Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Mueller

Caricato da

wilfredoruizDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Mueller

Caricato da

wilfredoruizCopyright:

Formati disponibili

4.

11

Rev. 9-09

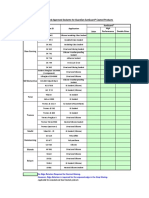

Nylon Ductile Iron Service Saddles for use on cast iron, ductile iron, steel pipe

Outlet tapped with either AWWA taper (C.C.) or AWWA I.P. thread (F.I.P.T.)

Single strap design rated at 250 psig (1724 kPa) maximum working pressure

ASTM A395 ductile iron body

Body is Nylon 11 (10 -12 mil)

Forged alloy steel strap

Rolled strap threads

Nitrile O-ring gasket

1/2" thru 2" tap sizes

Meets all applicable parts of ANSI/AWWA C800

NSF 61 Certied

* Important carefully check the range of the saddle with the O.D. of the pipe being used.

** The outside diameter of A-C pipe varies from manufacturer to manufacturer, to make certain you select the proper clamp:

1) Determine the O.D. of the pipe at the point of saddle installation;

2) From the pipe O.D. range column of the above chart, choose a saddle that has a pipe O.D. range that includes the determined pipe diameter

***CC=AWWA Taper; IP=AWWA IP thread (F.I.P.T)

TO ORDER SPECIFY QUANTITY, OUTLET TAPPING SIZE AND CATALOG NUMBER.

DR 1 A Series

MUELLER

DR1A SERIES DUCTILE IRON

SERVICE SADDLES - SINGLE STRAP

Pipe O.D. Range* Kind and Size of Pipe Single Alloy Strap

Inch mm A-C

Std.

Steel

Cast Iron,

Ductile Iron

Tap***

Thread

Base

Catalog

Number

Size of Tapping (add to "Base" to complete catalog number)

1/2" 3/4" 1" 1-1/4" 1-1/2" 2"

2.35-2.50 59.7-63.5

**

2" 2"* CC or IP DR1A0235 050 075 100 - - -

2.85-2.91 72.4-73.9 2-1/2" 2-1/2"* CC or IP DR1A0285 050 075 100 - - -

3.56-4.00 91.0-101.0 3-1/2" 3" CC or IP DR1A0356 050 075 100 - - -

4.47-5.32 113.5-135.1 4" 4" CC or IP DR1A0447 050 075 100 125 150 200

6.59-7.37 167.4-187.2 6" 6" CC or IP DR1A0659 050 075 100 125 150 200

8.54-9.79 216.9-248.7 8" 8" CC or IP DR1A0845 050 075 100 125 150 200

10.64-12.12 270.3-307.8 10" 10" CC or IP DR1A1064 050 075 100 - - -

12.62-14.38 320.5-365.3 12" 12" CC or IP DR1A1262 050 075 100 - - -

These machines may be used with the service saddles illustrated on this page

Machine Service Saddle Tap Size

1/2" 3/4" 1" 1-1/2" 2"

E-5 X X X X X

D-5 - X X X X

TRU-CUT - X X - -

MEGA-CUT X X X X X

PL-2 - X X - -

MUELLER

Service Saddles with Single Alloy Strap

WARNING: Use on A-C pipe, which contains a known carcinogen, requires appropriate protective equipment and procedures be employed.

UL / FM

B-1

Page B-1-14.2

SECTION

FIRE PROTECTION PRODUCTS

Rev. 9-12

FIRE PROTECTION PRODUCTS

Shaded area

indicates

change

O.S.&Y. RESILIENT WEDGE

GATE VALVES

FLANGED ENDS

Y-213

Y-5

Y-3

Y-4 (not shown)

Y-1

Y-214

Y-10

Y-7

Y-8

Y-23

Y-219

Y-16

Y-217

Y-211

Y-218

Y-209

Y-206 (not shown)

Y-212

R-2365

E

FFF

UU

FF

R

A(open)

AA(closed)

2-1/2", 3", 4", 6" AND 8" SIZES

MEETS OR EXCEEDS ALL APPLICABLE

REQUIREMENTS OF UL 262 AND FM 1120/1130

SPECIFICATIONS AND COMPLIES WITH NSF-61

DUCTILE IRON BODY WITH MUELLER

PRO-GARD

FUSION EPOXY COATED INTERIOR & EXTERIOR

SURFACES

OUTSIDE SCREW AND YOKE (O.S.&Y.)

