Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ECARO-25 Agent Storage Containers

Caricato da

ridipisaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ECARO-25 Agent Storage Containers

Caricato da

ridipisaCopyright:

Formati disponibili

ECARO-25

TM

AGENT STORAGE CONTAI NERS

DESCRI PTI ON

Fike Series 70 Clean Agent Containers are used in fire extinguishing systems to store the

Clean Agent until a fire develops and the agent must be released. The Clean Agent is

retained in the container by a valve assembly which contains a fast-acting rupture disc.

The disc will be ruptured, and the Clean Agent released, through the operation of an

actuator by an electric signal that is automatically or manually controlled. The valve is

available in three sizes: 1" (25mm), 2 1/2" (65mm) and 3" (80mm). The 1" (25mm) valve

is used on the 10 (4), 20 (8), 35 (15), 60 (27), and 100 pound (44 L) containers; the 2

1/2" (65mm) valve is used on the 125i (51 L) and 215i pound (90 L) containers; the 3"

(80mm) valve is used on the 215 (87), 375 (153), 650 (267) and 1000 pound (423 L)

containers. After a discharge, the valve is field reconditioned by simply replacing three

components.

Fike Series 70 Clean Agent Containers have passed extensive testing by Factory Mutual

and Underwriters Laboratory and are used in installations where 4 to 836 pounds (2.0 to

379.5 kg) of HFC-125 agent is required. To eliminate the need for multiple containers,

or using more Clean Agent than necessary, these containers can be filled in 1 pound (0.5

kg) increments to their maximum capacity.

Each container for ECARO-25 Clean Agent Systems is super pressurized with dry

nitrogen to 360 psig (25 bar), at 70 F (21 C), to provide a quick and effective discharge

in 10 seconds or less.

Fike Series 70 Clean Agent Containers are supplied with a pressure gauge that permits a

quick, visual, inspection of container pressure. Optional items include a Liquid Level

Indicator, and a Low Pressure Supervisory Switch. The Liquid Level indicator provides

the convenience of determining the container's agent weight without removing it from

its installed location. The Low Pressure Supervisory Switch provides constant

monitoring of the container's internal pressure, and can be either normally opened or

normally closed. In the event of a decrease in container internal pressure from 360 psig

to 288 psig (24.8 bar to 18.8 bar), the Supervisory Switch normally opened/closed

contacts will close/open. This will cause a supervisory trouble alarm at the system

control panel.

Fike Series 70 Clean Agent Containers are available for installation in the upright,

inverted or horizontal positions, depending upon the user's particular needs and the type

and size container specified. The mounting location of the container is quite flexible. It

can be mounted at the exact point of discharge or at a remote location by adding

distribution piping from the container to the nozzle system. (Refer to the Fike Design,

Installation and Maintenance Manual - P/N 06-285).

The operating temperature range is +32

to +120

F (0

to 49.0

C) in any installation. If

the Clean Agent reaches an internal temperature range of 130 to 150F (49.9 to

65.5), it will create a sufficient internal pressure to burst the rupture disc and release the

Clean Agent through the piping network.

704 S. 10th Street P.O. Box 610 Blue Springs, Missouri 64013-0610 U.S.A. (816) 229-3405 (816) 229-4615 www.fike.com

APPROVALS

UL Listed - Ex 4623

FM Approved - 3014476

Form# C.1.41.01-2

FIKE P/N SIZE (LB) VALVE (IN)

EMPTY WT

(LB)

HFC-125

AGENT FILL

RANGE(LBS)

VALVE

POSITION

D.O.T.

REGULATION

70-108 10 1 14 4-8 Horiz. or Upright 4B500

70-098 20 1 35 8-16 Horiz. or Upright 4B500

70-089 35 1 55 14-30 Horiz. or Upright 4B500

70-152 60 1 53 25-54 Horiz. or Upright 4BW500

70-153 100 1 60 39-87 Upright 4BW500

70-041 125i 2 1/2 180 46-101 Inverted 4BA500

70-077 215i 2 1/2 225 80-178 Inverted 4BA500

70-154 215 3 150 78-173 Upright 4BW500

70-155 375 3 218 136-302 Upright 4BW500

70-156 650 3 350 236-528 Upright 4BW500

70-157 1000 3 515 374-836 Upright 4BW500

Cl ean Agent St or age Cont ai ner Dat a - Met r i c

FIKE P/N SIZE (L) VALVE (MM)

EMPTY WT

(KG)

HFC-125

AGENT FILL

RANGE (KG)

VALVE

POSITION

D.O.T.

