Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Inert Gas System

Caricato da

piliyandalaleos100%(5)Il 100% ha trovato utile questo documento (5 voti)

841 visualizzazioni45 pagineInert Gas System is to reduce the oxygen content in the cargo tanks to below 8%. This will prevent cargo tank explosion, reduces corrosion and increases Pumping capacity. The hot, dirty gas is then passed through a scrubbing tower which cleans and cools it using seawater. This gas is then delivered to cargo tanks to prevent explosion of flammable cargo.

Descrizione originale:

Copyright

© © All Rights Reserved

Formati disponibili

PPSX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoInert Gas System is to reduce the oxygen content in the cargo tanks to below 8%. This will prevent cargo tank explosion, reduces corrosion and increases Pumping capacity. The hot, dirty gas is then passed through a scrubbing tower which cleans and cools it using seawater. This gas is then delivered to cargo tanks to prevent explosion of flammable cargo.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPSX, PDF, TXT o leggi online su Scribd

100%(5)Il 100% ha trovato utile questo documento (5 voti)

841 visualizzazioni45 pagineInert Gas System

Caricato da

piliyandalaleosInert Gas System is to reduce the oxygen content in the cargo tanks to below 8%. This will prevent cargo tank explosion, reduces corrosion and increases Pumping capacity. The hot, dirty gas is then passed through a scrubbing tower which cleans and cools it using seawater. This gas is then delivered to cargo tanks to prevent explosion of flammable cargo.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPSX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 45

1

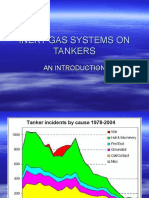

INERT GAS SYSTEM

&

FLUE GAS

SYSTEM

Presented by H.V Sithuruwan fernando

(Engineering Cadet/TPTM)

Introduction

The combustion & explosion of petroleum gasses, the corrosion of steel occur

only when oxygen is present

The object of the Inert Gas System is to reduce the oxygen content in the cargo

tanks to below 8%, well below the Explosion Limit of 11.5%

This will prevent cargo tank explosion, reduces corrosion and increases

Pumping capacity

Atmospheric air is burned using diesel in a combustion

chamber and the exhaust collected, the resulting exhaust

contains less than 5% oxygen, thereby creating

"inert gas".

with a typical make-up of:

Flammable Envelope

What is inert gas Generator ??

A visual demonstration

Inert gas generator (IGG) refers to machinery on board marine product tankers

Inert gas generators consist distinctively of a gas producer and a scrubbing system

Atmospheric air is burned using diesel in a combustion chamber and the exhaust

collected, the resulting exhaust contains less than 5% oxygen, thereby creating

"inert gas".

The hot, dirty gas is then passed through a scrubbing tower which cleans and cools it

using seawater.

This gas is then delivered to cargo tanks

to prevent explosion of flammable cargo.

This generator is sometimes confused

with flue gas systems, which draw inert

gas from the boiler systems of the ship.

Flue gas systems do not have a burner

but only "clean" and measure the air before delivering it to the cargo hold.

The Inert Gas generator System

Alternatively an inert gas generator may be used

when:

Typically a range between 0.2% to 2.0% oxygen content with

No soot is available to suit client requirements.

Inert Gas Generator

A typical Inert Gas Generator system as shown here includes

six major component parts, each having special features.

Inert Gas Generator

Combustion Air Blower

Deck Water Seal

Pressure/ Vacuum Breaker

Valves

Control System

Inert Gas Generator

Unique 'Sea Guardian' third generation design, incorporating

innovative integrated burner, swirl vane separator and patented

quench scrubber elements, eliminating the need for demister pads

and spray nozzles.

Combustion Air Blower

A Roots type blower of compact design. Selected for low noise and

low maintenance characteristics.

In-built safety relief valve.

