Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Report On Mejia Thermal Power Plant (DVC)

Caricato da

Pravin VishwakarmaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Report On Mejia Thermal Power Plant (DVC)

Caricato da

Pravin VishwakarmaCopyright:

Formati disponibili

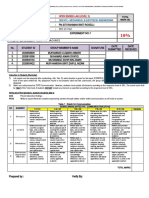

at

NAME:Pravin biswakarma

JALPAIGURI GOVT. ENGG. COLLEGE

ELECTRICAL ENGG. DEPARTMENT.

DATE OF TRAINING: From 13

th

June,14 to 03

th

July,14

VOCATIONAL TRAINING PROJECT REPORT ON MEJIA THERMAL POWER STATION

(M.T.P.S),DAMODAR VALLEY CORPORATION(D.V.C)

ABOUT M.T.P.S

Mejia Thermal Power Station is located at Durlovpur, Dist: Bankura, 26 km

from Durgapur city in West Bengal. Commissioned on 1996, MTPS is the largest thermal

power plant, in terms of electricity generating capacity in the state of West Bengal as

well as among other DVC power plants.

Power Plant:

Mejia Thermal Power Station has an installed capacity of 2340 MW. The plant has 8 units

under its operation. The individual units have the generating capacities as follows:

Unit No. Generating Capacity Commissioned on

U#1 210 MW 1996

U#2 210 MW 1998

U#3 210 MW 1999

U#4 210 MW 2005

U#5 250 MW 2008

U#6 250 MW 2009

U#7 500 MW 2010

U#8 500 MW 2010

Units 1 to 6 are collectively named as MTPS-phase1, while the extension of Units 7 & 8 is

called MTPS-phase 2. All the units have boilers, turbines and generators manufactured by

Bharat Heavy Electrical Limited (BHEL).

SUBJECT OF TRAINING: THERMAL POWER STATION GENERATING TRAINING

PLACE OF TRAINING:

DAMODAR VALLEY CORPORATION

Mejia Thermal Power Station

P.O:MTPS,Dist:Bankura-722183,West Bengal

Phone:03241-232201 FAX-03241-262231

ENGINEERS UNDER WHOM TRAINING IS PERFORMED:

1. Mr. Bidhayak Dutta

(Deputy Chief Engg. Elec)

2. Mr. P.K Dubey

(Training Advisor)

DURATION OF TRAINING: 13

TH

JUNE,2014 to 03

TH

JULY,2014

DAMODAR VALLEY CORPORATION

Mejia Thermal Power Station

P.O:MTPS,Dist:Bankura-722183,West Bengal

Phone:03241-232201 FAX-03241-262231

No.MT/PL/Voc.Trg./Vol.XII/1682 Dated:29

th

March2014

TO WHOM IT MAY CONCERN

This is to certify that Mr.Pravin Biswakarma, student of electrical engineering

of Jalpaiguri Government Engineering College, Jalpaiguri-735102(W.B)

undertook vocational training at Mejia Thermal Power Station, DVC, for the

period of 21(Twenty One) days w.e.f 13.06.2014 under Electrical Dept., MTPS.

During his training he has been found sincere, hard working and

well disciplined.

.........................................

(Shri Bidhayak Dutta)

The Dy Chief Engineer (Elect.)

MTPS, DVC

ACKNOWLEDGEMENT

Any project is the fruitful outcome of the hard work of many.

Through this document we would like to express our gratitude

towards those who supported us in making us an outcome from us.

Firstly, we would like to thank Shri. Bidhayak dutta(Deputy Chief

Engg. Elec.). He inspite of his tremendous workload helped us

admirably. Our humble thanks to Shri.P.K Dubey(Training Advisor)

who guided us in each and every step till our completion of our

training. We are thankful to them for their continued guidance and

support with their vast pool of knowledge, which was essential for

the completion of this project. Along the way , we were also ably

supported and guided by staffs of the various departments. And like

we mentioned, the help is even more credible, considering that the

workload of the staff was immense.

We would also like to thank our friends and family for providing

encouragement and moral support at every step. We recognise

everybodys helping hand.

CONTENTS

SL

NO

TOPIC

1

INTRODUCTION AND HISTORY

2

OVERVIEW OF A POWER PLANT

3

ELECTRICAL SYSTEM

a)

GENERATOR & AUXILIRIES

1. BASIC PRINCIPLE & CONSTRUCTION

2. EXCITATION SYSTEM

3. AVR

4. COOLING SYSTEM

5. PROTECTION SYSTEM

6. GENERATOR METERING & INSTUMENTATION

7. ELECTRICAL PROTECTION AND SAFETY INTERLOCKS

b)

OVERVIEW OF GT, UT, UAT,UST, ST, SAT,SST, NGT

c)

SWITCHYARD

1.VARIOUS COMPONENTS

2.PROTECTION

d)

STATION GROUNDING SYSTEM

e)

MOTORS

f)

g)

DC SYSTEM

DG SET

INTRODUCTION & HISTORY

DVC, a legacy to the people of India, emerged as a culmination of attempts made over a

whole century to control the wild and erratic Damodar river. The river spans over an area

of 25,000 km

2

covering the states of Bihar (now Jharkhand) & West Bengal.

Damodar Valley Corporation was established on 7

th

July 1948.It is one of the most

reputate company in the eastern zone of India. DVC is established on Damodar river. It

also consists of the Durgapur Thermal Power Plant in Durgapur. The hydel project in

Mython is one of the most flourishing part of DVC. The MTPS(Mejia Thermal Power

Station) under DVC is one of the largest thermal power plant in West Bengal. It is one of

the four thermal power stations of DVC in the states of West Bengal. The total power

plant campus area is surrounded by boundary walls and is basically divided into two

major parts, first power plant area itself and second is the colony area for the residence

and other facilities for MTPSs employees.

SALIENT FEATURES

Location: Mejia in Bankura District in West Bengal.

Installed Capacity: (210*4 MW+250*2 MW + 500*2 MW)=2340MW

Coal source: B.C.C.L and E.C.L, also imported from Indonesia

Fuel quantity:126 TPH(for unit 1 to 4 only)

150 TPH(for unit 5 and 6 only)

272 TPH (for unit-7 only)

Height of chimney: 220m[205+15](for unit 1 to 6)

279m (for phase II)

Water source: DAMODAR RIVER

Beneficiary State: WEST BENGAL, JHARKHAND

OVERVIEW OF POWER PLANT OPERATION

A power plant is basically an energy conversion mechanism. Thermal power plants

operate on modified Rankin Cycle with reheating and superheating. In essence , it is

modified from of the basic steam cycle to increase the cycle efficiency. Coal is burnt in a

boiler, which converts water into steam. The steam is expanded in a turbine, which

produces mechanical power driving the alternator coupled to the turbine. The working of

the power is divided into four main circuits:

Fuel and ash circuit.

Air and Fuel gas circuit.

Feed water and steam circuit.

Cooling water circuit.

THE ENERGY CONVERSION

Chemical energy to heat energy ---- In Boiler

Heat energy to kinetic energy ---- In Turbine

Mechanical energy to electrical energy --- In Generator

THERMAL POWER PLANT

WATER

FUEL

AIR

ELECTRICITY

FLUE GASES

ASH

ENERGY FLOW DIAGRAM OF DIFFERENT PART :

CHEMICAL ENERGY HEAT ENERGY

(COAL) (STEAM)

BOILER

HEAT ENERGY MECHANICAL ENERGY

(STEAM) (TURBINE)

TURBINE

MECHANICAL ENERGY ELECTRICAL ENERGY

(TURBINE) (GENERATOR)

GENERATOR

OVER VIEW OF A POWER PLANT

VARIOUS COMPONENTS OF A POWER PALNT:

DEAERATOR: The condensed water from the condenser is taken to deaerator where the

water is made free from oxygen mainly i.e. free from air. The deaerator is a direct heat

exchanger because the steam from IPT is sprayed to the condensed water from the

bottom and the water is sprayed from the top part of the deaerator. This results in de-

oxyfication i.e. removal of oxygen from the water.

BOILER FEED PUMPS (BFPs): The outlet of the deaerator is connected to boiler feed

pumps, there are three BFP in a row out of which two are in running condition and one is

at standby,in unit #1 to 6 all BFP are MDBFP,consumes highest power in the plant 4.6MW

in full load and unit#7 and 8 one of these is MDBFP( motor driven), and other two are

TDBFP(steam driven).MDBFP consumes the highest power in this plant i.e. 10MW.

