Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Rules For Classification and Construction I Ship Technology: 1 Seagoing Ships

Caricato da

LastunDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Rules For Classification and Construction I Ship Technology: 1 Seagoing Ships

Caricato da

LastunCopyright:

Formati disponibili

Rules for Classification and Construction

I Ship Technology

1 Seagoing Ships

12 Chemical Recovery Vessels

Edition 2005

The following Rules come into force on September 1

st

, 2005

Germanischer Lloyd Aktiengesellschaft

Head Office

Vorsetzen 35, 20459 Hamburg, Germany

Phone: +49 40 36149-0

Fax: +49 40 36149-200

headoffice@gl-group.com

www.gl-group.com

"General Terms and Conditions" of the respective latest edition will be applicable

(see Rules for Classification and Construction, I - Ship Technology, Part 0 - Classification and Surveys).

Reproduction by printing or photostatic means is only permissible with the consent of

Germanischer Lloyd Aktiengesellschaft.

Published by: Germanischer Lloyd Aktiengesellschaft, Hamburg

Printed by: Gebrder Braasch GmbH, Hamburg

Table of Contents

Section 1 General Conditions and Requirements

A. Scope .......................................................................................................................................... 1- 1

B. Definitions .................................................................................................................................. 1- 1

C. Characters of Classification ........................................................................................................ 1- 2

D. Documents to be Submitted for Approval .................................................................................. 1- 2

E. Surveys ....................................................................................................................................... 1- 3

Section 2 Arrangement and Separation of Spaces

A. General Requirements ................................................................................................................ 2- 1

B. Ship Arrangements ..................................................................................................................... 2- 1

Section 3 Machinery Installations

A. Machinery Spaces ...................................................................................................................... 3- 1

B. Cargo Area ................................................................................................................................. 3- 2

C. Fire Extinguishing and Alarm Equipment .................................................................................. 3- 2

D. Ventilation and Air Conditioning ............................................................................................... 3- 3

E. Gas Detection and Alarm System ............................................................................................... 3- 4

Section 4 Electrical Plant

A. General ....................................................................................................................................... 4- 1

B. Electrical Equipment in Hazardous Areas .................................................................................. 4- 1

Section 5 Safety Equipment and Operation

A. Safety and Protective Equipment for Personnel ......................................................................... 5- 1

B. Operations and Equipment Manual ............................................................................................ 5- 1

I - Part 1

GL 2005

Table of Contents Chapter 12

Page 3

Section 1

General Conditions and Requirements

A. Scope

1. Indications

These Rules apply to steel inland-waterway and sea-

going vessels with or without their own means of

propulsion, which in the event of an accident involv-

ing chemicals may be used for service in a hazardous

atmosphere. These may be auxiliary vessels for float-

ing equipment as well as independent operating ves-

sels. Vessels complying with these Rules may without

restriction be used for service in oil-covered waters.

If the vessel is intended to be used for restricted ser-

vices, materials other than steel may be used for con-

struction.

These Rules are for application in the case of toxic or

corrosive substances, and of substances having a flash

point not exceeding 60 C (closed cup-test).

These Rules can analogously be applied to appliances

bearing no resemblance to ships and which do not fall

within the scope of ship classification.

2. Other applicable rules

Applicable alongside these Rules are the specifically

relevant GL Rules Chapter 1 Hull Structures,

Chapter 2 Machinery Installations, Chapter 3 Elec-

trical Installations, Chapter 7 Chemical Tankers and

Chapter 21 Ventilation plus the GL Rules Part 2

Inland Waterway Vessels.

B. Definitions

In the context of these Rules the following definitions

apply:

1. Hazardous Area

The area of a ship, in which an explosive atmosphere

in a dangerous quantity is to be expected.

Hazardous areas are subdivided into Zones 0, 1 and 2

depending on the likelihood of the presence of an

explosive atmosphere. For a chemical recovery vessel,

the following subdivision applies:

1.1 Zone 0

Zone 0 comprises areas in which an explosive atmos-

phere is constantly present or for long periods of time.

The following areas correspond to Zone 0:

cargo tanks for hazardous substances as well as

the inside of pipelines and vessels belonging to

the cargo tank system

the area up to 1 m above the water surface/the

load waterline.

1.2 Zone 1

Zone 1 comprises areas in which an explosive atmos-

phere is liable to occur on occasion.

The following areas correspond to Zone 1:

cofferdams and other spaces adjacent to cargo

tanks

cargo pump rooms

enclosed or semi-enclosed spaces directly above

cargo tanks or with boundaries in line with

cargo tank bulkheads

stowage spaces for cargo hoses and for chemi-

cal-recovery equipment

holds for hazardous substances

areas on the open deck, including semi-enclosed

spaces, spherically within a radius of 3 m from

tank openings and openings from pump rooms,

holds or cofferdams (e.g. cargohatches, inspec-

tion openings, ventilation openings, accesses)

the open deck above Zone 0 for the full length

and breadth of the ship up to 3 m above the up-

permost continuous deck. For ships whose up-

permost continuous deck is Zone 0, Zone 1 ex-

tends up to 3 m above Zone 0

spaces not having overpressure ventilation,

directly accessible (without an air lock) from a

hazardous area in Zone 1 or with an opening to

this

enclosed or semi-enclosed spaces with pipelines

belonging to the cargo tank system.

1.3 Zone 2

Zone 2 comprises areas in which an explosive atmos-

phere is liable to occur rarely and only for short peri-

ods.

The following areas correspond to Zone 2:

areas above the hazardous areas of Zone 1 over

the full length and breadth of the ship

I - Part 1

GL 2005

Section 1 General Conditions and Requirements Chapter 12

Page 11

B

spaces not having overpressure ventilation,

directly accessible (without an air lock) from a

hazardous area in Zone 2 or with an opening to

this

2. Non-hazardous areas

Non-hazardous areas are ones not belonging to one of

the Zones 0, 1 or 2 (citadel area).

3. Hazardous substance

Toxic, corrosive or combustible substances trans-

ported on board inland-waterway- or seagoing ships in

solid, liquid or gaseous state as bulk cargo or in pack-

aged form.

4. Hazardous atmosphere

A hazardous atmosphere is one of gases or vapours in

dangerous concentration and quantity, noxious to

humans and/or explosive.

5. Cargo area

Area of the ship comprising all spaces and tanks, in-

cluding slop tanks, designated for the carriage of liq-

uid or solid packaged goods or cargo transported in

bulk. In addition, the cargo area comprises of cargo

pump rooms, ballast pump rooms, cofferdams, ballast

tanks or void spaces adjacent to cargo tanks, slop

tanks or cargo spaces plus deck areas covering the full

length and breadth of the ship, over the above-named

spaces.

Any tanks used for the temporary storage of sub-

stances such as settling tanks are to be considered as

cargo/slop tanks in the sense of this definition.