FLANGED END DIMENSIONS AND DRILLING

RUBBER ENCAPSULATED IRON WEDGE

ADJUSTABLE PACKING

HANDWHEEL OPEN LEFT OR OPEN RIGHT

250 PSIG (1723 KPA) MAXIMUM WORKING

PRESSURE - 500 PSIG (3447 KPA) STATIC TEST

EPOXY COATING MEETS OR EXCEEDS ANSI/AWWA

C550 AND COMPLIES WITH NSF-61

See page B-1-22 for ordering insturctions.

NOTE: Flanged end dimensions and drilling comply with ANSI B16.1, class 125.

*All dimensions are in inches. All weights are in pounds and are approximate.

** Fully encapsulated in molded rubber with no iron exposed.

R-2365-6: O.S.&Y. RESILIENT WEDGE GATE VALVE WITH FLANGE ENDS

PARTS LIST

DIMENSIONS

Options

STAINLESS STEEL FASTENERS: TYPE 316

PN10/PN16 DRILLING

Catalog

Part No. Description Material Material Standard

Y-1 Retaining Nut Carbon Steel E Coated ASTM A36

Y-3 Hand Wheel Ductile Iron ASTM A536 Grade 65-45-12

Y-4 Washer Brass ASTM B36

Y-5 Bush Nut Brass ASTM B16

Y-7 Gland Nut Silicon Bronze ASTM B98

Y-8 Packing Gland Ductile Iron ASTM A536 Grade 65-45-12

Y-10 Gland Bolt Stainless Steel Type 304

Y-16 Bonnet Bolts & Nuts Stainless Steel Type 304

Y-23 Stem Packing Lubricated Flax

Y-206 Guide Cap Bearings Acetyl

Y-209 Wedge, Rubber Encapsulated Cast Iron** ASTM A126 CL.B

Y-211 Bonnet O-ring SBR ASTM D2000

Y-212 Body Ductile Iron ASTM A536 Grade 65-45-12

Y-213 Stem Stainless Steel Type 431

Y-214 Bonnet & Yoke Ductile Iron ASTM A536 Grade 65-45-12

Y-217 O-ring Nitrile ASTM D2000

Y-218 Disc Nut Ductile Iron E Coated ASTM A536 Grade 65-45-12

Y-219 Stem Nut Pin Stainless Steel Type 303

Size

Dimension* 2-1/2" 3" 4" 6" 8"

A 20.33" 20.16" 23.63" 30.00" 37.37"

AA 16.53" 16.32" 18.94" 23.22" 28.60"

E 7.00" 7.00" 10.00" 12.00" 14.00"

R 7.00" 7.50" 9.00" 11.00" 13.50"

FF 7.50" 8.00" 9.00" 10.50" 11.50"

UU 5.50" 6.00" 7.50" 9.50" 11.75"

FFF (number and size of holes) 4--.75" 4--.75" 8--.75" 8--.88" 8--.88"

Turns to open 11 11 14 20.5 26.5

Weight (lbs.)* 50 52 76 119 182

UL / FM

Page E-1-1

FIRE PROTECTION PRODUCTS

Rev. 7-11

Shaded area

indicates

change

UL / FM

E-1

SECTION

MUELLER

Indicator Post are used in fre protection

systems and perform several functions. The Indicator

Post provides a means to operate a buried or otherwise

inaccessible valve. Also, the Indicator Post readily and

clearly indicates whether the valve is open or shut. All

Mueller Indicator Posts are UL/ULC listed and 4-14"

Indicator Posts are FM Approved. Mueller Indicator

Posts are designed to withstand up to 900 ft. - lbs. of

operating torque.

Mueller Indicator Posts are designed to operate 4"

through 24" post indicator valves requiring 14 to 75 turns

to open, and can be ordered to open left or open right.

They are available in adjustable, non-adjustable or wall

mount styles. All have a cast boss on the upper barrel that

is tapped with 1/2" NPT to allow a supervisory switch

to be installed.