REGULATION

70-108 4 25 6.4 2.0-3.5 Horiz. or Upright 4B500

70-098 8 25 16.0 3.5-7.5 Horiz. or Upright 4B500

70-089 15 25 25.0 6.5-13.5 Horiz. or Upright 4B500

70-152 27 25 24.0 11.5-24.5 Horiz. or Upright 4BW500

70-153 44 25 27.0 18.0-39.0 Upright 4BW500

70-041 51 65 82.0 21.0-46.0 Inverted 4BA500

70-077 90 65 103.0 36.5-81.0 Inverted 4BA500

70-154 87 80 68.0 35.5-78.5 Upright 4BW500

70-155 153 80 99.0 61.5-137.0 Upright 4BW500

70-156 267 80 159.0 107.0-239.5 Upright 4BW500

70-157 423 80 234.0 169.5-379.5 Upright 4BW500

DESCRI PTI ON (c ont .)

Rel i abi l i t y

Fike Series 70 Clean Agent Containers are manufactured in strict accordance with Department of Transportation (D.O.T.)

regulations. The Fike Series 70 Clean Agent Containers have successfully passed testing by Factory Mutual and Underwriters

Laboratories, Inc. Before leaving the factory, each container must pass extensive leakage testing, and pressure testing to 1000 psig

(69 bar). The containers are constructed from carbon steel alloys and painted with a durable, baked enamel finish.

I nst al l at i on

Fike Series 70 Clean Agent Containers are supplied with a mounting bracket that is designed to provide the most effective and

versatile installation for that particular container. The 10, 20 and 35 pound (4, 8 and 15 L) container brackets employ two U-bolts

for securing the container to the bracket. The 60 pound (27 L) container is secured using two quick connecting, over-center handle

clamps. The 125i and 215i pound (51 and 90 L) containers utilize an "L" shaped bracket for direct wall mounting or, with an

optional floor mounting kit, can be mounted on a floor in the "valve down" position. The 100 (44) and 215 (87) through 1000

pound (423 L) containers are supplied with one or two U-shaped mounting brackets, depending upon container size, for mounting

to a wall or other secure surface.

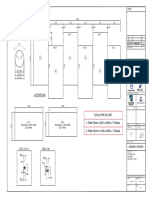

Cl ean Agent St or age Cont ai ner Dat a - U.S. St andar d

15

21

32

44

61

7

10

15

20

28

82

102

68

99

159

234

"A"

"B"

Liquid Level Boss

2-1/2" (65mm) Outlet

1/2" (15mm)

Electrical

Connection

Clean Agent Storage Container Dimensions

10 - 100LB (4 to 44L) Container

(LLi on 100LB (44L) only

125i and 215i LB (51 to 91L) Container

U.S. SIZES & DIMENSIONS

SIZE-LB 10 20 35 60 100 125i 215i 215 375 650 1000

A (in.) 5.5 7.25 7.25 10.75 10.75 20.00 24.00 20.00 20.00 24.00 24.00

B (in.) 19.75 21.50 32.50 28.00 38.75 20.25 23.75 28.87 42.50 48.75 70.00

METRIC SIZES & DIMENSIONS

SIZE-L 4 8 15 27 44 51 90 87 153 267 423

A (MM) 140 184 184 273 273 508 610 508 508 610 610

B (MM) 502 546 826 711 984 515 605 733 1080 1237 1778

"B"

"A"

Liquid Level Boss

1" (25mm) Outlet

1/2" (15mm)

Electrical

Connection

215 - 1000LB (87-423L) Container

7.0

14.13

178

359

"B"

"A"

Liquid Level Boss

3" (80mm) Outlet

1/2" (15mm)