6. Citadel

Internal area of the ship which is protected against

penetration by a hazardous atmosphere. The citadel

comprises of any space in the ship which is in con-

tinuous use during service or must, for safety reasons,

be accessible at all times.

7. Protected air

Air cleaned of hazardous substances in a filtration

station and fed into the citadel.

8. List of substances

List of substances for which a ship or parts of its

equipment are suitable.

9. Air lock

Space between two gastight doors at the entrances to

the citadel.

10. Operation centre

Compartment manned by a responsible person

throughout the operation in hazardous atmosphere and

in which all monitoring and control functions impor-

tant to the operation are concentrated.

C. Characters of Classification

1. Vessels complying with these Rules and

having facilities for the recovery of hazardous sub-

stances plus tanks for liquid substances in bulk and/or

holds for packaged and solid bulk goods, receive the

Notation CHEMICAL RECOVERY VESSEL after

their Character of Classification.

Vessels equipped with facilities for oil recovery re-

ceive the additional Notation OIL RECOVERY

VESSEL.

2. Vessels corresponding to 1., but having no

tanks or holds for the carriage of the recovered sub-

stances, receive in addition to the class designation the

entry "Without cargo tanks/holds" in the Certificate.

3. Vessels which have neither the necessary

facilities for the recovery of hazardous substances nor

tanks or holds for storage but otherwise comply with

these Rules and are suitable for service in a hazardous

atmosphere, in addition to the appropriate class desig-

nation such as TUG, SUPPLY VESSEL receive the

entry "Suitable for service in a hazardous atmosphere"

in the Certificate.

4. If there are restrictions with regard to the

carriage of hazardous substances or restriction to the

ship's service in a hazardous atmosphere, the ship

receives a list of substances as an Appendix to the

Class Certificate.

D. Documents to be Submitted for Approval

1. Apart from the documents listed in the GL

Rules Chapter 1 Hull Structures, Section 1, G. and in

the GL Rules Part 2 Inland Waterway Vessels,

Chapter 1 Hull Structures, Section 1, E., the follow-

ing documents are to be submitted in triplicate:

general arrangement drawing with information

about the position and applications of the

equipment used during service in a hazardous

atmosphere

details of accesses and openings which during

service in a hazardous atmosphere are in opera-

tional use and cannot be closed gastight

Chapter 12

Page 12

Section 1 General Conditions and Requirements I - Part 1

GL 2005

D

details of accesses and openings which during

service in a hazardous atmosphere must be

closed gastight

details of the arrangement and capacities of the

cargo tanks/holds

drawings of the cargo tanks/holds with details of

the materials

details of the supports and securing arrange-

ments of the cargo tanks if independent tanks

are intended to be provided

drawings showing the design and arrangement

of windows, together with information about

materials used

2. Apart from the documents listed in the GL

Rules Chapter 2 Machinery Installations, Section

15, A.3., and in the GL Rules Part 2 Inland Water-

way Vessels, Chapter 2 Machinery Installations, the

following documents are to be submitted in triplicate:

operations and equipment manual for service in

a hazardous atmosphere

schematic diagrams of the pumping and piping

arrangements connected to the ship during ser-

vice in a hazardous atmosphere

drawings from which are apparent the disposi-

tion and location of the chemical-recovery

equipment connected to the ship and carried

loose during service in a hazardous atmosphere,

with full technical details and material specifica-

tions

drawings from which the arrangement and loca-

tion of the ventilation system is apparent

constructional drawings of the most important

parts of the ventilation system

design calculation of the ventilation system

according to Section 3, D.2.

proof of the suitability of fitted air filters

ventilation plan of the spaces with overpressure

ventilation plus arrangement of the air locks

plan of closing appliances for service in a haz-

ardous atmosphere

3. Apart from the documents listed in the GL

Rules Chapter 3 Electrical Installations, Section 1,

C., and in the GL Rules Part 2 Inland Waterway

Vessels, Chapter 3 Electrical Installations, Section 1,

B., the following documents are to be submitted in

triplicate:

general arrangement drawing with details of the

areas of Zones 0, 1 and 2 subject to explosion

hazard during service in a hazardous atmosphere

and of the areas with overpressure from ventila-

tion

details of protection/ignition protection of the

fitted appliances in the areas listed under B.1.

details of the non-certified safe-type electrical

equipment in the hazardous area which during

service in a hazardous atmosphere have to be

shut down

details of the design of the gas detection equip-

ment with proof of suitability for the substances

to be measured plus drawings showing the ar-

rangement of the gas measuring points

electrical power balance for service in a hazard-

ous atmosphere

E. Surveys

1. With regard to surveys, chemical recovery

vessels shall be treated like chemical tankers. In addi-

tion to the range of inspections laid down in the GL

Rules Part 0 Classification and Surveys, Section 3,

the inspections listed below shall be carried out.

1.1 Initial Survey

The protected air system and the equipment provided

for service in a hazardous atmosphere shall, within the

framework of the initial inspection undergo a check of

whether it meets the safety specifications and service-

ability. In particular the working conditions for service

in a hazardous atmosphere have to be established

exactly as described in the operations and equipment

manual.

1.2 Annual survey

The protected air system and the equipment provided

for service in a hazardous atmosphere plus the associ-

ated safety equipment shall within the framework of

the annual inspection undergo a check to confirm that

it is in a satisfactory operational condition.

1.3 Class renewal survey

The protected air system and the equipment provided

for service in a hazardous atmosphere plus the associ-

ated safety equipment shall within the framework of

the class renewal inspection undergo a check in order

to ascertain that it has been thoroughly maintained. In

addition a thorough operational test is to be carried

out.

I - Part 1

GL 2005

Section 1 General Conditions and Requirements Chapter 12

Page 13

E

Section 2

Arrangement and Separation of Spaces

A. General Requirements

1. General

Regarding separation of the cargo area from the other

areas of the ship, the Rules Chapter 1 Hull Struc-

tures, Section 24, A.4. and Chapter 7 Chemical

Tankers, Section 3 and the GL Rules Part 2 Inland

Waterway Vessels, Chapter 1 Hull Structures, Sec-

tion 17, apply. Drycargo holds for hazardous sub-

stances shall be treated like cargo tanks. With regard

to the arrangement of the accommodation, machinery

and cargo areas, deviation from the Rules may be

possible after examination and with approval from the

competent authority.

2. Citadel

The citadel area is to be so designed that the protected

spaces can, during service in a hazardous atmosphere,

be kept at an overpressure relative to the outside at-

mosphere to preclude entry of hazardous substances

from outside. For further details refer to Section 3,

D.2.

3. Accesses and openings

Accesses and openings into the citadel which during

the service in a hazardous atmosphere are not in op-

erational use shall be capable of being closed gastight.

For accesses and openings in operational use suitable

measures are to be provided to prevent the entry of

hazardous substances/loss of overpressure. Means

shall be provided for decontaminating personnel con-

taminated with harmful substances.

