Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

2006 Mohammed Azad

Caricato da

IGNyomanAnomWijayaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

2006 Mohammed Azad

Caricato da

IGNyomanAnomWijayaCopyright:

Formati disponibili

DIPLOMA THESIS

SURFACE PHENOMENA IN GAS HYDRATE SYSTEMS

MOHAMMED MAMUN AZAD

STUDENT NUMBER 677698

________________________________________________________________________

Institutt for petroleumsteknologi og anvendt geofysikk

Department of petroleum engineering and applied geoscience

Norwegian university of science and technology (NTNU),

Trondheim

June 2006

NTNU

Norges teknisk-naturvitenskapelige Fakultet for ingenirvitenskap og teknologi

universitet Faculty of Engineering and Technology

Studieprogram i Geofag og petroleumsteknologi

Study Programme in Earth Sciences and Petroleum Engineering

Institutt for petroleumsteknologi og anvendt geofysikk

Department of Petroleum Engineering and Applied Geophysics

HOVEDOPPGAVEN/DIPLOMA THESIS/MASTER OF SCIENCE THESIS

Kandidatens navn/ The candidates name: MOHAMMED MAMUN AZAD.

Oppgavens tittel, norsk/Title of Thesis, Norwegian:

Oppgavens tittel, engelsk/Title of Thesis, English: Surface phenomena in gas hydrate systems.

Utfyllende tekst/Extended text:

This report presents experiments, observations and analysis of wetting tendency of different kinds

of oil samples on hydrate layers. The observations were carried out visually by using a digital

camera. This report also covers design and building of the cell where the experiments were to be

performed. The ultimate purpose of the experiments was to know the tendency of oils to form

hydrate plugs which may impede the flow.

Studieretning/Area of specialization: Petroleum Engineering

Fagomrde/Combination of subjects: Production

Tidsrom/Time interval:

Faglrer/Teacher

SKJEMAET TAS INN SOM SIDE 1 I HOVEDOPPGAVEN/PLEASE USE THIS FORM AS PAGE 1 IN

THE THESIS

Original: Student

Kopi: Fakultet

Kopi: Institutt

Abstract

Surface phenomena in gas hydrate systems are important for understanding the behaviour

of multiphase flow in pipelines, particularly regarding the tendency for oils to form

hydrate plugs which may impede the flow. It is important to gather more data on these

phenomena. Not many works have so far been done upon the surface phenomenon of gas

hydrates. In this work, a cell was designed and built based on the some new ideas and

sketches and then it was tested for the purpose of low pressure testing of gas hydrate,

water, oil surface phenomena, especially wetting angles. The tests were planned with

visual observations and measurements in the cell to determine wetting angles between a

hydrate surface and droplets of varying compositions of oil samples. During the entire

span of the experiments, the operating pressures were kept at laboratory conditions.

Tetrahydrofurane (THF) was used to form hydrates at the laboratory conditions. Different

oil samples such as Exxsol d80 (which is a condensate-like refined oil), Paladio crude oil

(from West Africa real oil straight from the well), and King crude oil from the Gulf of

Mexico as well as an unknown sample of a light oil from Norsk Hydro were used in order

to try to observe their wetting angles with hydrate layers. Then the experiments and

observations were compared with previous works. In addition to performing and

reporting on a brief literature study of the subject, a description of the equipment and

related experiments in detail is provided.

i

Acknowledgement

I would like to send my gratitude and appreciations to all who helped me in one way or

another to facilitate my Thesis. Special thanks to my supervisor Prof. Jon Steinar

Gudmundsson of Department of Petroleum Engineering and Applied Geophysics at

NTNU for his time dedication to assist me in various part of this study. I am also grateful

to him for his patience, co-operation and excellent supervision throughout this work.

I would specially like to thank Roar Larsen for contributing with the idea, feedback and

theoretical frameworks which had given me the foundation when executing this work. He

was always willing to answer my questions. I also appreciate his enthusiasm, patience

and encouragement.

I also wish to thank Mr. Helge Johansen and Knut Glas of the Refrigeration Lab. at

NTNU, Glshaugen for setting the cooling unit and building hydrate cell for me. I am

grateful to them for their willingness in repairing the problems with the cooling unit and

hydrate cell. I am grateful to Mr. Anwar Hossain Bhuiyan (PHD student) who offered me

tremendous supports during the formatting stage of the thesis.

I wish to thank NORAD for giving me the scholarship award and an opportunity to study

here in Norway.

I do remember my mother for her moral support. I specially appreciate my wife Sadia

Akter for providing me excellent support and encouragement during the entire period of

pursuing the thesis. Last but not least thanks to my friends and class-mates who helped

me in making numerous improvements not only to its wording but to its technical

contents.

ii

Nomenclature

A : Area.

Atm. : Atmosphere.

ID : Inner Diameter.

HCFC : Hydrochloroflourocarbon.

PMMA : Polymethyl methacrylate.

S : Second.

THF : Tetrahydrofuran.

: Surface tension.

A : Work.

A : Net minimum surface free energies.

: Surface tension of phase .

: Surface tension of phase .

: Surface tension between phases and .

SV

: Surface tension of phase between solid and vapor phases.

SL

: Surface tension of phase between solid and liquid phases.

LV

: Surface tension of phase between liquid and vapor phases.

: Angle of contact.

A

: Advancing contacting angles.

R

: Receding contact angles.

iii

Table of contents

Abstract............................................................................................................................... i

Acknowledgement ............................................................................................................. ii

Nomenclature ................................................................................................................... iii

Table of contents .............................................................................................................. iv

Table of Figures................................................................................................................ vi

1 Background .................................................................................................................... 1

1.1 Introduction........................................................................................................................... 1

1.2 Objective ............................................................................................................................... 1

1.3 Methodology......................................................................................................................... 2

1.4 Block Diagram...................................................................................................................... 2

2 Literature Review.......................................................................................................... 4

2.1 Introduction to Clathrate Hydrates........................................................................................ 4

2.2 The History of Gas Hydrates................................................................................................. 4

2.3 Basics of Hydrates ................................................................................................................ 7

2.4 Structures of Natural Gas Hydrates....................................................................................... 7

2.5 Gas Hydrate Formation......................................................................................................... 9

2.6 Kinetics and Morphology of Gas Hydrates......................................................................... 10

2.7 Fundamental Phase Equilibrium for Natural Gas Hydrates ................................................ 12

2.8 Hydrate Properties............................................................................................................... 14

2.9 Chemicals for Gas Hydrate Control .................................................................................... 15

2.9.1 Thermodynamic Inhibitors .......................................................................................... 15

2.9.2 Kinetic Inhibitors (KI) ................................................................................................. 16

2.9.3 Anti-Agglomerants (AA)............................................................................................. 17

2.10 Background of Colloids .................................................................................................... 20

2.11 The Classical Interface Model .......................................................................................... 21

2.12 Wetting Mechanism: Liquid on Solid............................................................................... 22

2.13 Static Contact Angles........................................................................................................ 23

2.14 Works of Hirata and Mori (1998) ..................................................................................... 24

2.14.1 Experiments ............................................................................................................... 24

2.14.2 Results and Discussion of Hirata and Moris Experiment......................................... 26

3 Set-up and Procedure of Experiment......................................................................... 28

3.1 Introduction......................................................................................................................... 28

3.2 Hydrate Cell ........................................................................................................................ 28

3.3 Leakage and Performance Tests.......................................................................................... 29

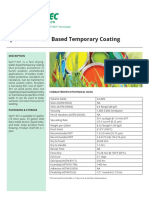

3.4 List of chemicals and samples............................................................................................. 30

3.5 Preparation of THF Solution............................................................................................... 31