The Mueller Adjustable Indicator Post has a 24.25" ad-

justment range* and can be easily adjusted in the feld

without disassembly. The unique telescoping stem shaft

design speeds feld adjustment and eliminates the need

to disassemble and saw off sections of stem. The base

bell is attached to the lower barrel with large diameter

set screws to speed installation. The upper barrel is made

of tough carbon steel, and the telescoping lower barrel

is made of schedule 40 PVC material (ductile iron is op-

tional). The Mueller design uses the operating wrench to

make the post tamper proof. The operating wrench can be

stored on the Indicator Post (as shown in the illustration

to the right) so that one end of wrench fts over the post

operating nut to secure it in position. A slot in the wrench

handle fts over a post on the barrel. A customer supplied

padlock can be used to lock the operating wrench to the

barrel to resist unauthorized operation.

INDICATOR POST

FEATURES

*Applies to "ORDER LENGTH" codes B through F; code A has 22" adjustment.

All 4"-14" Posts are preset for a Mueller 6" PIV Open Left

All 16"-24" Posts are preset for a Mueller 24" PIV Open Left

The Mueller Wall Mount Indicator Post is used to operate a valve installed behind a wall and indicates if that valve

is open or shut. The Post has a 12" diameter base with 3/4" bolt holes which can be mounted to a wall.

12.18

Rev. 9-09

* Fully encapsulated in molded rubber with no iron exposed

** Previous to 1999 these parts on 4"-12" valves were designed with a gasket instead of an O-ring and with additional bolts. Conrm the type of seal when

ordering a replacement gasket or O-ring.

Dirt seal on 4"-12" valves.

Stainless steel fasteners: Type 316

Handwheel

Catalog number--

T-2360-16 mechanical joint x anged ends (with mechanical joint unassembled accessories)

T-2360-19 mechanical joint x anged ends (less mechanical joint accessories)

Sizes--2", 3", 4", 6", 8", 10", 12"

Meets or exceeds all applicable requirements of ANSI/AWWA C509 Standard,

certied to ANSI/NSF 61 standard, listed by Underwriters Laboratories Inc.

and ULC, approved by Factory Mutual Corp.

Inlet ange complies with ANSI B16.1, class 125 drilling and with MSS SP-60.

Mechanical joint outlet complies with ANSI/AWWA C111 Standard.

Iron body with nominal 10 mils MUELLER

Pro-Gard

Epoxy Fusion Coated

interior and exterior surfaces.

Epoxy coating meets or exceeds all applicable requirements of

ANSI/AWWA C550 Standard and is certied to NSF 61.

Iron wedge, symmetrical & fully encapsulated with molded rubber; no exposed iron.

Non-rising stem (NRS).

Triple O-ring seal stufng box (2 upper &1 lower O-ring), with fourth O-ring serving as dirt seal

2" square wrench nut (optional handwheel available)--open left or open right.

2"-12" sizes--250 psig (1723 kPa) maximum working pressure,

500 psig (3447 kPa) static test pressure

Dirt seal on 4"-12 valves.

Options

2"-12" MUELLER T-2360 RESILIENT

WEDGE TAPPING VALVES - M.J. x FL. ENDS

M.J. accessories

shipped unassembled

T-2360-16

Position indicators

ASTM B98-C66100/H02 stem

SEE PAGE 12.25 FOR ORDERING INSTRUCTIONS

Resilient wedge gate v alve par ts

Catalog

P ar t

No.