4. Markings

All equipment requiring a change of setting for service

in a hazardous atmosphere (e.g. gastight doors, central

switches, closures to openings), shall be marked

prominently.

B. Ship Arrangements

1. Hull

1.1 All openings to rooms and tanks, except

those which are in operational use, must be so con-

structed, that they are capable of being closed gastight

when the ship is due to operate in a hazardous atmos-

phere.

1.2 Windows

1.2.1 Windows are to be produced as non-opening

type in accordance with ISO 21005, DIN ISO 1751 or

another international comparable standard and are to

be tested accordingly in the presence of the Surveyor.

1.2.2 The glass is to be tested in accordance with

DIN ISO 614 and shall be marked accordingly.

1.2.3 Windows shall be generally of laminated

type. The laminate has to consist of at least two layers

of thermally toughened safety glass, bonded by a foil.

1.2.4 The windows have to be designed to with-

stand a shock wave with a positive pressure of 0,3 bar

for at least 200 ms.

1.2.5 The local design loads according to Chapter

1 Hull Structures have to be applied.

1.2.6 In case of international service the 1966 load

line convention in its relevant edition is to be observed

regarding arrangement and specification. Deviations

must be approved by the relevant Administration.

1.2.7 Heated panes for wheelhouse windows are in

addition to be designed and tested according to

DIN ISO 3434.

1.2.8 Fire resistant windows, where necessary,

have to be considered separately, see DIN ISO 5797.

2. Air locks

2.1 The accesses to the citadel are to be provided

with air locks which ensure the maintenance of over-

pressure inside. An air lock must comprise two doors

not less than 1,5 m apart. The doors must be self-

closing and may not have any fixing devices. The door

sill must be at least 300 mm high. Legal stipulations

going beyond this are to be observed.

2.2 An alarm is to be provided which indicates if

more than one of the doors is not fully closed.

2.3 Air locks shall be so designed that they are

flushed with air from inside outwards in order to carry

out any hazardous substances brought in when using

the lock. There must be at least 20 air changes per

hour, related to the total volume of the air lock. Upon

agreement and approval of GL alternative installations

are permissible.

I - Part 1

GL 2005

Section 2 Arrangement and Separation of Spaces Chapter 12

Page 21

B

Section 3

Machinery Installations

A. Machinery Spaces

1. The combustion air for Diesel engines and

boilers shall be supplied either from the machinery

space or directly from outside.

When the supply of air is from the machinery space

additional demand of air has to be taken into account

during the design of the ventilation system.

If the air supply is directly from outside, the following

requirements have to be complied with:

The intake openings are to be located in Zone 2.

In exceptional cases locations of the intake

openings in Zone 1 may be permitted by Ger-

manischer Lloyd.

The air supplied is to be monitored for flamma-

ble gases and vapours near the intakes. Details

regarding the specification for the monitoring

equipment are to be taken from E.

Diesel engines must either be of gastight design

or totally encased.

If non-encased Diesel engines are fitted, these

shall be checked for tightness before use in a

hazardous atmosphere. An instruction to this

end is to be included in the Operations and

Equipment Manual.

Diesel engines shall be provided with automatic

overspeed protection which must also be effec-

tive if there are flammable gases or vapours in

the combustion air.

The air ducts are to be provided with flame

arrestors which have to be approved by a recog-

nized institution as being flame proof.

The air duct from the flame arrestors to the

engine has to be of an explosion-resistant de-

sign. For naturally aspirated engines this re-

quirement is regarded as being complied with if

the duct is designed for an internal pressure of

10 bar. For supercharged engines the duct has to

be designed according to the higher pressure

which is to be expected.

The number of dismountable pipe joints in the

combustion air ducts shall be kept to a mini-

mum.

If the charge air temperature after the turbo-

charger exceeds 135 C, a temperature sensor

has to be provided with a remote indication and

an alarm on the bridge.

2. The exhaust gas lines of Diesel engines and

boilers have to comply with the following require-

ments:

2.1 Approved spark arrestors have to be pro-

vided.

2.2 The outlet openings into the atmosphere may

not be located in Zone 0.

Outlet openings below the water line are acceptable if

the following requirements are complied with:

The maximum outlet temperature is 108 C. The

alarm mentioned in 2.4 has to be set accord-

ingly.

It is to be guaranteed by means of additional

measures or equipment such as a water seal or

injection of water, that no sparks will escape.

2.3 The temperature of the exhaust gases during

discharge into the atmosphere in Zone 1 or Zone 2

may not exceed 135 C.

2.4 The exhaust gas temperature has to be moni-

tored at the outlets into the atmosphere. A remote

indication has to be provided at the operation centre

mentioned in Section 1, B.10. An alarm shall be actu-

ated if the maximum permissible temperature is ex-

ceeded.

2.5 Approved flame arrestors have to be pro-

vided. Alternative arrangements can be accepted in

preventing the introduction of explosive gas-/vapour-

air mixtures into the exhaust gas piping if the engines

need to be started during an operation in a hazardous

atmosphere.

2.6 The number of dismountable pipe joints has

to be kept to a minimum.

3. Diesel engine crankcase vents are to be so

designed that no toxic or flammable vapours or gases

can enter the crankcase.

4. The heat released into the machinery and

service spaces by engines and power units shall be

removed via an air cooler. If Diesel engines are in-

stalled encapsulated, appropriate cooling equipment is

to be provided inside the encapsulation.

5. On ships with the class notation according to

Section 1, C.1., the supply of cooling water is to be so

I - Part 1

GL 2005

Section 3 Machinery Installations Chapter 12

Page 31

A

designed that the machinery can be cooled without

direct intake of sea water (e.g. box cooling or skin

cooling) during an operation in a hazardous atmos-

phere.

6. Vent pipes and filling connections of service

tanks shall be so designed or arranged that hazardous

substances cannot enter the tanks. The drinking-water

tank vent pipe outlets shall be located inside the cita-

del.

B. Cargo Area

1. Cargo tanks and compartments within the

cargo area shall be equipped in accordance with the

GL Rules Chapter 7 Chemical Tankers.

2. Following the GL Rules Chapter 2 Machin-

ery Installations, Section 12, P., holds shall be

equipped as follows:

A ventilation system for 30 changes of air per

hour is to be provided. Electric motors shall be

located outside the air stream.

Bilge pumping arrangements are to be provided

for in the cargo area.

A separate, permanently installed system is to be

provided for pumping and discharging hazard-

ous substances which might be released into the

hold.

A fire detection and alarm system shall be pro-

vided.

All openings have to be fitted with means for

gastight closure.

C. Fire Extinguishing and Alarm Equipment

1. Ships to which these Rules are applicable

have to be provided with fire protection and fire extin-

guishing equipment according to the GL Rules

Chapter 2 Machinery Installations, Section 12, re-

spectively Part 2 Inland Waterway Vessels, Chapter

2 Machinery Installations, Section 11.

2. Machinery spaces which are not permanently

manned during operations in a hazardous atmosphere

have to be provided with fire detection and alarm

system.

