Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Project Profiles For Small Enterprises - Mechanical Products-Ch23

Caricato da

ProfNDAcharya0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

23 visualizzazioni4 pagineProject Profiles For Small Enterprises - Mechanical Products-ch23

Titolo originale

Project Profiles For Small Enterprises - Mechanical Products-ch23

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoProject Profiles For Small Enterprises - Mechanical Products-ch23

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

23 visualizzazioni4 pagineProject Profiles For Small Enterprises - Mechanical Products-Ch23

Caricato da

ProfNDAcharyaProject Profiles For Small Enterprises - Mechanical Products-ch23

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 4

INTRODUCTION

Welded wire mesh is the latest

development in land wire product

industry. The welded wire, generally

called reinforcing wire, is mostly used

i n cement concr et e wor k f or

construction of buildings, National

Highway pavements, runways, dams,

ai rport s et c. I t i s al so used f or

fencing purposes and for partition

wal l s and as a saf et y guar d i n

engineering workshops.

MARKET POTENTIAL

Wel ded wi r e mesh i s used

extensively in constructional work

and fencing purposes. The wire mesh

i s made by aut omat i c wel di ng

process, thus saving a lot of human

labour and achieving uniformity in

distance and quality.

Welded Wire Mesh

PRODUCT CODE : 349910014

QUALITY AND STANDARDS : As per customers specifications.

PRODUCTION CAPACITY : Qty. : 3384 MT (per annum)

Value : Rs. 456.84 Lakhs

MONTH AND YEAR : January, 2003

OF PREPARATION

PREPARED BY : Small Industries Service Institute

New Colony,

Rayagada 765 001

(Orissa)

Phone No. : (06856) 222268

BASIS AND PRESUMPTIONS

1. The project profile has been

prepared on the basis of two

shifts per day of 8 hours duration

each having 300 working days

per year.

2. The capacity utilisation is

assumed as 75% for the first year

and 100% onwards.

3. Promoters contribution towards

margin money is taken as nil.

4. Interest is calculated both on fixed

and working capital at a simple

rate of 16%.

5. Rate of machinery and

equipments, raw material and

other items is based upon the

prices prevailing at the time of

preparation of the project.

6. Break-even point is calculated at

100% capacity utilisation.

23

118

IMPLEMENTATION SCHEDULE

Sl.No. Activity Period

1. Preparation of Project Report:

(a) Calling quotations 4 weeks

(b) Preparation 2 weeks

2. Provisional Registration 1 week

as SSI

3. Financial arrangement 12 weeks

with financial institutions

and others

4. Purchase and procurement 8 weeks

of machinery and equipment

5. Erection and electrification 3 weeks

6. Recruitment of personnel 4 weeks

Some activities shown above can be

undertaken simultaneously in order to

minimise the period.

TECHNICAL ASPECTS

Process of Manufacture

6 to 20 wires depending on the type

of mesh are fed horizontally, parallel to

one another over rollers to the machine.

Distance between these wires is as per

design. From the machine, a cross wire

overtapping the parallel wires is fed and

all the joints are electrically welded. The

rollers move the parallel wires further

and another cross wire comes in at

specified distance. The process goes on,

to give a wire mesh of desired

specification. The welded wire mesh is

pulled out for making rolls.

Quality Control and Standards

As the product is being processed in

an automatic welding machine, the

quality raw material of M.S. wire or G. I.

wire of standard gauges is to be used to

keep the production schedule of the

machine. The proper maintenance of

machine is necessary from time to time.

Production is done according to

specifications given by the customer.

Production Capacity (per annum)

Quantity : 3384 Mt.

Value : Rs. 507.60 Lakhs

Pollution Control

The level of pollution in this type of

industry is minimal. However,

permission and guidance from State

Pollution Control Board is to be sought

to meet its requirements.

FINANCIAL ASPECTS

A. Fixed Capital

(i) Land And Building (In Rs.)

