Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

20130424

Caricato da

Hamza Nouman0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

20 visualizzazioni1 paginasafety beacon

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentosafety beacon

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

20 visualizzazioni1 pagina20130424

Caricato da

Hamza Noumansafety beacon

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

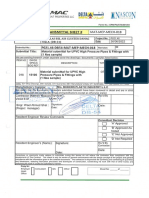

Messages for Manufacturing Personnel

http://www.aiche.org/CCPS/Publications/Beacon/index.aspx April 2013

24 www.aiche.org/cep April 2013 CEP

This Issue Sponsored by

www.iomosaic.com

Circle 103 on p. 71 for a free electronic subscription to the Beacon.

The Beacon is usually available in Afrikaans, Arabic, Czech, Chinese, Danish, Dutch, English, French, German, Greek, Gujarati, Hebrew, Hungarian, Italian,

Japanese, Korean, Malay, Marathi, Norwegian, Persian, Polish, Portuguese, Romanian, Russian, Spanish, Swedish, Telugu, Thai, Turkish, and Vietnamese.

AIChE 2013. All rights reserved. Reproduction for non-commercial, educational purposes is encouraged. However, reproduction for the purpose of

resale by anyone other than CCPS is strictly prohibited. Contact us at ccps_beacon@aiche.org or 646-495-1371.

I

n the November 2012 Beacon, many readers correctly

identifed one safety issue with the relief valve in Figure 1:

The block valve does not appear to have anything to prevent

someone from closing it, which would isolate the relief valve

so it could not provide protection against excess pressure. A

second possible problem, a piping system that may cause

the relief valve to chatter, was not identifed by nearly as

many people.

What is chattering?

Chattering is the rapid opening and closing of a pressure-

relief valve. The resulting vibration may cause misalignment,

valve seat damage, and, if prolonged, mechanical failure of

valve internals and associated piping.

Why does a relief valve chatter?

Some causes of chattering include: excessive inlet pres-

sure drop; excessive backpressure; an oversized relief valve;

and a relief valve that must handle widely varying fowrates.

We will explain the frst of these in more detail.

Under normal process conditions, the vessel pressure is

below the set pressure of the relief valve, and the pressure at

the relief valve is the same as the vessel pressure (Figure 2a).

If a process upset increases the vessel pressure, the pressure

at the relief valve increases by the same amount, and if the

pressure exceeds the relief valve set pressure, the valve opens

(Figure 2b). As soon as the valve opens, fow begins through

the pipe to the relief valve, and the fow results in a pressure

drop between the vessel and the valve. If this pressure drop

is large enough, the pressure at the relief valve can be low

enough that the relief valve closes (Figure 2c). The fow stops,

the pressure at the relief valve increases back to the vessel

pressure because there is no fow to cause pressure drop, and

the relief valve opens again (Figure 2d). This happens over

and over, and can be very rapid, causing vibration and dam-

age to the relief valve, pipes, and equipment.

Have You Heard a Pressure-Relief Valve Chatter?

If you observe a relief valve chattering, inform someone who is qualifed to

identify and correct the problem.

Look for potential problems in relief-valve piping design that could cause relief

valve chattering, such as:

w An inlet pipe to a relief valve that is smaller than the valve inlet (see Figure 3).

w Many valves, fttings, and other obstructions between a process vessel and a

relief valve, as in Figure 1.

w A very long pipe between a vessel and relief valve, or piping with a lot of

bends.

w Evidence of line plugging from corrosion or process materials observed when

removing a relief valve for maintenance.

What Can You Do?

Dont let your relief valves chatter!

c d

a b

Pipe smaller than

relief valve inlet

Figure 1 Figure 2

Figure 3

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- CV Hamza wORKSHOP eNGINEERDocumento3 pagineCV Hamza wORKSHOP eNGINEERHamza NoumanNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Direction On How To Replace A Fuel Filter.Documento5 pagineDirection On How To Replace A Fuel Filter.Hamza NoumanNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Replacing An Engine Drive BeltDocumento5 pagineReplacing An Engine Drive BeltHamza NoumanNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Quality Plan For WorkshopDocumento1 paginaQuality Plan For WorkshopHamza NoumanNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- List of Workshop Machines, 2011 RevisedDocumento3 pagineList of Workshop Machines, 2011 RevisedHamza Nouman100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Scaffolding: "It's Big, It's Ugly, It's There,"Documento2 pagineScaffolding: "It's Big, It's Ugly, It's There,"Hamza NoumanNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- List of Documetns, Rev-2, 29-09-2012Documento4 pagineList of Documetns, Rev-2, 29-09-2012Hamza NoumanNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- ER-Format (Version 1)Documento1 paginaER-Format (Version 1)Hamza NoumanNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Scaffold 2Documento2 pagineScaffold 2Hamza NoumanNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Guidelines For Access ScaffoldingDocumento28 pagineGuidelines For Access ScaffoldingHamza Nouman100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Muhammad Rehan Khan Maintenance EngineerDocumento13 pagineMuhammad Rehan Khan Maintenance EngineerHamza NoumanNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- GRG-WP-IMS-005 Derating of Cranes Dump Truck (Updated)Documento5 pagineGRG-WP-IMS-005 Derating of Cranes Dump Truck (Updated)Hamza NoumanNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