An approved fixed fire extinguishing system has to be

provided additionally in machinery spaces which are

not accessible during service in a hazardous atmos-

phere.

3. If Diesel engines are encapsulated the encap-

sulation has to be provided with a fire alarm system

and a fire extinguishing system. The design has to be

in accordance with the GL Rules Chapter 2

Machinery Installations, Section 12.

4. Ships with the Class Notation CHEMICAL

RECOVERY VESSEL according to Section 1, C.1.

must have a deck foam system for the cargo area.

Design and construction according to the GL Rules

Chapter 7 Chemical Tankers, Section 11.

The quantity of foam/water mixture to be generated is

to be calculated on the basis of 20 l/min/m

2

for the

deck area above the largest cargo tank or the largest

hold.

The foam system must be capable of protecting the

deck area above the cargo tanks and/or the deck area

above the holds.

5. For ships with the Class Notation

CHEMICAL RECOVERY VESSEL and the entry

"Without cargo tanks/holds" in the Certificate accord-

ing to Section 1, C.2. a foam fire extinguishing system

may be required if during the operation equipment for

the recovery of chemicals or parts thereof (pumps,

pipelines, hoses, etc.) is located on board.

6. A CO

2

fire extinguishing system shall be

provided for the holds.

7. Equipment, appliances and systems in

hazardous areas

7.1 For recovery equipment for chemicals, the

Rules listed in Section 1, A.2., so far as applicable, are

to be applied. The equipment and appliances must be

suitable for the envisaged service and be electrically

bonded to the hull.

7.2 Hoses for hazardous substances must be

adequately electrically conducting, see Chapter 2

Machinery Installations, Section 15, B.9.1.2.

7.3 By the selection of suitable materials and

appropriate protective measures, it shall be assured

that when equipment and appliances for the recovery

of chemicals are put into service there is no possibility

of sparks with ignition potential occurring, see also

Chapter 2 Machinery Installations, Section 15, B.9.

7.4 The surface temperature of equipment and

appliances may not exceed the following values:

108 C in Zone 0

135 C in Zones 1 and 2

Chapter 12

Page 32

Section 3 Machinery Installations I - Part 1

GL 2005

C

D. Ventilation and Air Conditioning

1. General

1.1 Accommodation and machinery spaces

The ventilation systems for the accommodation and

machinery spaces of seagoing ships are to be in accor-

dance with GL Construction Rules and in accordance

with Chapter 21 Ventilation. Any deviation from the

above-mentioned Rules requires GL approval.

For the ventilation and air conditioning of the citadel

during service in a hazardous atmosphere, additionally

suitable technical appliances such as a protected air

plant, drawing-in air from outside via a filter, or a

circulating-air regeneration plant, shall be provided.

1.2 Cargo area

With regard to the design, type and construction of

mechanical ventilation systems the GL Rules Chapter

2 Machinery Installations, Section 15 and Chapter 7

Chemical Tankers, Section 12, respectively Part 2

Inland Waterway Vessels, Chapter 2 Machinery

Installations, Section 14 are to be complied with.

2. Citadel

2.1 Design of the ventilation

The ventilation of the citadel is to be so designed that

during service in a hazardous atmosphere the over-

pressure never drops below 0,5 mbar relative to the

outside atmosphere in any of the spaces.

The following CO

2

concentrations of the air inside the

citadel may not be exceeded:

service spaces and rest rooms 0,15 %

mess rooms 0,25 %

workshops 0,50 %

The room temperatures shall comply with Chapter

21 Ventilation.

2.2 Layout of the ventilation system

During service in a hazardous atmosphere, machinery

spaces may be ventilated using exhaust from the ac-

commodation and engine enclosures using exhaust

from the machinery space.

The direction of flow from the accommodation to the

machinery spaces and from the machinery space into

the engine enclosure is to be ensured by an appropriate

gradation of overpressures.

Following values for overpressures relative to the

outside atmosphere may be used for guidance:

accommodation, work- and service spaces 4 mbar

engine room 3 mbar

engine enclosures 2 mbar

Openings connecting the accommodation to the ma-

chinery spaces shall be kept to a minimum. They are

to be provided with adjustable non-return valves as

well as closures. The closures must close automati-

cally if the engine room CO

2

fire extinguishing system

is activated. Manual closure from the accommodation

must also be possible.

2.3 Filtration plant

Protected air plants which draw in outside air via

filters must comply with the following requirements:

Intake of the plant from the outside atmosphere

is to be arranged in zone 2.

The filters must be suitable for separating haz-

ardous substances from the air being drawn in.

Proof of suitability of the filter material is to be

provided by certification from a recognised test-

ing institution.

A safety filter is to be fitted after the main filter.

In the case of ships with a classification charac-

ter according to Section 1, C.3., the safety filter

may be omitted if the supply of breathing air for

a period of 30 minutes for the personnel on

board is guaranteed by other suitable arrange-

ments.

The filtered air is to be monitored between main

and safety filter and after the latter. In each case

any penetration by hazardous substances shall

cause an alarm to be activated. For details see E.

The protected-air plant must be designed for a

flow rate which ensures an adequate supply of

breathing air for the ship's crew and the person-

nel involved in the clean-up operation after an

accident.

The protected air quantity may not drop below

the following value:

SLM =

3

2 1

a

ALM n m / h

b b

SLM = Protected-air quantity

ALM = Breathing-air quantity

resting 0,50 m

3

/h/person

on light work 0,75 m

3

/h/person

on heavy work 1,25 m

3

/h/person

n = Number of people on board

a = CO

2

content of air breathed out

(4 Vol. %)

b

1

= CO

2

content of outside air

(0,03 Vol. %)

I - Part 1

GL 2005

Section 3 Machinery Installations Chapter 12

Page 33

D

b

2

= permissible CO

2

content of the air in

the area under design

0,15 % in service spaces and rest

rooms

0,25 % in mess rooms

0,50 % in workshops

2.4 Regeneration plant

Regeneration plants must comply with the following

requirements:

The overpressure in the citadel shall be main-

tained from a reserve of compressed air carried

on board. This reserve must be sufficient for the

duration of service envisaged. The envisaged

duration of service is to be stated in the Opera-

tions and Equipment Manual.

All openings from the citadel to the outside

atmosphere shall be equipped with means for

gastight closure.

Maintenance of the values stated in 2.1 (over-

pressure and CO

2

content) must be possible.

2.5 Monitoring

The overpressures in the spaces within the citadel are

to be monitored. Pressure indicators for each area are

to be provided at the operation centre. Should the

pressure in any one of the areas fall below 0,5 mbar,

an audible and visual alarm shall be activated.