Electrical

Connection

ARCHI TECT AND ENGI NEERI NG SPECI FI CATI ONS

The Clean Agent shall be stored in Fike Series 70 Clean Agent Storage Containers. The containers shall be capable of being

filled, in one-pound (0.5kg) increments, to their listed maximum capacity. The Clean Agent container shall be activated by a

signal from the control panel which is processed by the Agent Release Module. This module shall store the power required to

operate the actuator. The valve shall contain a scored, non-fragmenting, rupture disc to provide an immediate, total discharge

of all the agent. HFC-125 Clean Agent is stored in the container as a liquid, having a natural vapor pressure of 200 psig at

77

o

F (13 barg at 25

o

C). To aid in discharge, the container shall be super-pressurized to 360 psig at 70

o

F (25 bar at 21

o

C) with

dry nitrogen. Agent discharge shall be completed in 10 seconds or less.

Clean Agent Storage Containers shall be actuated by an electrical signal that is automatically or manually controlled. Normal

operating temperature shall be +32

o

to +120

o

F (0

o

to 49

o

C) in any installation.

Clean Agent Storage Containers shall be equipped with a pressure gauge to display internal pressure. This gauge shall be an

integral part of the container and color coded for fast referencing of pressure readings. A Low Pressure Supervisory Switch

shall be made available, as an option. A decrease in internal container pressure from 360 to 288 psig (24.8 to 18.8 bar) shall

cause the normally opened/closed Supervisory Switch contacts to close/open, indicating a trouble or supervisory condition, at

the control panel.

Clean Agent Storage Containers shall be fastened to a wall, or other secure surface, using a mounting bracket that is designed

for the most effective and versatile installation of each container.

Copyright Fike Corporation All Rights Reserved.

Form No. C.1.41.01-2 February, 2005 Specifications are subject to change without notice.

Potrebbero piacerti anche

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingDa EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingValutazione: 5 su 5 stelle5/5 (3)

- Cylinder Data Sheet (FM200 Gas Bottle) PDFDocumento4 pagineCylinder Data Sheet (FM200 Gas Bottle) PDFKevin TsuiNessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Series 825Y Specification SheetDocumento2 pagineSeries 825Y Specification SheetFEBCONessuna valutazione finora

- Prevention of Actuator Emissions in the Oil and Gas IndustryDa EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNessuna valutazione finora

- SEVO 1230 Technical Data Sheets - All PDFDocumento18 pagineSEVO 1230 Technical Data Sheets - All PDFYeni Paola SierraNessuna valutazione finora

- Honeywell L404a D, F L604a L MDocumento12 pagineHoneywell L404a D, F L604a L Mcarlos-alberto-uceda-7837Nessuna valutazione finora

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsDa EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNessuna valutazione finora

- Choke E Series MasterFloDocumento14 pagineChoke E Series MasterFloianherzogNessuna valutazione finora

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDa EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNessuna valutazione finora

- Valves Grese NDocumento92 pagineValves Grese NYair Alexis Muñoz Rojas100% (1)

- Valves Grese NDocumento92 pagineValves Grese NRandall KirchbergNessuna valutazione finora

- 'C' Series Control ValvesDocumento12 pagine'C' Series Control Valvesابزار دقیق100% (1)

- Blow Down Control ValveDocumento2 pagineBlow Down Control ValveAmruth Babu V TNessuna valutazione finora

- Reg RedQ Specialy Regulators PDFDocumento20 pagineReg RedQ Specialy Regulators PDFDavid SaldarriagaNessuna valutazione finora

- VALVULA DE SOLENOIDE HS7 BulletinDocumento4 pagineVALVULA DE SOLENOIDE HS7 BulletinJoséMarcanoNessuna valutazione finora

- Pressosmart ProspectDocumento4 paginePressosmart Prospectiulian1000Nessuna valutazione finora

- Series 805YD Specification SheetDocumento2 pagineSeries 805YD Specification SheetFEBCONessuna valutazione finora

- Type 2600 Relief Valve Capacities GuideDocumento2 pagineType 2600 Relief Valve Capacities GuidetakenoveraccountNessuna valutazione finora

- Globe Valve Type Flow Switch: DescriptionDocumento4 pagineGlobe Valve Type Flow Switch: DescriptiongoparsucoNessuna valutazione finora

