Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Flywheel 2 PDF

Caricato da

victover0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

45 visualizzazioni4 pagineSERIES 60 SERVICE MANUAL All information subject to change without notice. 1.16.2. Inspect flywheel housing for cracks and any other damage. 1.16. Install the flywheel housing as follows: 1. Apply a continuous 1. Mm (1 / 16 in.) bead, of Loctite 518 gasket eliminator, or equivalent, to the cylinder block where it mates with the housing.

Descrizione originale:

Titolo originale

Flywheel 2.pdf

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoSERIES 60 SERVICE MANUAL All information subject to change without notice. 1.16.2. Inspect flywheel housing for cracks and any other damage. 1.16. Install the flywheel housing as follows: 1. Apply a continuous 1. Mm (1 / 16 in.) bead, of Loctite 518 gasket eliminator, or equivalent, to the cylinder block where it mates with the housing.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

45 visualizzazioni4 pagineFlywheel 2 PDF

Caricato da

victoverSERIES 60 SERVICE MANUAL All information subject to change without notice. 1.16.2. Inspect flywheel housing for cracks and any other damage. 1.16. Install the flywheel housing as follows: 1. Apply a continuous 1. Mm (1 / 16 in.) bead, of Loctite 518 gasket eliminator, or equivalent, to the cylinder block where it mates with the housing.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 4

SERIES 60 SERVICE MANUAL

All information subject to change without notice.

6SE483 9610 1998 DETROIT DIESEL CORPORATION From Bulletin 4-60-98 1-255

1.16.2.1 Inspection of Flywheel Housing and Rear Oil Seal Area of

Crankshaft

Inspect the flywheel housing as follows:

1. Inspect flywheel housing for cracks and any other damage.

[a] If sealing surface is damaged, repair with emery cloth.

[b] If cracked, repair is not possible.

2. Inspect the crankshaft where the rear oil seal makes contact.

[a] Check for groove in crankshaft.

[b] If crankshaft is grooved, install a wear sleeve over the crankshaft end. An oversized

I.D. rear oil seal must be used with the rear sleeve. Refer to section 1.8.5.

1.16.3 Installation of Flywheel Housing

Install the flywheel housing as follows:

1. Apply a continuous 1.6 mm (1/16 in.) bead, of Loctite 518 gasket eliminator, or

equivalent, to the cylinder block where it mates with the flywheel housing. See Figure

1-216.

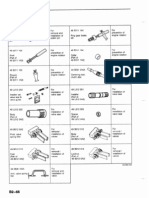

Figure 1-216 Gasket Eliminator Installation

2. Thread two aligning studs, J 35785, into the cylinder block to guide the housing in place.

See Figure 1-215.

3. Support the housing and position it over the crankshaft and against the cylinder block.

NOTE:

Whenever crankshaft rear seal is put over the crankshaft, use crankshaft oil seal

expander. Refer to section 1.8.5.

1.16 FLYWHEEL HOUSING

All information subject to change without notice.

1-256 From Bulletin 4-60-98 6SE483 9610 1998 DETROIT DIESEL CORPORATION

4. Install all of the housing bolts in their proper location, finger-tight.

5. Remove the pilot studs.

6. Tighten the eight short and four long flywheel housing bolts to the cylinder block using

the proper tightening sequence. See Figure 1-217.

[a] If the bolts are 12mm, torque to 112-126 Nm (83-93 lbft).

[b] If the bolts are 14mm, torque to 160-200 Nm (118-148 lbft).

Figure 1-217 Flywheel Housing Bolt Torque Sequence

7. Install the crankshaft rear main oil seal. Refer to section 1.8.5.

8. Install the flywheel. Refer to section 1.14.3.

9. Install oil pan; refer to section 3.11.4, and refill the engine with new oil; refer to section

13.8.1.

SERIES 60 SERVICE MANUAL

All information subject to change without notice.

6SE483 9610 1998 DETROIT DIESEL CORPORATION From Bulletin 4-60-98 1-257

1.16.3.1 Test for Flywheel Housing Bore Concentricity

Check the flywheel housing bore concentricity, and bolting flange run-out with tool set, J 9737-

C, as follows:

1. Thread the base post, J 9737-3, into one of the tapped holes on the outer edge of the

flywheel.

