Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

2.16 Ddec Iii/Iv Electronic Control Module

Caricato da

victover100%(1)Il 100% ha trovato utile questo documento (1 voto)

646 visualizzazioni6 pagineDDEC III / IV provides an indication of engine and vehicle malfunctions. The ECM continually monitors the DDEC II / IV system. Tag defective ECM for recore.

Descrizione originale:

Titolo originale

DDEC

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoDDEC III / IV provides an indication of engine and vehicle malfunctions. The ECM continually monitors the DDEC II / IV system. Tag defective ECM for recore.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

646 visualizzazioni6 pagine2.16 Ddec Iii/Iv Electronic Control Module

Caricato da

victoverDDEC III / IV provides an indication of engine and vehicle malfunctions. The ECM continually monitors the DDEC II / IV system. Tag defective ECM for recore.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 6

SERIES 60 SERVICE MANUAL

2.16 DDEC III/IV ELECTRONIC CONTROL MODULE

DDEC III/IV provides an indication of engine and vehicle malfunctions. The ECM continually

monitors the DDEC III/IV system. See Figure 2-74 and see Figure 2-75.

Figure 2-74

DDEC III/IV System Series 60 Diesel Engine

All information subject to change without notice.

6SE438 0010 Copyright 2001 DETROIT DIESEL CORPORATION

From Bulletin 1-60-01

2-141

2.16

DDEC III/IV ELECTRONIC CONTROL MODULE

Figure 2-75

DDEC III/IV System Series 60 Natural Gas Engine

All information subject to change without notice.

2-142

From Bulletin 1-60-01

6SE438 0010 Copyright 2001 DETROIT DIESEL CORPORATION

SERIES 60 SERVICE MANUAL

2.16.1

Repair or Replacement of the DDEC III/IV Electronic Control Module

The DDEC III/IV ECM is a sealed, nonserviceable unit. Tag defective ECM for recore.

2.16.2

Removal of the DDEC III/IV Electronic Control Module

Perform the following steps for ECM removal:

1. Carefully disengage the lock tab on the power harness and injector harness connectors

when removing.

2. Remove the two (2) wire and three (3) wire harness connections at the ECM.

3. Remove the two 30-pin connectors.

4. Remove the through-bolts holding the ECM to the engine.

5. Remove the ECM and cold plate from the engine, if so equipped.

6. Remove the screws securing the cold plate to the ECM. Remove the cold plate from

the ECM, if so equipped.

All information subject to change without notice.

6SE438 0010 Copyright 2001 DETROIT DIESEL CORPORATION

From Bulletin 1-60-01

2-147

2.16

DDEC III/IV ELECTRONIC CONTROL MODULE

2.16.3

Installation of the DDEC III/IV Electronic Control Module

Perform the following steps for ECM installation:

1. Install the cold plate on the ECM, if so equipped. Tighten the screws securing the cold

plate to the ECM. Use Loctite 262, or equivalent, on the cold plate-to-ECM screws.

Torque to 9.5-12 Nm (84-106 lbin.).

2. Inspect the ECM isolators for damage and replace if required.

3. Mount the ECM and cold plate to the engine.

4. Secure the ECM to the engine with through-bolts. Torque the ECM-to-engine bolts to

23-27 Nm (17-20 lbft).

5. Install the connectors in the ECM and torque the jack screws to 2.493.16 Nm (2228

lbin).

6. Engage the lock tab on the power harness and injector harness connectors.

7. Turn the ignition to the "ON" position. Observe the DDR for any diagnostic code(s). If

any code(s) other than code 25 is logged, refer to the Detroit Diesel DDEC III/IV Single

ECM Troubleshooting Manual (6SE497).

Diesel engine exhaust and some of its constituents are

known to the State of California to cause cancer, birth

defects, and other reproductive harm.

Always start and operate an engine in a well ventilated

area.

If operating an engine in an enclosed area, vent the

exhaust to the outside.

Do not modify or tamper with the exhaust system or

emission control system.

3

3

3

8. Start the engine, and check for leaks.

All information subject to change without notice.

2-148

From Bulletin 1-60-01

6SE438 0010 Copyright 2001 DETROIT DIESEL CORPORATION

SERIES 60 SERVICE MANUAL

This page is intentionally left blank.

All information subject to change without notice.