The picture represents a standard Inert Gas Generator (FU Type)

complete with air fans, fuel pumps, deck water seal and P/V breaker

The Inert Gas System

Regulations require the

oxygen content in cargo

tanks to be maintained at

not more than 8% by

volume

14

Gas Pressure Regulation Valves

Deck Water Seal

This is the principle

barrier in the system

A water trap is fitted

which permits inert gas

to be delivered to the

deck main but prevents

any back flow of cargo

gas

Even when the IG plan is

shut down

Deck Water Seal

Gas flow towards cargo tanks

Back pressure in cargo tanks

Liquid Filled Pressure Vacuum Breakers

Inert Gas Procedures

General Policy of Tank Atmosphere Control

Tanks should be inerted prior to loading

and maintained inert during loading, on

the loaded passage, during discharge and

during tank washing

Tanks should be kept in an inert condition

whenever they contain cargo residues or

ballast

Inert Gas Procedures

General Policy of Tank Atmosphere Control

After cleaning and gas freeing it is not

necessary to inert the tank

The transition from an inert condition to a

gas free condition MUST be made without

the tank atmosphere passing through the

flammable range/envelope.

This means purging the tank with inert gas

until it is below the Critical Dilution Line

Inert Gas Procedures

Primary Inerting

From a gas free condition the tanks should be inerted

prior to the loading of cargo until the tanks have an

oxygen content of less than 8% by volume

On completion of inerting all the tanks are to be

pressurised to a minimum of 100mm water gauge and

also kept common with the gas main

A positive pressure being maintained on all tanks by

topping up with IG as necessary

Pressure

Vacuum Valve

Pressure Vacuum

Breaker

Riser Main

Deck Master

Valve

Vent Pipe

Inert Gas Procedures

Loading or Ballasting

The IG plant is shut down and the deck isolating v/v closed,

unless loading is taking place at the same time as

deballasting (unusual???)

Tank vents are opened and IG is thus vented from the tank

as cargo or ballast is loaded into the tank

During loading closed ullaging is used

Pressure

Vacuum Valve

Pressure Vacuum

Breaker

Riser Main

Deck Master

Valve

Vent Pipe

Vapour

Line

Pressure

Vacuum Valve

Pressure Vacuum

Breaker

Riser Main

Deck Master

Valve

Vent Pipe

Inert Gas Procedures

Loaded / Ballast Passage

Tanks are re-pressurised for the loaded or ballast passage

A positive IG pressure should be maintained to prevent

possible ingress of air

Loss of pressure can normally be associated with leakage &

falling air and/or sea temperatures

If tank pressure falls below the low level it will necessitate

starting the IG plant to restore the correct operating

pressure

Inert Gas Procedures

Cargo or Ballast Discharge

Owners of the cargo, receivers and/or customs

authorities may require manual ullaging, water

dips and samples prior to discharge

(regulations permitting)

Pressure

Vacuum Valve

Pressure Vacuum

Breaker

Riser Main

Deck Master

Valve

Vent Pipe

This is acceptable provided a minimum number of

tank openings are open at any one time

On completion of ullaging, and before

commencing discharge the tanks are to be re-

pressurised

All tanks are made common with the gas main

Tank openings including vents are closed

The IG plant is operated and the deck isolating v/v is

opened to allow inert gas to replace the liquid being

discharged

After discharge a hydrocarbon content of up to 4% may

exist in an inerted tank however, it is preferable to

maintain the content at 2% which is below the CDL

This condition should be monitored & maintained during

the ballast passage

Inert Gas Procedures

Tank Washing including

COW

Tanks should be in the inert condition during tank

washing

Pressure

Vacuum Valve

Pressure Vacuum

Breaker

Riser Main

Deck Master

Valve

Vent Pipe

Inert Gas Procedures

Gas Freeing

To gas free a tank it should first be purged with IG to

reduce the Hydrocarbon content to 2% or less, below the

CDL

Pressure

Vacuum Valve

Pressure Vacuum

Breaker

Riser Main

Deck Master

Valve

Vent Pipe

The intended tank should always be isolated from

other tanks prior to starting gas freeing

If gas freeing is to be carried out by means of

portable/fixed fans connected to the cargo pipeline

system then the IG inlet should be isolated

If the method of using the IG fan to draw fresh air is

used then both the line back to the IG source and the

IG inlet to other tanks being kept inert should also be

isolated

A tank is said to be gas free when the entire tank is

found to have an oxygen content of 21% by volume

when tested with an oxygen analyser

Also a reading o less than 1% on a flammable gas

indicator

If toxic gasses such as benzene or hydrogen sulphide

are suspected to be present then gas freeing should

continue until such time as tests with an appropriate

device indicates that the content is below the

Threshold Limit Value (TLV)