2. Assemble the dial indicators on the base post with the attaching parts provided in the tool

set.

3. Position the dial indicators straight and square with the flywheel housing bell face and

inside bore of the bell. Make sure each indicator has adequate travel in each direction.

See Figure 1-218.

Figure 1-218 Measuring Flywheel Housing Bore Concentricity and Bolting Flange

Run-out

4. Tap the end of the crankshaft (not the crankshaft pulley) with a soft hammer to force it

toward one end of the block to ensure end play is in one direction only.

5. Adjust each dial indicator to read zero at the twelve o'clock position.

1.16 FLYWHEEL HOUSING

All information subject to change without notice.

1-258 From Bulletin 4-60-98 6SE483 9610 1998 DETROIT DIESEL CORPORATION

6. Bar the engine to rotate the crankshaft one complete revolution, taking readings at 90

intervals (4 readings each for the bore and bolting flange face). See Figure 1-219.

Figure 1-219 Flywheel Housing

7. Remove the wrench or cranking bar before recording each reading to ensure accuracy.

[a] The maximum total indicator reading must not exceed 0.33 mm (.013 in.) for either

the bore or the face.

[b] If the run-out exceeds the maximum limits, remove the flywheel and flywheel

housing and check for dirt or foreign material between the flywheel housing and the

cylinder block or oil pan.

8. Clean the mating surfaces once again. Refer to section General Information, Cleaning

in the beginning of this manual.

9. Install flywheel housing. Tighten the eight short and four long bolts to the cylinder block

using the proper tightening sequence. See Figure 1-217.

[a] If the bolts are 12mm, torque to 112-126 Nm (83-93 lbft).

[b] If the bolts are 14mm, torque to 160-200 Nm (118-148 lbft).

10. Install the flywheel. Refer to section 1.14.3.

11. Check the run-out again. If desired run-out cannot be accomplished, replace the flywheel

housing.

Potrebbero piacerti anche

- Detroit s60 Valve AdjustmentDocumento12 pagineDetroit s60 Valve AdjustmentÑengo Flow Full Record50% (2)

- Detroit s60 Valve Adjustment PDFDocumento12 pagineDetroit s60 Valve Adjustment PDFDiego Monroy50% (2)

- API RP 1102 SpreadsheetDocumento5 pagineAPI RP 1102 Spreadsheetdrramsay100% (4)

- Cylinder Head Gasket - Installation (01 - 2010 - ) (Cylinder Head Assembly) - ALLDATA Repair Toyota Camry 2.5LtsDocumento17 pagineCylinder Head Gasket - Installation (01 - 2010 - ) (Cylinder Head Assembly) - ALLDATA Repair Toyota Camry 2.5LtsFran SanchezNessuna valutazione finora

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Da EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Valutazione: 5 su 5 stelle5/5 (1)

- Cylinder Head - InstallDocumento6 pagineCylinder Head - InstallLeonardo PerezNessuna valutazione finora

- Cylinder Head Gasket - Installation (08 - 2013 - ) (Cylinder Head Assembly) - Toyota Sienna 3.5ltsDocumento8 pagineCylinder Head Gasket - Installation (08 - 2013 - ) (Cylinder Head Assembly) - Toyota Sienna 3.5ltsFran SanchezNessuna valutazione finora

- Installation Procedure: NoticeDocumento7 pagineInstallation Procedure: NoticeВиталий ОрловNessuna valutazione finora

- 1.8.7.1 Inspection of Crankshaft Oil Seal: Series 60 Service ManualDocumento2 pagine1.8.7.1 Inspection of Crankshaft Oil Seal: Series 60 Service ManualvictoverNessuna valutazione finora

- Sistema de TransmisionDocumento239 pagineSistema de TransmisionCez Lopez BañezNessuna valutazione finora

- Clutch ManualDocumento16 pagineClutch ManualCO BDNessuna valutazione finora

- Crankshaft - InstallDocumento7 pagineCrankshaft - InstallLeonardo PerezNessuna valutazione finora

- Series 60 Crank Seal11-60-04aDocumento22 pagineSeries 60 Crank Seal11-60-04aKeyser SözeNessuna valutazione finora

- Timing Gear Train Installation 4HK1Documento6 pagineTiming Gear Train Installation 4HK1Walker SkyNessuna valutazione finora