6SE438 0010 Copyright 2001 DETROIT DIESEL CORPORATION

From Bulletin 1-60-01

2-149

2.17

DDEC II ELECTRONIC CONTROL MODULE

2.17 DDEC II ELECTRONIC CONTROL MODULE

This system utilizes an engine-mounted ECM only with the EDU components of the DDEC I

system contained in the ECM. The replaceable PROM is an EPROM in the DDEC II ECM. The

ECM has isolator mounts for both vibration and electrical isolation. Depending upon application,

some units have fuel cooling of the ECM. The engine-mounted system simplifies vehicle wiring

for greater reliability.

The DDEC II ECM is a microprocessor. It is the control center of the DDEC II system.

See Figure 2-78.

Figure 2-78

Schematic Diagram of DDEC II

All information subject to change without notice.

2-150

From Bulletin 1-60-01

6SE438 0010 Copyright 2001 DETROIT DIESEL CORPORATION

Potrebbero piacerti anche

- Course Detroit Diesel Electronic Controls Ddec III IV Systems Components Hardware Repair Tools Electricy Troubleshooting PDFDocumento171 pagineCourse Detroit Diesel Electronic Controls Ddec III IV Systems Components Hardware Repair Tools Electricy Troubleshooting PDFLuis Lemus100% (4)

- Detroit Diesel Series 60 DDEC II To DDEC IV Conversion 18SP546Documento8 pagineDetroit Diesel Series 60 DDEC II To DDEC IV Conversion 18SP546wild04593% (14)

- Axial Power Turbine (09TS13)Documento2 pagineAxial Power Turbine (09TS13)ПавелNessuna valutazione finora

- 21414-3 Valves and Unit Injectors, AdjustDocumento11 pagine21414-3 Valves and Unit Injectors, AdjustTeguh Imam Adri100% (1)

- Ddec VDocumento30 pagineDdec VeduardonemoNessuna valutazione finora

- Detroit DD15 Engine Demand DetroitDocumento1 paginaDetroit DD15 Engine Demand Detroitziad khalilNessuna valutazione finora

- Pro DriverDocumento4 paginePro DriverJulian Esteban Arnaiz Vargas100% (1)

- EVO Engine Re ManufacturingDocumento2 pagineEVO Engine Re ManufacturingArthur Reeves0% (1)

- Ddec Iii - IvDocumento540 pagineDdec Iii - IvNeil50% (2)

- Detroit Diesel DDEC VI Series 60 Engine Performance Wiring DiagramDocumento19 pagineDetroit Diesel DDEC VI Series 60 Engine Performance Wiring DiagramGeraldin PuertoNessuna valutazione finora

- Frlo Lightning Series Manual ServiceDocumento98 pagineFrlo Lightning Series Manual ServiceAdal Vera100% (1)

- Detroit Series 60 Service Manual - Vibratoare Seismice - 19-60-00aDocumento20 pagineDetroit Series 60 Service Manual - Vibratoare Seismice - 19-60-00anguynthanhlongNessuna valutazione finora

- Gliderlink ManualDocumento8 pagineGliderlink ManualMagdiel Eliu Hernandez FloresNessuna valutazione finora

- DDEC Series 60-KenworthDocumento2 pagineDDEC Series 60-KenworthFabio Sierra100% (1)

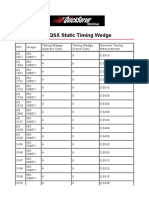

- 850-029 ISX, QSX Static Timing WedgeDocumento6 pagine850-029 ISX, QSX Static Timing WedgeDaniel OstapovichNessuna valutazione finora

- Allison - Automatic Neutral-Dual InputDocumento2 pagineAllison - Automatic Neutral-Dual InputPablo Antu Manque RodriguezNessuna valutazione finora

- Dealer license application instructionsDocumento11 pagineDealer license application instructionsJulyGarza100% (1)

- Detroit™ Transmissions Electronic Application and Installation ManualDocumento80 pagineDetroit™ Transmissions Electronic Application and Installation ManualSonder B0% (1)

- Ddec VDocumento30 pagineDdec Vllama100% (1)

- 320D-336D Excavator Elec. Control SysDocumento38 pagine320D-336D Excavator Elec. Control Sysjlrodriguezma91% (46)

- Jake Brake 1998 PDFDocumento10 pagineJake Brake 1998 PDFvictoverNessuna valutazione finora

- Jake Brake 1998 PDFDocumento10 pagineJake Brake 1998 PDFvictoverNessuna valutazione finora

- Cummins: Fault Code: 352 PID: S232 SPN: 620 FMI: 4 or 3Documento4 pagineCummins: Fault Code: 352 PID: S232 SPN: 620 FMI: 4 or 3Enrrique Lara100% (1)