- Series 007 Installation InstructionsDocumento8 pagineSeries 007 Installation InstructionsWattsNessuna valutazione finora

- PLL 2144Documento80 paginePLL 2144Amit TandelNessuna valutazione finora

- Fluid Components Full CatalogDocumento464 pagineFluid Components Full Catalognegg 348Nessuna valutazione finora

- Es F 856STDocumento4 pagineEs F 856STFEBCONessuna valutazione finora

- Riser Module 747m VictaulicDocumento2 pagineRiser Module 747m Victaulicrvalentino2012Nessuna valutazione finora

- 01042Documento4 pagine01042윤병택Nessuna valutazione finora

- Viking 062293Documento8 pagineViking 062293Lukman ZakariyahNessuna valutazione finora

- KIMRAY ValveDocumento16 pagineKIMRAY ValveDenny Iskandar 'S-chuck'Nessuna valutazione finora

- Proinert® Cylinder Completer Kit - Ig-541Documento2 pagineProinert® Cylinder Completer Kit - Ig-541Марко НакићNessuna valutazione finora

- Free Fall Valve Pg1-11Documento12 pagineFree Fall Valve Pg1-11Roshan ShanmughanNessuna valutazione finora

- Catálogo Master FloDocumento12 pagineCatálogo Master FloclaudioandrevalverdeNessuna valutazione finora

- ISO 9001 Certified Digital Control Valve GuideDocumento8 pagineISO 9001 Certified Digital Control Valve Guidecnrk777100% (1)

- Feed Water Heater - Isolation System: Features & BenefitsDocumento9 pagineFeed Water Heater - Isolation System: Features & BenefitsAkash PatilNessuna valutazione finora

- Ventilator - S&P - Vent (En)Documento8 pagineVentilator - S&P - Vent (En)Muhidin KozicaNessuna valutazione finora

- Municipal Water Supply Pump CatalogueDocumento23 pagineMunicipal Water Supply Pump CatalogueMandisa Sinenhlanhla NduliNessuna valutazione finora

- Reliable Automatic Sprinkler Co bulletin on deluge valve featuresDocumento12 pagineReliable Automatic Sprinkler Co bulletin on deluge valve featuresmuhamedzNessuna valutazione finora

- Series PWS20 and Series PWS20-2: Pure WaterDocumento4 pagineSeries PWS20 and Series PWS20-2: Pure WaterWattsNessuna valutazione finora

- VictaulicDocumento6 pagineVictaulicAndreyNessuna valutazione finora

- SCOH-K Tech Guide 0705Documento48 pagineSCOH-K Tech Guide 0705Emir OmerdicNessuna valutazione finora

- Series 825YD Specification SheetDocumento2 pagineSeries 825YD Specification SheetFEBCONessuna valutazione finora

- Fisher D4 Product BulletinDocumento12 pagineFisher D4 Product BulletindocrafiNessuna valutazione finora

- Series 858 Specification SheetDocumento2 pagineSeries 858 Specification SheetFEBCONessuna valutazione finora

- Backflow PreventersDocumento4 pagineBackflow PreventersSam WeberNessuna valutazione finora

- ReaktorDocumento46 pagineReaktorSultan SetiawanNessuna valutazione finora

- Norriseal 2200 2220 Brochure 080814Documento8 pagineNorriseal 2200 2220 Brochure 080814Vicente Elías Venegas LunaNessuna valutazione finora

- 1.eurospartan Ve411 ValvesDocumento5 pagine1.eurospartan Ve411 Valvesoep1969Nessuna valutazione finora

- Water Softeners Residential 6700XTR Upflow Valve Softeners Canadian ENGLISH ManualDocumento12 pagineWater Softeners Residential 6700XTR Upflow Valve Softeners Canadian ENGLISH ManualPromagEnviro.comNessuna valutazione finora

- FittingsDocumento24 pagineFittingsAmar Jabar Al BaajiNessuna valutazione finora

- Catálogo General de McdonellsDocumento139 pagineCatálogo General de McdonellsJuan Carlos Palomino JesusiNessuna valutazione finora

- Catalogo General McdonellmillerDocumento141 pagineCatalogo General McdonellmillerJesus CovarrubiasNessuna valutazione finora