3.6 Procedure of Experiment..................................................................................................... 31

4 Observations and Results............................................................................................ 33

4.1 Some Important Observations............................................................................................. 33

4.2 Results................................................................................................................................. 34

iv

5 Discussion...................................................................................................................... 37

5.1 Discussion of problems encountered and solutions ............................................................ 37

5.2 Discussion of Results .......................................................................................................... 38

5.3 Comparison with previous works of Hirata and Mori (1998)............................................. 40

6 Conclusion and Recommendation for Future Works .............................................. 41

6.1 Conclusion .......................................................................................................................... 41

6.2 Recommendations for future works .................................................................................... 42

References:....................................................................................................................... 43

APPENDICES ................................................................................................................. 45

v

Table of Figures

Figure 1.1 Block Diagram................................................................................................... 3

Figure 2.1 Schematic of Gas Hydrate Knowledge.............................................................. 6

Figure 2.3 Autocatalytic reaction mechanisms for hydrate formation ............................. 10

Figure 2.4 Cavities in gas clathrate hydrates .................................................................... 10

Figure 2.5 Hydrate Phase Diagram................................................................................... 12

Figure 2.6 Hydrate formation regions for C1 to C4 paraffins .......................................... 13

Figure 2.7 Equilibrium curve for methane hydrate and mixture hydrate ......................... 14

Figure 2.8 Monomer Units for Kinetic Inhibitor Polymers .............................................. 16

Figure 2.9 Interaction of a pendent alkylamide group of a kinetic inhibitor .................... 17

Figure 2.10 Structure of quaternary anti-agglomerants .................................................... 18

Figure 2.11 Hydrate Control Methods Tree...................................................................... 20

Figure 2.12 Interface between phase and phase ......................................................... 21

Figure 2.13 Equilibrium of a non-spreading drop on a planar solid................................. 22

Figure 2.14 Sessile bubble with axial symmetry on a solid surface ................................. 24

Figure 2.15 THF hydrate partly immersed in liquid phases ............................................. 25

Figure 2.16 Video graphic pictures................................................................................... 27

vi

1 Background

1.1 Introduction

Since the beginning of the 20

th

century, the production of natural gas has encountered

difficulties with the plugging of piping by the deposition of crystals, first thought to be

ice crystals. These crystals are in fact hydrates of natural gas which can appear far above

the temperature at which ice is formed. They are inclusion compounds which result from

the combination of water with some of the components of natural gas, and primarily

methane. The oil and gas industry is facing increasing costs in inhibiting gas hydrate

formation due to the development of offshore gas reservoirs. Recent international

estimates of the cost of the conventional inhibitor, methanol, alone are in excess of $150

million/year. Gas hydrates are likely to form in subsea flowlines unless the water is

removed down to the lowest dew point encountered, highly effective insulation is in

place, or inhibitors are used (Paez and Blok, 2001). Since complete stripping of water

from condensates and/or natural gas is prohibitively expensive, and effective insulation is

beyond current economic limits, the most effective solution includes the use of low

dosage hydrate inhibitors- Kinetic inhibitors and Anti-agglomerants. The understanding

of wetting phenomena, specially the wetting angles of kinetic inhibitors onto the hydrate

layers is very important.

1.2 Objective

The wetting phenomena of gas hydrates in oil or water are still not well known. One of

the most important properties of wetting phenomena is wetting or contact angle between

the hydrate phase and water or oil phase. In this thesis my main objective was to find the

contact angles between hydrate and oils of different types and compositions by doing

some tests. And, finally compare the observations and result with the previous works.

The tests would be carried out with visual observations and measurements in the cell to

determine wetting angles between the hydrate surface and droplets of varying

1

compositions. For this reason, a cell was to be designed and built at first using some

available sketches and ideas.

1.3 Methodology

This thesis was based on some observations of experiments with hydrates and oil in a

certain cell, which was at first designed and built with the help of some existing concepts

and sketches. Designing and building of the cell to meet the experimental requirements

were the important tasks of the thesis. Once the cell found ready, it should be connected

with a cooling unit and then its performance and leakage tests should be conducted by

using water.

Then hydrates were to be prepared in that cell in order to find the surface angles between

hydrate layer and oil layer. But the most favourable conditions for the formation of gas

hydrates are very high pressure or low temperature which is quite difficult to maintain in

laboratories. So, a mixture of tetrahydrofurane (21% vol) and water was used to form

hydrate because this mixture could form hydrates at atmospheric pressure and 4.4C.

96% (wt) of ethanol was circulated into the cell for cooling the THF solution below its

hydrate equilibrium temperature of 4.4C. Hydrates would presumably be formed at the

wall between the coolant and THF solution. Then the droplets of the oil to be tested were

allowed to be deposited upon the hydrate layer by using a syringe and a narrow needle.

Then the pictures of the contact surfaces were taken by a digital camera and sketches

were drawn to make visual observations and measurements of wetting angles between a

hydrate surface and droplets of oil of different compositions.

1.4 Block Diagram

The entire tasks and procedures planned to be performed in this thesis are given in the

following block diagram.

2

Literature

Studies

Design

Existing concepts

& ideas

Available

sketches

Building

Cell

ready

P

e

r

f

o

r

m

a

n

c

e

&

l

e

a

k

a

g

e

t

e

s

t

THF solution

preparation

Hydrate

preparation

Addition

of oil

droplets

O

b

s

e

r

v

a

t

i

o

n

Taking

pictures

Drawing

sketches

Discussion

Conclusion

Figure 1.1 Block Diagram

3

2 Literature Review

2.1 Introduction to Clathrate Hydrates

Clathrate hydrates are ice-like crystalline solid solutions each composed of hydrogen-

bonded water molecules (host molecules) and guest molecules of some other species.

Each guest molecule is enclosed, without the aid of any chemical bonding, in a cavity

created by the water molecules. Because water molecules account for a major proportion

in any clathrate hydrate, it is likely that the surfaces of clathrate hydrate phases are

hydrophilic, i.e. well wettable with liquid water (Hirata and Mori, 1993).

2.2 The History of Gas Hydrates

Revealing the truth in the history of development of any considerable scientific idea

usually turns out to be very complicated. Early scientists frequently would not pay proper

attention to a natural phenomenon he had revealed, especially if the discoverer had no use

for his contemporaries. The majority of scientific discoveries result from the absorbed

work of some creative individuals searching and constantly filling in the blank spaces in

science (Makogon, 1997).

The boundary between 18

th

and 19

th

centuries was a time when developing industry

acutely needed science, when every new discovery had a profound impact on the pace of

civilized developments and the hopes of the society were pinned to physics and

chemistry. It was then that gas hydrates, solid molecular compounds of water with gas,

were discovered. It is well known today there are vast natural gas hydrate accumulations

on Earth, however the first hydrates were synthesized in-vitro. Most specialists believe

that gas hydrates were first obtained in 1810 in the laboratory of Sir Humphrey Davy,

who cooled an aqueous solution saturated with chlorine gas below 9C to yield a

crystal/ice-like material. However, analysis of the preceding works allowed us to obtain

evidence of hydrate retrieval more than 30 years prior to H. Davy. The great English

philosopher and naturalist Joseph Priestley happened to obtain hydrate of sulphur dioxide

4

(SO

2

) both from its water solution and from its gaseous phase and ice. The results of the

experiments were reported in his three volume work Versuche und Beobachtungen uber

vershiedene Gattungen der Luft (Makogon Y. F., 1997).