(i) Land 1000 sq. mtrs. @ Rs. 150 per 1,50,000

sq. mtr including registration.

(ii) Cost of land development, fencing, 1,50,000

approach road, inside roads, land

scaping, drainage etc. @ Rs. 150/

sq. mtr.

(iii) Total built-up area would be 700

sq. mtrs. as follows:

Administrative building 100 sq.mtrs. 2,50,000

construction cost Rs. 2500 persq. mtr.

Factory shed 450 sq. mtr. 6,75,000

construction cost @ Rs. 1500 per sq. mtr.

Stores and staff canteen etc. 150 3,00,000

sq. mtrs @ Rs. 2000 per sq. mtr.

Total 15,25,000

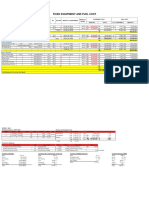

(ii) Machinery and Equipment

Sl. Description Qty. Amount

No. (In Rs.)

1. Semi-automatic wire mesh 1 19,70,000

Welder model WMW 1800

suitable for manufacturing

wire meshes having a width

of 6 feet with different sizes

and wire diameters varying

from 2 mm to 5.6 mm (pre-

straightened and cut to length)

complete with solid state synchr-

onous IC controller, thyristor

WELDED WIRE MESH

119

Sl. Description Qty. Amount

No. (In Rs.)

panel, 6 Nos. of water cooled

encapsulated transformers,

each having rating 100 KVA

at 50% duty cycle holder

assemblies and automatic

cross wire feeder mechanism.

The machine is suitable for

connecting 400/440 Volts,

2 line of a 3 phase 50 HZ

2. Weld mesh cutting machine 1 97,500

suitable for 8 mm dia rod

x 9' length with 10HP motor

3. Wire cutting and straightening 1 28,600

machine upto 8 mm dia

with 7.5 HP motor

4. Air compressor with 3 HP 1 11,700

motor 200 ltr. tank capacity

5. Wolf make portable hand 6" 1 2,500

grinder wheel dia

6. Wire but welding machine 1 14,300

6 KVA

7. Installation and line fitting. - 26,000

8. Step down transformer 250 KVA 1 1,82,000

9. Furniture and office equipment - 15,600

Total 23,48,200

(iii) Pre-operative Expenses - 13,000

Total Fixed Capital (i+ii+iii) 23,61,200

B. Working Capital (per month)

(i) Personnel

Sl. Designation Nos. Salary Total

No. (Rs.) (In Rs.)

1. General Manager 1 12,000 12,000

2. Production/ 1 7,250 7,250

Maintenance

Supervisor

3. Sales Supervisor 1 7,000 7,000

4. Skilled Workers 4 4,500 18,000

5. Un-skilled Workers 3 2,700 8,100

6. Helpers 3 1,800 5,400

7. Accountant 1 5,000 5,000

8. Clerk/Typist 1 3,000 3,000

9. Peon 1 2,500 2,500

10. Watchman 1 2,500 2,500

Total 70,750

Add Perquisites @ 20% 14,150

Total 84,900

Say 85,000

(ii) Raw Materials (In Rs.)

M.S. Wire coil 2 mm to 5.6 mm dia

300 MT @ Rs. 11,000 per MT 33,00,000

(iii) Utilities (In Rs.)

1. Electricity charge 27,000

2. Water charge 1,000

Total 28,000

( i v) Other Contingent Expenses (In Rs.)

1. Postage, stationery and other 5,000

office services

2. Consumable stores, tools, repair and 10,000

maintenance

3. Transport and conveyance 20,000

4. Advertisement and sales promotion 5,000

5. Wire conversion charge (drawing) 30,000

6. Insurance 1,000

7. Miscellaneous expenses 4,000

Total 75,000

( v) Total Recurring Expenditure (per month) (Rs.)