Venting Inert Gas into the

Atmosphere

In some regions of the world this is not

allowed

To overcome this the piping system can be

so arranged such that as cargo tanks are

being loaded/gas freed the displaced IG can

be transferred ashore

Unfortunately this may limit the speed of

loading to within the speed at which the IG

can be transferred ashore

Inert Gas Failure

Crude Tankers:-

Because of the dangers of ignition from

pyrophoric deposits, inerted tanks should

not be allowed to reach a flammable

state

In the event of failure of the IG plant

before or during discharge of cargo or

ballast then operations should cease and

close the deck isolating valve until the IG

plant is restored to full operation

Inert Gas Failure

Product Tankers:-

Discharge should not begin/resume

without the permission of all interested

parties

FLUE GAS SYSTEMS (FGS)

Generally used on crude oil tank ships where a higher quality inert

gas is not required for the unrefined cargo product.

The gas in this case is available as a by-product of boiler

combustion and is taken from the ships boiler uptake.

Typically a range between 3% to 5% O

2

content with some soot

content dependent upon flue gas quality.

A typical Flue Gas System as shown here includes six

major component parts, each having special features.

Scrubber Tower

Gas Fans

Deck Water Seal

Pressure/Vacuum Breaker

Valves

Control System

Scrubber Tower

Combining a high energy venture scrubber with a packed tower

scrubber enables high efficiency particulate removal, cool

quenching, cleaning and final demisting of boiler flue gases.

Scrubber Tower

36

Inert Gas Scrubber System

Inert Gas System Schematic

Inert Gas System Schematic

39

Re-circulating Arrangement

to regulate the flow of inert gas to the IG deck main

Gas Fans

Single stage centrifugal inert gas fans are used.

The fan impellers are dynamically balanced and manufactured in

corrosion resistant material.

The casings are internally glass flake coated to reduce

maintenance.

Gas Fans

Deck Water Seal

'Wet Type' design with an external seal pipe ensuring added safety

Water is displaced during normal gas flow forming a semi wet seal

Entrained water is expelled by swirling the gas in the vessel and

passing it through an integral demister.

Deck Water Seal

Pressure/Vacuum Breaker

Providing final protection by releasing excessive pressure or

vacuum from the cargo tanks ensures that the tank design

conditions cannot be exceeded.

The design is totally fail-safe.

Pressure/Vacuum Breaker

Valves

Gas delivery and control valves are normally of the butterfly type

with bonded rubber linings and corrosion resistant discs and shafts

Where remotely controlled, these valves use double acting

actuators.

The boiler uptake valves are of the butterfly wafer pattern type

suitable for high temperature with metal seating. These are

normally pneumatically operated and fitted with limit switches for

remote control and indications.

Valves

Control System

Utilizes a programmable logic controller to give the required

functions of control along with designated selective acceptance

of alarms.

The instrumentation and control panels are generally located in

the engine room, cargo room and bridge.

Control Panel

Potrebbero piacerti anche

- Inert Gas On Board Tankers - All You Need To Know!Documento11 pagineInert Gas On Board Tankers - All You Need To Know!Giorgi KandelakiNessuna valutazione finora

- Inert Gas SysDocumento21 pagineInert Gas SysPovenesan Krishnan100% (1)

- Inert Gas On Board Tankers - All You Need To KnowDocumento9 pagineInert Gas On Board Tankers - All You Need To KnowShoaib100% (1)

- IG SysDocumento59 pagineIG SysSergioi Indurain100% (1)

- IG SystemDocumento23 pagineIG SystemMr. Nehal Solanki100% (2)

- Inert Gas SystemDocumento69 pagineInert Gas SystemKishore Gopal89% (9)

- Framo Presentation With AnimationDocumento26 pagineFramo Presentation With AnimationManmadhaNessuna valutazione finora

- Group 1 Tanker Loading and UnloadingDocumento37 pagineGroup 1 Tanker Loading and UnloadingRupesh Kumar100% (5)

- Maintenance of Inert GasDocumento1 paginaMaintenance of Inert GasFarihna JoseNessuna valutazione finora