- HR E576qDocumento12 pagineHR E576qIsanka SathsaraneeNessuna valutazione finora

- 210-12 Pad Mount Data Sheet PDFDocumento12 pagine210-12 Pad Mount Data Sheet PDFRonald H Santos100% (1)

- VALVULAS - Series2200, NORRISEALDocumento8 pagineVALVULAS - Series2200, NORRISEALAndrea Hernández CarreñoNessuna valutazione finora

- 2Fph Series Pressure Compensated Flow Regulator/Diverter: - Priority StyleDocumento2 pagine2Fph Series Pressure Compensated Flow Regulator/Diverter: - Priority StylemaarwaanNessuna valutazione finora

- fp50 fp100 fp200Documento10 paginefp50 fp100 fp200ducmanh83Nessuna valutazione finora

- 370 377 Toilets Macerators TreatmentSystems ChemicalsDocumento8 pagine370 377 Toilets Macerators TreatmentSystems ChemicalsbrilrjetNessuna valutazione finora

- PETRO FILL-RITE 900 Series Meter Owner ManualDocumento4 paginePETRO FILL-RITE 900 Series Meter Owner Manualpaulm3565Nessuna valutazione finora

- DS-1201 - W60 - W80 - W90 Series LR 10 2014 - tcm11-10502Documento28 pagineDS-1201 - W60 - W80 - W90 Series LR 10 2014 - tcm11-10502ChemicalProgrammerNessuna valutazione finora

- ss-dfc7Documento56 paginess-dfc7ridipisaNessuna valutazione finora

- Syntax For Main and SubformsDocumento2 pagineSyntax For Main and SubformsridipisaNessuna valutazione finora

- VIB3000Documento11 pagineVIB3000ridipisaNessuna valutazione finora

- Vishay Siliconix: FeaturesDocumento7 pagineVishay Siliconix: Featuresمركز القدسNessuna valutazione finora

- COMOS WalkinsideDocumento2 pagineCOMOS WalkinsideridipisaNessuna valutazione finora

- MN417 PDFDocumento2 pagineMN417 PDFGabriel BolívarNessuna valutazione finora

- Rockwell DynarixDocumento39 pagineRockwell DynarixridipisaNessuna valutazione finora

- COMOS PortfolioDocumento8 pagineCOMOS PortfolioridipisaNessuna valutazione finora

- Job Instruction 12 - Quality Assurance and Control-Rev-FDocumento55 pagineJob Instruction 12 - Quality Assurance and Control-Rev-FridipisaNessuna valutazione finora

- Enerflex 381338Documento2 pagineEnerflex 381338midoel.ziatyNessuna valutazione finora

- Part E EvaluationDocumento9 paginePart E EvaluationManny VasquezNessuna valutazione finora

- Corruption in PakistanDocumento15 pagineCorruption in PakistanklutzymeNessuna valutazione finora

- Module 5Documento10 pagineModule 5kero keropiNessuna valutazione finora

- EPS Lab ManualDocumento7 pagineEPS Lab ManualJeremy Hensley100% (1)

- Social EnterpriseDocumento9 pagineSocial EnterpriseCarloNessuna valutazione finora

- 01 Automatic English To Braille TranslatorDocumento8 pagine01 Automatic English To Braille TranslatorShreejith NairNessuna valutazione finora

- 1st Exam Practice Scratch (Answer)Documento2 pagine1st Exam Practice Scratch (Answer)Tang Hing Yiu, SamuelNessuna valutazione finora

- Bank Statement AnalysisDocumento26 pagineBank Statement AnalysisAishwarya ManoharNessuna valutazione finora

- Meanwhile Elsewhere - Lizzie Le Blond.1pdfDocumento1 paginaMeanwhile Elsewhere - Lizzie Le Blond.1pdftheyomangamingNessuna valutazione finora

- Pyrometallurgical Refining of Copper in An Anode Furnace: January 2005Documento13 paginePyrometallurgical Refining of Copper in An Anode Furnace: January 2005maxi roaNessuna valutazione finora

- Calc Fields Networking and Sharing: Welcome ToDocumento42 pagineCalc Fields Networking and Sharing: Welcome Toprashant adhikariNessuna valutazione finora