1. Personnel 85,000

2. Raw material 33,00,000

3. Utilities 28,000

4. Other Contingent expenses 75,000

Total 34,88,000

Working capital is considered on an

average cycle of 1 months = Rs. 52,32,000

Hence, Working Capital = 1 months of recurring

expenses

C. Total Capital Investment

(i) Fixed Capital Rs. 38,86,200

(ii) Working Capital Rs. 52,32,000

Total Rs. 91,18,200

FINANCIAL ANALYSIS

(1) Cost of Production (per year) (In Rs.)

Total recurring expenditure 4,18,56,000

Depreciation on Building @ 5% 76,250

Depreciation on Machinery and 2,36,120

equipment @ 10%

Depreciation on office equipments @ 25% 3,900

WELDED WIRE MESH

120

(6) Break-even Point

Fixed Cost (per annum) (In Rs.)

1. Depreciation on building, machinery 2,37,680

equipment and office equipments

2. Insurance 12,000

3. Interest on total investment 14,58,900

4. 40% of salary and wages 33,600

5. 40% of other contingent expenses 30,000

excluding insurance

Total 17,72,180

B.E.P.

=

Fixed Cost 100

Fixed Cost + Profit

=

17,72,180 100

17,72,180+20,53,000

= 46.3%

Addresses of Machinery Supplier

1. M/s. Jaya Hind Sciaky Ltd.

D-1 Block,

Plot No. 18/1,

Chinchwad,

Pune - 411 019

Phone Nos. 7475579

7475089 (Purchase)

7475088 (Sales)

WELDED WIRE MESH

(1) Cost of Production (per year) (In Rs.)

Interest on total capital investment 14,58,900

Total 4,36,31,170

Say 4,36,31,000

(2) Turnover (per year) (In Rs.)

By sale of welded wire mesh 2-6mm 5,07,60,000

dia of cross and line wire of different

size 3384 MT @ Rs. 15,000/MT

Trade Commission @ 10% (-) 50,76,000

Total 4,56,84,000

(3) Net Profit (per year) (Before Income Tax)

Turnover Cost of Production

Rs. 4,56,84,000 Rs. 4,36,31,000

= Rs. 20,53,000

(4) Net Profit Ratio

=

Net Profit per year 100

Turnover per year

=

20,53,000 100

4,56,84,000

= 4.5%

(5) Rate of Return

=

Net Profit per year 100

Total Investment

=

20,53,000 100

91,18,200

= 22.5%

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- 2012 CE404 Quiz 1 Solution QDocumento5 pagine2012 CE404 Quiz 1 Solution QProfNDAcharyaNessuna valutazione finora

- Gujarat Technological University (Established Under Gujarat Act No. 20 of 2007)Documento1 paginaGujarat Technological University (Established Under Gujarat Act No. 20 of 2007)ProfNDAcharyaNessuna valutazione finora

- Public Health Engineering Organization: Tender Document For The WorkDocumento27 paginePublic Health Engineering Organization: Tender Document For The WorkProfNDAcharyaNessuna valutazione finora

- Hydraulic Structures - Course WebsiteDocumento10 pagineHydraulic Structures - Course WebsiteProfNDAcharyaNessuna valutazione finora

- Diversion Headworks: CEL351: Design of Hydraulic StructuresDocumento78 pagineDiversion Headworks: CEL351: Design of Hydraulic StructuresAlvaro Rodrigo Chavez Viveros100% (1)

- Is 6531 1994Documento16 pagineIs 6531 1994ProfNDAcharyaNessuna valutazione finora

- Hydraulic Structures - 2Documento34 pagineHydraulic Structures - 2Manmohit SinghNessuna valutazione finora

- Project Profiles For Small Enterprises - Mechanical Products-Ch25Documento6 pagineProject Profiles For Small Enterprises - Mechanical Products-Ch25ProfNDAcharyaNessuna valutazione finora

- CH 17Documento7 pagineCH 17ProfNDAcharyaNessuna valutazione finora

- Irrigation Structures - 1Documento13 pagineIrrigation Structures - 1lakumas15Nessuna valutazione finora