In the case of regeneration plant the following items

are to be monitored in addition:

The O

2

content of the air on leaving the regen-

eration plant. Should this drop below the lowest

permissible value an alarm shall be activated.

The pressure in the compressed air reservoir.

Should this drop below a value to be determined

in dependence on the system, an alarm shall be

activated.

E. Gas Detection and Alarm System

1. General

1.1 A permanently installed gas detection and

alarm system for the detection of flammable as well as

toxic gases and vapours in the outside atmosphere

shall be provided. The equipment must be capable of

detecting all gases and vapours that occur and are

toxic and/or explosive and/or damaging to human

health. If limiting values are exceeded, audible and

visual alarms are to be activated. A clearly recognis-

able collective alarm is to be provided on deck; indi-

vidual alarms on the ship's bridge or at the operation

centre. The equipment must be type-tested by Ger-

manischer Lloyd.

1.2 If the air supply to the citadel is effected via

filters, for monitoring of the protected air a detection

and alarm system which indicates any deviation from

the normal composition of clean air may be accepted.

1.3 If the gas detection equipment after the filter

is not suitable for detecting all hazardous substances

that occur, the ship is to be supplied with a list of

those substances for which the equipment is suitable.

2. Measuring points

2.1 Measuring points of the gas detection and

alarm system shall be located as follows:

2.1.1 For toxic substances and substances which

are damaging to human health:

on the main deck, low down

near the air inlets to the citadel (where air is

supplied to the citadel via filters)

2.1.2 For flammable gases and vapours:

on the main deck, low down

near the combustion air inlets to Diesel engines

and boilers

near the air inlets to the citadel (where air is

supplied to the citadel via filters)

2.1.3 For gases and vapours which are damaging to

human health or toxic or flammable (where air is

supplied to the citadel via filters):

after the main filter

after the safety filter

If there is no safety filter provided on ships with

a character of classification according to Section

1, C.3., a second measuring point has to be ar-

ranged after the main filter.

2.2 The measuring point after the safety filter

which is the second measuring point after the main

filter has to be independent of the general gas detec-

tion and alarm system. The audible and visual alarm

activated by the measuring point has to be different

from all other alarms and must be clearly audible on

the bridge and in the accommodation.

2.3 Further measuring points may be required by

Germanischer Lloyd on account of special construc-

tional circumstances and service conditions.

3. Set-Points

The settings of the gas detection and alarm system

shall be such that alarms are activated if the following

limits are exceeded:

Chapter 12

Page 34

Section 3 Machinery Installations I - Part 1

GL 2005

E

3.1 Measuring points according to 2.1.1:

Settings have to be established in co-operation with

the responsible administration. The basis shall be the

substance which is the most damaging to human

health.

3.2 Measuring points according to 2.1.2:

30 % of the lower explosive limit (LEL), referred to

Toluene.

3.3 Measuring points according to 2.1.3:

As per 3.1 and 3.2.

For detection equipment according to 1.2, deviation

from the normal composition of clean air.

4. Portable instruments

In addition to the permanently installed equipment,

portable measuring instruments for the determination

of flammable substances in the atmosphere shall be on

board.

Further requirements from the appropriate authorities

are to be adhered to.

I - Part 1

GL 2005

Section 3 Machinery Installations Chapter 12

Page 35

E

Section 4

Electrical Plant

A. General

1. The electrical plant on board ships with the

Class Notation CHEMICAL RECOVERY VESSEL

must comply with the GL Rules Chapter 3 Electrical

Installations, Section 13, C. and Chapter 7 Chemical

Tankers, Section 10, or else the GL Rules Part 2

Inland Waterway Vessels, Chapter 3 Electrical In-

stallations, Section 2.

2. Ship's power supply systems

2.1 For ships not having their own cargo tanks in

accordance with Section 1, C.2. and for ships accord-

ing to Section 1, C.3., systems complying with the GL

Rules Chapter 3 Electrical Installations, Section 1,

G. are permitted.

2.2 For ships with the Class Notation

CHEMICAL RECOVERY VESSEL in accordance

with Section 1, C.1. systems have to comply with the

GL Rules Chapter 3 Electrical Installations, Section

13, C.

B. Electrical Equipment in Hazardous Areas

1. Non-certified safe-type equipment

For the duration of service in a hazardous atmosphere

non-certified safe-type equipment of hazardous areas

must be capable of being disconnected and safe-

guarded against unauthorized reconnection at a central

point in the safe area and shall be marked accordingly.

2. Permitted electrical equipment

In hazardous areas electrical appliances are to be re-

stricted to essential operation.

2.1 In areas comparable to Zone 0 the following

is permitted:

intrinsic safety Ex ia or intrinsically safe equip-

ment/circuits certified for Zone 0

other certified safe-type equipment with special

permission from Germanischer Lloyd in the

combination of two types of protection, such as

Ex d plus Ex e, if there is a compelling require-

ment for their use in this area.

2.2 In areas comparable to Zone 1 the following

is permitted:

flameproof enclosure Ex d

pressurized enclosure Ex p

increased safety Ex e

sand-filled apparatus Ex q

encapsulation Ex m

intrinsic safety Ex i

2.3 In areas comparable to Zone 2 the following

is permitted:

certified safe-type equipment for Zones 0 and 1

equipment with explosion protection type Ex n

equipment whose temperatures cannot rise

above 135 C and in which no sources of igni-

tion occur when in service

equipment with a casing, conforming to mini-

mum protection class IP 55, whose surface tem-

perature does not exceed 135 C

3. Temperature class/explosion group

Explosion-proof electrical equipment must meet at

least the following requirements:

explosion group IIB

temperature class T4

I - Part 1

GL 2005

Section 4 Electrical Plant Chapter 12

Page 41

B

Section 5

Safety Equipment and Operation

A. Safety and Protective Equipment for Per-

sonnel

1. For the protection of personnel, safety

equipment following the GL Rules Chapter 7

Chemical Tankers, in accordance with Section 14,

14.2 must be carried on board. The extent has to be

agreed on in each case.

2. For every person on board during operation

in hazardous atmosphere a self-contained breathing set

according to 14.2.8 of the Rules quoted under 1. must

be carried on board.

3. On ships with the Class Notation

CHEMICAL RECOVERY VESSEL there shall

additionally be provided:

3.1 Protective equipment in accordance with 14.1

of the Rules quoted under 1., for each crew member

engaged in the service of combating the chemicals.

3.2 At least one shower suitably arranged for

washing-off hazardous substances, plus an eyewash.

Both the shower and the eyewash must be operable at

all ambient temperatures.