In the beginning of the 20

th

century, oil and gas became important in the world of energy

balance. During the 1920s large gas pipelines were constructed and put into operation in

the United States. Gas was supplied under pressure through these pipes from the gas

fields to the consumption centres. Solid plugs complicated the transportation of gas

during autumn and spring periods. Plugs were misinterpreted to form from water

remaining in the pipelines after construction and hydraulic pressurizing. This estimate led

to a deadlock in solving the problem. However, an important conclusion was made by the

American chemist E. G. Hammerschmidt in 1934. Not ice but hydrate plugs were

responsible for gas transport complications in the pipeline sections.

The history of studies on natural gas hydrates had been presented in numerous articles,

scientific reports and addresses. A great number of patents have been taken out based on

the investigations in hydrate properties. Today two major directions have formed in the

problem: technogenic and natural gas hydrates. Both these directions are based on the

results of fundamental research of the genesis and properties of gas hydrates. Figure 2.1

presents a principal schematic of the major directions of studying gas hydrates (Makogon,

1997).

5

Figure 2.1 Schematic of Gas Hydrate Knowledge (Makogon, 1997)

6

2.3 Basics of Hydrates

Hydrates are solid crystalline metastable compounds whose properties and stability

depend on the values of pressure and temperature. Clathrate hydrates designate a

particular class of crystalline solid compounds.

Now-a-days, clathrate hydrates are increasingly involved in various technological aspects

of energy utilization by human beings. Examples include the prediction and prevention of

plugging due to hydrate formation in the pipelines for transporting natural gas including

water vapour, the formation and storage of clathrate hydrates as cool storage media for

residential air conditioning, and the ocean disposal of liquefied carbon dioxide, a green-

house effect gas, separated at fossil-fuel-fired power plants. The formation of a clathrate

hydrate includes a variety of physical, chemical and/or physicochemical processes. When

the guest species and liquid water are sparingly soluble in each other and hence the

formation of clathrate hydrate is inherently limited to the macroscopic interface between

the two fluid phases, the water/guest reaction at the interface, the diffusive transport of

water and/or the guest across the interface, and the diffusive transport of the heat of

hydrate formation away from the interface are considered to be the processes possibly

controlling the hydrate formation while the hydrate is spread over no more than a

considerable proportion of the interfacial area. If the liquid water is not saturated with the

guest species, the hydrate once formed may continuously decompose, releasing the

molecules of the guest species which will be dissolved into the water, causing a mass

transfer process. As the hydrate phase grows so as to spread over a significant proportion

of the interface or even cover the entire interface, the further growth of the hydrate phase

must depend on the penetration of water and/or the guest species across the very hydrate

phase to maintain the mutual contact. This penetration process has been little investigated

so far, and it is not well understood (Sugaya and Mori, 1995).

2.4 Structures of Natural Gas Hydrates

Gas hydrates are a large subgroup of clathrate hydrates forming mostly under high

pressure or/and low temperatures. Hydrates of natural gases prevail in deep-sea sediments

7

and permafrost, and could play an important role in the formation of the planetary

nebulae (Lovanob et. al., 2005).

All common natural gas hydrates seem to belong to the three crystal structures, cubic

structure (s), cubic structure (s), or hexagonal structure H (sH) shown in figure 2.2.

Structure is formed with molecules smaller than 6 , such as methane, ethane, carbon

dioxide, and hydrogen sulphide. Nitrogen and smaller molecules (d<4.2 ) are

exceptions and form structure as single guests. Somewhat larger (6 <d<7 ) single

guest molecules such as propane or iso-butane will form structure . Still larger

molecules (7 <d<9 ) such as iso-pentane or neohexane can form structure H when

accompanied by smaller molecules such as methane, hydrogen sulphide, or nitrogen

(Sloan, 1997).

Figure 2.2 Structures of Clathrate Hydrates (Makogon, 1997)

In these structures, the water molecules form polyhedra. The pentagonal dodecahedron,

designed by the notation 5

12

, is a basic building block of hydrate structures. It is not

possible to fill space entirely with dodecahedra. Because of to this restriction

dodecahedra are necessarily associated with other types of polyhedron to form the

structure of the hydrates. Structure I is composed of two small cavities formed by a

8

dodecahedron and six large cavities formed by a tetradecahedron with twelve pentagonal

faces and two hexagonal faces referenced as 5

12

6

2

(Figure 2.2). Structure II is composed

of sixteen small cavities (5

12

) and eight large cavities, formed by a hexadecahedron with

twelve pentagonal faces and four hexagonal faces. Each of these polyhedra forms a cavity

which can contain a molecule of natural gas components with which it forms a hydrate.

Methane fits into the small cavities (5

12

) of structures I and II, and in the large cavities

(5

12

6

2

) of structure I. Nitrogen, propane and isobutene form structure-II hydrates. In the

pure state, methane, ethane, carbon dioxide and hydrogen sulfide form structure-I

hydrates. However, since propane and isobutene molecules can enter only the large

cavities of structure II, a natural gas containing propane and isobutane generally forms

structure-II hydrates. Normal butane does not form hydrates as a pure component.

Hydrate formation can occur when normal butane is mixed with other components (Rojey

et al., 1994; Sloan, 1997). The structure H was determined through diffraction and NMR

studies. In this structure, the 5

12

dodecahedra coexist with 4

3

5

6

6

3

dodecahedra as well as

5

12

6

8

polyhedra, with twelve pentagonal faces and eight hexagonal faces, forming large

cavities. The small cavities are stabilized by molecules like Xe, H

2

S and CH

4

, and the

large cavities by hydrocarbons with much higher molecular weights such as adamantine

and methylcyclohexane. The role that structure-H hydrates may play in natural gas

production is still unclear. However, it has been proven that hydrocarbon molecules

commonly found in condensates or oils, together with methane, can form this new

hydrate structure, under pressure and temperature conditions easily encountered in

production and transport facilities (Ryba, 2005).

2.5 Gas Hydrate Formation

Kinetics of hydrate formation is still a current research topic and it is discussed

elaborately in the next section. Since this process is not well understood, several theories

have been developed explaining the mechanisms of hydrate formation. Lederhos et al.

(1996) proposed that gas hydrates form in an autocatalytic reaction mechanism, when

water molecules cluster around natural gas molecules in structures similar to the ones

shown in Figure 2.3.

9

Figure 2.3 Autocatalytic reaction mechanisms for hydrate formation (Lederhos et al., 1996)

This attraction between neighbouring guest molecules is termed hydrophobic bonding,

which can be described as an attraction between the apolar molecules inside the clusters

(B). Large and small clusters forming structures I and II are termed labiles because

they are easy to break down, but relatively long-lived. Labiles can dissipate, or grow to

become hydrate unit cells forming what are known as metastable nuclei (C). Then,

growth can continue until crystals are stable, indicating the onset of secondary nucleation

(D). This process is illustrated in Figure 2.4.

Figure 2.4 Three cavities in gas clathrate hydrates: (a) 5

12

, (b) 5

12

6

2

, (c) 5

12

6

4

(Paez et al., 2001)

2.6 Kinetics and Morphology of Gas Hydrates

Many articles have been published concerning the processes of gas hydrate formation.