- 2.2 2.3 Hydraulic and Structure DesignDocumento144 pagine2.2 2.3 Hydraulic and Structure DesignSriram Nambi100% (1)

- Project Profiles For Small Enterprises - Mechanical Products PDFDocumento2 pagineProject Profiles For Small Enterprises - Mechanical Products PDFProfNDAcharyaNessuna valutazione finora

- 0838 Bhavnagar Port 2Documento1 pagina0838 Bhavnagar Port 2ProfNDAcharyaNessuna valutazione finora

- Barrages PresentationDocumento109 pagineBarrages PresentationFaisal RashidNessuna valutazione finora

- Project Profiles For Small Enterprises - Mechanical Products-ForewardDocumento2 pagineProject Profiles For Small Enterprises - Mechanical Products-ForewardProfNDAcharyaNessuna valutazione finora

- CH 22Documento5 pagineCH 22ProfNDAcharyaNessuna valutazione finora

- Project Profiles For Small Enterprises - Mechanical Products-Ch24Documento4 pagineProject Profiles For Small Enterprises - Mechanical Products-Ch24ProfNDAcharyaNessuna valutazione finora

- Offset Printing Press (Job Work) : NtroductionDocumento4 pagineOffset Printing Press (Job Work) : NtroductionMMjagpreetNessuna valutazione finora

- CH 21Documento5 pagineCH 21ProfNDAcharyaNessuna valutazione finora

- CH 15Documento4 pagineCH 15ProfNDAcharyaNessuna valutazione finora

- Bolt Nuts MFG ProcessDocumento5 pagineBolt Nuts MFG ProcessscribddaduNessuna valutazione finora

- CH 20Documento5 pagineCH 20ProfNDAcharyaNessuna valutazione finora

- CH 16Documento4 pagineCH 16ProfNDAcharyaNessuna valutazione finora

- CH 11Documento7 pagineCH 11ProfNDAcharyaNessuna valutazione finora

- CH 9Documento5 pagineCH 9ProfNDAcharyaNessuna valutazione finora

- Domestic Pressure Cookers: NtroductionDocumento5 pagineDomestic Pressure Cookers: NtroductionKumar PhanishwarNessuna valutazione finora

- CH 13Documento6 pagineCH 13ProfNDAcharyaNessuna valutazione finora

- CH 12Documento4 pagineCH 12Vijay KiranNessuna valutazione finora

- CH 10Documento5 pagineCH 10ProfNDAcharyaNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- CHE655 - Plant Design Project #5 Summer 2010 Design of An Ehtyl Benzene Production ProcessDocumento13 pagineCHE655 - Plant Design Project #5 Summer 2010 Design of An Ehtyl Benzene Production ProcessAyşe ÖztürkNessuna valutazione finora

- Quote US105785Documento4 pagineQuote US105785Yamydal Bog-aconNessuna valutazione finora

- Invoice: Cliche Mode, IncDocumento1 paginaInvoice: Cliche Mode, IncShiro Daisuke XzeroNessuna valutazione finora

- DTDW On Wood Craft AKR Ranchi 2014Documento90 pagineDTDW On Wood Craft AKR Ranchi 2014magadhishilpi100% (1)

- Presentation On Nutmeg Oil For IPB NOV 2022Documento34 paginePresentation On Nutmeg Oil For IPB NOV 2022KushDaiwikNessuna valutazione finora

- Hapag-Lloyd Aktiengesellschaft, Hamburg: Multimodal Transport or Port To Port ShipmentDocumento3 pagineHapag-Lloyd Aktiengesellschaft, Hamburg: Multimodal Transport or Port To Port ShipmentMahmod MohammedNessuna valutazione finora

- Akmen 5 QuizDocumento5 pagineAkmen 5 QuizNabilah AdediaNessuna valutazione finora

- Tutorial Letter 202/1/2017: Distinctive Financial ReportingDocumento6 pagineTutorial Letter 202/1/2017: Distinctive Financial ReportingItumeleng KekanaNessuna valutazione finora