Description Material Material standar d

G-16 Bonnet Bolts & Nuts Stainless Steel Type 304

G-41 St uffi ng Bo x Bo lt s & Nu ts Stainless Steel Type 304

G-49 Stem O-rings (3) Rubber ASTM D2000

G-79 Inlet flange gasket Co mp os it io n

G-80 In le t fl an ge bo lt s a nd nu ts Steel

G-200 Wrench Nut Cap Screw

G-201 Stuffing Box Seal Rubber ASTM D2000

G-202 Wrench Nut Cast Iron ASTM A126 CL.B

G-203 Stem Bronze ASTM B138

G-204 Hand Wheel (not shown) Cast Iron ASTM A126 CL.B

G-205 Stem Nut Bronze ASTM B62

G-206 Guide Cap Bearings Celcon

G-207 Stuffing Box with

dirt seal

Cast

Rubber

iron ASTM

--

A126 CL.B

G-208 Anti-friction Washers (2) Celcon

G-209

Wedge,

Rubber Encapsulated

Cast

SBR

Iron* ASTM

--

A126 CL.B

G-210** Bonnet Cast Iron ASTM A126 CL.B

G-211** Bonnet Gasket Rubber ASTM D2000

G-212** Body Cast Iron ASTM A126 CL.B

Stainless Steel Type 304

12.8

Rev. 9-09

Size of

main

Size of outlet

flange

Available sleeve O.D. ranges Class and type of pipe

Inch mm

4" 3", 4" . 4.50 - 4.90

4.80 - 5.00

114.30 - 124.46 Iron Pipe Size PVC; C900 Cast Iron OD PVC; Cast Iron

100-250, A, B, C, D; Ductile iron; AC 100

6" 4", 6"

.

.

.

.

Iron Pipe Size PVC; C900 Cast Iron OD PVC; Cast Iron

100-250, A, B, C, D; Ductile iron; AC 100, 150

6.59 - 6.99 167.39 - 177.55

6.89 - 7.30 175.00 - 185.42

7.10 - 7.50 180.34 - 190.50

7.40 - 7.80 187.96 - 198.12

8" 4", 6"

Iron Pipe Size PVC; C900 Cast Iron OD PVC; Cast Iron

100-250, A, B, C, D; Ductile iron; AC 100, 150, 200

7.90 - 8.30 200.66 - 210.82

8.62 - 9.06 218.95 - 230.12

9.04 - 9.45 229.62 - 240.03

9.20 - 9.60 233.68 - 243.84

4", 6", 8"

9.60 - 10.00 243.84 - 254.00

10" 4", 6", 8"

Iron Pipe Size PVC; C900 Cast Iron OD PVC; Cast Iron

100-250, A, B, C, D; Ductile iron; AC 100, 150, 200

9.90 - 10.30 251.46 - 261.62

10.73 - 11.13 272.54 - 282.70

11.05 - 11.45 280.67 - 290.83

11.70 - 12.10 297.18 - 307.34

4", 6", 8", 10"

12.00 - 12.40 304.80 - 314.96

12" 4", 6", 8", 10", 12

C900 Cast Iron OD PVC; Cast Iron 100-250, A, B, C, D;

Ductile iron; AC 100, 150, 200; C905 IPS O.D. PVC (14")

12.50 - 12.90 317.50 - 327.66

13.16 - 13.56 334.26 - 344.42

13.60 - 14.09 345.44 - 378.46

14.10 - 14.58 358.14 - 370.33

14" 4", 6", 8", 10", 12

C905 Cast Iron OD PVC; Cast Iron 100-250, A, B, C, D;

Ductile iron; AC 100, 150, 200; C905 IPS O.D. PVC (16")

15.25 - 15.65 387.35 - 397.51

15.60 - 16.00 396.24 - 406.40

16.38 - 16.73 416.05 - 424.94

16.48 -16.88 418.59 - 428.75

16" 4", 6", 8", 10", 12

C905 Cast Iron OD PVC;Cast Iron 100-250, A, B, C, D;

Ductile iron; AC 100, 150, 200; C905 IPS O.D. PVC (18")

17.40 - 17.80 441.96 - 452.12

17.54 - 17.94 334.26 - 344.42

17.85 - 18.25 445.52 - 463.55

18.15 - 18.55 461.01 - 471.17

18" 4", 6", 8", 10", 12 C905 Cast Iron OD PVC; Cast Iron 100-250, A, B, C, D;

Ductile iron; C905 IPS O.D. PVC (20")

19.30 - 19.70 490.22 - 500.38

19.70 - 20.10 500.38 - 510.54

20" 4", 6", 8", 10", 12

C905 Cast Iron OD PVC; Cast Iron 100-250, A, B, C, D;

Ductile iron

21.40 - 21.80 543.56 - 553.72

21.90 - 22.30 556.26 - 566.42

22.30 - 22.70 566.42 - 576.58

24" 4", 6", 8", 10", 12

C905 Cast Iron OD PVC; Cast Iron 100-250, A, B, C, D;

Ductile iron

23.30 - 23.70 591.82 - 601.98

23.80 - 24.10 604.52 - 612.14

25.60 - 26.00 650.24 - 660.40

18.60 - 19.00 472.44 - 482.60

STAINLESS STEEL TAPPING SLEEVE

4" - 24"

Catalog number-- H-304 Stainless Steel Tapping Sleeve

Sizes-4"*-24" main and outlet (see chart below for available size combinations).