- 6Documento4 pagine6George GuerreroNessuna valutazione finora

- Steel Piston PDFDocumento14 pagineSteel Piston PDFvictoverNessuna valutazione finora

- Caterpillar Cat 225 EXCAVATOR (Prefix 76U) Service Repair Manual (76U01200-02728)Documento26 pagineCaterpillar Cat 225 EXCAVATOR (Prefix 76U) Service Repair Manual (76U01200-02728)rpoy9396615Nessuna valutazione finora

- Section 10 - Power Take-OffDocumento19 pagineSection 10 - Power Take-OffMiller Andres ArocaNessuna valutazione finora

- Figure 1-17 Location of Engine Serial and Model Numbers: Series 60 Service ManualDocumento2 pagineFigure 1-17 Location of Engine Serial and Model Numbers: Series 60 Service ManualvictoverNessuna valutazione finora

- Remove & Install Connecting Rod BearingsDocumento4 pagineRemove & Install Connecting Rod BearingsRichard ChuaNessuna valutazione finora

- Ajuste de Valvulas PDFDocumento8 pagineAjuste de Valvulas PDFRoberto Rincon Robles100% (1)

- Cylinder Head Gasket (Hatchback) - Installation (05 - 2013 - ) (Cylinder Head Assembly) - Yaris HeadDocumento9 pagineCylinder Head Gasket (Hatchback) - Installation (05 - 2013 - ) (Cylinder Head Assembly) - Yaris HeadFran SanchezNessuna valutazione finora

- Service Manual PDFDocumento2 pagineService Manual PDFvictoverNessuna valutazione finora

- Compressor WabcoDocumento6 pagineCompressor Wabcoruben_cruz_34Nessuna valutazione finora

- Char-Lynn: Series 10 Steering Control Units 001 Disassembly/ReassemblyDocumento9 pagineChar-Lynn: Series 10 Steering Control Units 001 Disassembly/ReassemblyIslam ShoukryNessuna valutazione finora

- 3013C Pistons and Connecting Rods - Install - PDF Version 1 PDFDocumento4 pagine3013C Pistons and Connecting Rods - Install - PDF Version 1 PDFJaime Herrera LaraNessuna valutazione finora

- Forged Steel Piston PDFDocumento14 pagineForged Steel Piston PDFvictoverNessuna valutazione finora

- Crankshaft Main Bearings - Install: NoticeDocumento2 pagineCrankshaft Main Bearings - Install: Noticejoe_black15Nessuna valutazione finora

- Valve Lash AdjustmentsDocumento13 pagineValve Lash AdjustmentsEnriqueNessuna valutazione finora

- ENGINE C15 (Torque de Bielas)Documento4 pagineENGINE C15 (Torque de Bielas)Maquinaria Pesada ServisNessuna valutazione finora

- Engine AssemblyDocumento13 pagineEngine AssemblyJacob SilverstielkNessuna valutazione finora

- 3408E and 3412E Crankshaft Main Bearings - InstallDocumento6 pagine3408E and 3412E Crankshaft Main Bearings - Installalonso100% (1)

- Rear SealDocumento9 pagineRear SealHammad Uddin JamilyNessuna valutazione finora

- 1 Mbe4000 06aDocumento38 pagine1 Mbe4000 06azahar222Nessuna valutazione finora

- Crankshaft Oil 2 PDFDocumento2 pagineCrankshaft Oil 2 PDFvictoverNessuna valutazione finora

- Rocker Shaft and Push Rods - InstallDocumento5 pagineRocker Shaft and Push Rods - InstallRajan MullappillyNessuna valutazione finora

- Crankshaft Main Bearings - Install: Shutdown SISDocumento4 pagineCrankshaft Main Bearings - Install: Shutdown SISOecox Cah DjadoelNessuna valutazione finora

- SB1208 - ZF As Tronic - Clutch Component LubricationDocumento12 pagineSB1208 - ZF As Tronic - Clutch Component LubricationCarlos José FariaNessuna valutazione finora

- Volvo D13H Shop Armed Vol1Documento33 pagineVolvo D13H Shop Armed Vol1Roberth Sanchez100% (1)

- Tecbrake Installation Guide For Caterpillar 3406, 3406B and 3406CDocumento18 pagineTecbrake Installation Guide For Caterpillar 3406, 3406B and 3406CJunior Lester100% (2)