The researchers became well aware from the experiments that at the beginning of hydrate

formation the temperature can vary widely, at one and the same pressure. As a result of

experimental studies it was determined that the process of hydrate formation starts at the

free gas water surface:

a. on a free contact surface of liquid water-gas or liquid water-liquid gas,

b. on the surface of the water drop-water film that condensed in a gas volume,

10

c. on the surface of gas bubbles that separate out within a water volume,

d. on the interface of the condensed gas drops-dispersed condensed gas, as the

condensed gas evaporates within a volume of free gas saturated with water vapours,

e. on the water-metal interface where the absorption of the molecules of gas dissolved

in the water takes place,

After the formation of critical size nuclei, a hydrate film forms around them and blocks

the free interface. After the hydrate film formation over the whole gas-water interface,

the surface-contact process becomes a diffusive one, when the molecules which form

hydrate on the sorptional surface of the growing crystal through defects in the formed

hydrate film. Sorptional surface can be on the free surface of growing crystal (massive

hydrate crystals) and at the base of the growing crystals (whiskery crystals). Molecules of

water and gas diffuse to the sorptional surface both from a volume of gas and from a

volume of water through the hydrate film at the gas-water interface. During the formation

of whiskery crystals, hydrate forming molecules go to the sorption surface on the surface

of growing whiskery crystals by means of tunnel diffusion. Tunnels are formed at the

vessel-growing hydrate interface. During tunnel diffusion the size of the diffusion

channels are much smaller than during the sorption by an open surface of a growing

crystal. Massive crystals grow more often in a volume of gas. Whiskery crystals grow

both in a volume of gas and a bulk of water. Gel-like crystals are formed at certain

conditions in bulk of water, whose nature will be studied further. In redistribution of mass

and volume of crystals a change occurs in P-T conditions- possibly changes in crystals

also occur. Crystals may sublimate in a volume of gas, dissolve in a volume of water, and

form new forms of crystals.

Unfortunately, the mechanism of nucleation and growth of hydrate crystals in static

conditions and in fluid flow is unknown at this time. Previous models for hydrate kinetics

that are quantified have normally been limited to the regime of steady crystal growth.

Kinetics of hydrate formation was viewed only from the aspect of hydrate accumulation,

depending on the degree of flow super cooling and turbulence. These are only the

external factors of hydrate formation. The kinetics of hydrate dissociation was studied

11

very little. Morphology of hydrate crystals has hardly been studied at all, although it

allows us to discover the crystals nucleation and growth. The modern theory of hydrate

formation processes can not answer many fundamental questions (Makogon, 1997).

2.7 Fundamental Phase Equilibrium for Natural Gas Hydrates

The phase equilibria of natural gas hydrates represents the most important set of

properties which differ from those to ice. In contrast to kinetic phenomena, hydrate phase

equilibrium is well-defined and determines a boundary to the kinetic problem (Sloan,

1997). Figure 2.5 shows the main features of the phase diagram when a hydrate is formed

with a pure hydrocarbon.

Figure 2.5 Hydrate Phase Diagram (Rojey et al., 1997)

In this figure, curve 1 represents the vapour pressure of the hydrocarbon. Curve 2, 2, 2

delimits the hydrate formation region. The slope change at LQP corresponds to the water-

ice phase change. At point LQP (low quadruple point), the gaseous hydrocarbon, liquid

water, ice and hydrate phases coexist. The slope change at HQP corresponds to the phase

change of the hydrocarbon. At point HQP (high quadruple point), the liquid hydrocarbon,

vapour hydrocarbon, liquid water and hydrate phases coexist. For hydrates to be formed,

12

the presence of liquid water has traditionally been considered necessary (Katz et al.,

1959).

Figure 2.6 Hydrate formation regions for C1 to C4 paraffins (Katz and Lee, 1990)

However, Sloan (1997) indicates that this is not an absolute prerequisite. If the

thermodynamic conditions necessary for hydrate formation are satisfied, the absence of

liquid water introduces a limitation of a kinetic order, making hydrate formation unlikely

but not impossible, especially if nucleation seeds are present. In general, hydrate

formation is favoured by the presence of fine particles acting as crystallization seeds,

such as hydrate microcrystals and solid particles (dust, corrosion products). It is also

favoured by factors that tend to influence flow turbulence, such as a high flow velocity,

pressure pulsation and any type of agitation. To remove the hydrates formed, it is

normally sufficient to establish temperature and pressure conditions lying outside the

formation region. However, the disappearance of hydrate crystals may take relatively

long time, and may be difficult to achieve. Hydrates remaining outside equilibrium for

periods of several days have been observed in the laboratory and in depressurized

13

collecting systems. Microscopic crystals generally persist for long periods after the

hydrates have disappeared visually (Rojey et al., 1997). Figure 2.6 shows the hydrate

formation ranges for methane, ethane, propane and butanes determined from the data

presented by Katz and Lee (1990).

2.8 Hydrate Properties

Natural gas hydrate contains about 180 Sm

3

of gas per m

3

of hydrate and can be used to

store and transport natural gas. The hydrate needs to be refrigeration to a temperature in

the range -20C to -10C to be stable at near atmospheric pressure. The pressure suitable

for making hydrates (formation pressure) will be in the range 60-90 bar, depending on

temperature. Natural gas hydrate formed at equilibrium conditions contains about 15%

wt. gas and 85% wt. water. The exact pressure-temperature conditions for hydrate

formation and decomposition are governed by thermodynamic equilibrium. Equilibrium

curves for methane hydrate and a mixture hydrate (93% mol methane, 5% mol ethane and

3% mol propane) are shown in figure 2.7. Methane hydrate needs higher pressure to form

than mixture hydrate; similarly, methane hydrate decomposes into gas and water at

higher pressure than mixture hydrate. The heat of natural gas hydrate formation is about

410 KJ/Kg compared to 333.5KJ/Kg for ice. The higher heat of formation of hydrate is

due to the inclusion of gas molecules in the ice-like hydrate structure. It follows that

considerable heat must be removed before natural gas hydrate forms. In industrial

processes, the hydrate heat of formation must be removed in heat-exchange equipment.

Figure 2.7 Equilibrium curve for methane hydrate and mixture hydrate (Gudmundsson et. Al., 2000)

14

When heat is removed, hydrate will also be formed, provided the pressure is above the

equilibrium line. This is one of the major challenges in designing commercial NGH

processes. The high heat of NGH formation contributes also its stability at atmospheric

pressure. NGH particles at temperature in the range -20C to -10C and atmospheric

pressure will be below the equilibrium line. Given enough time, the refrigerated particles

will decompose into gas and water. However, hydrate particles refrigerated -20 C to -10

C and stored in large-volume tanks will be surrounded by other hydrate particles. If the

large-volume tanks are insulated, there will be no or limited heat flow from the outside.

The refrigerated hydrate particle will therefore not receive the heat needed to melt

(Gudmundsson et. al., 2000).

2.9 Chemicals for Gas Hydrate Control

Gas hydrate formation can cause problems in several areas of the gas and oil industry

including drilling operations (particularly in deep water), production and process, well

workovers, and injection pressure support operations where gas and water come into

contact.

There are three basic ways in which chemicals can be applied to prevent gas hydrates

from plugging pipes and flowlines. They are categorised as follows:

2.9.1 Thermodynamic Inhibitors

These chemicals change the bulk thermodynamic properties of the fluid system, thereby

shifting the equilibrium conditions for hydrate formation to lower temperatures. Thus

they can be used to prevent hydrate formation and also melt existing hydrate deposits.

They are added at high concentrations, often 10-50% based on the water phase to shift the

chemical potential of a system for hydrate formation to lower temperature at a given

pressure or higher pressure at a given temperature. They are also called anti-freezes and

by far the most common chemical class used to prevent hydrate formation and remove

hydrate plugs. The most commonly used classes of thermodynamic inhibitors are

alcohols, glycols and salts (Kelland, 2000).

15

2.9.2 Kinetic Inhibitors (KI)

These chemicals delay hydrate nucleation (slow crystal growth) for long enough periods

to allow the fluids to be transported or operations to be carried out without hydrate

formation. They are added at less than 1 wt.%.