- 09 - Cargo Heating - Operational Advice PDFDocumento4 pagine09 - Cargo Heating - Operational Advice PDFrpichoNessuna valutazione finora

- Inerting Oil TankersDocumento22 pagineInerting Oil TankersDebashish Priyanka Sinha100% (1)

- Discharging Operation in Oil TankersDocumento6 pagineDischarging Operation in Oil TankersSatyabrat Gaan100% (1)

- Tanker Questions With Answers (Phase-1) IndiaDocumento28 pagineTanker Questions With Answers (Phase-1) IndiaRohit KarwasraNessuna valutazione finora

- Capt. Vadakyil Wall Wash MethodDocumento3 pagineCapt. Vadakyil Wall Wash Methodpushkarsidhaye100% (2)

- Crude Oil WashingDocumento60 pagineCrude Oil Washingmadhav sai100% (10)

- Chemical Tankers 2Documento59 pagineChemical Tankers 2Paolo Ferjančić100% (10)

- Cargo Line Clearance Safe Procedure For Chemical TankersDocumento8 pagineCargo Line Clearance Safe Procedure For Chemical TankersJeet SinghNessuna valutazione finora

- Cargo Pumping SystemDocumento24 pagineCargo Pumping SystemMedha Jog Katdare100% (1)

- 3.oil and Chemical Cargo Operation Handout WORD PDFDocumento163 pagine3.oil and Chemical Cargo Operation Handout WORD PDFSatyabrat Gaan100% (1)

- Basic Training For Oil and Chemical Tankers CargoDocumento140 pagineBasic Training For Oil and Chemical Tankers CargoCamilla Alba100% (8)

- Inert Gas SystemsDocumento69 pagineInert Gas Systemspilotboygps100% (1)

- Inert Gas SystemDocumento13 pagineInert Gas SystemBisrat100% (1)

- Tanker Technology Cargo Oil SystemDocumento98 pagineTanker Technology Cargo Oil SystemHerlambang s100% (3)

- Inert Gas SystemDocumento274 pagineInert Gas SystemReynante P. Consul100% (3)

- Oil Tanker Cargo Loading Procedure at SBMDocumento10 pagineOil Tanker Cargo Loading Procedure at SBMdinar rosandy100% (1)

- HermatixDocumento24 pagineHermatixmbloexNessuna valutazione finora

- Tanker Operation ProcedureDocumento2 pagineTanker Operation ProcedureAnand KhotNessuna valutazione finora

- Imo Inert Gas SystemDocumento95 pagineImo Inert Gas SystemMehmet Tokad93% (14)

- Tanker Ship's Discharging Operation and COW PDFDocumento40 pagineTanker Ship's Discharging Operation and COW PDFAnonymous fpLGbRDl100% (1)

- Specialized Training For Oil Tankers CH 09 INERT GAS SYSTEMDocumento41 pagineSpecialized Training For Oil Tankers CH 09 INERT GAS SYSTEMLaurentiu Matei100% (2)

- CARGO CYCLe Oil TankerDocumento19 pagineCARGO CYCLe Oil Tankersukhjit78100% (1)

- Marine Auxiliary BoilersDocumento31 pagineMarine Auxiliary Boilerskojet90100% (5)

- Pipeline Arrangement in Oil TankersDocumento11 paginePipeline Arrangement in Oil TankersManpreet SinghNessuna valutazione finora

- Cargo Tank Over&Under PressurisationDocumento7 pagineCargo Tank Over&Under PressurisationArchie Smiley100% (2)

- Framo Operation ManualDocumento16 pagineFramo Operation Manualcaptulcc100% (2)

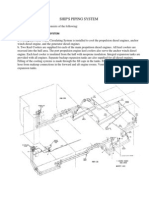

- SHIP Piping SystemDocumento5 pagineSHIP Piping Systemsurnaik100% (1)

- Chemical Tankers CourseDocumento59 pagineChemical Tankers Coursenoz1989100% (2)

- PV Valves Operation and Maintenance ProcedureDocumento6 paginePV Valves Operation and Maintenance ProcedureJeet SinghNessuna valutazione finora

- Oil TankerDocumento3 pagineOil Tankerbruzlik100% (1)

