Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PPE Notes

Caricato da

jasminepop50%(2)Il 50% ha trovato utile questo documento (2 voti)

223 visualizzazioni34 pagineppe

Titolo originale

PPE Notes[1]

Copyright

© © All Rights Reserved

Formati disponibili

DOC, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoppe

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

50%(2)Il 50% ha trovato utile questo documento (2 voti)

223 visualizzazioni34 paginePPE Notes

Caricato da

jasminepopppe

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 34

Personal Protective Equipment

These notes will help you to

Examine your workplace,

Review the work procedures you require your employees to follow,

Select appropriate PPE (except for respirators and insulating ruer equipment! to

protect your employees, and Teach your employees how to wear and care for the PPE

you provide"

These notes will help you comply with #S$%&s general PPE requirements" This standard requires

employers to estalish general procedures, called a PPE program, to give employees necessary

protective equipment and to train them to use it properly" Respirators and insulating devices are

not included in this guide ecause #S$% requires employers to develop separate programs

specifically addressing the issues associated with those types of protective" %lthough not

specifically directed to construction and maritime industry, the information, methods, and

procedures in this guide are also applicale to, and will help you comply with, #S$%&s general

PPE requirements for the construction industry"

What is personal protective equipment?

Personal protective equipment, or PPE, includes a variety of devices and garments to protect

workers from in'uries" (ou can find PPE designed to protect

Eyes,

)ace,

$ead,

Ears,

)eet,

$ands and arms, and

*hole ody"

PPE includes such items as

+oggles,

)ace shields,

Safety glasses,

$ard hats,

Safety shoes,

+loves,

,ests,

Earplugs, and

Earmuffs"

Respirators and ruer insulating equipment (gloves, sleeves, lankets! are also considered

PPE, ut ecause #S$% has specific requirements for those kinds of PPE, this general guide

does not address such equipment"

The Need For PPE

Who must provide PPE?

(ou must provide PPE for your employees if

Their work environment presents a ha-ard or is likely to present a ha-ard to any part of

their odies.

Their work processes present a ha-ard or are likely to present a ha-ard to any part of

their odies.

/uring their work, they might come into contact with ha-ardous chemicals, radiation, or

mechanical irritants.

%0/ you are unale to eliminate their exposure or potential exposure to the ha-ard y

engineering, work practice, or administrative controls"

Eye and Face Protection

When must I provide eye protection for employees?

(ou must provide eye protection for employees whenever they are exposed to potential eye

in'uries during their work if work practice or engineering controls do not eliminate the risk of in'ury"

Some of the things that might cause eye in'uries include the following1

/ust and other flying particles, such as metal shavings or wool fiers"

2olten metal that might splash"

%cids and other caustic liquid chemicals that might splash"

3lood and other potentially infectious ody fluids that might splash, spray, or splatter"

4ntense light such as that created y welding arcs and lasers"

How do I select the proper protective eyewear for employees?

3egin with the following criteria1

Eye protection must protect against the specific ha-ard(s! encountered in the workplace"

4t must e reasonaly comfortale to wear"

Eye protection must not restrict vision or movement"

Eye protection must e durale and easy to clean and disinfect"

Eye protection must not interfere with the function of other required PPE"

4n addition, the %merican 0ational Standards 4nstitute, 4nc" (%0S4! has issued standard

requirements for the design, construction, testing, and use of protective devices for eyes and

face"

#S$% requires that all protective eyewear you purchase for your employees meet the

requirements of %0S4 567"898:6: for devices purchased after ;uly <, 8::=, and %0S4 567"898:>6

for devices purchased efore that date"

If employees wear eyeglasses with prescription lenses may I consider these eye

protection?

0o" Eyeglasses designed for ordinary wear do not provide the level of protection necessary to

protect against workplace ha-ards" Special care must e taken when choosing eye protectors for

employees who wear eyeglasses with corrective lenses such as the following1

Prescription spectacles, with side shields and protective lenses meeting the requirements

of %0S4 567"8, that also correct the individual employee&s vision"

+oggles that can fit comfortaly over corrective eyeglasses without disturing the

alignment of the eyeglasses"

+oggles that incorporate corrective lenses mounted ehind protective lenses"

(ou also must provide protective eyewear to employees who wear contact lenses and are

exposed to potential eye in'ury" Eye protection provided to these employees may also incorporate

corrective eyeglasses" Thus, if an employee must don eyeglasses in the event of contact lens

failure or loss, he or she will still e ale to use the same protective eyewear"

What !ind of eye and face protectors are there? What are they for?

"afety spectacles# These protective eyeglasses are made with safety frames

constructed of metal and?or plastic and are fitted with either corrective or plano impact9

resistant lenses" They come with and without side shields, ut most workplace operations

will require side shields"

Impact$resistant spectacles# This eyewear can e used for moderate impact from

particles produced y such 'os as carpentry, woodworking, grinding, and scaling"

"ide shields" These protect against particles that might enter the eyes from the side"

Side shields are made of wire mesh or plastic" Eye9cup type side shields provide the est

protection"

%oggles# (ou may choose from many different types of goggles, each designed for

specific ha-ards" +enerally, goggles protect eyes, eye sockets, and the facial area

immediately surrounding the eyes from impact, dust, and splashes" Some goggles fit over

corrective lenses"

Welding shields# @onstructed of vulcani-ed fier or fierglass and fitted with a filtered

lens, these protective devices are designed for the specific ha-ards associated with

welding" *elding shields protect your employees& eyes from urns caused y infrared or

intense radiant light, and they protect face and eyes from flying sparks, metal spatter, and

slag chips produced during welding, ra-ing, soldering, and cutting"

&aser safety goggles" Aaser safety goggles provide a range of protection against the

intense concentrations of light produced y lasers" The type of laser safety goggles you

choose will depend upon the equipment and operating conditions in your workplace"

Face shields" These transparent sheets of plastic extend from the row to elow the chin

across the entire width of the employee&s head" Some are polari-ed for glare protection"

@hoose face shields to protect your employees& faces from nuisance dusts and potential

splashes or sprays of ha-ardous liquids"

'an face shields protect employees instead of goggles or protective spectacles?