MDBFP is used only at the starting time for its huge power consumption.

HIGH PRESSURE HEATER: The HPHs are also mechanical heaters that receives the

heating medium from exhaust of HPT and IPT. There are two HPH named as HPH#5 and

HPH#6. HPH#5 receives steam from IPT and HPH#6 receives steam from HPT . The BFP

outlet is connected to the HPH#5 and HPH#6 is connected to HPH#5. Steam of HPT and

IPT heats the water up to 253:C and the pressure is also increased up to 175kg/sq. cm,

which is then passes through economiser this done to increase the efficiency of the

boiler. Extn. Steam Pressure to HPH#5: 16.65 kg/sq. cm and temp. 415:C. Extn. Steam

pressure to HPH#6: 42.84 kg/sq. cm. and temp. 337.8:C.

ECONOMISER: Economiser is another heat exchanger type heater. Here the water from

HPH comes to get more heated up for better steam production and high enthalpy

resulting in greater efficiency of the boiler and unit as well. The economiser receives the

heat for heating the water from the flue gas. The flue gas which has very high

temperature comes from air pre-heater to the economiser and heats up the water

mechanically which finally reaches the boiler drum. Economiser inlet tepm. is 254:C and

outlet temp. is 315:C.

BOILER DRUM: Boiler drum is the part of boiler where the de-mineralized water is stored

and is inserted into the boiler through three BCW(Boiler circulating water pump). It is

also houses the steam that is formed in the boiler. Water stored in the drum comes down

to the top of the boiler and forms a water ring which is then inserted into the boiler

through the 6 water walls. Water walls are basically tubes along the walls of the furnace,

it is here where the water is converted into steam at 130:C and then the produced steam

is taken back to the boiler drum. The drum has a propeller that rotates at high speed and

makes the steam and water separated due to centrifugal force. The pressure of boiler

drum is 192 kg/sq. cm and must be always maintained. Water in the drum comes from

feed control station via economiser.

FURNACE AND BOILER:-Boiler is the main section where the steam is produced by

coal combustion. Boiler consists of boiler drum, water walls, wind box, heaters. The

boiler has 8 elevations named as A-B-C-D-E-F-G-H. Coal is inserted into the boiler from A-

B-C-D-E-F-G-H. There is 8 mills for feeding the pulverized coal to the furnace. Each mill

has 4 pipe for firing in the four corners of furnace. Furnace is divided into two parts

named as first pass and second pass. The combustion takes place in the first pass and the

heating of steam through SH takes place in the second pass.

SUPER HEATER: The important point is to be always kept in mind that all the heaters

that are used in thermal power plant are mechanical type heaters i.e. heat exchanged

phenomena heats one medium by exchanging heat from another hotter medium. Super

heaters are actually suspended pipes in the second pass section of the boiler, the flue gas

having very high temperature heats the steam that comes from the drum before they hit

the turbines to a temperature up to 540:C. The pressure of steam is kept constant when

passing through super heater. The main concept behind making the steam super heated

is to make the steam absolutely moisture free before they hit the turbine because

moisture content of steam will damage the blades of turbine by corrosion.

TURBINE SECTION: The turbine section consists of three parts named as HPT(High

pressure turbine), IPT(Intermediate pressure turbine),LPT(Low pressure turbine). The

superheated steam from the Superheater enters the HPT and hits the blades at 176.2

kg/sq. cm and 540:C and rotates the shaft. The exhaust steam of HPT is taken to IPT

through a reheating section called Reheater(RH) for enabling the steam to regain its

previous steps. The exhaust steam of IPT enters LPT directly. The exhaust of LPT is taken

to condenser.

CONDENSER: The exhaust steam of LPT is fed to the condenser where the steam is

converted into water by the principle of condensation. The condenser has three

extraction pumps known as Condensate Extraction Pumps (CEP-A, CEP-B, CEP-C).

These pumps create a negative pressure i.e. vacuum in the condenser for better suction

of the condensate. The outlet of the CEP is connected to low pressure heater(LPH);

where the temperature of condensed water is raised to little higher temperature for

better efficiency of overall unit.

FLUE GAS PATH :

AIR PREHEATER: The flue gas produced as a result of combustion of fossil fuel in the

furnace is taken to the air pre heater. The air pre heater is used to heat up the

atmospheric air to make hot air used for combustion and transport of coal dust from mill

to furnace; which called secondary air. This heater has a unique process of heating, it has

a shaft attached to rotating wheel type structure(like turbine but arrangement blades are

different). Atmospheric air are sucked by FD fans passes through one side of the rotating

shaft and the hot flue gas passes through another side. This way heat of the flue gas gets

transferred to the atmospheric air and gets heated. There are two air pre heaters for

each unit named as AH-A and AH-B.

ELECTROSTATIC PRECIPITATOR (ESP) :-

Under government rules and regulation for industrial pollution control, ESP is must to

each and every industry which deals high ash as residing. An electrostatic precipitator is a

large , industrial emission-control unit. It is used in industries like thermal power plant,

cement, paper, chemicals, metallurgical industries etc, which emit particles. In the

thermal power plant it is designed to trap and remove ash particle from the exhaust gas

of boiler. Clean gas, up to 99.9% cleaner than when it enter is then passes out of the

precipitators.

collecting electrode

weakest field

Emitting electrode

WORKING PRINCIPLE OF ESP

An ESP is a chamber in which flue gas from the furnace is forced into FD fans.

Electrostatic precipitation is a physical process by which particles suspended in gas

stream are charged electrically, and under the influenced of electric field are separated

from the gas stream. The precipitation system consists of negatively charged high voltage

discharged electrode wire suspended amidst positively charged collecting electrode

surfaces. At a very high DC voltage of the order of 20KV-35 KV, a corona discharged

occurs close to the negative electrode, setting up an electric field between the emitter

and the charged surface. When the particle laden gas passes through the ESP fields, the

gas close to the negative electrode is thus ionised upon passing through the corona . As

the negative ions and electrons migrate towards the charged surface, they in turn charge

the passing particle. The electrostatic field then draws the particles to the collector

surface where they are deposited. Periodically, the collected particles are removed from

the collecting surface by rapping or vibrating the collector to dislodge the particles. The

dislodged particles drop below the electrical treatment zone and are collected through

hoppers for ultimate disposal.

The major components that accomplished above activities in ESP are as follows:

High voltage discharge electrodes

Grounded collecting electrodes

Rapping systems

Power supplies and control components

Hoppers

In practice the ESP shall consists of several such fields in series in the direction of

gas flow. There may be two or more parallel passes of such series combination to meet

the desire level of dust removal from the flue gas . Here four passes and 72 fields are in

place.

DRAFT FANS:

There are basically three types of fans in a thermal power plant.

i. INDUCED DRAFT (ID FAN)

ii. FORCED DRAFT FAN (FA FAN)

iii. PRIMARY AIR FAN (PA FAN)

INDUCED DRAFT FAN/ ID FAN:

This fan is used to create negative pressure in the furnace

i.e. furnace pressure is lower than atmospheric pressure, as a result of which fire balls

inside the furnace can not come out of the furnace.ID fans also drives the flue gas

through out its path and finally ejects it out of chimney. It sucks air from the furnace and

ejects it to the atmosphere. Mechanically ID fan is coupled with one 3-ph synchronous

type motor. It is the only synchronous motor in the power plant because it gives more

accurate control to its speed by V/f method for maintaining negative pressure as

controlling of negative pressure is the most vital factor in any thermal power plant. There

are two ID fan for each unit.

FORCED DRAFT FAN:-

Unlike ID fan, the FD fan is meant for creating positive pressure in

the furnace and also supplies air from PA fan and secondary air for combustion. The FD

fan takes air from atmosphere and expel it to the plant (i.e. in the furnace, wind box

etc).Mechanically FD fan consist of one 3-ph induction motor, main bearing (antifriction

bearing) and lube oil system.

PRIMARY AIR FAN/PA FAN: -

Primary air fan is used for mixing of cold air of FD fan outlet

with hot air of air pre-heater outlet. The main function of this is to transport pulverised

coal from the mill to furnace. Mixing of hot air and cold air is necessary because it is

needed to maintain the temperature of the pulverised coal from 80:C to 90:C for better

transport of coal and better combustion in the furnace. Mechanically the construction of

PA fan is same as FD fan.