- DDEC FOR MBE (MBE 900/4000) Vehicle Interface Harness: Power WiringDocumento1 paginaDDEC FOR MBE (MBE 900/4000) Vehicle Interface Harness: Power WiringDayro Jose Geney OrtizNessuna valutazione finora

- DDDL CPC Params PDFDocumento7 pagineDDDL CPC Params PDFManuel KusminskyNessuna valutazione finora

- Detroit Diesel - DDEC II To III-IV ConversionDocumento8 pagineDetroit Diesel - DDEC II To III-IV ConversionValter MortaguaNessuna valutazione finora

- Chapter5 Efi SystemDocumento74 pagineChapter5 Efi SystemDavid Perez NavarroNessuna valutazione finora

- E7 TiempoDocumento12 pagineE7 TiempoJonatan Arango Gomez67% (3)

- Diésel San Pedro-Ddec III - IVDocumento663 pagineDiésel San Pedro-Ddec III - IVLuísNessuna valutazione finora

- Wiring Schematic: Detroit Diesel Series 60 EnginesDocumento1 paginaWiring Schematic: Detroit Diesel Series 60 EnginesMario PattyNessuna valutazione finora

- Epa07 Ddec Vi Electronic Controls A I Manual (Ddc-Svc-Man-0054)Documento39 pagineEpa07 Ddec Vi Electronic Controls A I Manual (Ddc-Svc-Man-0054)Jose Amador Guardado100% (1)

- Service Information OverviewDocumento568 pagineService Information OverviewJulio Gaston Castellanos Duran100% (3)

- 2011-08-04 114144 Fl70cumisbiscwiring PDFDocumento6 pagine2011-08-04 114144 Fl70cumisbiscwiring PDFVM Elliott II100% (1)

- FAULT CODE 271 (ISC/QSC/ISL/QSL Automotive, Industrial, and Marine Application) High Fuel Pressure Solenoid Valve Circuit - Voltage Below Normal or Shorted To Low SourceDocumento13 pagineFAULT CODE 271 (ISC/QSC/ISL/QSL Automotive, Industrial, and Marine Application) High Fuel Pressure Solenoid Valve Circuit - Voltage Below Normal or Shorted To Low SourceAhmedmahNessuna valutazione finora

- Ddec Iii-Iv EcmDocumento5 pagineDdec Iii-Iv EcmDavid Apablaza OlivaresNessuna valutazione finora

- 301 12 PDFDocumento13 pagine301 12 PDFEduardo VillatoroNessuna valutazione finora

- 176-fc5298 Código de FallaDocumento3 pagine176-fc5298 Código de FallaHamilton MirandaNessuna valutazione finora

- 7SA742-0203 C2002 CH7 DDEC-IV Application and InstallationDocumento38 pagine7SA742-0203 C2002 CH7 DDEC-IV Application and Installationtgit28Nessuna valutazione finora

- Fault Code 5655: Aftertreatment 1 SCR Conversion Efficiency - Condition ExistsDocumento3 pagineFault Code 5655: Aftertreatment 1 SCR Conversion Efficiency - Condition Existspanchoreyes1100% (2)

- DD15 and DD16 Axial Power Turbine Gear Box ManualDocumento7 pagineDD15 and DD16 Axial Power Turbine Gear Box ManualRaul Gerardo Delatour CarreroNessuna valutazione finora

- 21 60 03arevDocumento4 pagine21 60 03arevAdal VeraNessuna valutazione finora

- Data Codes Ddec III and IV.Documento10 pagineData Codes Ddec III and IV.FeDe Aavina GlezNessuna valutazione finora

- 900 Speedometer Calibration SettingsDocumento20 pagine900 Speedometer Calibration SettingsllamaNessuna valutazione finora

- Ddec I Ii Iii IvDocumento2 pagineDdec I Ii Iii IvKaiser IqbalNessuna valutazione finora

- Detroit - DD5 GHG17 (2017 - Newer) .ACM2.1Documento8 pagineDetroit - DD5 GHG17 (2017 - Newer) .ACM2.1nenadNessuna valutazione finora

- Injector s60Documento15 pagineInjector s60Alex Forero100% (7)

- JCB 802.7plus MINI EXCAVATOR Service Repair Manual SN 747084 To 747210 PDFDocumento50 pagineJCB 802.7plus MINI EXCAVATOR Service Repair Manual SN 747084 To 747210 PDFfjksemfmmdNessuna valutazione finora