)ace shields do not protect employees from impact ha-ards" (ou may use however, face shields

in comination with goggles or safety spectacles, to protect against impact ha-ards, even in the

asence of dust or potential splashes, for additional protection eyond that offered y goggles or

spectacles alone"

How do I choose the correct eye protection from among all the different types?

Each kind of protective eyewear is designed to protect against specific ha-ards" 3y completing

the ha-ard assessment of your workplace outlined in the previous section, you will identify the

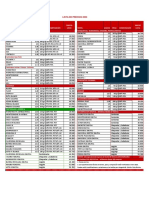

specific workplace ha-ards that pose a threat to your employees& eyes and faces" Tales 8

through B and )igure 8 will help you find the protective devices most suited for your employees

and your workplace" Aocate the operations and ha-ards most similar to those in your workplace in

Tale 8 and match the numer to the corresponding drawing in )igure 8" *elding and laser

operations require lenses to e tinted to a degree sufficient to protect against the specific intensity

of light present during that tasks your employees perform (see Tales C and B!"

How dar! do lenses on welding helmets and goggles need to (e?

The intensity of light or radiant energy produced y welding, cutting, or ra-ing operations varies

according to a numer of factors including the task producing the light, the electrode si-e, and the

arc current" Tale C shows the minimum protective shade for a variety of welding, cutting, and

ra-ing operations" To protect employees who are exposed to intense radiant energy, egin y

selecting a shade too dark to see the welding -one" Then try lighter shades until you find one that

allows a sufficient view of the welding -one without going elow the minimum protective shade"

How do I protect employees from e)posure to laser (eams?

(ou must provide safety goggles specifically designed to protect the employees& eyes from the

specific intensity of light produced y the laser" The level of protection will vary according the level

of radiation emitted y the laser" 4f your employees are exposed to laser eams, you must

determine the maximum power density, or intensity, that the lasers can produce" 3ased on this

knowledge, you must select lenses that will protect against this maximum intensity" Tale B shows

the minimum optical density of lenses required for various laser intensities" Employers with lasers

emitting radiation etween two measures of power density (or light locking capaility! must

provide lenses that offer protection against the higher of the two intensities"

How can I (e sure that laser safety goggles provide enough protection?

Every pair of safety goggles intended for use with laser eams must ear a lael with the

following information1

The laser wavelengths for which they are intended to e used"

The optical density of those wavelengths"

The visile light transmission"

*nce I have selected the appropriate eye protection equipment how do I ma!e sure

employees use it properly?

Train your employees to use the protective eyewear" @hecklist @ will help you prepare your

employees to use and care for the eye protection you provide"

+y wor!place gets pretty dirty# How will my employees !eep their protective eyewear clean

and effective?

Train your employees how to clean the eye protectors" %llow them time at the end of their shifts to

do the following1

/isassemle goggles or spectacles,

Thoroughly clean all parts with soap and warm water,

@arefully rinse off all traces of soap, and

Replace all defective parts"

#ccasionally, you must disinfect the protective eyewear" To do so, after cleaning you can do the

following1

4mmerse and swa all parts for 8D minutes in a germicidal solution"

Remove all parts from the solution and hang in a clean place to air dry at room

temperature or with heated air"

/o not rinse the parts after sumerging them in the disinfectant" Rinsing will remove the

germicidal residue that remains after drying"

%lso use ultraviolet disinfecting and spray9type disinfecting solutions also may e used

after washing"

+y employees wor! in shifts# 'ould I provide one pair of protective eyewear for each

position instead of each employee?

(es" 4f you do this, however, you must disinfect shared protective eyewear after each use" 4f the

goggles or spectacles do not have to e individually designed to incorporate an employee&s

corrective lenses and you disinfect the eyewear etween uses y different employees, more than

one employee may use the same set of protective eyewear"

Head Protection

When do my employees need head protection?

(ou must provide head protection for your employees if1

#'ects might fall from aove and strike them on the head.

They might ump their heads against fixed o'ects, such as exposed pipes or eams. or

They work near exposed electrical conductors"

What should I loo! for in head protection?

4n general, protective helmets, or hard hats, should

Resist penetration y o'ects,

%sor the shock of a low,

3e water resistant and slow urning, and

@ome with instructions explaining proper ad'ustment and replacement of the suspension

and headand"

Hard hats require a hard outer shell and a shock-absorbing lining. The lining should

incorporate a head band and straps that suspend the shell from 1 to 1 1/4 inches (2.54 cm

to .1! cm" a#a$ from the user%s head. This design pro&ides shock absorption during

impact and &entilation during #ear.

's #ith de&ices designed to protect e$es( the design( construction( testing( and use of

protecti&e helmets must meet standards established b$ ')*+. ,rotecti&e helmets

purchased after -ul$ 5( 1..4( must compl$ #ith ')*+ /!..1-1.!0((1" #hereas( those

purchased before this date must meet the ')*+ /!..1-1.0. standard.

What types of head protection are availa(le?

$ard hats are divided into three industrial classes1

'lass ,# These helmets are for general service" They provide good impact protection ut

limited voltage protection" They are used mainly in mining, uilding construction,

shipuilding, lumering, and manufacturing"

'lass -# @hoose @lass 3 helmets if your employees are engaged in electrical work" They

protect against falling o'ects and high9voltage shock and urns"

'lass '# /esigned for comfort, these light9weight helmets offer limited protection" They

protect workers from umping against fixed o'ects ut do not protect against falling

o'ects or electric shock"

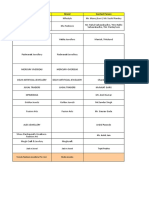

2ook at the inside of an$ protecti&e helmet $ou are considering for $our emplo$ees( and

$ou should see a label sho#ing the manufacturer%s name( the ')*+ standard it meets( and

its class. 3igure 2 sho#s the basic design of hard hats.