The Electrical System:-

The electrical system basically starts at the turbo alternator and through the

GT(generator transformer) to the switchyard and finally to the transmission lines. In

between the network consists of many isolators, circuit breakers, CT, PT and other

mechanisms. At MTPS the turbo alternator generates a voltage of

15.75KV(Unit#1/2/3/4),16.6KV(Unit#5/6), 21 KV( Phase II). The GTs steps this up to 220

KV(400KV for Phase II). The transmission is to Kalyaneswari ,Burnpur,Borjora,Durgapur

and for phase IIthe transmission is to Mython, DSTPS, Jamshedpur.

Therefore the electrical system is :

For Unit#1 to 6 :

Generator GT 220 KV switchyard Transmission Lines

For Unit#7 and 8:

Generator GT 400 KV switchyard Transmission Lines

Apart from these, the electrical system is intricately intertwined with the entire plant,

considering that the entire protection and control is somehow done electrically.

GENERATOR

BASIC PRINCIPLE AND CONSTRUCTION:

Principle:

Generator converts mechanical power into electrical form and feeds it into the power

system network . The working principle behind the operation of generator is

Faradays Laws of electromagnetic induction. The induced alternating voltage in a

generator can be expressed as-

E=4.44fT Volt

Where,

E= Voltage induced in volt.

f=frequency of rotation in Hz.

T=No. of turns

=flux per pole in Wb.

The frequency of the alternating voltage is given by the following equation

f=PNs/2

where,

f=freq in Hz.

P=no. of poles

Ns=revolution/sec.

Components of Generator:

The main components of a Generator are:

1.Stator 2.Rotor

3.Bearing and lubrication 4.Terminal Bushing and Bus duct

5.Excitation system 6. Slip ring and Brush gear assembly

7.Cooling system 8. Sealing system

Stator:

The stator embodies the core, stator winding and hydrogen coolers and provides a gas

tight enclosure for hydrogen gas. It comprises of an inner and an outer frame. The outer

frame is a rigid fabricated structure of welded steel plates capable of bearing the

pressure due to minor explosion of H within the casing. Within the cylindrical barrel, a

fixed cage is formed by grider built circular and axial ribs. These ribs divide the yoke into

annular components through which cooling gas flows into radial ducts in the stator core

and

TURBO GENERATOR

Exchanges heat in the Hydrogen gas coolers housed horizontally parallel to the rotor

shaft in the frame. The inner cage is usually fixed to the yoke by an arrangement of

springs to dampen vibration. Rigid end shields close the stator ends and supports and

shaft seals.

ROTOR:

The rotor forms the rotating magnetic poles of the generator. This is cylindrical type and

constructed form a cast Chromium , Nickel, Molybdenum and Vanadium steel through

several stages of machining. Slots are machined on the outer surface to incorporate

windings . Holes are also drilled for ventilation purposes. High grade copper with 0.03%

to 1% silver is used for the windings with layers of mica or epoxy impregnated glass cloth

as the insulation. A mechanically strong insulation (e.g. micanite) is used for lining the

slots. With increase in generator capacity rotor windings used to carry a fairly high direct

current for sufficient magnetic strength. This higher loading causes considerable amount

of heat loss and large rotors incorporate combination of hollow conductors with slots or

holes arranged to provide for circulation of the cooling gas through the actual conductors

by gap pick up method .Due to very high rotational speed centrifugal force tries to lift the

winding out of the slots.

So they are contained in proper place by duralumin wedges. The end turns outside the

slots are covered by non-magnetic steel retaining end rings and are secured to the rotor

body. The end winding are insulated from retaining rings with the help of glass epoxy

molded segments. The retaining ring is a single piece forging which protects the rotor end

winding from high centrifugal force.

EXCITATION SYSTEM OF TURBO GENERATOR:-

The purpose of excitation system is to continuously provide the appropriate amount of

D.C field current to the generator field winding. The excitation system is required to

function reliably under the following conditions of the generator and the system to which

it is connected .

i)During start up of the generator.

ii)During steady state operating condition.

iii)At the time of transient disturbances (due to sudden applications or removal of load).

iv)During prolonged system disturbances.

The simplest case is that of during start up when the generator is

running at rated speed with generator circuit breaker open(armature open circuited). The

terminal voltage will increase with the increase in field current. Amount of field current

required will be a function of only the terminal voltage. Because of magnetic saturation

more field current will be required to produce an increment of armature voltage at high

voltage than at low voltage. This will be governed by open circuit characteristics(O.C.C) of

the machine. After the closing of generator circuit breaker the machine is connected to

the system and operates in parallel with other machines connected to the system. The

amount of field current required will be a function of the terminal voltage as before and

also the load current and the power factor. This will be governed by the V-curves of the

machine. Unlike the previous case if the generator is connected to a large system change

in excitation current controls the reactive power(VAR) and the power factor only with a

very minor influence of the terminal voltage. More severe duty the excitation system

requires to perform upon is during system disturbances. At the time of transient

disturbances the generator voltage may dip or rise momentarily. The excitation system

must response fast to correct this quickly and stably. During prolonged

disturbances(which may last from several seconds to several minutes) the excitation

system may require to operate at it maximum or ceiling output. Thus properly designed

excitation system should permit

a)Close control of the generator voltage to match closely to the system voltage before

synchronization.

b)Close control of VAR after synchronization of the machine, without loss of stability or

overheating of the field system.

c)Operation of the system at its maximum or ceiling at the time of disturbances in the

system.

DEVELOPEMENT OF EXCITATION SYSTEM:

With increase in generator capacity and

complexity of interconnection in power system, improved techniques in generator

excitation have been developed with the aim to achieve higher capacity, ideal rate of

response, simplicity, reliability, accuracy, sensitivity etc. In the earlier designs several

concepts govern the majority of the excitation system, such as

a) Exciters were commutator type and self excited.

b) Exciters were shaft driven and motor driven rotating machines.

c) Voltage regulators included magnetic or rotating amplifiers or combination of both.

d) Manual control was by means of a rheostat.

Next generation of excitation system introduced newer concepts. Some of

which were

a) Use of semiconductors for rectification.

b) AC(automatic) voltage regulator with transistor pre-amplifiers and thyristors .

c) New concepts of manual control.

d) Elimination of commutators.

e) New physical arrangements,

f) New maintenances procedures .

Present day excitation system have been promoted by

a) Capacity to meet very high values of excitation suitable for unit capacities as high as

500MW or even more.

b) Use of HF AC exciters as source of powers.

c) Use of digital technologies for control, protection and switching.

d) Higher stability unit and excellent performance during transient and fault conditions.

e) Elimination of carbon brushes in brushless excitation system.

TYPES OF EXCITATION SYSTEM:-

The types of excitation system are

i) DC excitation

ii) Static excitation

iii) Brushless excitation

In MTPS Carbon Brush Excitation is used in Unit#1 to 4 and in Unit#5to 8 brushless

excitation system is used.

BRUSHLESS EXCITATION:-

Supply of high current by means of carbon brush involves

considerable operational and maintenance problems. These problems are eliminated in

brushless excitation system which consists of AC main exciter ,a PMG, a rotating non-

controlled rectifiers, all mounted on the T.G shaft and static AVR. Field of the PMG which

is permanent salient pole magnet rotates along with the generator shaft and generates

permanent voltage (usually 400 v at 400 Hz freq.) at the stator windings. These outputs

from the PMG is connected to the thyristors located in the AVR panel. The controlled DC

output from the AVR panel is connected to the stationary field of the main exciter. The

output from the rotating armature is connected to the diodes placed along with the

rotating at the same speed that of the rotating armature of the exciter and generator

field winding. Thus there is no flow of current between any moving part and stationary

part and hence they use of brush gear is eliminated. The diodes are arranged on rectifier

wheels in a three phase configuration .These are protected with fuse and RC network.

During operation the fuses are monitored with the help of stroboscope. The entire

arrangement is totally enclosed and the hot air is cooled in two or more cooler arranged

alongside the exciter.

Apart from the fuse monitoring unit, other features provided in brushless excitation

system are ground fault detection,field current measurements etc.