B. Operations and Equipment Manual

An approved Operations and Equipment Manual is to

be carried on board. It must contain documentation

and descriptions of the fitted technical installations as

well as the necessary safety measures required in

preparation for and the execution of a service in a

hazardous atmosphere. This includes:

a plan showing all closing appliances including

the measures for the achievement of the closed-

down condition with respect to personnel- and

explosion protection

a plan of the spaces with overpressure (citadel)

showing the arrangement of the air locks

measures for building-up the overpressure in the

citadel

activating the gas detection equipment

a list of all electricity-consumers requiring to be

switched-off for operation in hazardous atmos-

phere

switching-off arrangements of all non-

explosion-proof consumers in the hazardous

area

a list of the equipment and appliances provided

for operation in hazardous atmosphere or recov-

ery operation with installation and operating in-

structions

plans from which the arrangement of the equip-

ment and appliances for operation in hazardous

atmosphere or recovery operation are apparent

lists of substances, insofar as applicable

a check-list of the measures to be carried out in

preparation for operation in hazardous atmos-

phere or recovery operation

appropriate measures in case of alarms:

general gas alarm

30 % of the lower explosive limit in the

combustion air of the Diesel engines or boil-

ers

overpressure in the citadel below 0,5 mbar

exhaust gas temperature exceeding the per-

mitted value

charge air temperature after turbocharger

exceeding 135 C

fire in the engine room

gas after main filter (where air is supplied to

the citadel via filters)

gas alarm after safety filter or alarm acti-

vated by the second independent measuring

point after main filter (where air is supplied

to the citadel via filters)

pressure in the compressed air vessel low

(where an air regeneration plant is installed)

O

2

content of the air from the regeneration

plant too low

I - Part 1

GL 2005

Section 5 Safety Equipment and Operation Chapter 12

Page 51

B

Potrebbero piacerti anche

- Proclamation 1258 — Rules for the Measurement of Vessels for the Panama CanalDa EverandProclamation 1258 — Rules for the Measurement of Vessels for the Panama CanalNessuna valutazione finora

- Rules For Classification and Construction I Ship Technology: 1 Seagoing ShipsDocumento20 pagineRules For Classification and Construction I Ship Technology: 1 Seagoing Shipskanav.abidanoNessuna valutazione finora

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryDa EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNessuna valutazione finora

- Rules For Classification and Construction I Ship Technology: 1 Seagoing ShipsDocumento20 pagineRules For Classification and Construction I Ship Technology: 1 Seagoing Shipsmotajif702Nessuna valutazione finora

- International Regulations for Preventing Collisions at SeaDa EverandInternational Regulations for Preventing Collisions at SeaNessuna valutazione finora

- General: 1.1 ApplicationDocumento12 pagineGeneral: 1.1 ApplicationJiby John JosephNessuna valutazione finora

- Commercial Ship Surveying: On/Off Hire Condition Surveys and Bunker SurveysDa EverandCommercial Ship Surveying: On/Off Hire Condition Surveys and Bunker SurveysValutazione: 4.5 su 5 stelle4.5/5 (6)

- Gas Tankers by PankajDocumento13 pagineGas Tankers by Pankajpankaj kumar100% (1)

- Rules For Classification and Construction Ship Technology: Seagoing Ships 9 Oil Recovery VesselsDocumento16 pagineRules For Classification and Construction Ship Technology: Seagoing Ships 9 Oil Recovery Vesselskanav.abidanNessuna valutazione finora

- Rules For Classification and Construction Ship Technology: Seagoing Ships 9 Oil Recovery VesselsDocumento16 pagineRules For Classification and Construction Ship Technology: Seagoing Ships 9 Oil Recovery Vesselskanav.abidanNessuna valutazione finora

- The Shipbroker’s Working Knowledge: Dry Cargo Chartering in PracticeDa EverandThe Shipbroker’s Working Knowledge: Dry Cargo Chartering in PracticeValutazione: 5 su 5 stelle5/5 (1)

- Safety Tanker Containers Coswp Anchoring RVDocumento49 pagineSafety Tanker Containers Coswp Anchoring RVDeekshith raiNessuna valutazione finora

- Marine Logistics including Liquid Cargo and Bulk CargoDa EverandMarine Logistics including Liquid Cargo and Bulk CargoNessuna valutazione finora

- Ibc Code: Administration (Port) See Port AdministrationDocumento2 pagineIbc Code: Administration (Port) See Port AdministrationNihat DğnNessuna valutazione finora

- Bombers' Training, and Application of Same in Trench WarfareDa EverandBombers' Training, and Application of Same in Trench WarfareNessuna valutazione finora

- Module 2k - Coursework To Duy AnhDocumento3 pagineModule 2k - Coursework To Duy AnhTuTuy AnNessuna valutazione finora

- Mormugao Port (Handling of Freight Container Containg Dangerous and Hazardous Cargo) Regulation 1988)Documento24 pagineMormugao Port (Handling of Freight Container Containg Dangerous and Hazardous Cargo) Regulation 1988)Latest Laws TeamNessuna valutazione finora

- Mormugao Port (Handling of Freight Container Containg Dangerous and Hazardous Cargo) Regulation 1988)Documento24 pagineMormugao Port (Handling of Freight Container Containg Dangerous and Hazardous Cargo) Regulation 1988)Latest Laws TeamNessuna valutazione finora

- Imsbc Code Extract - Ammonium Nitrate Un1942Documento3 pagineImsbc Code Extract - Ammonium Nitrate Un1942Harman SandhuNessuna valutazione finora

- Tank Types, Tank Vents & Tank Environmental Control For Chemical TankersDocumento6 pagineTank Types, Tank Vents & Tank Environmental Control For Chemical TankersSamiulNessuna valutazione finora

- Imdg SegregationDocumento52 pagineImdg Segregationcaptlakho6501Nessuna valutazione finora

- Liquid Chemicals Cargo On Ships - Complete Details Including DiaDocumento35 pagineLiquid Chemicals Cargo On Ships - Complete Details Including DiaShoaib100% (1)

- Safety: Terms and DefinitionsDocumento8 pagineSafety: Terms and DefinitionsAditya SinghNessuna valutazione finora

- Chemical Tanker: Main Characteristics of Chemical TankersDocumento6 pagineChemical Tanker: Main Characteristics of Chemical TankersTri Wahyu PrastiyoNessuna valutazione finora

- Week 15 TheoryDocumento5 pagineWeek 15 Theoryjon.Nessuna valutazione finora

- Seam ReviewerDocumento5 pagineSeam ReviewerNizza Claire BusaNessuna valutazione finora

- General Precautions For Carrying Chemical CargoesDocumento6 pagineGeneral Precautions For Carrying Chemical CargoesHoàng Anh PhạmNessuna valutazione finora

- Solas For TankerDocumento25 pagineSolas For TankerlalindaNessuna valutazione finora

- NavigasiDocumento87 pagineNavigasiFerry Arifin100% (2)

- Ship Arrangements: 3.1 Segregation of The Cargo AreaDocumento8 pagineShip Arrangements: 3.1 Segregation of The Cargo AreaPutra AdamNessuna valutazione finora