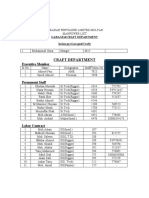

- Craft Department: Executive MemberDocumento2 pagineCraft Department: Executive MemberHamza NoumanNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Chlorine Bromine 320 Installation GuideDocumento6 pagineChlorine Bromine 320 Installation GuideCJ10aNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Different Types of Tubing Used in Heating Domrac UnitsDocumento10 pagineDifferent Types of Tubing Used in Heating Domrac UnitsLinard MalubayNessuna valutazione finora

- Type U' Bops: Shear Bonnet IdentificationDocumento4 pagineType U' Bops: Shear Bonnet IdentificationJeneesh ShanmughanNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- ECS 3-0-0 - 2 - 800869e9Documento5 pagineECS 3-0-0 - 2 - 800869e9Florin Daniel AnghelNessuna valutazione finora

- Super Duplex Steel s32750 Flanges SuppliersDocumento3 pagineSuper Duplex Steel s32750 Flanges SuppliersRajtilak MetalNessuna valutazione finora

- Construction SpecificationDocumento4 pagineConstruction Specificationradha krishnanNessuna valutazione finora

- Plumbing Venting Brochure 2018Documento20 paginePlumbing Venting Brochure 2018Alexandra Bantegui100% (2)

- Sanitary Drainage SystemsDocumento21 pagineSanitary Drainage Systemspepito manalotoNessuna valutazione finora

- Basics - Hydraulics SystemDocumento31 pagineBasics - Hydraulics SystemMuhammad FirdhausNessuna valutazione finora

- RadiatorFactoryVol1 New9Documento53 pagineRadiatorFactoryVol1 New9seanmeehan145Nessuna valutazione finora

- Plumbing System - Jetty Control Building - Calculation ReportDocumento8 paginePlumbing System - Jetty Control Building - Calculation ReportDaniel NjokuNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Care Maintenance (Company Profile 2023)Documento21 pagineCare Maintenance (Company Profile 2023)Hr Saad Al KaabiNessuna valutazione finora

- Piping Isometric ChecklistDocumento21 paginePiping Isometric ChecklistNguyen Anh Tung50% (2)

- Kuliah 4 Dan 5 Internal Incompressible Viscous FlowDocumento66 pagineKuliah 4 Dan 5 Internal Incompressible Viscous FlowPrayudha Naufal WijayaNessuna valutazione finora

- Dis 15Documento8 pagineDis 15IranthaMuthuNessuna valutazione finora

- E Pipe & Fittings With SampleDocumento138 pagineE Pipe & Fittings With Samplep4p7 projectsNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- CEO-Certificate of Completion-Plumbing-editedDocumento1 paginaCEO-Certificate of Completion-Plumbing-editedEdward PagayonaNessuna valutazione finora

- Hydraulic Schematic T2556 (S/N A8FR11001 AND ABOVE) T2566 (S/N A8G311001 AND ABOVE)Documento3 pagineHydraulic Schematic T2556 (S/N A8FR11001 AND ABOVE) T2566 (S/N A8G311001 AND ABOVE)Manuel Carvallo100% (3)

- Arrestor ListDocumento4 pagineArrestor ListHassan GDOURANessuna valutazione finora

- Particle SizeDocumento3 pagineParticle SizeGlyra RosalemNessuna valutazione finora

- Technical Specifications: Asbuilt Plan of (1) One Storey Commercial Building W/ MezzanineDocumento8 pagineTechnical Specifications: Asbuilt Plan of (1) One Storey Commercial Building W/ MezzanineDrew GozarNessuna valutazione finora

- Water Hammer Analysis Using Caesar IIDocumento4 pagineWater Hammer Analysis Using Caesar IIramesh100% (1)

- CE-212: Fluid Mechanics-II Minor Loss Problems, Laminar Flow Entrance Condition and Velocity ProfileDocumento11 pagineCE-212: Fluid Mechanics-II Minor Loss Problems, Laminar Flow Entrance Condition and Velocity ProfileMashal Shah JehanNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hdpe Price List June 2021Documento12 pagineHdpe Price List June 2021Twins VenturesNessuna valutazione finora

- Vent Capacity Calculation Sheet Sankyo Frontier Factory: 1. Design CodeDocumento1 paginaVent Capacity Calculation Sheet Sankyo Frontier Factory: 1. Design CodehdtNessuna valutazione finora

- Flange Insulation Kit SISCO (SIZE) - 1Documento3 pagineFlange Insulation Kit SISCO (SIZE) - 1Aldi AQPANessuna valutazione finora

- Process Industry Practices PipingDocumento4 pagineProcess Industry Practices PipingjojonNessuna valutazione finora

- Expansion JointsDocumento4 pagineExpansion Jointsjeff501Nessuna valutazione finora

- Chiksan Piping On Oes TeamworkDocumento3 pagineChiksan Piping On Oes TeamworkChukwuma Emmanuel OnwufujuNessuna valutazione finora

- Samson CatalogDocumento170 pagineSamson CatalogFelipe SalvatierraNessuna valutazione finora