AUTOMATIC VOLTAGE REGULATOR(AVR):-

Automatic voltage regulator (AVR) is the heart of excitation system of generator. Now a

days the AVR uses semiconductor elements to achieve high reliability with very fast

response. It has two independent channels, the Auto channel with closed loop voltage

regulation and the Manual channel with open loop regulation. The two channels of the

voltage regulator are designed for operation either on i) a station auxiliary AC power

supply and ii) power supply from generator terminal or pilot exciter as the case may be.

Both the auto and manual channels consist of a power part and a control part.

Some of the salient features of AVR are :

a) Capability of maintaining constant terminal voltage over a wide operating range

and maintaining proper share of reactive load among the parallel running

machines.

b) Provision for raising the excitation level quickly (field forcing ) in case of fault or

voltage dip to increase the transient stability limit of the system.

c) In corporation of suitable circuitry to make the reference voltage as a linear

function of frequency or turbo generator up to the edge frequency can be set

depending on the requirement and constant reference voltage beyond edge

frequency.

d) Provision of automatic follow up circuit to supervise and match the firing angles of

the pulses in auto-channel and manual channel so that the disturbance on the

generator terminal is minimum during transfer from auto regulation to manual

regulation.

e) Provision of stator current limiter , rotor current limiter and rotor angle limiter

circuits for optimum utilisation of the lagging and leading reactive capabilities of

the generator.

f) Provision of automatic transformer from auto regulation to manual regulation in

case of measuring PT fuse failure or some internal faults in the auto channel.

g) Facility for remote control of voltage both in auto and manual channel.

Generator Cooling and Sealing System:-

STATOR WATER SYSTEM

Stator water-cooling is a closed loop system

There are two full capacity single stage centrifugal pumps with change over facility

3Ph.415V A.C motors drive the pumps

The stator water cooler is shell and tube type heat exchanger

DM water flows through shell

There are two mechanical filters and one magnetic filter

Mechanical filters are of wire mesh type

Magnetic filter is having permanent magnet

GAS SYSTEM

Generator gas system constitutes of hydrogen gas used to cool the rotor and certain

parts of stator. H-air mixture is explosive. So filling the Generator with H by replacing air

which is dangerous. So initially air is replaced by CO and since CO is heavier than air CO

is being filled from the bottom. Purging of air with CO is being done till the purity of CO.

Cooling fans- Propeller type cooling fans at both the ends of rotor are provided for forced

circulation of H(H cooled machines ) or air(air cooled machines )inside the generator.

Fan hubs are made from alloy steel forgoing and are shrunk fitted on the rotor shaft. The

alloy steel cast fan blades are fixed on the fan hub throughout its periphery with the help

of strength alloy steel non-magnetic conical pins. These fan blades are easily removable

from the hub. Fan shields are provided to guide the gas flow. Fan shields are fixed to the

end shields.

SPECIFICATION OF TURBO GENERATOR:-

For unit#1 to 4

KW:210MW

p.f:0.85 lag

KVA:247,000

Stator voltage:15.75 KV

Stator ampere:9050 A

Rotor voltage:310 V

Rotor ampere:2500A

Rpm:3000

Frequency:50 Hz

Connection: Y Y

Coolant: Water & Hydrogen

Gas pressure: 3.5 bar(G)

Insulation class: F

Specification: IS:5422

IEC:34

For unit#5 and 6

KW:250MW

p.f:0.85 lag

KVA:294100

Stator voltage:16.5 KV

Stator ampere:10291 A

Rotor voltage:292V

Rotor ampere:2395A

Rpm:3000

Frequency:50 Hz

Connection: Y Y

Coolant: Hydrogen

Gas pressure: 3 bar(G)

Insulation class: F

Specification: IS:5422

IEC:34

For Unit#7 and 8

KW:500 MW

p.f:0.85 lag

KVA:588,000

Stator voltage:21 KV

Stator ampere:16,200 A

Rotor voltage:340 V

Rotor ampere:4040 A

Rpm:3000

Frequency:50 Hz

Connection: Y Y

Coolant: Water & Hydrogen

Gas pressure: 3.5 bar(G)

Insulation class: F

Specification: IS:5422

IEC:34

SPECIFICATION OF PILOT & MAIN EXCITER(Unit#5 & 6)

Main Exciter Pilot Exciter

Apparent Power: -- 35KVA

Active Power: 1344KW --

Current: 3200A 105A

Voltage: 420V 220+/-22V

Speed: 50/S 50/S

Freequency: 150Hz 400Hz

SPECIFICATION OF PMG(Unit#7 & 8):-

KW:39

KVA:65

Volts:220

Amps:195

Rpm:3000

Phase:3

Coolant: Air

Insulation Class: F

Connection: Y Y Y Y

Y Y Y Y

Specification: IFC-34

SPECIFICATION OF BRUSHLESS EXCITER(Unit#7& 8):-

KW:3780

Volts DC:600

Amps DC:6300

Excitation Volts DC:107

Excitation Amps DC:142

Rpm:3000

Coolant: Air

Insulation Class: F

Specification: IFC-34

GENERATOR PROTECTION:-

With the ever increasing size of the generator cost of the

machine, the expenses for repair and loss of energy during the outage of the machine are

very high. Hence it is necessary to provide a reliable elaborate protection system to

safeguard against damage and loss of generation and ensure long life of the machine.

Generator protection concerns especially the electrical protection of machines and

associated circuits. The purpose of generator protection is to provide protection against

abnormal operating condition and during fault condition. In the first case the machine

and the associated circuit may be in order but the operating parameters (load, frequency,

temperature) and beyond the specified limits. Such abnormal running condition would

result in gradual deterioration and ultimately lead to failure of the generator. It may be

possible to correct the running of the generator. It may be possible to correct the running

condition after the protective relay gives an alarm, there by avoiding the loss of revenue

and damage of the machine. In the later case , it is necessary to restrict the damage of

the machine and associate circuit to a minimum by taking it out from the service.

PROTECTION UNDER ABNORMAL RUNNING CONDITIONS: -

a)Over current protection: The over current protection is used in generator protection

against external fault as back up protection. Normally external short circuits are cleared

by protection of the faulty section and are not dangerous to the generator. If this

protection fails the short circuit current contributed by the generator is normally higher

than the rated current of the generator and caused over heating of the stator, hence the

generators are provided with back up over current protection which is usually definite

time lag over current relay.

b)Over load protection: Persistent over load in rotor and stator circuit cause heating of

winding and temperature rise of the machine. Permissible duration of the stator and

rotor over load depends upon the class of insulation, thermal time constant, cooling of

the machine and is usually recommended by the manufacturer. Beyond these limits the

running of the machine is not recommended and over load protection thermal relays fed

by current transformer or thermal sensors are provided.

c)Over voltage protection: The over voltage at the generator terminals may be caused

by sudden drop of load and AVR malfunctioning. High voltage surges in the system

(switching surges or lightning) may also cause over voltage at the generator terminals.

Modern high speed voltage regulators adjust the excitation current to take care against

the high voltage due to load rejection. Lightning arresters connected across the

generator transformers terminals take care of the sudden high voltages due to external

surges. As such no special protection against generator high voltage may be needed.

Further protection provided against high magnetic flux takes care of dangerous increase

of voltage.

d)High flux density: High flux density in the machine causes saturation core leading to

over heating in the iron core of both the generator and the transformer due to increased

iron losses and additional losses from the eddy currents. High magnetic flux density may

occur because of over excitation at no load or due to low frequency running. A relay

which operates on V/f (volts per Hz) basis is recommended as a preventive measure for

protection against high flux densities.

e)Unbalance loading protection: Unbalance loading is caused by single phase short

circuit out side the generator, opening of the one of the contacts of the generator circuit

breaker snapping of conductors in the switchyard or excessive single phase load.