Outlet choices: ange or integral MJ outlet.

Outlet ange material options: 304L Stainless steel, carbon steel, or ductile iron outlet

ange which meets or exceeds all applicable requirements of ANSI B16.1, class 125

and in accordance with MSS-SP60.

Integral MJ ange is 304L stainless steel.

Certied to ANSI/NSF 61.

3/4" NPT brass test plug (Stainless Steel optional).

4"-12" sizes--250 psig (1723 kPa) maximum working pressure.

14"-24" sizes--200 psig (1379 kPa) maximum working pressure.

How to determine a Mueller Tapping Sleeve Part Number

Select the appropriate numbers from the pipe information chart that follows.

Example: For 6"x6" with 7.30-7.50 O.D. Range and stainless steel ange

Resulting Part No. 0606H304SS0750

*3" outlet ange only available in stainless steel

** H-304 is constant for all Mueller Stainless Steel Tapping Sleeves listed here

** SS = stainless steel ange, CS = carbon steel ange,

DI = ductile iron ange, MJ=integral mechanical

joint outlet.*

H-304SS

Tapping Sleeve pipe information

Main Outlet Model Flange Maximum

Size Size No. Material O.D.

06 06 H-304* SS** 0750

H-304MJ

Potrebbero piacerti anche

- Sol Operated - 2014Documento9 pagineSol Operated - 2014wilfredoruizNessuna valutazione finora

- Mechanical Valves 2014Documento1 paginaMechanical Valves 2014wilfredoruizNessuna valutazione finora

- BC Base and Body 2014Documento7 pagineBC Base and Body 2014wilfredoruizNessuna valutazione finora

- Yamada-America Product-Guide ENG GB0810Documento32 pagineYamada-America Product-Guide ENG GB0810wilfredoruizNessuna valutazione finora

- Catalogo Vidro PDFDocumento8 pagineCatalogo Vidro PDFGerman YaibonaNessuna valutazione finora

- Brochure General Big BredelDocumento12 pagineBrochure General Big BredelwilfredoruizNessuna valutazione finora

- BC Body Ported-2014Documento1 paginaBC Body Ported-2014wilfredoruizNessuna valutazione finora

- Mueller Tapping V Section12 18Documento1 paginaMueller Tapping V Section12 18wilfredoruizNessuna valutazione finora

- Mueller Indicator PostDocumento16 pagineMueller Indicator PostwilfredoruizNessuna valutazione finora

- Mueller Gate Valve OS&Y 2365Documento1 paginaMueller Gate Valve OS&Y 2365wilfredoruizNessuna valutazione finora

- Mueller DI Saddles Alloy Sec 411Documento1 paginaMueller DI Saddles Alloy Sec 411wilfredoruizNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5782)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Civil Landscape Holabird Bid Set DrawingsDocumento53 pagineCivil Landscape Holabird Bid Set DrawingskarthikNessuna valutazione finora

- Zurn Z886 6-1/4Documento1 paginaZurn Z886 6-1/4Enak CenirNessuna valutazione finora

- FRP Rebar (AFRP CFRP GFRP)Documento6 pagineFRP Rebar (AFRP CFRP GFRP)Thilan SenarathneNessuna valutazione finora

- Elenco Documentazione Tecnica - o1astG6nQvOYEs9CP4f2Documento36 pagineElenco Documentazione Tecnica - o1astG6nQvOYEs9CP4f2aviomarleoNessuna valutazione finora

- Torlon Processing and PostprocessingDocumento26 pagineTorlon Processing and Postprocessingfrox123Nessuna valutazione finora