- Vetting CDI ObservationsDocumento42 pagineVetting CDI Observationsstopless_dalian685100% (5)

- Piping Arrangement - Conventional Oil Tanker BasicsDocumento11 paginePiping Arrangement - Conventional Oil Tanker BasicsEmon Anowar100% (1)

- Oil Tanker Cargo WorkDocumento12 pagineOil Tanker Cargo WorkAshutosh Singh100% (4)

- Crude Oil Washing: Group 1Documento8 pagineCrude Oil Washing: Group 1Bacalso C. Joseph FerdinandNessuna valutazione finora

- A Guide To Crude Oil Washing and Cargo Heating Criteria PDFDocumento45 pagineA Guide To Crude Oil Washing and Cargo Heating Criteria PDFMasterPie1950Nessuna valutazione finora

- LNG FamiliarisationDocumento80 pagineLNG FamiliarisationGee Villadarez100% (1)

- Chemical Tanker Vessel: ClassificationDocumento2 pagineChemical Tanker Vessel: ClassificationGimurtu Cristian67% (3)

- BUNKERINGDocumento4 pagineBUNKERINGMeghali Borle100% (1)

- Crude Oil Washing: Prepared By: Capt. Nitin PathakDocumento7 pagineCrude Oil Washing: Prepared By: Capt. Nitin PathakNIKHIL JASWAL100% (1)

- Entry Into Enclosed Spaces - Part 1 AwarenessDocumento20 pagineEntry Into Enclosed Spaces - Part 1 AwarenessDaniel RolandiNessuna valutazione finora

- Errors in Oil Record Book Part I EntriesDocumento3 pagineErrors in Oil Record Book Part I EntriesAbdul Anis100% (1)

- IntertankoDocumento45 pagineIntertankoBrijendra Kumar Srivastava100% (1)

- 3.oil and Chemical Cargo Operation Handout WORDDocumento163 pagine3.oil and Chemical Cargo Operation Handout WORDanujbhatnagar009100% (2)

- Marpol IdiotDocumento52 pagineMarpol IdiotKeshav Shahi100% (1)

- DCOM Petroleum & ChemicalDocumento400 pagineDCOM Petroleum & Chemicalpled100% (3)

- Tanker Cargo SystemsDocumento8 pagineTanker Cargo SystemsChayszar Wisnu100% (1)

- Unit - 5 IG SystemsDocumento74 pagineUnit - 5 IG SystemsRagunath Palanichamy100% (1)

- Inert Gas System With Its Alarms and Trips Are Compulsory Safety Equipment On Oil Tankers Under SOLAS ConventionDocumento5 pagineInert Gas System With Its Alarms and Trips Are Compulsory Safety Equipment On Oil Tankers Under SOLAS Conventionvihaan100% (1)

- Inert Gas SystemDocumento3 pagineInert Gas Systemmehedi2636Nessuna valutazione finora

- Inspire NewsletterDocumento16 pagineInspire NewsletterpiliyandalaleosNessuna valutazione finora

- Oil Tanker Design EquipmentDocumento59 pagineOil Tanker Design EquipmentBorislav Petrov100% (3)

- Yellow Book: Presented by-H.V.Sithuruwan Fernando (Engineering Cadet)Documento24 pagineYellow Book: Presented by-H.V.Sithuruwan Fernando (Engineering Cadet)piliyandalaleosNessuna valutazione finora

- TPTM CompanyDocumento21 pagineTPTM CompanypiliyandalaleosNessuna valutazione finora

- INSPIRE - NEWSLETTER - Chapter II - LEOS OF PILIYANDALADocumento15 pagineINSPIRE - NEWSLETTER - Chapter II - LEOS OF PILIYANDALApiliyandalaleosNessuna valutazione finora

- INSPIRE - NEWSLETTER - Chapter I - LEOS OF PILIYANDALADocumento15 pagineINSPIRE - NEWSLETTER - Chapter I - LEOS OF PILIYANDALApiliyandalaleosNessuna valutazione finora

- Short Rectang Dissipative SiDocumento2 pagineShort Rectang Dissipative SiLuis Gabriel BautistaNessuna valutazione finora

