Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Success in Global Sourcing

Caricato da

dp89090 valutazioniIl 0% ha trovato utile questo documento (0 voti)

19 visualizzazioni3 pagineSourcing is a critical business capability that can reap significant revenue and profit growth. Supply professionals have a great opportunity to show their contribution to their organizations' bottom line. Making sure these questions are considered and then answered ensures that the organization's "shoring" move will be smooth and most advantageous.

Descrizione originale:

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoSourcing is a critical business capability that can reap significant revenue and profit growth. Supply professionals have a great opportunity to show their contribution to their organizations' bottom line. Making sure these questions are considered and then answered ensures that the organization's "shoring" move will be smooth and most advantageous.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

19 visualizzazioni3 pagineSuccess in Global Sourcing

Caricato da

dp8909Sourcing is a critical business capability that can reap significant revenue and profit growth. Supply professionals have a great opportunity to show their contribution to their organizations' bottom line. Making sure these questions are considered and then answered ensures that the organization's "shoring" move will be smooth and most advantageous.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 3

Success in Global Sourcing: Making

a List and Checking It Twice

by Marilyn Gettinger,

The ability to offshore, nearshore, onshore, or insource

(producing at the organizations own location) is a

critical business capability that can reap significant

revenue and profit growth or significant headaches.

Organizations today and in the future must be able to

purchase, ship, store, and manufacture goods at and

from various locations throughout the world based on

the lowest ultimate cost at any particular time. If an

organization is moving product from its own

manufacturing facility to a growing market, it may be

more cost-effective to produce and ship within that

market. Also, if a company has significant sales in a particular country or countries, purchasing

from or manufacturing in the area is a good business and public relations decision.

In order to make the correct global sourcing decision, the organization must be able to capture

all of the costs involved. Many organizations rapidly moved their production offshore to capture

the low wages of foreign factories only to find that logistics and importing costs more than offset

the wage savings.

Supply professionals have a great opportunity to show their contribution to their organizations

bottom line by asking the right questions before their organizations go global, move production

from one offshore location to another emerging country, or evaluate its current strategy. Making

sure these questions are considered and then answered ensures that the organizations

shoring move will be smooth and most advantageous.

Making a list and checking it twice include the following:

1. Is the cost of goods being used as the baseline for comparison an accurate number?

1. What is included in the cost of goods?

2. Are all direct labor, direct materials, overhead, and general and administrative

charges captured?

2. How will the organization handle overhead charges when the product is no longer

produced in the organizations manufacturing site? Will it increase overhead charges to

existing products?

3. How will the organization gain information on potential suppliers offshore or nearshore?

4. How will the organization perform the supplier selection process in an offshore or

nearshore situation? What will this pre-transaction activity cost?

5. What does the organization know about the business culture of the country?

6. What impact will the business culture of that country have on the cost of producing the

product?

7. How involved will the government of that country be in the buying or producing

organizations business? How will national and local government requirements add to

the cost of the product?

8. Will the foreign government expect the buying organization to use local suppliers for

materials or other countertrade demands?

9. Will there be employable people in the area to perform the necessary work? What

training will be necessary and the cost?

10. Will the buying organization need to make changes to the product or product

specifications to accommodate the offshore or nearshore manufacturer?

11. Will there be significant investment in developing a relationship prior to beginning the

business discussion? If so, what will this add to pre-transaction landed costs?

12. How much time and effort will be necessary in maintaining the business relationship

once established?

13. Will the buying organization need to provide tooling, molds, machinery, etc? If so, the

buying organization will need to declare this to customs as an Assist and include this in

its total landed cost estimate.

14. What is the logistics infrastructure of the country? How much pipeline or transportation

inventory will the buying organization need to hold to support delays due to

infrastructure challenges?

15. What is the lead time from the time an order is placed until the goods arrive at the

buyers backdoor? How much inventory safety stock will be needed to support this

cycle?

16. What law will govern the bill of sale?

17. What are the working conditions of the offshore or nearshore facility? What changes will

the buying organization need to request to support social responsibility factors such as

the environment, human rights, safety, and community?

18. Will the buying organization need to employ someone to oversee the quality of product

and the meeting of required standards?

19. How will the buying organization manage the move to an overseas market without

running out of inventory?

20. Who will oversee the offshore or near shore start-up and day-to-day management?

21. What marketplace factors will trigger the decision to move to a more cost-effective

location?

22. Did the organization check that the material, product, or component

1. Is allowed into the country of importation

2. Is allowed to be exported

3. Is allowed but must be registered with one or more government agencies

4. Is a product under a quota

5. Requires special marking and labeling

6. Requires country of origin marking and documentation

23. What International Commercial Term (Incoterm) has the buying organization selected?

Is the supplier clear on the exact interpretation of that Incoterm? What logistics costs

will the buyer incur?

24. What are all of the pre-lading requirements for a container prior to being loaded onto a

ship coming into the United States or into an offshore location?

25. What documents will be required and when and how will they be made available?

26. What certifications will be necessary such as The Lacey Act (wood in the product must

not be from endangered rain forests)?

27. What is the best port of entry that will minimize logistics costs?

28. What is the Harmonized Tariff Schedule for this material, product, or component? What

are the duties on the product?

29. Does the organization have the logistics expertise to manage international shipments or

does it need to source and select a freight forwarder?

30. Does the freight forwarder employ customs brokers or does the buying organization

need to source and select a customs broker?