How do I choose the correct protective helmets from among the different types?

Each kind of protective helmet is designed to protect against specific ha-ards" 3y completing the

ha-ard assessment outlined aove, you will identify the specific workplace ha-ards that pose a

threat to your employee&s head"

I have purchased new hard hats that meet the ,N"I requirements# Have I fulfilled my

responsi(ility to protect my employees. heads?

0o" 4ssuing appropriate head protection to employees is a ma'or first step, ut you must make

sure that the hard hats continue to provide sufficient protection to your employees" /o this y

training your employees in the proper use and maintenance of hard hats including daily

inspection of them" 4f your employees identify any of the following defects, remove the hard hats

from service1

The suspension system shows signs of deterioration such as1

@racking,

Tearing, or

)raying"

The suspension system no longer holds the shell from 8 inch to 8 8?= inches (C"<=cm 9 B"86cm!

away from the employee&s head" The rim or shell is cracked, perforated, or deformed" The rim

or shell shows signs of exposure to heat, chemicals, ultraviolet light, or other radiation" Such

signs include1

Aoss of surface gloss,

@halking, or

)laking (a sign of advanced deterioration!"

'ould employees wearing hard hats and wor!ing at elevations create a potential ha/ard

for the employees wor!ing (elow?

To protect employees working elow, you must provide chin straps for the protective helmets

worn y employees working at higher elevations, whether in an aerial lift or at the edge of a pit"

The chin straps should e designed to prevent the hard hats from eing umped off the

employees& heads"

'an I require employees to cut their hair if it is long enough to get tangled in machinery?

Aong hair (longer than four inches! can e drawn into machine parts such as chains, elts,

rotating devices, suction devices, and lowers" $air may even e drawn into machines otherwise

guarded with mesh" %lthough you need not require your employees to cut their hair, you must

require them to cover and protect their hair with andanas, hair nets, turans, soft caps, or the

like" These items, however, must not themselves present a ha-ard"

*nce I have selected helmets to protect my employees. heads how do I ma!e sure they

use them properly?

Train your employees to use the hard hats" @hecklist / will help you instruct your employees to

use and care for the head protection you provide"

How do I ma!e sure that the hard hats I provide will (e !ept in good condition?

(ou must train your employees to maintain and care for the head protection" (our training

communicates the importance of wearing head protection and taking proper care of it" 4mportant

information you will want to consider when training employees on how to care for their hard hats

includes the following1

Paints, paint thinners, and some cleaning agents can weaken the shell of the hard hat

and may eliminate electrical resistance" @onsult the helmet manufacturer for information

on the effects of paint and cleaning materials on their hard hats" Eeep in mind that paint

and stickers can also hide signs of deterioration in the hard hat shell" Aimit their use"

Fltraviolet light and extreme heat, such as that generated y sunlight, can reduce the

strength of the hard hats" Therefore, employees should not store or transport hard hats

on the rear9window shelves of automoiles or otherwise in direct sunlight"

%lso, instruct employees to clean the protective helmets periodically y1

4mmersing for one minute in hot (approximately 8=D

o

), or >D

o

@! water and detergent,

Scruing, and

Rinsing in clear hot water"

Foot and &eg Protection

When must I provide foot and leg protection?

(ou must provide foot and leg protection if your workplace ha-ard assessment reveals potential

dangers to these parts of the ody" Some of the potential ha-ards you might identify include the

following1

$eavy o'ects such as arrels or tools that might roll onto or fall on employees& feet"

Sharp o'ects such as nails or spikes that might pierce the soles or uppers of ordinary

shoes"

2olten metal that might splash on feet or legs

$ot or wet surfaces"

Slippery surfaces"

What are the types of protection and where do I use them?

The type of foot and leg protection you provide your employees will depend upon the specific

workplace ha-ards you identify and the specific parts of the feet or legs exposed to potential

in'ury" Safety footwear must meet minimum compression and impact performance standards and

testing requirements estalished y %0S4" Protective footwear purchased after ;uly <, 8::=, must

meet the requirements of %0S4 5=898::8" Protective footwear ought efore that date must

comply with %0S4 5=898:>7" )oot and leg protection choices includes the following1

&eggings" Fse these to protect the lower legs and feet from heat ha-ards, like molten

metal or welding sparks" Safety snaps allow leggings to e removed quickly"

+etatarsal guards" 2ade of aluminum, steel, fier, or plastic, these guards maye

strapped to the outside of shoes to protect the instep area from impact and compression"

Toe guards# Toe guards may e made of steel, aluminum, or plastic" They fit over the

toes of regular shoes" These guards protect only the toes from impact and compression

ha-ards"

'om(ination foot and shin guards" These guards may e used in comination with toe

guards when greater protection is needed"

"afety shoes# These sturdy shoes have impact9resistant toes and heat9resistant soles

that protect against hot work surfaces common in roofing, paving, and hot metal

industries" The metal insoles of some safety shoes protect against puncture wounds"

Safety shoes may also e designed to e electrically conductive to prevent the uildup of

static electricity in areas with the potential for explosive atmospheres, or nonconductive

to protect workers from workplace electrical ha-ards"

What should I loo! for when choosing safety shoes for my employees?