- Example de CV Union EuropeenneDocumento4 pagineExample de CV Union EuropeenneJean Wesley ThosiacNessuna valutazione finora

- Bangladesh: Rising Star of Asia?Documento18 pagineBangladesh: Rising Star of Asia?taiteelNessuna valutazione finora

- Classification of IndustriesDocumento7 pagineClassification of IndustriesJeet ShahNessuna valutazione finora

- Study Guide August 2020Documento31 pagineStudy Guide August 2020Darren KhewNessuna valutazione finora

- Budget Operation Agm-Mje 1 Fleet 2 BargeDocumento6 pagineBudget Operation Agm-Mje 1 Fleet 2 BargeAchmad DjunaidiNessuna valutazione finora

- Citizen's Charter: Metro Cotabato Water DistrictDocumento44 pagineCitizen's Charter: Metro Cotabato Water DistrictMaddie SyNessuna valutazione finora

- Materi Webinar SA 500 Bukti Audit - Audit Berbasis ISA Studi Kasus Di Indonesia, Australia, Dan SingapuraDocumento37 pagineMateri Webinar SA 500 Bukti Audit - Audit Berbasis ISA Studi Kasus Di Indonesia, Australia, Dan SingapuraIkhsan Uiandra Putra SitorusNessuna valutazione finora

- Safe Self RelianceDocumento1.029 pagineSafe Self RelianceTheNatureDoctorNessuna valutazione finora

- CBRE Market Insight Q1 2017 AmCham enDocumento49 pagineCBRE Market Insight Q1 2017 AmCham enMai HuynhNessuna valutazione finora

- Bezaktiv Application en WEBDocumento40 pagineBezaktiv Application en WEB宋德欽Nessuna valutazione finora

- MGT 504 - MidtermDocumento12 pagineMGT 504 - MidtermhamzaNessuna valutazione finora

- Harvey Metabank Jan22Documento1 paginaHarvey Metabank Jan22Mark Dewey0% (1)

- Microeconomics Australia in The Global Environment Australian 1st Edition Parkin Solutions ManualDocumento17 pagineMicroeconomics Australia in The Global Environment Australian 1st Edition Parkin Solutions Manualdetectchittrahjgn100% (20)

- SQ00001544 SICIM RFQ SA010-MR-005 REV.A MANUAL BALL VALVES - UnpricedDocumento4 pagineSQ00001544 SICIM RFQ SA010-MR-005 REV.A MANUAL BALL VALVES - UnpricedMohamed Wasim ShaikhNessuna valutazione finora

- 12th Economics Model Unit Test - 02Documento5 pagine12th Economics Model Unit Test - 02Raaja YoganNessuna valutazione finora

- Ucsp Worksheet Q2 W1 FinalDocumento8 pagineUcsp Worksheet Q2 W1 FinalCHRISTIAN DAVED BARROZONessuna valutazione finora

- Rexa Uni CatalogDocumento18 pagineRexa Uni CatalogLupu AlinNessuna valutazione finora

- 01 Activity 1Documento1 pagina01 Activity 1Monaliza PepitoNessuna valutazione finora

- Gold Is Money - Sennholz, HDocumento214 pagineGold Is Money - Sennholz, HBozhidar Malamov PetrovNessuna valutazione finora

- Term I Practice Examination-2021-22 Class: X Max - Marks: 40 Sub: English Time: 90 Minutes General InstructionsDocumento16 pagineTerm I Practice Examination-2021-22 Class: X Max - Marks: 40 Sub: English Time: 90 Minutes General InstructionsMallipudi SphoorthiNessuna valutazione finora

- MAC (Misdirected Directive Case Analysis)Documento3 pagineMAC (Misdirected Directive Case Analysis)Prasad GowdNessuna valutazione finora

- Aur020508176724 Soa BlyDocumento5 pagineAur020508176724 Soa Blyganga.ram208Nessuna valutazione finora