- Midterm Module Week 1Documento13 pagineMidterm Module Week 1Bryan James ParanaqueNessuna valutazione finora

- Inspect and Report Defect and Damage To Cargo SpacesDocumento1 paginaInspect and Report Defect and Damage To Cargo SpacesRisq FirmansyahNessuna valutazione finora

- LNG Questions (PHASE-1) INDIADocumento21 pagineLNG Questions (PHASE-1) INDIARohit KarwasraNessuna valutazione finora

- What Is International Grain CodeDocumento3 pagineWhat Is International Grain CodeJames JarabeloNessuna valutazione finora

- Seam 213Documento8 pagineSeam 213John Gonzaga EscuadroNessuna valutazione finora

- BC Code Some Important Definitions Angle of Repose: Max Slope Angle of Free-Flowing Non-Cohesive) Granular MaterialDocumento3 pagineBC Code Some Important Definitions Angle of Repose: Max Slope Angle of Free-Flowing Non-Cohesive) Granular MaterialsaifNessuna valutazione finora

- 3rd Week ReviseDocumento27 pagine3rd Week ReviseCarlo ValdezNessuna valutazione finora

- Chemical Tankers Safety Precaution For Gas FreeingDocumento4 pagineChemical Tankers Safety Precaution For Gas FreeingHoàng Anh PhạmNessuna valutazione finora

- April 2023Documento12 pagineApril 2023Vladyslav VolkovNessuna valutazione finora

- Oil Tanker Design EquipmentDocumento59 pagineOil Tanker Design EquipmentBorislav Petrov100% (3)

- Code of Safe Practice For Solid Bulk CargoesDocumento5 pagineCode of Safe Practice For Solid Bulk CargoesRohit KakadeNessuna valutazione finora

- Iec60092-502sup ZONAS CLASIFICADADocumento6 pagineIec60092-502sup ZONAS CLASIFICADAacastanopadilla4100Nessuna valutazione finora

- Segregating of Dangerous GoodsDocumento47 pagineSegregating of Dangerous GoodsAbdel Nasser Al-sheikh YousefNessuna valutazione finora

- Module 2l - Coursework To Duy AnhDocumento3 pagineModule 2l - Coursework To Duy AnhTuTuy AnNessuna valutazione finora

- MARPOL Annex V 2 PDFDocumento11 pagineMARPOL Annex V 2 PDFravilullaNessuna valutazione finora

- Safety Data Dri B ChipsDocumento5 pagineSafety Data Dri B ChipsDavid PapelonNessuna valutazione finora

- Seam214 Cargo Handling and Stowage Dangerous Goods and Inspection Prelim ReviewerDocumento23 pagineSeam214 Cargo Handling and Stowage Dangerous Goods and Inspection Prelim ReviewerRed SkiNessuna valutazione finora

- Gas TankersDocumento23 pagineGas Tankers16 - AniruthNessuna valutazione finora

- MARPOL 1 To 6Documento9 pagineMARPOL 1 To 6Jaycel Custodio100% (1)

- Ukp Paket A FUNGSI 2 29-30Documento9 pagineUkp Paket A FUNGSI 2 29-30Yoga PNessuna valutazione finora

- Section 10, Conducting The Well TestDocumento24 pagineSection 10, Conducting The Well TesthammamiNessuna valutazione finora

- LPG Tanker Practice Hyproc SCDocumento128 pagineLPG Tanker Practice Hyproc SCIlyes ArNessuna valutazione finora

- 5.7 Tank Farm Safety and Dyke ArrangementsDocumento20 pagine5.7 Tank Farm Safety and Dyke ArrangementsD Srinivasa RaoNessuna valutazione finora

- Precautions For Loading Bulk GrainDocumento6 paginePrecautions For Loading Bulk GrainGaurav Harjai100% (1)

- SOLAS Fuel Oil TankDocumento5 pagineSOLAS Fuel Oil TankjosearnejoNessuna valutazione finora

- Imo Circ 860 Guidelines For Offshore ContainersDocumento6 pagineImo Circ 860 Guidelines For Offshore ContainersMohammed Abd El Rahman100% (2)

- The IMSBC Code and Its ContentDocumento7 pagineThe IMSBC Code and Its ContentAgar SailNessuna valutazione finora

- Assignment For Class 2 COCDocumento24 pagineAssignment For Class 2 COCSam BillimoriaNessuna valutazione finora

- Rules For Classification and Construction Ship TechnologyDocumento34 pagineRules For Classification and Construction Ship TechnologyLastunNessuna valutazione finora

- Rules For Classification and Construction I Ship Technology: 1 Seagoing ShipsDocumento30 pagineRules For Classification and Construction I Ship Technology: 1 Seagoing ShipsLastunNessuna valutazione finora

- Rules For Classification and Construction I Ship Technology: 1 Seagoing ShipsDocumento16 pagineRules For Classification and Construction I Ship Technology: 1 Seagoing ShipsLastunNessuna valutazione finora

- Rules For Classification and Construction I Ship Technology: 1 Seagoing ShipsDocumento22 pagineRules For Classification and Construction I Ship Technology: 1 Seagoing ShipsLastunNessuna valutazione finora

- Rules For Classification and Construction I Ship Technology: 1 Seagoing ShipsDocumento44 pagineRules For Classification and Construction I Ship Technology: 1 Seagoing ShipsLastunNessuna valutazione finora

- Rules & Guidelines General: Code EditionDocumento7 pagineRules & Guidelines General: Code EditionLastunNessuna valutazione finora

- Rules For Classification and Construction I Ship Technology: 1 Seagoing ShipsDocumento612 pagineRules For Classification and Construction I Ship Technology: 1 Seagoing ShipsLastunNessuna valutazione finora

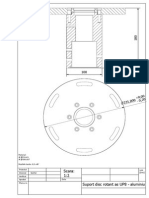

- Suport Disc Rotant As Up8 FlansaDocumento1 paginaSuport Disc Rotant As Up8 FlansaLastunNessuna valutazione finora

- Suport Disc Rotant As Up8Documento1 paginaSuport Disc Rotant As Up8LastunNessuna valutazione finora

- Hydraulic Pressure Test Procedure For Prs Chemical Cutter Parts Above The Chemical CylinderDocumento5 pagineHydraulic Pressure Test Procedure For Prs Chemical Cutter Parts Above The Chemical CylinderdocrafiNessuna valutazione finora

- Unica - Svi Uredjaji Ramovi Unica Basic, Colors, Allegro, PLDocumento24 pagineUnica - Svi Uredjaji Ramovi Unica Basic, Colors, Allegro, PLurcoadNessuna valutazione finora

- King Jouet CaseDocumento2 pagineKing Jouet CaseAndres Jaramillo BoteroNessuna valutazione finora

- BOBCAT S150 SKID STEER LOADER Service Repair Manual SN 526911001 & Above PDFDocumento53 pagineBOBCAT S150 SKID STEER LOADER Service Repair Manual SN 526911001 & Above PDFfujsjejfksekmem40% (10)