+enerally, safety shoes must e sturdy and must have impact9resistant safety toes, instep

protection, and heat9resistant soles (see )igure B!" %ll safety shoes must comply with the %0S4

standard(s! mentioned aove" 4n addition, depending on the types of worker exposures, you may

need to provide specially designed safety shoes such as conductive or electrical9ha-ard safety

shoes"

'onductive "hoes1 Electrically conductive shoes protect against the uildup of static electricity"

Essentially, these shoes ground the employees wearing them" Employees working in explosive

and ha-ardous locations such as explosives manufacturing facilities or grain elevators must wear

conductive shoes to reduce the risk of static electricity uildup on an employee&s ody that could

produce a spark and cause an explosion or fire" /uring training, employees must e instructed

not to use foot powder or wear socks made of silk, wool, or nylon with conductive shoes" )oot

powder insulates and retards the conductive aility of the shoes" Silk, wool, and nylon produce

static electricity"

@onductive shoes are not general9purpose shoes and must e removed upon completion of the

tasks for which they are required" Employees exposed to electrical ha-ards must never wear

conductive shoes"

Electrical ha/ard safety$toe shoes are nonconductive and will prevent your employees& feet

from completing an electrical circuit to the ground" They can protect employees against open

circuits of up to >DD volts in dry conditions" Electrical ha-ard, safety9toe shoes should e used in

con'unction with other insulating equipment and precautions to reduce or eliminate the potential

for your employees& odies or parts of their odies to provide a path for ha-ardous electrical

energy" 0ote1 0onconductive footwear must not e used in explosive or ha-ardous locations. in

such locations, electrically conductive shoes are required"

Train your employees to recogni-e that the insulating protection of electrical ha-ard, safety9toe

shoes may e compromised if

The shoe is wet

The ruer sole is worn through

2etal particles ecome emedded in the sole or heel. or

#ther parts of the employees& odies come into contact with conductive, grounded

items"

Foundry "hoes0 4n addition to insulating your employees& feet from the extreme heat of molten

metal, foundry shoes prohiit hot metal from lodging in shoe eyelets, tongues, or other parts"

These snug9fitting leather or leather9sustitute shoes have leather or ruer soles and ruer

heels" 4n addition, all foundry shoes must have uilt9in safety toes"

*nce I have selected equipment to protect my employees. feet and legs how do I ma!e

sure they use it properly?

Train your employees to use the protective footwear" @hecklist E will help you instruct your

employees to use and care for the foot and leg protection you provide"

Hand and ,rm Protection

When must I provide hand and arm protection?

4f your workplace ha-ard assessment reveals that your employees risk in'ury to their hands and

arms, and engineering and work practice controls do not eliminate the ha-ards, you must provide

your employees with appropriate protection" The in'uries you may need to guard against in your

workplace include the following1

3urns

3ruises

%rasions

@uts

Punctures

)ractures

%mputations

@hemical exposures"

What !ind of equipment is necessary to protect the hands and arms?

)or many workplace operations, machine guards such as point9of9operation guards will e

sufficient" )or example, install a arrier that makes it impossile for employees to put their hands

at the point where a tale saw lade makes contact with the wood it cuts" )or other ha-ardous

operations, you may e ale to institute work procedures that eliminate the risk of in'ury to your

employees& hands or arms" *hen such measures fail to eliminate the ha-ard, however, protective

gloves will e the primary means of protecting employees& hands" *hen the risk of in'ury includes

the arm, protective sleeves, often attached to the gloves, may e appropriate"

Is there one !ind of glove that will protect against all wor!place ha/ards?

0o" The nature of the ha-ard(s! and the operation to e performed will determine your selection

of gloves" The variety of potential occupational hand in'uries may make selecting the appropriate

pair of gloves more difficult than choosing other protective equipment" Take care to choose gloves

designed for the particular circumstances of your workplace"

What !inds of protective gloves are availa(le?

+loves made from a wide variety of materials are designed for virtually every workplace ha-ard"

4n general, however, they may e divided into four groups1

/urale work gloves made of metal mesh, leather, or canvas"

)aric and coated faric gloves"

@hemical and liquid resistant gloves"

4nsulating ruer gloves"

+etal +esh &eather or 'anvas %loves1 Sturdy gloves made from metal mesh, leather, or

canvas provide protection against cuts, urns, and sustained heat"

&eather gloves1 Aeather gloves protect against sparks, moderate heat, lows, chips, and rough

o'ects" *elders in particular need the duraility of higher9quality leather gloves"

,lumini/ed gloves1 These gloves usually are used for welding, furnace, and foundry work

ecause they provide reflective and insulating protection against heat" %lumini-ed gloves require

an insert made of synthetic materials that protect against heat and cold"

,ramid fi(er gloves1 %ramid is a synthetic material that protects against heat and cold" 2any

glove manufacturers use aramid fier to make gloves that are cut9 and arasive9resistant and

wear well"

*ther synthetic materials1 Several manufacturers make gloves with other synthetic farics that

offer protection against heat and cold" 4n addition to protection against temperature extremes,

gloves made with other synthetic materials are cut9 and arasive9resistant and may withstand

some diluted acids" These materials do not stand up against alkalis and solvents"

Fa(ric and 'oated Fa(ric %loves1 These gloves are made of cotton or other faric to provide

varying degrees of protection"

Fa(ric gloves1 These gloves can protect against dirt, slivers, chafing, and arasion" These

gloves do not provide sufficient protection, however, to e used with rough, sharp, or heavy

materials" %dding a plastic coating to some faric gloves strengthens them and makes them

effective protection for a variety of tasks"

'oated fa(ric gloves1 2anufacturers normally make these gloves from cotton flannel with

napping on one side" 3y coating the unnapped side with plastic, faric gloves are transformed

into general9purpose hand protection offering slip9resistant qualities" These gloves are used for

tasks ranging from handling ricks and wire rope to handling chemical containers in laoratory

operations" *hen selecting gloves to protect against chemical exposure ha-ards, always check

with the manufacturer (or review the manufacturer&s product literature! to determine the gloves&

effectiveness against the specific chemicals and conditions in the workplace"