Unbalance load produces ve phase sequence current which cause over heating of the

rotor surface and mechanical vibration. Normally 10% of unbalance is permitted provided

phase current do not exceed the rated values. For ve phase sequence currents above

5-10% of rated value dangerous over heating of rotor is caused and protection against

this is an essential requirement. The relay provided for this is an inverse characteristic

with definite minimum time delay relay connected to a network which segregates the

ve sequence current from the positive and zero sequence currents. The I2t

characteristics of the relay is matched to the rotor heating characteristic.

f)Loss of excitation protection: The loss of excitation in a synchronous machine may be

caused by tripping of field circuit breaker or trouble in AVR. On loss of excitation the

generator starts drawing reactive power from the grid instead of supplying it. The power

factor of the generator becomes capacitive and as a result of this asynchronous running

( higher slip frequency) over heating of the rotor surface takes place. In case the

generators connected to the system can not supply this reactive power there will be large

voltage drop in the system leading to instability. The protection provided against loss of

excitation is by an off-set Mho relay. Its operating characteristics is so chosen that during

extremely low excitation faults within the tripping zone.

g) Loss of prime mover protection: In the event of loss of prime mover the generator

operates as a motor and drives the prime mover itself. In some cases this condition could

be very harmful as in the case of steam turbine sets where steam acts as coolant,

maintaining the turbine blades at a constant temperature and the failure of steam results

in over heating due to friction and windage loss with subsequent distortion of the turbine

blade. This can be sensed by a power relay with directional characteristics and the

machine can be taken out of bar under the condition. Because of the same reason a

continuous very low level of output from the thermal sets are not permissible. The

generator breaker is tripped under this condition by the use of a relay measuring the

electrical power output of the generator designed to operate when the power output

faults below selected pre-set value.

h)Pole slip protection: A generator may loss synchronism with system without losing the

excitation. In this condition the machine may be subjected to severe mechanical torque

and oscillation with consequent variation of current, voltage and power factor. If the

angular displacement of the rotor exceeds the stable limit, the rotor will slip a pole pitch.

If the disturbance persist the machine must be isolated from the system to prevent

damage to the generator and to minimize power system disturbance. The pole slipping

protection relay operates on the criteria that the angle of the generator EMF exceeds a

certain fixed value with the operation of the reverse power relay. The occurrence of

these criteria are counted and the machine is tripped out after a certain number of

oscillations. These relays are capable of detecting the first pole slip condition when a slip,

corresponding to the speed of pole slipping is in the range of +0.1% to +10% on a 50Hz

basis. The protection must remain inoperative for steady state lading, power switching

and correctly cleared system fault condition.

PROTECTION UNDER FAULT CONDITION:-

a)Stator short circuit: Short circuits are among the faults which cause the heaviest

damage to the generator. Not only do they result in thermal damages such as the

welding of the core laminations and burning of the winding but also result in possible

mechanical damage like deformation of the ends of the coil. Very fast operating

protection is required , otherwise the damage may be beyond repair. Differential

protections, inter turn short circuit protections are the main protection against short

circuits in stator winding. As back up protection for the same faults, minimum impedance

and over current protections are used.

b)Differential protection: The protection is used for detection of internal faults in a

specified zone defined by the CTs supplying the differential relay. For an unit connected

system separate differential relays are provided for generator, generator transformer

and unit transformer in addition to the overall differential protection. In order to restrict

damage very high differential relay sensitivity is demanded but sensitivity is limited by CT

errors, high inrush current during external fault and transformer tap changer variations.

c) Inter turn fault protection: Inter turn faults comprise of insulation failure between

turns of the same winding or between the parallel winding of the same phase which can

not be detected by longitudinal differential protection. Inter turn faults have commonly

been disregarded on the basis that if the occur the will quickly develop into earth faults

or phase to phase faults which will be detected by the sensitive protections provided for

these faults. With this idea sometimes no specific protection for inter inter-turn fault is

provided. However considering the risk of severe damage to the machine before the

faults convert into above types of faults inter turn fault protection is recommended, In

large machine as all the three windings are brought out separately it is possible to

employ a system to transverse differential protection consisting of balanced current

arrangement between current transformers connected in the line ends of the windings in

which current in the parallel paths of the windings are compared. A bias system is always

used as it is not possible to guarantee in advance that exact current sharing between

windings take place.

d) Back-up impedance protection: This protection is basically designed as back up

protection for the part of the installation situated between the generator and the

generator and unit transformers. A back up protection in the form of minimum

impedance measurement is used, in which the current windings are connected to the

CTs in the neutral connection of the generator and its voltage windings through a PT to

the phase to phase terminal voltage. The pick up impedance is set to such a value that it

is only energised by short circuits in the zone specified above does not respond to faults

beyond the transformers.

e) Stator earth fault protection: The earth fault protection is the protection of the

generator against damages caused by the failure of insulation to earth. Present practice

of grounding the generator neutral is so designed that the earth fault current is limited

within 5 and 10 AMPs. Fault current beyond this limit may caused serious damage to the

core laminations. This leads to very high eddy current loss with resultant heating and

melting of the core.

f) 95% stator earth fault protection: Inverse time voltage relay connected across the

secondary of the high impedance neutral grounding transformer relay is used for

protection of around 95% of the stator winding against earth fault.

g)100% stator earth fault protection: earth fault in the entire stator circuits are detected

by a selective earth fault protection covering 100% of the stator windings. This 100% E/f

relay monitors the whole stator winding by means of a coded signal current continuously

injected in the generator winding through a coupling. Under normal running condition

the signal current flows only in the stray capacitances of the directly connected system

circuit. In case of an earth fault , this capacitance is bypassed and the monitoring current

which is determined mainly by the resistance to earth increases. This increased current

value and reproduction of the signal code are used for the operation of the relay.

h)Rotor earth fault protection: Normally a single rotor earth fault is not so dangerous as

the rotor circuit is unearthed and current at fault point is zero. So only alarm is provided

on occurrence of first rotor earth fault. On occurrence of the second rotor earth fault

between the points of fault the field winding gets short circuited. The current in field

circuit increases, resulting in heating of the field circuit and the exciter. But the more

dangerous is disturbed symmetry of magnetic circuit due to partial short circuited coils

leading to mechanical unbalance. Severe vibration may seriously damage the machine.

Thus the protection circuit should be so designed as to give an alarm in case of

development of 1

st

rotor earth fault and it should trip the machine on the occurrence of

2

nd

earth fault.

GENERATOR OPERATION:-

The operation of the generator is concerned with the basic processes of synchronization,

loading , voltage maintenance, stability and safe tripping/shutting down of the machine.

In the power system the generator is required to operate in parallel with other running

machines and to share both active and reactive power demand of the system.

Synchronization of generator: The process of interconnection of the generator with the

grid to which a number of generators are already connected is known as synchronization.

For successful synchronization and parallel operation of the generator the voltage,

frequency and phase sequence of the incoming generator must be same as that of the

grid(running system ). To determine the exact instant of synchronism synchroscope with

three lamps is provided at the generator control desk. In some machine auto

synchronization facility is also provided. Before rolling of the TG to match the speed of

the machine corresponding to the grid frequency and increasing generator terminal

voltage readiness of the machine itself and it is various auxiliaries are to be ensure. The

synchronization process is to be in close co-ordination with the mechanical system of the

power house. In general following operation and checking are to be carried out in steps

before synchronization of the generator.

Before machine starts rolling check and ensure-

Generator auxiliary system:-

a)The lube oil flow to generator bearings is adequate with correct pressure and

temperature and there is no oil leakage.

b)Casing H pressure is adequate and with required purity. There is no sign of drop in gas

pressure. The machine may be synchronized at a lower H pressure within allowable limit

but in that case load is to be restricted as per the manufacturers recommendation.

Hydrogen extractor fan is in service.

c)Stator cooling water flow is established and distillate conductivity is below 5 micro

mho-cm.

d)Generator exciter end bearing pedestal insulation is clean and free from dust , dirt or

oil.

Generator bus duct:

All the inspection windows are properly closed and there is no oil or water dropping over

the duct. The dehumidifier blower is off.

Neutral grounding transformer(NGT):

a)All the doors are properly closed and locked.

b)There is no drop of oil or water on the cubicle.

Generator P.T and surge protection cubicles:

a)All PT drums are completely rotated towards/inserted in service position and locked in

that position and doors are properly closed.

b)PT fuses are o.k. and tightly inserted within the grips. Door for the box containing fuses

and terminal strip is closed.

ELECTRICAL PROTECTION AND SAFETY INTERLOCKS:

Various failsafe protection

and safety interlocks are provided in the power plant for safe starting, running and

shutting down of electrical equipments. These interlocks play vital role to prevent or

reduce damage of costly equipments during internal fault or fault in connected system/

equipments operational error as well as for safety of personnel and the system as a

whole.