The key ingredients in kinetic inhibitors are water-soluble polymers or copolymers with

pendent alkylamide groups. Polyoxyalkylenediamines have also been used. A variety of

polymer classes have been investigated but to date the only polymer classes in

commercial use are based on vinyl pyrrolidone or N-methyl-N-venyl acetamide. Other

classes of polymers which have been shown to have significant performance as KIs

include amide derivatives of maleic anhydride (now commercially available), and

alkylacrylamides (Figure 2.8).

Figure 2.8 Monomer Units for Kinetic Inhibitor Polymers: Vinyl Pyrolidone (top left) and

Vinylcaprolactam (top right), Isobutylamine Derivative of Maleic Anhydride (bottom left), Acryloyl

Pyrrolidine (bottom middle) and isopropylacrylamide (bottom right) (Kelland, 2000)

There are two proposed theories on the mechanism of inhibition by kinetic inhibitors. The

first is related to the perturbation of the water by the inhibitor preventing hydrate

embryos from reaching the thermodynamically stable critical nuclear size. The second

theory states that interaction of the inhibitor with the hydrate embryos delays (prevents)

their growth to the critical nuclear size. This second theory has evidence both from

experimental and molecular modelling studies to suggest that it accounts for at least part

of the inhibition mechanism. For example, kinetic inhibitors have been shown

16

conclusively to adsorb to tetrahydrofurane hydrate crystal surfaces, which are Structure

type. Secondly, molecular modelling indicates that the alkylamide side chains of kinetic

inhibitors interact strongly with the cavitous surface of hydrates. The pendent alkylamide

groups can interact in two ways with the hydrate surface. Firstly, the alkyl group

penetrate an open cavity, and then the amide group hydrogen-bonds to the hydrate

surface via the carbonyl group locking the alkylamide to the surface (Figure 2.9).

Figure 2.9 Crude illustration of the interaction of a pendent alkylamide group of a kinetic inhibitor

polymer with a cavity of a gas hydrate (Kelland, 2000)

2.9.3 Anti-Agglomerants (AA)

Anti-agglomerants prevent the deposition and agglomeration of hydrates by forming

slurry of hydrate particles which can be transported in the remaining fluid comprising

mostly liquid hydrocarbon. They are surfactants and are added at less than 1 wt. % based

on the water phase. The need for a liquid hydrocarbon phase restricts their use to oil and

gas condensate fields. There are two methods by which a surfactant can function as an

anti-agglomerant. Firstly, the surfactant interacts via its polar headgroup with the hydrate

surface affecting the crystal growth process. In addition, the hydrophobic tail of the

molecule oil-wets the hydrate particles preventing their agglomeration and dispersing

them in the liquid hydrocarbon phase. Secondly, the surfactant forms a tight water-in-oil

emulsion with the produced fluids. Hydrate formation occurs within the water droplets

and is confined to the droplets. This prevents hydrate agglomeration and produces a

dispersion of hydrate particles. The surfactant has no significant interaction with the

hydrate crystal surface. These products are also known as hydrate dispersant additives.

Products that function by the first mechanism were first developed by Shell. The best

17

performing anti-agglomerants are quaternary ammonium surfactants in which the

ammonium headgroup has two or three butyl or pentyl groups attached to the quaternary

nitrogen. The surfactant can be twin-tailed or mono-tailed (Figure 2.10).

Figure 2.10 Structure of quaternary anti-agglomerants; R is a long alkyl chain, R

1

is H, or methyl,

and R2 is butyl or pentyl (Kelland, 2000)

Besides inhibiting the hydrate crystal growth, the quaternary anti-agglomerants function

in the following ways:

Keep the walls of the pipeline oil-wet, hindering hydrate formation and

deposition at the walls (act as weak corrosion inhibitors).

Concentrate at the water-hydrocarbon interface, where hydrate formation is

most pronounced, and thereby raise the local concentration of ions to freezing

point depressing levels.

Modify the structure of the water near the water-hydrocarbon interface in such

a way as to hinder the formation of hydrate crystals.

Impede further access of water molecules to the hydrate crystal after

attachment to the hydrate crystal.

Prevent agglomeration of hydrate crystals by making their surface

hydrophobic.

The second anti-agglomerant mechanism, involving emulsion technology, was developed

by IFP. One product has been field trialled twice in Argentina with varying success. The

active emulsifier is a complicated mixture of polymerised fatty amides and fatty asters.

Since this technology does not rely on slowing the growth rate of hydrate formation, but

only confining it to the emulsified water droplets, it has the potential to work at any

18

subcooling. For all anti-agglomerant products, one must consider the transportability of

the hydrate slurry. The hydrate particles must be kept transportable and not deposit or

build up at any point in the line. Most applications will be restricted to a water-cut of

maximum 30-40%, since above this value the slurry rheology changes significantly

which may cause flow problems and unwanted pressure drop in the line. Anti-

agglomerants must be compatible with other production chemicals as well as with

sealants and other pipeline materials. The products should not cause any process upsets

such as emulsion separation problems and discharge water quality. Finally, the products

must also be compatible with downstream processing facilities such the condensate

stabiliser equipment, i. e. they must degrade at a suitable rate at the system temperature

(often 150-200C). Some crude oils contain components which act as anti-agglomerants.

By understanding the conditions under which these oils are able to prevent hydrate

plugging, it should be possible to avoid the use of artificial hydrate inhibitors in some

applications (Kelland, 2000).

Kinetic inhibitors and anti-agglomerants are collectively known as low dosage hydrate

inhibitors or LDHIs. LDHIs have only recently been applied in the field but offer

significant cost savings and other benefits compared to non-chemical hydrate methods or

the more traditional thermodynamic inhibitors. In addition to the above methods, a fourth

chemical method is possible, so-called heat-generating chemicals. However, their use

seems more applicable to melting existing hydrate deposits rather than preventing hydrate

formation and deposition (Kelland, 2000).

Different types of hydrate control methods are shown in a Hydrate Control Methods

tree upon a ground of Sound Engineering Practice/design in Figure 2.11.

19

Figure 2.11 Hydrate Control Methods Tree (Gjertsen, 2000)

2.10 Background of Colloids

The concepts and the name of colloid are credited to Thomas Graham (1861). His two

criteria were: (a) restricted diffusivity (colloids being held back by a membrane), (b)

optical turbidity (light scattering). Both indicate the presence of particles much larger

than ordinary molecules such as sucrose. Nowadays it is clear that the former typify

dispersions of optically sub-microscopic particles, while the latter consist of stable

solutions of very large molecules. The first class is now referred to as lyophobic

colloids (i.e. disliking their environment, and hence potentially unstable) and the second

as lyophilic (liking and spontaneously soluble in their liquid). Colloids seemed not to

20

fit the standard laws of the classical physical chemists, and were simply disregarded by

many of them. Qualitative ideas about electrical charges on colloidal particle were

around long before 1930. However, calculating the repulsion forces between particles as

a function of the distance between them is not a simple matter of applying Coulombs

law. A start on the problem was made around 1938. By then it was realized that all

colloidal particles have an influence on the liquid around them. Lyophobic particles,

when charged, exert an effect on the ionic environment; lyophilic particles interact with

their solvent medium in the same way as sucrose does. Already in the 1920s the great

classical colloid chemist H. Freundlich realized that the key to colloid science was to be

found in the special phenomenon associated with surfaces (most of the information in this

section is taken from Laskowski and Ralston, 1992).

2.11 The Classical Interface Model

Phase

Phase

i

Phase

Phase

i

Figure 2.12 Interface between phase and phase

An interface is boundary between two phases (such as Gas/Liquid, Liquid/Solid, L

1

/L

2

; in

Figure 2.12). To the eye it appears perfectly sharp. The very fact that the phases do not

intermingle shows that there is a drastic difference in the molecular environment on the

opposite sides. The difference may lie in the packing (as for a solid at its m. p.) or

molecular kind (as for oil/water). Long before it became possible to analyze

intermolecular forces at interfaces, valuable understanding was achieved through the

dynamic approach- a method which, within limits, is still valid and useful. Capillary

phenomena indicate that a force is required to extend a liquid meniscus the classical

model of surface tension. Experiment shows that the tension () does not change with

21

extension of area (A) and does not depend on the size or form of the liquid surface, but

does depend on the substance.