- Area Access Manager (Browser-Based Client) User GuideDocumento22 pagineArea Access Manager (Browser-Based Client) User GuideKatherineNessuna valutazione finora

- Empowerment Technologies Learning ActivitiesDocumento7 pagineEmpowerment Technologies Learning ActivitiesedzNessuna valutazione finora

- LPM 52 Compar Ref GuideDocumento54 pagineLPM 52 Compar Ref GuideJimmy GilcesNessuna valutazione finora

- ABS Rules for Steel Vessels Under 90mDocumento91 pagineABS Rules for Steel Vessels Under 90mGean Antonny Gamarra DamianNessuna valutazione finora

- John GokongweiDocumento14 pagineJohn GokongweiBela CraigNessuna valutazione finora

- Milwaukee 4203 838a PB CatalogaciónDocumento2 pagineMilwaukee 4203 838a PB CatalogaciónJuan carlosNessuna valutazione finora

- Legal Techniques (2nd Set)Documento152 pagineLegal Techniques (2nd Set)Karl Marxcuz ReyesNessuna valutazione finora

- Welding MapDocumento5 pagineWelding MapDjuangNessuna valutazione finora

- Ralf Behrens: About The ArtistDocumento3 pagineRalf Behrens: About The ArtistStavros DemosthenousNessuna valutazione finora

- Defect Prevention On SRS Through ChecklistDocumento2 pagineDefect Prevention On SRS Through Checklistnew account new accountNessuna valutazione finora

- Law of TortsDocumento22 pagineLaw of TortsRadha KrishanNessuna valutazione finora

- Computers As Components 2nd Edi - Wayne WolfDocumento815 pagineComputers As Components 2nd Edi - Wayne WolfShubham RajNessuna valutazione finora

- Haul Cables and Care For InfrastructureDocumento11 pagineHaul Cables and Care For InfrastructureSathiyaseelan VelayuthamNessuna valutazione finora

- Beams On Elastic Foundations TheoryDocumento15 pagineBeams On Elastic Foundations TheoryCharl de Reuck100% (1)

- Individual Differences: Mental Ability, Personality and DemographicsDocumento22 pagineIndividual Differences: Mental Ability, Personality and DemographicsAlera Kim100% (2)

- Introduction To Succession-1Documento8 pagineIntroduction To Succession-1amun dinNessuna valutazione finora

- CFEExam Prep CourseDocumento28 pagineCFEExam Prep CourseM50% (4)

- Fundamental of Investment Unit 5Documento8 pagineFundamental of Investment Unit 5commers bengali ajNessuna valutazione finora

- Kintsugi Wellness: The Japanese Art of Nourishing Mind, Body, and SpiritDa EverandKintsugi Wellness: The Japanese Art of Nourishing Mind, Body, and SpiritValutazione: 4.5 su 5 stelle4.5/5 (3)

- How to Manage Your Home Without Losing Your Mind: Dealing with Your House's Dirty Little SecretsDa EverandHow to Manage Your Home Without Losing Your Mind: Dealing with Your House's Dirty Little SecretsValutazione: 5 su 5 stelle5/5 (338)

- The Martha Manual: How to Do (Almost) EverythingDa EverandThe Martha Manual: How to Do (Almost) EverythingValutazione: 4 su 5 stelle4/5 (11)

- The Buy Nothing, Get Everything Plan: Discover the Joy of Spending Less, Sharing More, and Living GenerouslyDa EverandThe Buy Nothing, Get Everything Plan: Discover the Joy of Spending Less, Sharing More, and Living GenerouslyValutazione: 4 su 5 stelle4/5 (40)

- Plan and Organize Your Life: Achieve Your Goals by Creating Intentional Habits and Routines for SuccessDa EverandPlan and Organize Your Life: Achieve Your Goals by Creating Intentional Habits and Routines for SuccessValutazione: 5 su 5 stelle5/5 (19)

- Dwelling: Simple Ways to Nourish Your Home, Body, and SoulDa EverandDwelling: Simple Ways to Nourish Your Home, Body, and SoulValutazione: 4.5 su 5 stelle4.5/5 (9)

- The Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyDa EverandThe Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyValutazione: 4 su 5 stelle4/5 (275)