GENERATOR

In general, it is based if generator protection relays initiate non-sequential

trip mode(Class A) for unit isolation. However, sequential tripping (Class B) provides a

better means of tripping a steam turbine generator on some abnormal operating

condition where delayed tripping of the generator will not result in increased damage to

the turbine, generator or other electrical equipment. The reason for sequentially tripping

a steam turbine generator is to avoid the over-speed condition that results when the

generator main breaker is tripped while steam is supplied to the turbine.

Proper control logic is critical to the design of a sequential tripping scheme

switches, trip oil system pressure switches etc) which is supervised by an electrical Low

Forward Power relay/ Reserve Power relay. This relay is normally set to detect very low

power levels and incorporates a brief time delay of the order of few seconds for added

security.

It has been recommended that generator protective relays, initiates non-sequential

trip mode for isolation of the unit due to electrical faults. Only devices protecting unit

from an abnormal mechanical operating condition or an abnormal (not faulted) electrical

condition or normal shut down should initiate a sequential trip.

Class A Lockout Relay will operate for the following conditions indicating major

electrical faults in the Generator stator, Generator rotor, Generator Transformer and

Unit Auxiliary Transformers and excitation transformer and associated field Breaker

Cubicle and similar other faults as detailed below:

a) Generator stator differential relay operated.

b) Generator stator inter-turn differential relay operated.

c) Generator Transformer differential operated

d) Generator Transformer overall differential relay operated

e) Unit auxiliary transformer differential relay operated

f) Generator stator E/F relay(0-95%)operated

g) Generator stator E/F relay (95-100%) operated

h) Generator rotor earth fault relay operated

i) Loss of excitation relay operated

j) Generator transformer restricted E/F relay operated

k) Generator over voltage relay operated

l) Generator reverse power relay operated

m) Generator transformer over-fluxing relay operated

n) Generator transformer back-up E/F relay operated

o) UAT back-up E/F relay operated

p) Back-up distance relay operated

q) Generator negative sequence relay operated

r) Bus differential protection relay operated

s) GT buchholz relay operated

t) UAT buchholz relay operated

u) Thyristor bank failure

v) Generator Neutral isolator open

w) EBP pressed

x) GT SPR(Sudden pressure relay)

Class-B lockout relay will operate for the following conditions:

a)Boiler trip

b) Turbine trip

c)UAT backup O/C relay operated

d)AVR protection

Class-C lockout relay will operate for the following conditions:

a)Back-up distance relay operated stage I

b)Generator negative sequence stage I

c)GT breaker protection

d)GT winding temperature/ oil temperature operated

e) Under frequency relay operated

Unit trip sequence:

The difference sequence of tripping shall be as mention below:

a)Boiler to Turbine to Generator

b)Turbine to Generator

c)Generator to Turbine

Generator field breaker interlocks:

Generator field breaker can only be closed if the

following per missives are available

a)Turbine is running at its rated speed(3000 rpm for thermal machine with

+/- tolerance).

b)To be detected by speed switch contact at ATRS cubicle

c)All generator class-A lockout relay are in reset condition

d)Field flushing system is healthy

Generator field breaker trip interlocks:

Generator field breaker can trip through the

following initiating contacts:

a)Class-A relays operated

Generator field breaker manual trip block interlocks:

When generator is in service

manual tripping of field breaker is not permitted owing to loss of excitation and

subsequent harmful effects on the machine. Operation of F8S relay indicate that

generator is in service(connected in the grid) with its own breaker of bus coupler breaker.

One NC contact of F8S relay is used in series with the manual tripping circuit of the field

breaker.

Generator field breaker auto-trip block interlocks:

When generator is in service, auto

tripping (through Class-A lockout contacts) of field breaker is permitted only after

opening of generator breaker or transfer B/C breaker as case may be and there by

drop out of F8S relay to avoid momentary loss of excitation and subsequent harmful

effect on the machine.

Single Line Diagram Of Generating Station(unit#5 and 6)

SINGLE LINE DIAGRAM OF GENERATING STATION(UNIT-7)

GENERATOR TRANSFORMER

Transmission of power at generated voltage is not economical. The need for transformers

is paramount for a power system considering the fact that transmission losses are

minimum for high voltages where as a distribution has to be done at the relatively safe

voltage. In essence the transformer transforms a voltage and current one level to a

voltage and current at another level while keeping the frequency and power level

unaltered. So generator output voltage is step up to the transmission voltage system

voltage by a transformer known as Generator transformer(GT). Capacity of generator

transformer is determined based on the MVA capacity of generator. The open type

terminals of the HV bushing of the generator transformer are connected to switchyard

conductor through GCB. The LV terminals are kept suitably enclosed to facilitated

connection to generator bus duct. Cooling method adopted is OFAF.

In MTPS Unit#1 to 6, GTs are single 3 phase transformer and in phase II, GTs are a bank

of three single phase transformers . The only step up transformer is GT in this station.

GENERATOR TRANSFORMER

Specification of GT:-

Unit# 1 to 4

Make: BHEL

Type of cooling: ONAN/ONAF/OFAF

Rating of HV(MVA): 150/200/250

Rating of LV(MVA): 150/200/250

Frequency(Hz): 50

Phase: 3

Connection symbol: YNd1

No Load Voltage of HV(KV): 240

No Load Voltage of LV(KV): 15.75

Line Current of HV(Amp): 301/482/602

Line Current of LV(Amp): 3505/7340/9175

Temperature rise of oil(:C): 40 over ambient of 50:C

Temperature rise of winding(:C): 45 over ambient of 50:C

Weight:

Core and windings(kg): 139000

Complete Transformer including oil(kg): 38070

Transport(kg): 237100

Insulation level: HV SI 750 LI 1050

LV LI 95 AC 50

H.V.N LI 170 AC 70

Unit# 5 and 6

Make: BHEL

Type of cooling: ONAN/ONAF/OFAF

Rating of HV(MVA): 109/252/315

Rating of LV(MVA): 109/252/315

Frequency(Hz): 50

Phase: 3

Connection symbol: YNd1

No Load Voltage of HV(KV): 220

No Load Voltage of LV(KV): 16.5

Line Current of HV(Amp): 757.77

Line Current of LV(Amp): 11022.14

Temperature rise of oil(:C): 40 over ambient of 50:C

Temperature rise of winding(:C): 45 over ambient of 50:C

Weight:

Core and windings(kg): 165000

Complete Transformer including oil(kg): 253250

Transport(kg): 180000

Oil quantity(lit): 57000

Insulation level: HV SI 750 LI 1050

LV LI 95 AC 50

H.V.N LI 170 AC 70

Unit#7 and 8

Make: BHEL

Type of cooling: ONAN/ONAF/OFAF

Rating of HV(MVA): 120/160/200

Rating of LV(MVA): 120/160/200

Frequency(Hz): 50

Phase: 1

Connection symbol: YNd11

No Load Voltage of HV(KV): 420/3

No Load Voltage of LV(KV): 21

Line Current of HV(Amp): 824.79

Line Current of LV(Amp): 9523.8

Temperature rise of oil(:C): 40 over ambient of 50:C

Temperature rise of winding(:C): 45 over ambient of 50:C

Weight:

Core and windings(kg): 153520

Complete Transformer including oil(kg): 257500

Transport(kg): 174900

Oil quantity(lit): 56220

Insulation level: HV SI 1180 LI 1425-AC 38

CHOPPED LI 1570

LV 125-AC 50

UNIT TRANSFORMER:

There is one unit transformer for each unit in phase ii. There are some machines whose

operating voltage is 11kv.To supply these machines we have to step down the generating

voltage. These can be done by unit transformer by tapping from generating terminal.

Unit transformer step down the voltage 21kv to 11 kv. This is a three phase transformer.

But, in case of unit#1to 6 there is no need of UT, because there is only two

voltage level-6.6kv and 415v.

