Fluid ArvindArjun MishraNessuna valutazione finora

- GDJP Unit-IiDocumento2 pagineGDJP Unit-IiPazhani VelNessuna valutazione finora

- Droplet Breakup Quantification and Processes in Constant and PDFDocumento6 pagineDroplet Breakup Quantification and Processes in Constant and PDFSanthanakrishnan RangasamyNessuna valutazione finora

- Air Problems in Pipelines PDFDocumento90 pagineAir Problems in Pipelines PDFjohndagheNessuna valutazione finora

- How Squat, Bank and Bank Cushion Effects Influence Ships in Restricted Waters?Documento7 pagineHow Squat, Bank and Bank Cushion Effects Influence Ships in Restricted Waters?shubham100% (1)

- Skid Calculation GasDocumento5 pagineSkid Calculation GasBaskar KannaiahNessuna valutazione finora

- Mekflu Lect4A Basic Pump and PumpingDocumento42 pagineMekflu Lect4A Basic Pump and Pumpingbima0407Nessuna valutazione finora

- WHITE - Buku TextDocumento11 pagineWHITE - Buku TextNameis GhoffarNessuna valutazione finora

- 2023 05 Wax Additives ASIA EN Ccab91fb0aDocumento24 pagine2023 05 Wax Additives ASIA EN Ccab91fb0alongNessuna valutazione finora

- CBSE Class 11 Physics Chapter 10 - Mechanical Properties of Fluids Important Questions 2022-23Documento91 pagineCBSE Class 11 Physics Chapter 10 - Mechanical Properties of Fluids Important Questions 2022-23Iron ManNessuna valutazione finora

- Chapter 6Documento37 pagineChapter 6Eyasu demsewNessuna valutazione finora

- Cooling TowerDocumento27 pagineCooling Towerjogedhayal100% (1)

- Phar Analysis 2 - Mod 4-7 - Lecture NotesDocumento3 paginePhar Analysis 2 - Mod 4-7 - Lecture NotesLeen JordanNessuna valutazione finora

- Fundamentals of Fluid Mechanics: Chapter 2 Fluids at Rest - Pressure and Its EffectDocumento49 pagineFundamentals of Fluid Mechanics: Chapter 2 Fluids at Rest - Pressure and Its EffectangeljosNessuna valutazione finora

- HSA (10) HSpeed NotesDocumento5 pagineHSA (10) HSpeed NotesmohdrashdansaadNessuna valutazione finora

- Advanced Transport Phenomena Module 2 Lecture 8Documento47 pagineAdvanced Transport Phenomena Module 2 Lecture 8Shiva KumarNessuna valutazione finora

- Chapter 9 Pump SelectionDocumento40 pagineChapter 9 Pump SelectionDuke ThibbotuwawaNessuna valutazione finora

- Ping Pong Ball Drop - Published ArticleDocumento2 paginePing Pong Ball Drop - Published ArticleSosocorimAreyanoNessuna valutazione finora

- Model Questions and Answers On Marine Hydrodynamics by T. Sahoo Dept. of Ocean Engineering and Naval Architecture, IIT, Kharagpur, INDIADocumento60 pagineModel Questions and Answers On Marine Hydrodynamics by T. Sahoo Dept. of Ocean Engineering and Naval Architecture, IIT, Kharagpur, INDIAbrian5412Nessuna valutazione finora

- WelChem FloatValveTray 2020-3Documento8 pagineWelChem FloatValveTray 2020-3JNessuna valutazione finora

- Unit Iv Boundary Layer: Sri Vidya College of Engineering & Tech Question Bank-Unit - IvDocumento7 pagineUnit Iv Boundary Layer: Sri Vidya College of Engineering & Tech Question Bank-Unit - IvBahman JadidiNessuna valutazione finora

- Ecw437/Ecw421 Laboratory Manual 2016Documento3 pagineEcw437/Ecw421 Laboratory Manual 2016Syahir HamidonNessuna valutazione finora