31. Does the buying organization have an all-inclusive total landed cost model to determine

the true cost to manufacture, purchase, and move a material, product, or component

from an offshore or near shore location?

32. Finally, has the organization compared the offshore, near shore, or onshore total landed

costs to each other and to the original cost of producing the product in its own factory?

Going global, selecting the best shore, and managing the ongoing process is important to the

organizations bottom line. If an organization quotes delivery to its customers without a real

understanding of costs and effort, it may find that the pre-transaction, transaction, and post-

transaction costs of doing business globally have eliminated their profit margin and may also

force the organization into losing money.

Again, supply managers need to understand the global sourcing process, its costs, and its

challenges. Organizations need help in understanding the positive and negative impact of global

sourcing. Supply professionals should grab the opportunity.

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

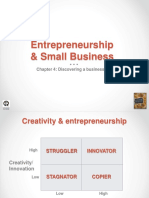

- Entrepreneurship & Small Business: Chapter 4: Discovering A Business IdeaDocumento42 pagineEntrepreneurship & Small Business: Chapter 4: Discovering A Business IdeaPooja SheoranNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Annual Report 2017 enDocumento202 pagineAnnual Report 2017 enkbalamuruganNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Green Supply Chain Management Initiatives by WallmartDocumento13 pagineGreen Supply Chain Management Initiatives by Wallmartkamal pipersaniyaNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Supply Chain Management - MGMT614: Supplier Relationship Management Rationale and LogicDocumento11 pagineSupply Chain Management - MGMT614: Supplier Relationship Management Rationale and LogicSyed Abdul Mussaver ShahNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Available To Promise (ATP) and The Scope of Check - SAP BlogsDocumento14 pagineAvailable To Promise (ATP) and The Scope of Check - SAP BlogsManibudh SankasemNessuna valutazione finora

- Global Freight & Transportation Management SystemsDocumento65 pagineGlobal Freight & Transportation Management SystemsGabriele LorussoNessuna valutazione finora

- Modular ArchitectureDocumento14 pagineModular ArchitectureAnuja JadhavNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Orange Line Open House PresentationDocumento61 pagineOrange Line Open House PresentationMetro Los AngelesNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Entrepreneurship PaperDocumento5 pagineEntrepreneurship PaperNuman ButtNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- CBPSDocumento30 pagineCBPSvanshcool714Nessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Manajemen LogistikDocumento68 pagineManajemen LogistikArief HadiNessuna valutazione finora

- Building Lean Fulfillment StreamsDocumento3 pagineBuilding Lean Fulfillment StreamsChet MarchwinskiNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Planning Engineer Asmaa Abdulrahman-3Documento5 paginePlanning Engineer Asmaa Abdulrahman-3nermeen shawkyNessuna valutazione finora

- Chartering and Shipping TermsDocumento76 pagineChartering and Shipping TermsOlivin100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Material Handling Air Cargo Automation: WWW - Als.aeroDocumento12 pagineMaterial Handling Air Cargo Automation: WWW - Als.aeroBudi IswahyudiNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- H&M - Case AnalysisDocumento17 pagineH&M - Case Analysiskirt diazNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Aportes Actividad 1Documento8 pagineAportes Actividad 1Ale ZapataNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- "TOP 10" Key Issues Principles in Logistic and Supply Chain Management and Apply To A Real World SituationDocumento11 pagine"TOP 10" Key Issues Principles in Logistic and Supply Chain Management and Apply To A Real World SituationPovenesan Krishnan100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Kockums Industrier Megaswing DUODocumento6 pagineKockums Industrier Megaswing DUOAnand Raj DoraisingamNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Defining and Understanding Service Chain ManagementDocumento18 pagineDefining and Understanding Service Chain ManagementAnonymous Jqasp3dl8gNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- SM9636 w21068666 06052023 DraftDocumento23 pagineSM9636 w21068666 06052023 DraftJorris NgNessuna valutazione finora

- Chapter 07: Warehouse Management Exercise 07-03: Warehouse Management-Procurefrom Plant ProcessDocumento20 pagineChapter 07: Warehouse Management Exercise 07-03: Warehouse Management-Procurefrom Plant ProcessToàn Vũ Đại0% (2)

- Import Export AssignmentDocumento13 pagineImport Export Assignmentpandey_hariom12Nessuna valutazione finora

- Quick Transport Profile PDFDocumento4 pagineQuick Transport Profile PDFJaveed TajiNessuna valutazione finora

- Port and Logistics Supply ChainsDocumento21 paginePort and Logistics Supply Chainsboi yo100% (1)

- 000 V IMP Procurement 4.0 Factors Influencing PDFDocumento20 pagine000 V IMP Procurement 4.0 Factors Influencing PDFsalauddin.dhk6397Nessuna valutazione finora

- Avinash Singh: Most Proud of ExperienceDocumento2 pagineAvinash Singh: Most Proud of ExperienceAvinash SinghNessuna valutazione finora

- Cost Accounting - GuerreroDocumento18 pagineCost Accounting - GuerreroRose Ann De Guzman43% (7)

- Data Transfer For Batches in ERP and EWM - SAP DocumentationDocumento5 pagineData Transfer For Batches in ERP and EWM - SAP Documentationlostrider_991Nessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- McDonald's SCM (Report)Documento17 pagineMcDonald's SCM (Report)Maria Kerawala100% (2)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)