- Cojinetes de Bancada de Cigueñal - Instalar PDFDocumento4 pagineCojinetes de Bancada de Cigueñal - Instalar PDFfernando castro padillaNessuna valutazione finora

- Install Cylinder HeadDocumento5 pagineInstall Cylinder HeadbagoesNessuna valutazione finora

- Instalacion y Pueta PuntoDocumento5 pagineInstalacion y Pueta PuntoBrayan Sánchez ParedesNessuna valutazione finora

- Crankshaft Main Bearing Bolts Torque (Converted)Documento5 pagineCrankshaft Main Bearing Bolts Torque (Converted)Nasser Ayoub100% (3)

- Calibre Valvulas MP8 s34-5116Documento20 pagineCalibre Valvulas MP8 s34-5116Jose AGNessuna valutazione finora

- Engine Disassembly Assembly 1Documento9 pagineEngine Disassembly Assembly 1Moaed KanbarNessuna valutazione finora

- Pinion Assemblies - AssembleDocumento4 paginePinion Assemblies - Assemblemijael1393Nessuna valutazione finora

- Remove and Install Crankshaft Main BearingsDocumento3 pagineRemove and Install Crankshaft Main Bearingsramom candido de macedoNessuna valutazione finora

- Torque Bolt Main Bearing Engine GS1141 CATDocumento3 pagineTorque Bolt Main Bearing Engine GS1141 CATM WahyudiNessuna valutazione finora

- Cylinder Head Assembly: Service and RepairDocumento6 pagineCylinder Head Assembly: Service and RepairJose PichinteNessuna valutazione finora

- Remove and Install Crankshaft Main BearingsDocumento4 pagineRemove and Install Crankshaft Main BearingsMayumi Lizarme BuezoNessuna valutazione finora

- Remove and Install Crankshaft Main BearingsDocumento4 pagineRemove and Install Crankshaft Main BearingsMax Will Carrasco SantiNessuna valutazione finora

- 18SP635Documento8 pagine18SP635giovanni ampueroNessuna valutazione finora

- Installation and Adjustment of 3161 Governor On 3500 Family of Engines (1264)Documento23 pagineInstallation and Adjustment of 3161 Governor On 3500 Family of Engines (1264)aliNessuna valutazione finora

- Install Cylinder HeadDocumento6 pagineInstall Cylinder Headrahmat sanusiNessuna valutazione finora

- Pistons and Connecting Rods - InstallDocumento3 paginePistons and Connecting Rods - InstallLeonardo PerezNessuna valutazione finora

- 2010 D 2.5 TCI-4D56 Sistema Mecanico de Motor Conjunto Culata Motor Conjunto Culata Motor Procedimientos de Reparaci ÓnDocumento8 pagine2010 D 2.5 TCI-4D56 Sistema Mecanico de Motor Conjunto Culata Motor Conjunto Culata Motor Procedimientos de Reparaci Óncarlos Gutierrez De La HozNessuna valutazione finora

- Ciguenal NelsonDocumento5 pagineCiguenal NelsonEckard GuendelNessuna valutazione finora

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDa EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNessuna valutazione finora

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDa EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Water Pump PDFDocumento2 pagineWater Pump PDFvictoverNessuna valutazione finora

- 8.2.3.2 Checking 12-Rib Poly-Vee Belt-Driven 50 DN Alternator Belt TensionDocumento2 pagine8.2.3.2 Checking 12-Rib Poly-Vee Belt-Driven 50 DN Alternator Belt TensionvictoverNessuna valutazione finora

- 1.16.1 Repair or Replacement of Flywheel HousingDocumento2 pagine1.16.1 Repair or Replacement of Flywheel HousingvictoverNessuna valutazione finora

- Engine Coolant 2 PDFDocumento3 pagineEngine Coolant 2 PDFvictoverNessuna valutazione finora

- Connecting Rod PDFDocumento9 pagineConnecting Rod PDFvictoverNessuna valutazione finora

- Nteq Lesson PlanDocumento4 pagineNteq Lesson Planeva.bensonNessuna valutazione finora

- NRP Grade 11 READING ENHANCEMENT March 1Documento3 pagineNRP Grade 11 READING ENHANCEMENT March 1LORELYN DELA CRUZNessuna valutazione finora