- Clinical Trial Regulation in NepalDocumento7 pagineClinical Trial Regulation in NepalB.pharm 16th BatchNessuna valutazione finora

- k219 2005-02 eDocumento12 paginek219 2005-02 eDoru HacaNessuna valutazione finora

- Offshore Technical Safety FAQDocumento12 pagineOffshore Technical Safety FAQPillai Sreejith100% (15)

- Load and Resistance Factors For Concrete Design: Aci Journal Technical PaperDocumento9 pagineLoad and Resistance Factors For Concrete Design: Aci Journal Technical PaperHasanain AlmusawiNessuna valutazione finora

- University of Houston Master Construction SpecificationsDocumento5 pagineUniversity of Houston Master Construction SpecificationsTaher AmmarNessuna valutazione finora

- Rail WheelDocumento8 pagineRail WheelAbdulhmeed MutalatNessuna valutazione finora

- Huawei eRAN Feature DocumentationDocumento63 pagineHuawei eRAN Feature Documentationdolapchiev75% (4)

- VX Reversing II, Sasser B-VirusDocumento19 pagineVX Reversing II, Sasser B-VirusStill Bligha100% (3)

- Tikona Tariff Plan NationalDocumento2 pagineTikona Tariff Plan NationalIndianMascotNessuna valutazione finora

- Reference GuideDocumento24 pagineReference GuideasadiqbalansariNessuna valutazione finora

- T-5 Service ManualDocumento85 pagineT-5 Service Manualapi-2614064450% (2)

- Correspondence Between ISO 9001 2015 ISODocumento2 pagineCorrespondence Between ISO 9001 2015 ISOMumtaz TSM100% (1)

- Upgrading To HTTPS With StunnelDocumento5 pagineUpgrading To HTTPS With StunnelJoxNessuna valutazione finora

- Amt 226Documento5 pagineAmt 226Jio GayonNessuna valutazione finora

- Information SecurityDocumento22 pagineInformation Securitydebleena mondalNessuna valutazione finora

- Screw Thread FormsDocumento2 pagineScrew Thread FormsLorettaMayNessuna valutazione finora

- Rabbitmq Dotnet Client 2.7.1 User GuideDocumento52 pagineRabbitmq Dotnet Client 2.7.1 User GuideLokesh SpNessuna valutazione finora

- ASTM (Hammer Test)Documento3 pagineASTM (Hammer Test)Efri Dwiyanto100% (1)

- Manual Centrala Victrix Tera 28 - ENGLISHDocumento56 pagineManual Centrala Victrix Tera 28 - ENGLISHssoriniNessuna valutazione finora

- HNT Task 1 (1217) : Experiences-Handbook/Teachers-College - Code-of-Ethics-Professional - Behaviors-And/ta-P/109Documento2 pagineHNT Task 1 (1217) : Experiences-Handbook/Teachers-College - Code-of-Ethics-Professional - Behaviors-And/ta-P/109Rachel MeyerNessuna valutazione finora

- BRC Management ReviewDocumento8 pagineBRC Management ReviewTamar MakhviladzeNessuna valutazione finora

- Om MP AddsDocumento78 pagineOm MP AddsIon Cezar CristianNessuna valutazione finora

- Ruggednet: Gpoe+/SiDocumento4 pagineRuggednet: Gpoe+/SiGiorgi SujashviliNessuna valutazione finora

- Math002 ReviewerDocumento4 pagineMath002 ReviewerIan Bertonel BalcuevaNessuna valutazione finora

- KRBS Dtailed Index - Volume 1 To 4Documento19 pagineKRBS Dtailed Index - Volume 1 To 4kushaljp8989Nessuna valutazione finora

- Normality - Questionnaire SampleDocumento6 pagineNormality - Questionnaire SampleFatin NurNessuna valutazione finora

- 3900 Series Base Station Technical Description (Draft A) (PDF) - enDocumento421 pagine3900 Series Base Station Technical Description (Draft A) (PDF) - enMostifa MastafaNessuna valutazione finora

- 3500 32m 4-Channel Relay 141533l 0Documento6 pagine3500 32m 4-Channel Relay 141533l 0Asad SuhailNessuna valutazione finora

- Katalog PDFDocumento32 pagineKatalog PDFiinNessuna valutazione finora