- Akocontrol Cat en 2-3Documento27 pagineAkocontrol Cat en 2-3Alberto PinhoNessuna valutazione finora

- Bridge Fatigue GuideDocumento65 pagineBridge Fatigue Guideaapennsylvania100% (1)

- 14386l Camu 11670 Rev34 IngleseDocumento253 pagine14386l Camu 11670 Rev34 Inglesejohnysonycum0% (1)

- Section II A SA-216 - SA-216MDocumento4 pagineSection II A SA-216 - SA-216MSocrates MoralesNessuna valutazione finora

- New Microsoft Word DocumentDocumento2 pagineNew Microsoft Word DocumentZahid Rahman100% (1)

- Elbow Connector 24-400A 150sqmmDocumento2 pagineElbow Connector 24-400A 150sqmmoktaricoNessuna valutazione finora

- Hydrolub: Grey Cast Iron Gear Pump For Industrial ProcessesDocumento2 pagineHydrolub: Grey Cast Iron Gear Pump For Industrial ProcessesWafi BaliemNessuna valutazione finora

- Aviation GasolineDocumento4 pagineAviation GasolineAnonymous QM0NLqZONessuna valutazione finora

- BS EN 00003-3-1996 ScanDocumento16 pagineBS EN 00003-3-1996 ScanRinu RavikumarNessuna valutazione finora

- Wire and CableDocumento32 pagineWire and CableEliasNessuna valutazione finora

- MASE lABDocumento3 pagineMASE lABAli Aslam100% (1)

- Lincoln Laser PolygonsTech Paper 2 17 2015 PDFDocumento35 pagineLincoln Laser PolygonsTech Paper 2 17 2015 PDFAndrei TaranuNessuna valutazione finora

- SWD Aci 530 11Documento57 pagineSWD Aci 530 11Stephanie Miyata100% (2)

- 6.6 KV - 11 KV SWGRDocumento6 pagine6.6 KV - 11 KV SWGRAnmohieyNessuna valutazione finora

- Anti Rodent TestDocumento5 pagineAnti Rodent TestVô Cảm100% (1)

- Bernoulis TheoremDocumento14 pagineBernoulis TheoremKhairulAzwanizamNessuna valutazione finora

- AAI SpecificationDocumento799 pagineAAI SpecificationAditya VuthaNessuna valutazione finora

- ACAK2Documento51 pagineACAK2muhammad fachroziNessuna valutazione finora

- Joya CatalogueDocumento20 pagineJoya CatalogueKCFUNGNessuna valutazione finora

- Mini Blast FurnaceDocumento8 pagineMini Blast FurnaceTAHIR SAIFNessuna valutazione finora

- As Built DrawingsDocumento26 pagineAs Built DrawingsSathish KumarNessuna valutazione finora

- Piping - Canada Culvert CSP ManualDocumento12 paginePiping - Canada Culvert CSP ManualRotax_KidNessuna valutazione finora

- Technical Data Sheet Chryso Armourcote 560 - 6049 - 1336 PDFDocumento2 pagineTechnical Data Sheet Chryso Armourcote 560 - 6049 - 1336 PDFAarish KhanNessuna valutazione finora

- MLL Study Materials Science Class X 2020-21-1Documento223 pagineMLL Study Materials Science Class X 2020-21-1Ajit Mote100% (1)

- Bentonite Wastewater Treatment PDFDocumento12 pagineBentonite Wastewater Treatment PDFBiljana TausanovicNessuna valutazione finora

- Heat Transfer Enhancement in Heat Recovery Steam Generator Using Dry Ice Co Blasting Cleaning MethodDocumento2 pagineHeat Transfer Enhancement in Heat Recovery Steam Generator Using Dry Ice Co Blasting Cleaning MethodDimas PalgunadiNessuna valutazione finora

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemDa EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNessuna valutazione finora

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsDa EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsValutazione: 4 su 5 stelle4/5 (11)

- Electrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EDa EverandElectrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EValutazione: 3 su 5 stelle3/5 (6)

- Fire Protection Engineering in Building DesignDa EverandFire Protection Engineering in Building DesignValutazione: 4.5 su 5 stelle4.5/5 (5)

- Benchmarking Best Practices in Maintenance ManagementDa EverandBenchmarking Best Practices in Maintenance ManagementNessuna valutazione finora

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisDa EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisValutazione: 5 su 5 stelle5/5 (1)

- Introduction to Petroleum Process SafetyDa EverandIntroduction to Petroleum Process SafetyValutazione: 3 su 5 stelle3/5 (2)

- Workbook to Accompany Maintenance & Reliability Best PracticesDa EverandWorkbook to Accompany Maintenance & Reliability Best PracticesValutazione: 3.5 su 5 stelle3.5/5 (3)

- A Complete Guide to Safety Officer Interview Questions and AnswersDa EverandA Complete Guide to Safety Officer Interview Questions and AnswersValutazione: 4 su 5 stelle4/5 (1)

- Culture, Health and Illness: An Introduction for Health ProfessionalsDa EverandCulture, Health and Illness: An Introduction for Health ProfessionalsNessuna valutazione finora

- Incidents That Define Process SafetyDa EverandIncidents That Define Process SafetyNessuna valutazione finora

- Workers' Inferno: The untold story of the Esso workers 20 years after the Longford explosionDa EverandWorkers' Inferno: The untold story of the Esso workers 20 years after the Longford explosionNessuna valutazione finora

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesDa EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesNessuna valutazione finora

- The Invisible Rainbow: A History of Electricity and LifeDa EverandThe Invisible Rainbow: A History of Electricity and LifeValutazione: 4.5 su 5 stelle4.5/5 (21)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDa EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNessuna valutazione finora

- What Went Wrong?: Case Histories of Process Plant Disasters and How They Could Have Been AvoidedDa EverandWhat Went Wrong?: Case Histories of Process Plant Disasters and How They Could Have Been AvoidedValutazione: 5 su 5 stelle5/5 (2)

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesDa EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesValutazione: 5 su 5 stelle5/5 (1)

- Handbook of Hazardous Chemical PropertiesDa EverandHandbook of Hazardous Chemical PropertiesValutazione: 5 su 5 stelle5/5 (1)

- Guidelines for Auditing Process Safety Management SystemsDa EverandGuidelines for Auditing Process Safety Management SystemsNessuna valutazione finora

- Rules of Thumb for Maintenance and Reliability EngineersDa EverandRules of Thumb for Maintenance and Reliability EngineersValutazione: 4.5 su 5 stelle4.5/5 (12)

- Fire Fighting Pumping Systems at Industrial FacilitiesDa EverandFire Fighting Pumping Systems at Industrial FacilitiesValutazione: 4.5 su 5 stelle4.5/5 (3)