It follows that at constant temperature and pressure, an interface of area A and tension

requires work A to form it and this work must somehow be stored by the molecules. It is

recoverable and is therefore surface free energy. For pure liquids the surface free energy

per unit area (measured in mJm

-2

) in numerically equal to its surface tension (mNm

-1

).

All the phenomena of capillarity can be perfectly explained surface tension model,

provided that the system is macroscopic. The model is not valid for exceedingly small

bodies (Laskowski and Ralston, 1992).

2.12 Wetting Mechanism: Liquid on Solid

Spreading or retraction of a liquid over a solid depends on the principle of surface tension

of that liquid. Here, firstly,

and

can not be identified with measurable tensions, but

must be read as surface free energies. Secondly, the problem is simplified only if the

solid surface can be assumed to be ideally smooth and uniform in molecular nature; if it

is not, there may be barriers to the movement of a meniscus. Thirdly, the liquid is

assumed to be both pure and a non-solvent for the solid. As with liquid substrates, three

types of behaviors may be found with different materials. There may be complete

spreading, as with water on perfectly clean glass. Or there may be non-spreading, the

liquid shrinking into one drop (e. g. mercury on glass, water on paraffin wax). Or there

may be initial spreading, followed by liberation of droplets with an invisible monolayer

between them- as happens with certain polar oils on metals or polar solids.

Figure 2.13 Equilibrium of a non-spreading drop on a planar solid (Laskowski and Ralston, 1992)

22

In an ideal system of the kind defined above, a retracting drop shrinks in area until it

reaches an equilibrium form. Its perimeter can be seen to meet the solid at a certain angle,

the angle of contact, , measured in the liquid phase at the 3-phase line (Figure 2.13). The

equilibrium angle corresponds again to the net minimum of surface free energies, A,

for which Thomas Young in 1805 gave the equation named after him, namely:

SV

=

SL

+

LV

cos

Where, the subscripts S, L and V stand for solid, liquid and vapour phases, respectively.

As before, the values must be those for mutually equilibrated phases. The form of the

bulk of the drop is governed by the minimum of surface plus gravitational energy,

unaffected by (Laskowski and Ralston, 1992).

2.13 Static Contact Angles

A bubble or a droplet minimizes its free energy by adopting a spherical shape in the

absence of gravity. When the bubble or droplet contacts either a solid or a liquid substrate

it will still minimize its free energy. Essentially the sum:

LV

A

LV

+

SV

A

SV

+

SL

A

SL

, must be minimized where is a surface on interfacial tension,

A is an area and the subscripts LV, SV and SL denote the respective interfaces between

the liquid, vapor and solid phases. If, say, a drop is placed on a solid surface it may

spread to form a thin liquid film or it may remain as a discrete droplet. In the first

instance the behavior may be described as complete wetting whilst the latter corresponds

to partial wetting. Similar behavior is exhibited by a bubble contacting a substrate. There

will certainly be some interaction between the fluid and the solid substrate upon which it

rests, even if this is due only to Van der Waals forces. Some type of surface interaction,

such as adsorption or ionization of surface groups is likely in many cases.

23

Figure 2.14 Sessile bubble with axial symmetry on a solid surface immersed in a liquid in a constant

temperature chamber (Laskowski and Ralston, 1992)

As shown in figure 2.14, the contact angle is the angle contained between planes tangent

to the surfaces of the solid and the liquid at the Wetting perimeter. In the example shown,

is measured through the vapor phase. The wetting perimeter is frequently referred to as

the three-phase line of contact (tplc) but really is a small zone where the three phases

merge. One needs to distinguish, in practice, between situations where the fluid is tending

to advance over or retreat from the surface in question. The limiting static angles

determined for these two cases correspond to the advancing (

A

) and receding (

R

)

contact angles. In general,

A

R

(Laskowski and Ralston, 1992).

2.14 Works of Hirata and Mori (1998)

Hirata and Mori used a simple experimental technique in order to observe the

axysymmetric menisci formed on vertically-oriented cylindrical rods of a polycrystalline

clathrate hydrate. They observed the menisci formed with water/fluorocarbon, air/water

and air/fluorocarbon pairs so that they could evaluate, though rather roughly, how water

and a fluorocarbon wet, in a macroscopic sense, clathrate hydrate surfaces when they are

displacing, or displaced by, the fluorocarbon or air.

2.14.1 Experiments

An aqueous THF solution adjusted at the theoretical composition of THF hydrate

(THF.17H

2

O) into vertically held 12 mm ID silicon rubber tubes each stoppered at its

both ends with rubber plugs and axially pierced by a 2 mm diameter stainless steel rod.

24

These tubes charged with the THF solution were kept in a refrigerator till the solution

was totally solidified. The tubes were then cleaved carefully so that the cylindrical THF

hydrate rods (12 mm in diameter and typically some ten centimeters long, each holding a

steel rod on its axis) could be taken out. The steel rod was to serve as a weight to enable a

gravity dependent immersion of the hydrate rod. Then each hydrate rod was vertically

hung in a low temperature chamber by thread which was connected to a fine motor-

driven screw-gear mechanism. Manipulating this mechanism, the hydrate rod could be

pulled up or down at a prescribed speed. A 300 cm3 glass beaker (72 mm ID) holding

HCFC-123 and water or HCFC-123 only or a 100x100x100 mm rectangular vessel made

of transparent PMMA [polymethyl methacrylate] plates holding water only was placed,

together with a rectangular PMMA-made water bath, in the chamber such that the hydrate

rod was immersed partly in the liquid (or liquids) or contained in the beaker or the

PMMA vessel, crossing the water/HCFC-123, air/water or air/HCFC-123 interface

(Figure 2.15).

Figure 2.15 THF hydrate partly immersed in liquid phases contained in a water-jacketed test vessel

(Hirata and Mori, 1998)

Some portion of the inside beaker wall including the water/HCFC-123 interface level was

covered with a thin, semitransparent Teflon film to modify the shape of the meniscus

formed on the wall in such a way that it no longer interfered with the meniscus formed on

25

the hydrate rod. A thin vinyl chloride sheet, instead of a Teflon film, was attached onto

the inside wall of the PMMA vessel to almost vanish the water meniscus on the wall. The

temperatures of the test liquids as well as the ambient air temperature were kept below

the critical dissociation temperature of THF hydrate, 4.1C. It is well known that the

macroscopic contact angle measurement through a liquid phase partly wetting a solid

surface inherently depends on the direction and the speed of liquid-to-solid relative

motion. Therefore every experiment was so operated that it could continuously be

observed with the aid of a video camera, the geometry of a liquid/liquid or air/ liquid

interface while a hydrate rod was pulled down across the interface at a constant speed as

low as .06 mm/s, or pulled up at the same speed. The contact angle of the denser liquid

observed on the hydrate rod being pulled down should approximate the advancing contact

angle, while that observed on the rod being pulled up should approximate the receding

contact angle.