Specification of UT:-

Make: BHEL

Type of cooling: ONAF/ONAN

Rating of HV(MVA): 45/36

Rating of LV(MVA): 45/36

Frequency(Hz): 50

Phase: 3

Connection symbol: Dyn1

No Load Voltage of HV(KV): 21

No Load Voltage of LV(KV): 11.5

Line Current of HV(Amp): 1238.64

Line Current of LV(Amp): 2261.87

Temperature rise of oil(:C): 40 over ambient of 50:C

Temperature rise of winding(:C): 45 over ambient of 50:C

Weight:

Core and windings(kg): 40065

Complete Transformer including oil(kg): 86205

Transport(kg): 50000

Oil quantity(lit): 25580

Insulation level: HV LI 125-AC 50

LV LI 75-AC 28

Unit Auxiliary Transformer:

The normal source of HV power to unit auxiliaries is unit auxiliary transformer. The sizing

of the UAT is usually based on the total connected capacity of running unit auxiliaries i.e

excluding the stand by drives. It is safe and desirable to provide about 20% excess

capacity than calculated. With the help of UAT we stepped down the generated 15.75kv

(in case of unit#1to4) and 16.6 kv(in case of unit#5,6) into 6.6kv to supply the 6.6kv

auxiliary drives. But, in case of phase II UAT is used to stepped down the 11kv voltage

into 3.3kv to supply the 3.3 kv machines and its high voltage terminal is connected to a

UT and there is two UAT for each UT.

Specification of UAT:-

For Unit# 1to 4

Make: Atlanta Electrical Pvt.Ltd.

Type of cooling: ONAF/ONAN

Rating of HV(MVA): 16/12.50

Rating of LV(MVA): 16/12.50

Frequency(Hz): 50

Phase: 3

Connection symbol: Dyn11

No Load Voltage of HV(KV): 15.7

No Load Voltage of LV(KV): 6.9

Line Current of HV(Amp): 586.5 /458.2

Line Current of LV(Amp): 1338.8/1045.9

Temperature rise of oil(:C): 40:C

Temperature rise of winding(:C): 45:C

Weight:

Core and windings(kg): 14300

Weight of oil(kg): 8600

Total weight(kg): 30500

Oil quantity(litre): 7650

Insulation Level:

HV : 95 KVP 38 KV rms

LV : 30 KVP 20 KV rms

For Unit#5 and 6

Make: BHEL

Type of cooling: ONAF/ONAN

Rating of HV(MVA): 20/16

Rating of LV(MVA): 20/16

Frequency(Hz): 50

Phase: 3

Connection symbol: Dyn11

No Load Voltage of HV(KV): 16.5

No Load Voltage of LV(KV): 6.9

Line Current of HV(Amp): 699.81/559.85

Line Current of LV(Amp): 1673.479/1338.783

Temperature rise of oil(:C): 50:C

Temperature rise of winding(:C): 55:C

Weight:

Core and windings(kg): 20600

Weight of oil(kg): 15050

Total weight(kg): 46300

Oil quantity(litre): 16900

Insulation Level:

HV : 95 KVP 38 KV rms

LV : 30 KVP 20 KV rms

For Unit#7 and 8

Make: BHEL

Type of cooling: ONAF/ONAN

Rating of HV(MVA): 16/12.50

Rating of LV(MVA): 16/12.50

Frequency(Hz): 50

Phase: 3

Connection symbol: Dyn1

No Load Voltage of HV(KV): 11

No Load Voltage of LV(KV): 3.45

Line Current of HV(Amp): 839.78/656.08

Line Current of LV(Amp): 2677.57/2091.85

Temperature rise of oil(:C): 40:C

Temperature rise of winding(:C): 45:C

Weight:

Core and windings(kg): 16700

Weight of oil(kg): 9800

Total weight(kg): 40000

Oil quantity(litre): 11000

Insulation Level:

HV : LI 75 KVP AC 28 KV rms

LV : LI 40 KVP AC 10 KV rms

DISTRIBUTION TRANSFORMER

To supply the 415v rated motors we use this distribution transformer which actually

steps down the 6.6kv supply into 415v.Some of the distribution transformer are dry type

i.e natural cooling system is used here.For each unit(1 to 6) there are 8 distribution

transformer inside plant.

:RATING:

Make: BHEL

Type of Cooling: AN

Rating(KVA): 1250

Rated Current H.V(Amps): 109.4

Rated Current L.V(Amps): 1666.7

Vector Group: DyN11

Model: CAST RESIN DRY TYPE

Freequency: 50Hz

Temperature Rise Over 50

0

c Ambient

at 85.5% rated voltage: 80

0

c

Insulation level H.V: 75KVp/28KV rms

Insulation Class: F

Weight(Kg): 5500

STATON SERVICE TRANSFORMER(SST):

Normal source to the station auxiliaries and stand by source to the unit auxiliaries during

start up and after tripping of the unit is Station Service transformer. Quantity of station

Service transformers and there capacity depends upon the unit sizes and numbers. Each

station service transformer shall be one hundred percent stand by of the other. Station

service transformers shall cater to the simultaneous load demand due to start up power

requirements for the largest unit, power requirement for the station auxiliaries required

for running the station and power requirement for the unit auxiliaries of a running unit in

the event of outage of the unit source of supply. There is three SST for unit#1 to 4 and

two SST for unit#5 and 6.Its steps down 220 kv grid voltage to 6.6 kv voltage and supply

two board-CAB(Common Auxialiary Board) and SEB(Start-up Emergency Board).

For unit#1 to 4

Make: BHEL

Type of cooling: ONAF/ONAN

Rating of HV(MVA): 31.5/25.2

Rating of LV(MVA): 31.5/25.2

Frequency(Hz): 50

Phase: 3

Connection symbol: YNyn0d1

No Load Voltage of HV(KV): 230

No Load Voltage of TV(KV): 11

No Load Voltage of LV(KV): 6.6

Line Current of HV(Amp): 79.1

Line Current of TV(Amp): 2635.8

Temperature rise of oil(:C): 40

Temperature rise of winding(:C): 45

Weight:

Core and windings(kg): 34400

Weight of oil(kg): 29550

Total weight(kg): 214000

For unit#5 and 6

Make: BHEL

Type of cooling: ONAF/ONAN

Rating of HV(MVA): 40/25

Rating of LV(MVA): 25/15.625

Frequency(Hz): 50

Phase: 3

Connection symbol: YNyn0yn0

No Load Voltage of HV(KV): 230

No Load Voltage of LV1(KV): 6.9

LV2(KV): 6.9

Line Current of HV(Amp): 100.408/62.755

Line Current of LV1(Amp) and LV2: 2091.848/1307.405

Temperature rise of oil(:C): 40

Temperature rise of winding(:C): 45

Weight:

Core and windings(kg): 48000

Weight of oil(kg): 46000

Total weight(kg): 132000

But in case of phase II this scheme is different and this is elaborated below-

STATION TRANSFORMER (ST):

Normal source to the station auxiliaries and stand by source to the unit auxiliaries during

start up and after tripping of the unit is Station transformer. Quantity of station

transformers and there capacity depends upon the unit sizes and numbers. Each station

transformer shall be one hundred percent stand by of the other. Station transformers

shall cater to the simultaneous load demand due to start up power requirements for the

largest unit, power requirement for the station auxiliaries required for running the

station and power requirement for the unit auxiliaries of a running unit in the event of

outage of the unit source of supply. We have two station transformer in 400kv

switchyard. It steps down the 400kv grid voltage to 11kv voltage.

STATION AUXILIARY TRANSFORMER(SAT):

Station auxiliary transformer is also a step down transformer. It steps down 11kv voltage

to 3.3kv voltage. It is mainly used to supply the 3.3 kv machines. Its high voltage is

connected to the secondary of the ST. Its use is similar to the UAT at starting condition

and tripping condition. There is two SAT for each ST.

Specification of ST:-

Make: BHEL

Type of cooling: ONAN/ONAF

Rating of HV(MVA): 72/90

Rating of LV(MVA): 72/90

Frequency(Hz): 50

Phase: 3

Connection symbol: Yn0 Yn0 Yn0

No Load Voltage of HV(KV): 400

No Load Voltage of LV1(KV): 11.5

LV2(KV): 11.5

Line Current of HV(Amp): 130

Line Current of LV1(Amp): 2261.9

LV2(Amp): 2261.9

Temperature rise of oil(:C): 40

Temperature rise of winding(:C): 45

Weight:

Core and windings(kg): 9769

Weight of oil(kg): 58450

Total weight(kg): 214000

Oil quantity(litre): 67180

Insulation level:

HV : LI 1300-AC38

LV 1: LI 75- AC28

LV2: LI 75-AC28

Specification of SAT:-

Make: BHEL

Type of cooling: ONAN/ONAF

Rating of HV(MVA): 16/12.50

Rating of LV(MVA): 16/12.50

Frequency(Hz): 50

Phase: 3

Connection symbol: DyN1

No Load Voltage of HV(KV): 11

No Load Voltage of LV(KV): 3.45

Line Current of HV(Amp): 839.78/656.08

Line Current of LV(Amp): 2677.57/2091.85

Temperature rise of oil(:C): 40

Temperature rise of winding(:C): 45

UST & SST:- There are other two types of step-down 3 phase transformer for internal

operation, known as UST and SST. UST is fed from UT switch board and SST is fed from ST

switch board. These are dry type cast resin transformer. The voltage ratio is 11KV/433V

for both the transformer. Air natural cooling and Dyn1 connection is used.