- BrederoShaw PDS 3LPPDocumento2 pagineBrederoShaw PDS 3LPPdipankarbasakNessuna valutazione finora

- Reebol: High Performance Environmental Friendly Mould Release AgentDocumento2 pagineReebol: High Performance Environmental Friendly Mould Release AgentKrishna PrakashNessuna valutazione finora

- ListDocumento12 pagineListashishtaneja30Nessuna valutazione finora

- Production Technology Ch31Documento9 pagineProduction Technology Ch31Nimmagadda BharathNessuna valutazione finora

- Eutectic 29029Documento2 pagineEutectic 29029Imam SitumeangNessuna valutazione finora

- FRP Epoxy Pultrusion CatalogDocumento7 pagineFRP Epoxy Pultrusion CatalogKVRamananNessuna valutazione finora

- Polydeck 1000: Abrasion Resistant Car Park Coating SystemDocumento2 paginePolydeck 1000: Abrasion Resistant Car Park Coating SystemAlexi ALfred H. TagoNessuna valutazione finora

- Standard Specification For Structural Steel For Bridges: Designation: A709/A709MDocumento8 pagineStandard Specification For Structural Steel For Bridges: Designation: A709/A709MLeviGatsosNessuna valutazione finora

- The Reinforced Concrete Beam Deflection and Cracking Behavior With Additional Fiber SteelDocumento5 pagineThe Reinforced Concrete Beam Deflection and Cracking Behavior With Additional Fiber SteelNamaku AndaNessuna valutazione finora

- En 14399 Preloaded AssembliesDocumento47 pagineEn 14399 Preloaded AssembliesAngelo VieitoNessuna valutazione finora

- General Construction SpecificationsDocumento6 pagineGeneral Construction SpecificationsCOMPASS LanguageAndskillsTrainingNessuna valutazione finora

- MIM Design Guide: Complex Metal PartsDocumento13 pagineMIM Design Guide: Complex Metal Partsgnk68Nessuna valutazione finora

- R75i Parts Manual Comp Nuevo LaborDocumento280 pagineR75i Parts Manual Comp Nuevo Laboralex100% (3)

- Golf Village BrochureDocumento8 pagineGolf Village BrochureSanthosh SNessuna valutazione finora

- Experimental Study On Concrete Using Copper Slag As Fine Aggregate With Bacterial Admixture Ashok.C1, Ravishankar.D2, Devaraj.M3, Saravanan.S4Documento5 pagineExperimental Study On Concrete Using Copper Slag As Fine Aggregate With Bacterial Admixture Ashok.C1, Ravishankar.D2, Devaraj.M3, Saravanan.S4GR DesignsNessuna valutazione finora

- AL REScheck CertificateDocumento6 pagineAL REScheck Certificatebcap-oceanNessuna valutazione finora

- Soluble Silicates in Refractory MixturesDocumento6 pagineSoluble Silicates in Refractory MixturesnameNessuna valutazione finora

- Pds Sikaceram flx23Documento5 paginePds Sikaceram flx23mertelululalalolo23Nessuna valutazione finora

- Master Schedule and Progress Report for Warehouse and Office Service Construction ProjectDocumento28 pagineMaster Schedule and Progress Report for Warehouse and Office Service Construction ProjectRd Nur MuhammadNessuna valutazione finora

- Powder Perfect: Tungsten Carbide ProductsDocumento3 paginePowder Perfect: Tungsten Carbide ProductsNadjNessuna valutazione finora

- Guardian Approved Sealants List PDFDocumento1 paginaGuardian Approved Sealants List PDFWaqas FareedNessuna valutazione finora

- Advanced Abrasive Machining ProcessesDocumento28 pagineAdvanced Abrasive Machining ProcessesVeerendra ChallabathulaNessuna valutazione finora

- Jotun Sales Training - Beginner's ModuleDocumento63 pagineJotun Sales Training - Beginner's ModuleAnthonio Mostert100% (2)

- Hydraulic Hose Types GuideDocumento67 pagineHydraulic Hose Types Guidepaolomoreano88Nessuna valutazione finora

- Backup Rings Respaldo de OringsDocumento8 pagineBackup Rings Respaldo de OringsRPINILLA (EICO S.A.)Nessuna valutazione finora