2.14.2 Results and Discussion of Hirata and Moris Experiment

Figure 2.16 summarizes typical video-graphic pictures obtained with three kinds of

interfaces each advancing or receding on a THF hydrate rod as the result of its

descending or ascending motion. The temperature was held almost constant during each

run but slightly different from run to run; the liquid temperatures measured in the runs in

which the pictures shown in figure 2.15 were obtained fell in the range 1.0-2.1C. Since

the hydrate rods were kept at an even lower temperature before use, it was likely that

there was a weak spatial temperature variation inside the test vessel in each experimental

run. Nevertheless, no evidence was found for even a minute thermocapillary or free-

convection motion inside the vessel and hence assumed that any temperature variation

possibly present in that experimental system little affected the wetting behavior of present

interest.

26

Figure 2.16 Video graphic pictures (a) water/HCFC-123, (b) air/water, and (c) air/HCFC-123

deformed by THF hydrate rods in vertical motion across the interfaces (Hirata and Mori, 1998)

In the first two pairs of pictures, (a) and (b), given in figure 2.16, it was readily noted that

liquid water had small contact angles, whether it was faced with a fluorocarbon liquid or

air, on the surface of a hydrate phase. This fact indicated that THF hydrate and

presumably clathrate hydrates in general had highly hydrophilic surfaces. On the other

hand, the last pair of pictures, (c), suggested that in the absence of any liquid water, even

hydrophobic liquids may contact the hydrate surfaces at small contact angles. In their

work, the quantitative evaluation of the on-hydrate contact angles based on the

observations was abandoned. This was because the surfaces of hydrate-rod samples were

not highly smooth and hence the location of the three-phase contact line on each video

image could not be specified with a sufficient accuracy. Nevertheless, the present study

has provided with some fundamental knowledge of liquid wetting on hydrate surfaces.

27

3 Set-up and Procedure of Experiment

3.1 Introduction

Different from the works of Hirata and Mori (1998), where they used hydrate rods, I tried

with a cell (Figure 3.1) designed and built for conducting the experiment of hydrates.

Then I should be able to compare the observations and findings from these two methods.

For safety and avoiding hazards, I should at first make some leakage and performance

tests of the cell. Then, I should make solution of THF and water to make hydrate with

proper safety measures. The procedures of THF solution preparation with necessary

safety measures and experiments are given in the next sections in details.

3.2 Hydrate Cell

The cell (Figure 3.1) was an almost cube-shaped box with 15 cm. x 15 cm. base-area and

10 cm. height. There was a horizontal partition at 3 cm. below the top. This partition

completely isolated the upper chamber from the lower chamber. The cell and the partition

are made of PMMA. The upper chamber was used for coolant circulation and THF

solution was kept inside the lower chamber. For filling THF solution into the lower

chamber, there was a hole at the bottom of the THF chamber. Normally this hole was

closed but can be opened while filling or emptying was required.

28

Figure 3.1 Hydrate Experiment Cell

There were two lines into the upper chamber, one for coolant inlet while the other for

coolant outlet. These were connected to a cooling unit which circulates 96% pure ethyl

alcohol across the cell. There was a temperature controlling system at the cooling unit,

which helped to control the circulation temperature. A hydrate layer is normally formed

at the top of the THF chamber (lower chamber), where the temperature is achieved as low

as the coolant temperature. There was no insulation or cooling of the rest of the cell

ensuring that it would have ambient temperature at the bottom. So it would give a finite

layer of hydrate without filling the entire chamber. Oil droplet was then allowed to

deposit underneath the hydrate layer by the use of an inverted needle and syringe. Once

the oil droplet contacts the hydrate layer, the contact angle could be observed by taking

pictures. From the observations, contact angles could be measured as a function of crude

oil composition, temperature etc.

3.3 Leakage and Performance Tests

Once the hydrate cell was found ready for conducting our specific experiment, it was

necessary to carry out certain leakage and performance tests in order to be sure if there

29

was any leakage in the joints or partitions of the cell and if it functioned well along with

the cooling unit. At first the bottom chamber was filled completely with water for few

hours. If no leakage was found around the cell then the circulation of coolant was started

at a very low temperature (say -9C). If the cooling unit functioned properly then one

would be able to find a layer of ice at the top of water phase in the bottom chamber after

some time (Figure 3.2). There would be no pressure test because the experiment would be

carried out at atmospheric conditions.

Figure 3.2 Performance test of hydrate cell

3.4 List of chemicals and samples

The following chemicals and samples were used in the experiments:

Tetrahydrofuran (for hydrate preparation),

Water,

Ethyl Alcohol (for circulation of coolant),

Exxsol d80 which is a condensate-like refined oil (Sample-1),

30

King crude oil from the Gulf of Mexico (Sample-2),

Paladio crude oil from West Africa real oil straight from the well (Sample-

3),

Unidentified light oil from Norsk Hydro which is light condensate-like refined

oil (Sample-4).

3.5 Preparation of THF Solution

To mix a solution which would form hydrates, I should do the following:

In a mixing container, I poured in carefully 19% by weight THF and 81%

by weight water; this is the same as 21% by volume THF and 79% by

volume water.

I mixed the solution properly, by gentle stirring.

I poured the mixture into the cell carefully using a funnel to avoid spilling.

I used gloves and glasses for protection and tried to avoid breathing the

fumes.

I closed the cell carefully, making sure that it was completely full.

I should not pour the remaining extra solution back into the THF bottle. I

covered it well (with plastic, to avoid evaporation) and saved for future

use.

3.6 Procedure of Experiment

At first I filled the bottom chamber completely with 21% (volume) of THF

in water.

I connected the inlet and outlet lines of the upper chamber with cooling

unit.

Then I started circulation of coolant at -9C. Although the hydrate

formation temperature for this mixture is 4.4C, I set the circulation

temperature at -9C just to get the hydrate layer quickly.

After circulating for few hours, layer of hydrate was formed. But it was

not a regular shaped layer. The hydrate layer was extremely rough and

irregular.

31

A sample of oil was taken into the syringe.

Very little (1 or 2 droplets) amount of the sample oil was deposited

underneath the hydrate layer with the help of the syringe.

The oil droplet went just below the hydrate layer and the contact surfaces

between the hydrate layer and oil droplet were observed.

To make better observation, I took some pictures and drew sketches.

Then I attempted to measure the contact angle.

I repeated the experiments with other samples.

Variation of contact angles for different kinds of samples was observed.

32

4 Observations and Results

4.1 Some Important Observations

The cell designed and built by me, passed the performance and leakage tests

satisfactorily. The cooler performed very well and could cool down the water inside the

cell satisfactorily. During performance test, a thin layer of ice was noticed over the water

level after circulating the coolant across the cell. The thickness of ice remained constant

when equilibrium (thermally) was achieved (as shown in figure 4.1).

Alcohol

T

h

i

c

k

n

e

s

s

o

f

i

c

e

Water

Figure 4.1 Observation of Performance test

Gel-like white hydrate was produced at the top of THF chamber from THF and water

mixture at very low (-9C) temperature. After that the THF chamber of the cell gradually

became opaque. So the hydrate layer was not seen clearly. But its existence was observed

by injecting coloured water. The hydrate layer was existing above the coloured water

phase (Figure 4.2). Here the cell was vertically rotated by 180 to bring the THF chamber

up.

33

Hydrate Level

Figure 4.2 Existence of hydrate level

Coloured Water

Alcohol

Among the four samples, Exxsol d80 (Sample-1) was almost transparent. Nothing

was observed when droplets of this sample were deposited underneath the hydrate

layer with the help of the syringe. But satisfactory observations were possible for the

other samples. All of them showed wetting angles although all the angles were not

clear but some ideas were possible to find out. Pictures of these observations are

given in Appendix A-6.

4.2 Results

The cell for hydrate experiment was built successfully. The dimensions of

the cell are given in figure 3.1. It was made of transparent polymethyl

methacrylate (PMMA) plates and the plates were fitted with each-other by

glue. A partition of PMMA plate inside the cell was also fitted by using

glue. The roof plate was fitted with several bolts. Then it passed the

performance and leakage tests satisfactorily. The cell functioned well

during the experiments only except some problems which were

manageable. These are discussed in details in chapter-5.