NGT (NEUTRAL GROUNDING TRANSFORMER):

The NGT is used to prevent the generator from earth faults. It comprises of primary

winding and secondary winding, the secondary winding is connected with a low value

resistance. When ever a earth fault arises heavy current flows to the primary winding and

as a result an emf is induced in the secondary. The voltage drop across the resistance is

sensed by the NGT relay and it actuates to actuate the GCB(generator circuit breaker)

and thus the generator is tripped. Basically NGT is a step-down(21KV/220V) transformer.

TRANSFORMER AUXILARIES:

For proper functioning of the transformer it is provided with several auxiliaries sub

systems. Basically they are:

COOLING SUB SYSTEM:

Considering the substantial amount of load delivered by a power transformer a

proper cooling system has to be in place in order to prevent any hazards. Mostly,

OFAF(Oil Forced Air Forced) or ONAF(Oil Natural Air Forced) schemes are used.

There are radiators and fans as well. For OF type cooling butterfly valve is kept to

pump oil.

CONSERVETOR:

Since the oil plays a major role in the cooling of a transformer hence it has to be

maintained. The conservator preserves the oil of the transformer while expansion

of oil.

BUCHHOLZ RELAY:

It is a protective device used only in oil immersed transformer. It provides

protection against two types of fault, incipient fault and severe fault. Under

incipient fault it gives an alarm and under severe fault it trips the transformer from

the line by using two floats which acts as a switch. It is universally use for

transformer having rating more than 750 KVA.

BREATHER:

The breather basically absorbed any moisture that may be caused due to

vaporization of the oil in transformer. It contains silica gel, which changes colour

from blue to off-white as it absorbs moisture. Thus it provides an indicator

mechanism for the quality of the oil.

PROTECTION MECHANISMS:

There are temperature sensors, which can alarm if the temperature rises beyond a

certain limit. Also the water supply gets activated in case of hazards like fire.

There are also kept RTD(resistance temperature detector) and PRV(pressure relief valve)

for safety.

SWITCHYARD

It is a switching station ,which has the following credits:

Main link between generating plant and transmission system, which has a

large influence on the security of the supply.

Step-up and/or step-down the voltage levels depending upon the Network node.

Switching ON/OFF reactive power control devices, which have effect on quality of

power.

In MTPS has mainly two switchyards. one is 220KV and another one is 400KV.

These two switchyards are of three bus system(also called, one and half bus system).

1. Main bus I

2. Main bus II

3. Transfer bus

Single Line Diagram of 220kv switchyard

Single Line Diagram Of 400kv Switchyard

EQUIPMENTS COMMONLY FOUND IN SWITCHYARD:-

1. Circuit Breakers

2. Current Transformer

3. Potential Transformer

4. Capacitor Voltage Transformer

5. Isolator

6. Earth Switch

7. Lightning Arrester

8. Wave traps

9. Bus bar & Clamp fittings

1. CIRCUIT BREAKERS:-

It is an on-load switch which can break the circuit under any fault

condition which can damage other instrument in the station. It works automatically and

also manually.

There are mainly two types CB are used. These are a). SF gas CB, b). Vacuum Circuit

Breaker.

In the 220KV switchyard we have SF CBs (single break) and in the 33kv switchyard we

have VCB.

In the 400kv switchyard we have double break SF CB. This type of CB arrangement

consist of i) gradient capacitor, ii) break, iii) pre-insert resistor. The gas is put inside the

circuit breaker by force under high pressure. When if the gas gets decreases there is a

motor connected to the circuit breaker. The motor starts operating if the gas went lower

than 20.8 bar. There is a meter connected to the breaker so that it can be manually seen

if the gas goes low. The circuit breakers use the SF gas to reduce the torque produce in it

due to any fault in the line. The circuit breaker has a direct link with the instruments in

the station, when any fault occur alarm bell rings.

In a single break type only the bus bar end is isolated but in a double break type, both

bus bar(source) and cable (load) ends are broken.

CIRCUIT BREAKER

(Double Break) (Single Break)

2. CURRENT TRANSFORMER:-

Current transformers are basically used to take the reading of the currents entering the

station. This transformer steps down the current from 1600amps to 1 amp. This is done

because we have no instruments to measure such type of huge amount current. This

type of transformer are used to i) protection & ii) measurement purpose.

There are 5 cores used in this type of CT.

CURRENT TRANSFORMER

3.POTENTIAL TRANSFORMER:-

Potential transformers serve a number of functions in a power system.

They are required for the operation of many types of instrumentations and relay

protective systems. They are mainly used to step down the high magnitude of voltage to

a save value to incorporate measuring and protection logics. They measures voltage and

in conjunction with CT, they measure power. They feed synchronizing equipments. They

can be used as coupling capacitor in power line carrier network.This is used in 220KV

Switchyard.

(POTENTIAL TRANSFORMER)

4. CAPACITOR VOLTAGE TRANSFORMER(CVT):-

A capacitor voltage transformer (CVT) is a

transformer used in power system to step down extra high voltage signals and provide

low voltage signal either for measurement or to operate protective relay. In

its most basic form it consist of three parts: two

capacitor across which the voltage signal is split, an

inductive element used to tune device to the supply

frequency and a transformer to isolate and further step

down voltage for instrumentation and protective relay.

The device has at least four terminals, a high voltage

terminal for connection of high voltage signal, a ground

terminal and at least one set of secondary terminals for

connecting to the instrumentation and protective relay.

CVTs are typically single phase device used for measuring voltage in excess of one

hundred kilovolts where the use of voltage transformer would be uneconomical. In

practice the first capacitor, C1 is often replaced by a stack capacitor connected in series.

This result in large voltage drop across the stack of capacitor that replaced the first

capacitor and a comparatively small voltage drop across the second capacitor, C2 and

here the secondary terminals.

5.ISOLATOR:-

Basically an isolator is off-load switch. The use of this isolator is to protect

the transformer from the other instrument in the line. The isolator isolates the extra

voltage to the ground and thus any extra voltage cannot enter the line. Thus an isolator is

used after the bus for protection also. Two isolator must be kept in both side of a

breaker.

Type of isolator used in 220KV:

i)Central Rotate Double Break

(CRDB)

Types of isolator used for 400KV:

i) HCB(horizontal central break)

ii) pantograph

HCB Pantograph isolator

6. EARTH SWITCH:-

Earth switch discharges the capacitive voltage stored in line on

generator side in isolated system just after opening of CB and isolator. When earth switch

is connected to the isolated but un-discharged system it discharges the stored energy to

the earth, so that maintenance work can be carried out either in line or in generator side.

Earth switch should be operated only when the isolators are open. In MTPS all earth

switches can be operated manually.

EARTH SWITCH

7. LIGHTENING ARRESTOR:-

Lightening arrestors are the instruments that are used in the

incoming feeders so that to prevent the high voltage entering the main station.

This high voltage is very dangerous to the instruments used in the substation. Even

the instruments are very costly, so to prevent any damage lightening arrestors are

used. The lightening arrestors do not let the lighting to fall on the station. If some

lightening occurs the arrestors pull the lightening and ground it to the earth. In any

sub-station the main important is of protection which is firstly done by these

lightening arrestors. The lightening arrestors are grounded to the earth so that it

can pull the lightening to the ground. The lightening arrestors work with an angle

of 30: to 45: making a cone. In 400kv switchyard gap-less arrestor are used & gap

less material is ZnO.

LIGHTENING ARRESTOR WAVE TRAP

8. Wave Traps:-

Wave trap is nothing but a L-R circuit which can trap the high frequency

communication signals sent on the line from the remote substation and diverting

them to the telecom/tele protection panel in the substation control room (through

coupling capacitor and LMU).This is relevant in Power Line carrier

Communication(PLCC) systems for communication among various substation

without dependence on the telecom company network. The signals are primarily