- Survival Mom: How to Prepare Your Family for Everyday Disasters and Worst-Case ScenariosDa EverandSurvival Mom: How to Prepare Your Family for Everyday Disasters and Worst-Case ScenariosValutazione: 3.5 su 5 stelle3.5/5 (8)

- The Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterDa EverandThe Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterValutazione: 4 su 5 stelle4/5 (466)

- Success at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.Da EverandSuccess at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.Valutazione: 4 su 5 stelle4/5 (17)

- How to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingDa EverandHow to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingValutazione: 4.5 su 5 stelle4.5/5 (842)

- The Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and OrganizingDa EverandThe Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and OrganizingValutazione: 4 su 5 stelle4/5 (2993)

- Martha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeDa EverandMartha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeNessuna valutazione finora

- Simplified Organization: Learn to Love What Must Be DoneDa EverandSimplified Organization: Learn to Love What Must Be DoneNessuna valutazione finora

- Nobody Wants Your Sh*t: The Art of Decluttering Before You DieDa EverandNobody Wants Your Sh*t: The Art of Decluttering Before You DieValutazione: 4.5 su 5 stelle4.5/5 (21)

- Let It Go: Downsizing Your Way to a Richer, Happier LifeDa EverandLet It Go: Downsizing Your Way to a Richer, Happier LifeValutazione: 4.5 su 5 stelle4.5/5 (67)

- The Everything Organize Your Home Book: Eliminate clutter, set up your home office, and utilize space in your homeDa EverandThe Everything Organize Your Home Book: Eliminate clutter, set up your home office, and utilize space in your homeValutazione: 3 su 5 stelle3/5 (1)

- Identity Clutter: The Whats, Whys, and Hows of Every Angle of DeclutteringDa EverandIdentity Clutter: The Whats, Whys, and Hows of Every Angle of DeclutteringValutazione: 5 su 5 stelle5/5 (44)

- Tortoise and Hare Decluttering: The Whats, Whys, and Hows of Every Angle of DeclutteringDa EverandTortoise and Hare Decluttering: The Whats, Whys, and Hows of Every Angle of DeclutteringValutazione: 4.5 su 5 stelle4.5/5 (51)

- Extraordinary Projects for Ordinary People: Do-It-Yourself Ideas from the People Who Actually Do ThemDa EverandExtraordinary Projects for Ordinary People: Do-It-Yourself Ideas from the People Who Actually Do ThemValutazione: 3.5 su 5 stelle3.5/5 (3)

- The Homesteader's Handbook: Mastering Self-Sufficiency on Any PropertyDa EverandThe Homesteader's Handbook: Mastering Self-Sufficiency on Any PropertyNessuna valutazione finora

- Homegrown & Handmade: A Practical Guide to More Self-Reliant LivingDa EverandHomegrown & Handmade: A Practical Guide to More Self-Reliant LivingValutazione: 3.5 su 5 stelle3.5/5 (6)

- Declutter Like a Mother: A Guilt-Free, No-Stress Way to Transform Your Home and Your LifeDa EverandDeclutter Like a Mother: A Guilt-Free, No-Stress Way to Transform Your Home and Your LifeValutazione: 4.5 su 5 stelle4.5/5 (164)

- M.O.M. Master Organizer of Mayhem: Simple Solutions to Organize Chaos and Bring More Joy into Your HomeDa EverandM.O.M. Master Organizer of Mayhem: Simple Solutions to Organize Chaos and Bring More Joy into Your HomeValutazione: 4.5 su 5 stelle4.5/5 (25)

- Super Attractor Manifestation Meditations work your magic: limitless luck happiness joy abundance, activate your grid, quantum physics, instant result, miracles life changing, ultra serotoninDa EverandSuper Attractor Manifestation Meditations work your magic: limitless luck happiness joy abundance, activate your grid, quantum physics, instant result, miracles life changing, ultra serotoninValutazione: 2 su 5 stelle2/5 (1)

- Organizing for the Rest of Us: 100 Realistic Strategies to Keep Any House Under ControlDa EverandOrganizing for the Rest of Us: 100 Realistic Strategies to Keep Any House Under ControlValutazione: 4.5 su 5 stelle4.5/5 (204)