- Ficha Tecnica Castrol Hyspin AWS RangeDocumento2 pagineFicha Tecnica Castrol Hyspin AWS Rangeel pro jajaja GonzalezNessuna valutazione finora

- Configuration Diagrams: Group 80ADocumento24 pagineConfiguration Diagrams: Group 80ASaHdo AbdelHamid100% (1)

- Imarest 2021 Warship Development 1997Documento43 pagineImarest 2021 Warship Development 1997nugrohoNessuna valutazione finora

- Analysis and Design of Cantilever Slab Analysis and Design of Cantilever SlabDocumento3 pagineAnalysis and Design of Cantilever Slab Analysis and Design of Cantilever SlabMesfinNessuna valutazione finora

- Executive Summary: 0.1 Name of The WorkDocumento12 pagineExecutive Summary: 0.1 Name of The WorkDevdoot SahuNessuna valutazione finora

- Final PaperDocumento12 pagineFinal PaperReikooNessuna valutazione finora

- NAAC 10.12.1888888 NewDocumento48 pagineNAAC 10.12.1888888 Newచిమ్ముల సందీప్ రెడ్డిNessuna valutazione finora

- A Presentation On Organizational Change ModelDocumento4 pagineA Presentation On Organizational Change ModelSandeepHacksNessuna valutazione finora

- 翻译件 2021 The - Early - Life - of - Marx's - "Mode - 【彩云小译】Documento61 pagine翻译件 2021 The - Early - Life - of - Marx's - "Mode - 【彩云小译】James BNessuna valutazione finora

- Piramal Revanta - Tower 3Documento13 paginePiramal Revanta - Tower 3bennymahaloNessuna valutazione finora

- Stearic Acid MSDSDocumento6 pagineStearic Acid MSDSJay LakhaniNessuna valutazione finora

- (Checked) 12 Anh 1-8Documento9 pagine(Checked) 12 Anh 1-8Nguyễn Khánh LinhNessuna valutazione finora

- 2 Design Thinking - EN - pptx-ALVDocumento18 pagine2 Design Thinking - EN - pptx-ALVSalma Dhiya FauziyahNessuna valutazione finora

- Restrictions AOP30 enDocumento1 paginaRestrictions AOP30 enRicardo RamirezNessuna valutazione finora

- El Nido RW 33 Headwind 1120 + CLWDocumento2 pagineEl Nido RW 33 Headwind 1120 + CLWRanny LomibaoNessuna valutazione finora

- Lifestyle Mentor. Sally & SusieDocumento2 pagineLifestyle Mentor. Sally & SusieLIYAN SHENNessuna valutazione finora

- Sources of LawDocumento27 pagineSources of LawIshita AgarwalNessuna valutazione finora

- Integrated Curriculum For Secondary Schools: Mathematics Form 2Documento139 pagineIntegrated Curriculum For Secondary Schools: Mathematics Form 2Izawaty IsmailNessuna valutazione finora

- ExerciseDocumento10 pagineExerciseNguyen Mai QuynhNessuna valutazione finora

- Ens Air To Water Operation ManualDocumento8 pagineEns Air To Water Operation ManualcomborNessuna valutazione finora

- Grade 8 For Demo Cigarette SmokingDocumento3 pagineGrade 8 For Demo Cigarette SmokingSteven TaperoNessuna valutazione finora

- Business Design Thinking - Nguyễn Quang MinhDocumento39 pagineBusiness Design Thinking - Nguyễn Quang MinhbuikimhoangoanhtqkNessuna valutazione finora

- Employment Under Dubai Electricity & Water AuthorityDocumento6 pagineEmployment Under Dubai Electricity & Water AuthorityMominur Rahman ShohagNessuna valutazione finora

- M 02 0001Documento3 pagineM 02 0001Miguel ruizNessuna valutazione finora

- Biogas Technology Suppliers Directory 2018: Internati NalDocumento6 pagineBiogas Technology Suppliers Directory 2018: Internati NalRazvan PetricaNessuna valutazione finora

- Awb 4914934813Documento1 paginaAwb 4914934813Juandondr100% (1)

- DP 900T00A ENU TrainerHandbookDocumento288 pagineDP 900T00A ENU TrainerHandbookAndré baungatnerNessuna valutazione finora