'hemical$ and &iquid$1esistant %loves0 +loves made of ruer (latex, nitrile, or utyl!, plastic,

or synthetic ruer9like material such as neoprene protect workers from urns, irritation, and

dermatitis caused y contact with oils, greases, solvents, and other chemicals" The use of ruer

gloves also reduces the risk of exposure to lood and other potentially infectious sustances"

Some common gloves used for chemical protection are descried elow" 4n addition, Tale =

rates various gloves as protectors against specific chemicals and will help you select the most

appropriate gloves to protect your employees"

-utyl ru((er gloves1 These gloves protect against nitric acid, sulfuric acid, hydrofluoric acid, red

fuming nitric acid, rocket fuels, and peroxide" $ighly impermeale to gases, chemicals, and water

vapor, utyl ruer gloves also resist oxidation and o-one corrosion" 4n addition, they resist

arasion and remain flexile at low temperatures"

Natural late) or ru((er gloves1 The comfortale wear and pliaility of latex gloves as well as

their protective qualities make them a popular general9purpose glove" 4n addition to resisting

arasions caused y sandlasting, grinding, and polishing, these gloves protect workers& hands

from most water solutions of acids, alkalis, salts, and ketones" *hen selecting hand protection,

you should e aware that latex gloves have caused allergic reactions in some individuals and

thus may not e appropriate for all of your employees" $ypoallergenic gloves, glove liners, and

powderless gloves are possile alternatives for individuals who are allergic to latex gloves"

Neoprene gloves" These gloves have good pliaility, finger dexterity, high density, and tear

resistance which protect against hydraulic fluids, gasoline, alcohols, organic acids, and alkalis"

Nitrile ru((er gloves" These sturdy gloves provide protection from chlorinated solvents such as

trichloroethylene and perchloroethylene " %lthough intended for 'os requiring dexterity and

sensitivity, nitrile gloves stand up to heavy use even after prolonged exposure to sustances that

cause other gloves to deteriorate" 4n addition, nitrile gloves resist arasions, punctures, snags,

and tears"

How do I ma!e sure my employees properly use the equipment I have selected?

Train your employees to use the protective gloves and sleeves" @hecklist ) will help you teach

your employees how to use and care for the equipment"

-ody Protection

When must I provide my employees with full (ody protection?

(ou must provide ody protection for employees if they are threatened with odily in'ury of one

kind or another while performing their 'os, and if engineering, work practice, and administrative

controls have failed to eliminate these ha-ards" *orkplace ha-ards that could cause odily in'ury

include the following1

4ntense heat

Splashes of hot metals and other hot liquids

4mpacts from tools, machinery, and materials

@uts

$a-ardous chemicals

@ontact with potentially infectious materials, like lood

Radiation"

If only part of the (ody faces potential in2ury must I provide my employees with full (ody

protection?

%s with all protective equipment, protective clothing is availale to protect against specific

ha-ards" (ou need to provide personal protective equipment only for the parts of the ody

exposed to possile in'ury" /epending upon ha-ards in your workplace, you may need to provide

your employees with one or more of the following1

,ests

;ackets

%prons

@overalls

Surgical gowns

)ull ody suits"

4f your ha-ard assessment indicates that you must provide full ody protection against toxic

sustances or harmful physical agents, you must1

4nspect the clothing carefully,

Ensure proper fit, and

2ake sure the protective clothing functions properly"

From what material should protective clothing (e made?

Protective clothing comes in a variety of materials, each suited to particular ha-ards" @onduct

your ha-ard assessment" 4dentify the sources of any possile odily in'ury" 4nstall any feasile

engineering controls, and institute work practice controls to eliminate the ha-ards" 4f the possiility

of odily in'ury still exists, provide protective clothing constructed of material that will protect

against the specific ha-ards in your workplace" 2aterials for protective clothing include the

following1

Paperli!e fi(er# /isposale suits made of this material provide protection against dust

and splashes"

Treated wool and cotton# Protective clothing made from treated wool and cotton adapts

well to changing workplace temperatures and is comfortale as well as fire resistant"

Treated cotton and wool clothing protects against dust, arasions, and rough and

irritating surfaces"

3uc!# This closely woven cotton faric protects employees against cuts and ruises

while they handle heavy, sharp, or rough materials"

&eather# Aeather protective clothing is often used against dry heat and flame"

1u((er ru((eri/ed fa(rics neoprene and plastics# Protective clothing made from

these materials protects against certain acids and other chemicals"

3e aware that different materials will protect against different chemical and physical ha-ards"

*hen chemical or physical ha-ards are present, check with the clothing manufacturer to make

sure that the material selected will provide protection from the specific chemical or physical

ha-ards in your workplace"

How do I ma!e sure employees properly use the (ody protection I provide?

Train your employees to use the protective clothing" @hecklist + will help you instruct

them in the use and care of the ody protection"

Hearing Protection

When must I provide hearing protection for my employees?

/etermining the need to provide hearing protection can e tricky" Employee exposure to

excessive noise depends upon a numer of factors1

$ow loud is the noise as measured in deciels (d3%!G

*hat is the duration of each employee&s exposure to the noiseG

/o employees move etween separate work areas with different noise levelsG

4s noise generated from one source or multiple sourcesG

+enerally, the louder the noise, the shorter the exposure time efore you must provide hearing

protection" )or instance, employees may e exposed to a noise level of :D d3% for 6 hours per

day efore you must provide hearing protection for them" Suppose, however, that the noise level

reaches 88< d3% in your workplace" Then you must provide hearing protection if their anticipated

exposure exceeds 8< minutes"

Tale < shows when you must provide hearing protection to employees exposed to occupational

noise at specific levels for specific periods" 0oises are considered continuous if the interval

etween occurrences of the maximum noise level is 8 second or less" 0oises not meeting this

definition are considered impact or impulse noises" Exposure to impact or impulse noises (loud

momentary explosions of sound! must not exceed 8=D d3" Examples of impact or impulse noises

may include the noise from a powder9actuated nail gun, the noise from a punch press, or the

noise from drop hammers"

Will earplugs reduce employee e)posure to high noise levels?