During the experiment gel-like hydrate was formed. As per available

literatures, it was structure-II hydrate.

The transparent and light Exxsol d80 (sample-1) did not give any good

result, because it was mixed into the THF chamber immediately after

being injected by the syringe. From figure 4.3, the angle was assumed to

34

be some 10. But this value was extremely rough because the wetting was

not clear and the droplets were mixed into the THF solution very quickly.

Figure 4.3 Wetting angle of Exxsol d80

King Crude Oil (Sample-2) showed a clear angle of 100 with completely

non-wetting tendency with the hydrate phase. The picture of this

experiment is shown in figure 4.4.

Figure 4.4 Wetting angle of King Crude Oil

In the next experiment, Paladio Crude Oil (Sample-3) produced an angle

of 45 with partially wetting with the hydrate phase (shown in figure 4.5).

35

Figure 4.5 Wetting angle of Paladio Crude Oil

The last sample of unidentified light oil from Norsk Hydro (Sample-4)

showed slightly different result than Exxsol d80. It roughly showed an

angle of some 29 (figure 4.6) with a tendency of mixing into the THF

solution.

Figure 4.6 Wetting angle of light oil from Norsk Hydro

36

5 Discussion

5.1 Discussion of problems encountered and solutions

Sometimes the alcohol level inside the cooling unit went down and

circulation of coolant was stopped giving an alarm. In these

circumstances, some alcohol was added (make up) into the alcohol

chamber of the cooling unit to start it again.

The quality of THF deteriorated while conducting the experiments. As a

result, the THF chamber became completely cloudy, and nothing inside

the chamber could be seen clearly (Figure A-5, Appendix A-6). It was thus

impossible to observe the wetting angles of the oil samples. The THF

chamber was washed with warm water, alcohol and at last with soap but it

was not as clear as at the early stages of experiments. And this not due to

the cell itself, as the same clouding was observed in glass containers. Due

to scarcity of THF, it was not possible to change the THF. A new solution

of THF was prepared and the previous solution was replaced by the new

solution. But it showed the similar behavior. The replaced solution was

stored safely in jars covered with plastic (Figure A-6, Appendix A-6).

Then the injecting needle was cut short such as the droplets of sample oil

contact the hydrate layer somewhere very close to the wall of the cell. This

time it was possible to see the droplets and take pictures.

While carrying out the experiments, some leakages at the partition inside

the cell were gradually being noticed. Then the leakages were repaired

with glue and the cell was filled with alcohol. It was observed for 24 hours

and no leakage was found. Whenever the experiment was started with

THF solution, it was leaking again at the partition. Then it was suspected

that the glues were poisoned by the low quality THF. Another possible

reason was that the glue might have been affected by the velocity of

37

alcohol circulation which was not encountered when the cell was filled up

with alcohol remaining stationary (figure 5.1).

Alcohol

Molecule

Glue

Alcohol

Molecule

Glue

Figure 5.1 Attack of alcohol molecules on the surface of glue

Figure 5.1 shows an idea of one possible reason of damage of glue due to

attack of high velocity alcohol molecules upon the surface of glue.

For the ease of observation and measurement of angles, the hydrate surfaces

were assumed to be plane but in reality these were very rough (figures A-1, A-

2, A-3 & A-4 in Appendix A-6).

The hydrate surface was assumed to be in equilibrium with the surroundings

(i. e. no more hydrate will be formed under those conditions) when the oil

samples were injected into the chamber although it was very difficult to notice

the equilibrium. It was not very unrealistic to run the circulation for several

hours at much lower temperature than the hydrate formation temperature of

the solution (4.4C at 1 atm. Pressure) and to assume that the surface to be in

equilibrium with the surroundings.

5.2 Discussion of Results

According to Hove (1998), a wetting surface is not a precise description. It can be

divided into the categories complete, partial and no wetting. The difference will be

due to the composition of wetting liquid and contact angles between the liquid and

38

hydrate surface. The liquid droplets may have different configurations on a hydrate

surface. On a plane surface they may be like anyone in figure 5.2. If the contact angle

between the droplet and the surface is higher than 90 as shown in figure 5.2 (a), the

surface is not wetted. If it is lower than 90 as in figure 5.2 (b), the surface will be

partially wetted. If the contact angle is close to zero like figure 5.2 (c), the surface is

completely wetted.

Figure 5.2 Wetting on hydrate surface

If figure 5.2 and figure 4.2 are compared then it can be clearly noticed that the

wetting angle for Exxsol d80 (sample-1) was close to zero (10). So sample-1 had a

tendency of wetting the hydrate surface.

King Crude Oil (sample-2) in figure 4.4 was clearly showing same wetting nature as

figure 5.2 (a). In figure 5.2 (a), the wetting angle was higher than 90 and for King

Crude Oil the angle was found 100. So it had no wetting tendency with the hydrate

layer.

Paladio Crude Oil had tendency of partial wetting with the hydrate layer because its

wetting angle was found 45 from figure 4.5, i. e. the wetting angle was <90 which

was same as figure 5.2 (b).

An unidentified light oil from Norsk Hydro (sample-4) showed wetting angle of 29

(figure 4.6). Its wetting angle was in between that of Exxsol d80 and Paladio Crude

Oil. So it had more wetting tendency than Paladio Crude Oil but less than Exxsol d80.

39

5.3 Comparison with previous works of Hirata and Mori (1998)

In Hirata and Moris experiment, a hydrate rod was pulled down pulled up at the

same speed (figure 2.16). The geometry of liquid/liquid or air/liquid interface was

observed with aid of a video camera. From the observations it was readily noted that

liquid water had small contact angles which indicated that clathrate hydrates in

general have highly hydrophilic surfaces.

Hirata and Mori (1998) abandoned to quantitatively evaluate the on-hydrate contact

angles based on observations because the surfaces of the hydrate rod samples were

not highly smooth and hence they could not specify the location of the three phase

contact line on each video image with a sufficient accuracy. However their study

could provide some important fundamental knowledge of liquid wetting on hydrate

surfaces.

I did not have any arrangement for observing wetting characteristics of water upon

clathrate hydrate surfaces. The excellent idea of Hirata and Moris experiment was

that they could observe the wetting angles of different substances in different phases

at the same time. But the problem was it had been very difficult to find the wetting

angle from their experiment. Since both the hydrate layer and THF solution were

stationary in our experiment, it was easier to observe and measure the wetting angles.

Hirata and Mori used extra pure grade THF (99.0 wt % certified purity) supplied

from Junsei Chemical Co. Ltd., Tokyo while I used 99.8% pure THF from Merck

KGaA, 64271, Dramstadt, Germany (properties are given in Appendix A-1). They

used de-ionized and distilled water but I used fresh tap water. In my case, the THF

was showing some inexplicable clouding features, which the manufacturer was

unable to explain. As a result, they could not form very good hydrates. For obtaining

better observation and quantitative data, a considerable refinement of experimental

techniques and higher quality chemicals are required.

40

6 Conclusion and Recommendation for Future Works

6.1 Conclusion

Hydrate wettability is found to be a governing parameter for hydrate morphology and

hence, the hydrate plugging tendency. The wettability of clathrate hydrates is

significantly altered on addition of chemical additives at low concentrations.

Moreover the chemical effect is crucially dependent upon crude oil composition and

same additive may give different effects on different crude oils. Study of wetting

phenomenon/wetting angle of crude oil with clathrate hydrates is now-a-days very

important issue because it determines the complete, partial or non-wetting tendency