%s with other types of ha-ards, you must implement feasile engineering controls and work

practices efore resorting to PPE such as earplugs or earmuffs" 4f engineering and work practice

controls do not lower employee exposure to workplace noise to acceptale levels, then you must

provide employees with appropriate PPE"

What if my employees are e)posed to different levels of noise throughout the day?

4f employees move from location to location and the noise level is different in each location, or if

the noise levels in an area change throughout the day (e"g", equipment turns on or off!, you must

calculate an Hequivalent noise factorH to determine whether you must provide hearing protection"

2easure the noise level at each location in which the employee works"

)or each noise level, find the allowale duration in Tale <"

)or each location, divide the actual time the employee spends there y the permissile duration

for the noise at the measured level, according to Tale <"

%dd all the results from your division"

4f the total is greater than one, you must implement engineering controls or work practices or

provide hearing protection to your exposed employees"

The formula for calculating this exposure is as follows1

What !inds of devices protect against high noise levels? Is cotton sufficient as earplugs?

Plain" cotton does not effectively protect against occupational noise" (ou may, however, choose

from several products that are effective at protecting your employees& hearing"

"ingle$use earplugs" 2ade of waxed cotton, foam, or fierglass wool, these ear plugs are self9

forming and, when properly inserted, work as well as most molded earplugs"

Preformed or molded earplugs" Sometimes single use and disposale, these plugs must e

individually fitted y a professional" 0ondisposale plugs should e cleaned after each use"

Earmuffs# Earmuffs require a perfect seal around the ear" +lasses, long sideurns, long hair, and

facial movements such as chewing may reduce the protective value of earmuffs" (ou may

purchase special earmuffs designed for use with eyeglasses or eards"

If I provide my employees with hearing protection can they then wor! in areas with any

level of noise for any period of time?

0o" $earing protectors reduce only the amount of noise that gets through to the ears" The

amount of this reduction is referred to as attenuation" %ttenuation differs according to the type of

hearing protection used and how well they fit" The hearing protectors you choose must e

capale of achieving the attenuation needed to reduce the employee&s noise exposure to within

the acceptale limits noted in Tale <" #nce 4 have selected equipment to protect my employees&

hearing, how do 4 make sure they use it properlyG

Train your employees to use the hearing protection" @hecklist $ will help you train your

employees to use and care for the earplugs or earmuffs that you provide"

*nce I have provided my employees with hearing protection and training in how to use it

how do I !now that it is really protecting their hearing?

4f your employees are exposed to occupational noise at or aove 6< d3% averaged over an 69

hour period, then you must institute a hearing conservation program that includes regular testing

of employees& hearing y qualified professionals"

"ummary

(ou must consider many factors when selecting PPE to protect your employees from workplace

ha-ards" *ith all of the types of operations that can present ha-ards and all of the types of PPE

availale to protect the different parts of a worker&s ody from specific types of ha-ards, this

selection process can e confusing and at times overwhelming" 3ecause of this, #S$% requires

that you implement a PPE program to help you systematically assess the ha-ards in the

workplace and select the appropriate PPE that will protect your workers from those ha-ards" %s

part of this PPE program, you must do the following1

%ssess the workplace to identify equipment, operations, chemicals, and other workplace

components that could harm your employees"

4mplement engineering controls and work practices to control or eliminate these ha-ards to the

extent feasile"

Select the appropriate types of PPE to protect your employees from ha-ards that cannot e

eliminated or controlled through engineering controls and work practices"

4nform your employees why the PPE is necessary and when it must e worn"

Train your employees how to use and care for the selected PPE and how to recogni-e PPE

deterioration and failure"

Require your employees to wear the selected PPE in the workplace"

The asic information presented here attempts to estalish and illustrate a logical, structured

approach to ha-ard assessment and PPE selection and application for you to use as a starting

point for your PPE program"

Potrebbero piacerti anche

- Chapter 3 Stress ManagementDocumento22 pagineChapter 3 Stress ManagementManthan Ashutosh MehtaNessuna valutazione finora

- 1-Introduction To Occupational Safety and HealthDocumento36 pagine1-Introduction To Occupational Safety and HealthelickNessuna valutazione finora

- Basic First Aid TrainingDocumento109 pagineBasic First Aid TrainingFarrukh AhmedNessuna valutazione finora

- Introduction To First AidDocumento16 pagineIntroduction To First AidEmmanuel R. SiwilaNessuna valutazione finora

- At Risk Behavior: Thiokol PropulsionDocumento14 pagineAt Risk Behavior: Thiokol Propulsiongeorge_rusuNessuna valutazione finora

- Control Bleeding and ShockDocumento6 pagineControl Bleeding and ShockElianeOliveiraNessuna valutazione finora

- Pe 212Documento86 paginePe 212Kyle Carreon CaraganNessuna valutazione finora

- WEEK 1 - Concept of CommunityDocumento5 pagineWEEK 1 - Concept of Communitypoleene de leonNessuna valutazione finora

- Breast Examination: 1. Preparation Health ProviderDocumento1 paginaBreast Examination: 1. Preparation Health ProviderAufi FillaNessuna valutazione finora

- Protocol For Needle Stick Injur1Documento1 paginaProtocol For Needle Stick Injur1Prem KumarNessuna valutazione finora

- Workplace MalpracticesDocumento14 pagineWorkplace MalpracticesUmar AhsanNessuna valutazione finora

- Female Welfare ProgrammeDocumento6 pagineFemale Welfare ProgrammeAnnapurna DangetiNessuna valutazione finora

- Pdca HHDocumento5 paginePdca HHFaozan FikriNessuna valutazione finora

- 13 Needle-Stick InjuriesDocumento9 pagine13 Needle-Stick InjuriesveraNessuna valutazione finora

- Knowledge Attitude and Practices of Health Workers On Puerperal Sepsis Preventions at Bundibugyo Hospital Bundibugyo DistrictDocumento21 pagineKnowledge Attitude and Practices of Health Workers On Puerperal Sepsis Preventions at Bundibugyo Hospital Bundibugyo DistrictKIU PUBLICATION AND EXTENSIONNessuna valutazione finora

- Learning in ObDocumento19 pagineLearning in Obhibrework kassaNessuna valutazione finora

- Occupational Hazards in Health Care ProfessionalsDocumento33 pagineOccupational Hazards in Health Care Professionalsdocshirin100% (1)

- 18 Family WelfareDocumento45 pagine18 Family WelfareMonika JosephNessuna valutazione finora

- DPP Unit - VDocumento59 pagineDPP Unit - V153-B RAKSHITHANessuna valutazione finora

- Family Care PlanDocumento5 pagineFamily Care PlanDarwin VillestasNessuna valutazione finora

- ExamNotes - Disaster Management Keypoints From ARC ReportDocumento36 pagineExamNotes - Disaster Management Keypoints From ARC ReportRamakadrama100% (1)

- Ergonomics: Pallavi WakodeDocumento49 pagineErgonomics: Pallavi WakodeAkshay BangadNessuna valutazione finora

- 4a. Managerial GridDocumento9 pagine4a. Managerial GridMohammed Ali NaikNessuna valutazione finora

- WORKPLACE READINESS FOR COVID Part 3Documento37 pagineWORKPLACE READINESS FOR COVID Part 3LNessuna valutazione finora

- Work Place SafetyDocumento21 pagineWork Place SafetyHitesh GulabaniNessuna valutazione finora

- Code of Ethics For NursesDocumento14 pagineCode of Ethics For Nursesaron frondaNessuna valutazione finora

- Machinery, Equipments & LinenDocumento73 pagineMachinery, Equipments & Linenbuvan eswarNessuna valutazione finora

- Crush Injury of Hand PDFDocumento22 pagineCrush Injury of Hand PDFmilananand0% (1)

- Irst ID: A Lecture Is Basics of First Aid and The Medical Treatment For Minor Injuries Diana Tahir, MpharmDocumento36 pagineIrst ID: A Lecture Is Basics of First Aid and The Medical Treatment For Minor Injuries Diana Tahir, Mpharmsarila sNessuna valutazione finora

- Flood SafetyDocumento2 pagineFlood SafetyCatholic Charities USANessuna valutazione finora

- Lesson Plan of Conference PDFDocumento44 pagineLesson Plan of Conference PDFRahul DamorNessuna valutazione finora

- Occupational Safety and Health: Lecture NotesDocumento7 pagineOccupational Safety and Health: Lecture NotesJonathan TungalNessuna valutazione finora

- Group 2: Presenters Isikanda Mataa Beauty MuntangaDocumento76 pagineGroup 2: Presenters Isikanda Mataa Beauty MuntangaShemo MukelabaiNessuna valutazione finora

- Communicable DiseaseDocumento193 pagineCommunicable DiseaseLuvastranger Auger100% (2)

- MSDS TccaDocumento6 pagineMSDS Tccamita wahyuniNessuna valutazione finora

- 15.infection Control ProtocolDocumento22 pagine15.infection Control ProtocolVin Bernales100% (1)

- Personal Protective EquipmentDocumento18 paginePersonal Protective EquipmentBryan Jagroop100% (1)

- Conflict ManagementDocumento24 pagineConflict ManagementRamandeep SidhuNessuna valutazione finora

- Human Development TheoriesDocumento40 pagineHuman Development TheoriesMichelle Villareal CuevasNessuna valutazione finora

- Lecture 8-Occupational Diseases-Dr. Dr. Lientje Setyawati K Maurits, MS, SpOk (RSA) (2019)Documento19 pagineLecture 8-Occupational Diseases-Dr. Dr. Lientje Setyawati K Maurits, MS, SpOk (RSA) (2019)Rafi NabihNessuna valutazione finora

- Cord Care: By: Abella, Wenalyn Grace ZDocumento6 pagineCord Care: By: Abella, Wenalyn Grace ZWenalyn Grace Abella Llavan100% (1)

- Needle Stick InjuryDocumento5 pagineNeedle Stick Injurypsc anandNessuna valutazione finora

- Bandaging NotesDocumento7 pagineBandaging NotesJudith De Loyola AgadNessuna valutazione finora

- Development TheoriesDocumento169 pagineDevelopment TheoriesSaurabh Suman100% (1)

- Definition of ErgonomicsDocumento11 pagineDefinition of ErgonomicsmichaelNessuna valutazione finora

- Reporting PDFDocumento4 pagineReporting PDFMaria Diaz FrancoNessuna valutazione finora

- PromotionDocumento22 paginePromotioncpadiyarNessuna valutazione finora

- Oral Health 1-3&5Documento38 pagineOral Health 1-3&5Umar FarouqNessuna valutazione finora

- Development and Validation of Students' Stress Rating Scale (SSRS)Documento8 pagineDevelopment and Validation of Students' Stress Rating Scale (SSRS)Pretty GangNessuna valutazione finora

- Chapter 6 - Mouth, Throat, and Nose AssessmentDocumento10 pagineChapter 6 - Mouth, Throat, and Nose AssessmentCnette S. LumboNessuna valutazione finora

- Basic First Aid QuizDocumento33 pagineBasic First Aid QuizIamJmlingconNessuna valutazione finora

- Disaster Management: Mahendra ChoudharyDocumento43 pagineDisaster Management: Mahendra ChoudharyROHIT SAGARNessuna valutazione finora

- Health Care Delivery System in IndiaDocumento14 pagineHealth Care Delivery System in IndiaSaumiya NairNessuna valutazione finora

- Hand Hygiene and HandwashingDocumento7 pagineHand Hygiene and HandwashingFaith Dianasas RequinaNessuna valutazione finora

- Factors Influencing HealthDocumento10 pagineFactors Influencing Healthzach felixNessuna valutazione finora

- Module 7 Heirarchy of ControlsDocumento56 pagineModule 7 Heirarchy of ControlsDaneNessuna valutazione finora

- Nurses' Knowledge and Practice Regarding Oral Care in Intubated Patients at Selected Teaching Hospitals, ChitwanDocumento8 pagineNurses' Knowledge and Practice Regarding Oral Care in Intubated Patients at Selected Teaching Hospitals, ChitwanAnonymous izrFWiQNessuna valutazione finora

- Accident Prevention Manual For Business & Industry:: Engineering & Technology 13th EditionDocumento48 pagineAccident Prevention Manual For Business & Industry:: Engineering & Technology 13th EditionAmeerUlHaqNessuna valutazione finora

- Personal Protective Equipment - Eye and Face Protection: Risk Control Resources, LLC Printed On: 01/29/2009Documento71 paginePersonal Protective Equipment - Eye and Face Protection: Risk Control Resources, LLC Printed On: 01/29/2009M_E_AdamsNessuna valutazione finora

- Eye and Face ProtectionDocumento2 pagineEye and Face ProtectionAbu LeoNessuna valutazione finora

- Final Major Project: ResearchDocumento31 pagineFinal Major Project: ResearchevefisherNessuna valutazione finora

- Robe of PeaceDocumento2 pagineRobe of PeaceJahongirYunusovNessuna valutazione finora

- Fall 13 Horny Toad Workbook - Women's Collection: Part 2Documento10 pagineFall 13 Horny Toad Workbook - Women's Collection: Part 2HornyToadClothingNessuna valutazione finora

- Biology ProjectDocumento10 pagineBiology ProjectGaby UtraNessuna valutazione finora

- Harold GUIDELINES FOR THE 2023 LGU UNIFORMDocumento1 paginaHarold GUIDELINES FOR THE 2023 LGU UNIFORMHarold AponestoNessuna valutazione finora

- HANDMADE High ResolutionDocumento92 pagineHANDMADE High Resolutiondan6861Nessuna valutazione finora

- Daily Express 2011.04.30Documento104 pagineDaily Express 2011.04.30Ник ЧенNessuna valutazione finora

- Lista de Precios Por Uso-2023-SportsDocumento1 paginaLista de Precios Por Uso-2023-SportsMichelle SanchezNessuna valutazione finora

- The Chronicle of FroissartDocumento512 pagineThe Chronicle of FroissartSalvador Miquelet100% (1)

- Denim: Shahrukh ShahbazDocumento22 pagineDenim: Shahrukh ShahbazShahrukhNessuna valutazione finora

- Fragancia Fabricante Genero Tipo ML: PrecioDocumento22 pagineFragancia Fabricante Genero Tipo ML: PrecioAFERNessuna valutazione finora

- Jewellery VendorsDocumento55 pagineJewellery VendorsSatvinder Deep SinghNessuna valutazione finora

- Reps Haul SpreadsheetDocumento12 pagineReps Haul SpreadsheetImran FetahovicNessuna valutazione finora

- International Marketing of Khadi Project Report - Collegeprojects1.Blogspot - inDocumento21 pagineInternational Marketing of Khadi Project Report - Collegeprojects1.Blogspot - inHarsh SavlaNessuna valutazione finora

- Costume Designing For Hollywood and Bollywood: January 2015Documento21 pagineCostume Designing For Hollywood and Bollywood: January 2015Leidy Dayana Del PortilloNessuna valutazione finora

- Essential Stitches and SeamsDocumento48 pagineEssential Stitches and SeamsPal Bowler100% (1)

- Lessons 10A DDocumento9 pagineLessons 10A DFrankNorbethAlfaroBermudezNessuna valutazione finora

- Harley Davidson Fall CatalogDocumento17 pagineHarley Davidson Fall CatalogAmplified LocalNessuna valutazione finora

- MojarisDocumento40 pagineMojarisDeepak NadarNessuna valutazione finora

- FC 1Documento2 pagineFC 1Suramya SoodNessuna valutazione finora

- 20 Odd JobsDocumento23 pagine20 Odd JobsLuis CamposNessuna valutazione finora

- Verbele in EnglezaDocumento7 pagineVerbele in EnglezaAllexa AlexandraNessuna valutazione finora

- Etro RTW Ss21Documento60 pagineEtro RTW Ss21luz pulidoNessuna valutazione finora

- Uniform & Supplies InquiryDocumento3 pagineUniform & Supplies InquiryIngyinn HlaingNessuna valutazione finora

- Design Innovation by Japanese Designers PDFDocumento6 pagineDesign Innovation by Japanese Designers PDFIvona SpasovskaNessuna valutazione finora

- Victorian AgeDocumento13 pagineVictorian AgeAzhelNessuna valutazione finora

- Sorce: New English File Pre-Intermediate, Oxford University PressDocumento20 pagineSorce: New English File Pre-Intermediate, Oxford University Presspham giahuyNessuna valutazione finora

- EF Preintermediate WordlistDocumento24 pagineEF Preintermediate WordlistBalzaquiana BáquicaNessuna valutazione finora

- History of Fashion 1900-2000 Timeline - Timetoast TimelinesDocumento2 pagineHistory of Fashion 1900-2000 Timeline - Timetoast TimelinesZa-c Pelangi SenjaNessuna valutazione finora