- Detroit Diesel - Low Power Bulletin - MBE4000-07Documento40 pagineDetroit Diesel - Low Power Bulletin - MBE4000-07Juan Pablo Montaño Rivas100% (1)

- Ddeciii IV Level II PDFDocumento353 pagineDdeciii IV Level II PDFxxxxxxxxxxxx100% (1)

- 02 Operationandsensors2Documento23 pagine02 Operationandsensors2libertyplusNessuna valutazione finora

- DDC SVC MAN 0054.ch5Documento188 pagineDDC SVC MAN 0054.ch5aldo jesus100% (1)

- 5 Ddecvi 07Documento12 pagine5 Ddecvi 07octavio hernandez100% (1)

- Caterpillar 3408C, 3412C and 3412D High Performance Marine Engine GuideDocumento6 pagineCaterpillar 3408C, 3412C and 3412D High Performance Marine Engine GuideYudha GaganNessuna valutazione finora

- Ddec IvDocumento140 pagineDdec IvАлексей100% (1)

- ABS Manual 3Documento102 pagineABS Manual 3musah ayubaNessuna valutazione finora

- Ej800blfph W800 Street 2019-20 PDFDocumento88 pagineEj800blfph W800 Street 2019-20 PDFAlbert DepanoNessuna valutazione finora

- Engine Coolant 2 PDFDocumento3 pagineEngine Coolant 2 PDFvictoverNessuna valutazione finora

- Multi-ECM Engines For Commercial and Industry Application PDFDocumento18 pagineMulti-ECM Engines For Commercial and Industry Application PDFmortezaNessuna valutazione finora

- DDEC and Diagnostic Link FAQDocumento12 pagineDDEC and Diagnostic Link FAQAlex Anaya MendozaNessuna valutazione finora

- Engine, Description Engine, Description: Service Information Service InformationDocumento16 pagineEngine, Description Engine, Description: Service Information Service InformationАдыль БабировNessuna valutazione finora

- Informacion Del ECM International Vehiculos Serie 4000Documento88 pagineInformacion Del ECM International Vehiculos Serie 4000Amadeus De La Cruz100% (1)

- Cirrus: 4 PLC'S 2 PLC'SDocumento6 pagineCirrus: 4 PLC'S 2 PLC'SmidunNessuna valutazione finora

- MBE 4000 Aplica e InstalacionDocumento224 pagineMBE 4000 Aplica e InstalacionOmar Alberto Vicenteño SanchezNessuna valutazione finora

- H25CT Manual+LindeDocumento513 pagineH25CT Manual+LindeJan100% (1)

- Figure 6-18A Checking Wastegate CalibrationDocumento6 pagineFigure 6-18A Checking Wastegate Calibrationvictover100% (2)

- Affidavit Details Car Accident DamageDocumento2 pagineAffidavit Details Car Accident DamageDevona JNessuna valutazione finora

- So21970 Engine Parts Catalog: Shandong Lingong Construction Machinery Co.,LtdDocumento156 pagineSo21970 Engine Parts Catalog: Shandong Lingong Construction Machinery Co.,LtdBazzie100% (1)

- B737 Normal ChecklistDocumento2 pagineB737 Normal ChecklistVinícius VazNessuna valutazione finora

- 06873E - Manual, T700 PDFDocumento366 pagine06873E - Manual, T700 PDFCharles LeiftonNessuna valutazione finora

- Replacement: Engine Rating Tier Rating Interlock Code Interlock Code Camshaft Injector Group Piston Body Assembly TurboDocumento3 pagineReplacement: Engine Rating Tier Rating Interlock Code Interlock Code Camshaft Injector Group Piston Body Assembly TurboSergio Ramos RiveraNessuna valutazione finora

- Calibracion Valvulas Motor c12 CaterpillarDocumento5 pagineCalibracion Valvulas Motor c12 CaterpillarOmar Diaz Segura100% (1)

- Engine Oil Cooler - Remove - Engine Oil Cooler With A Low Mounted Filter Base (KENR6081-15)Documento4 pagineEngine Oil Cooler - Remove - Engine Oil Cooler With A Low Mounted Filter Base (KENR6081-15)Anderson Oliveira SilvaNessuna valutazione finora

- Engine Oil Cooler - Remove - Engine Oil Cooler With A High Mounted Filter Base (KENR6081-15)Documento4 pagineEngine Oil Cooler - Remove - Engine Oil Cooler With A High Mounted Filter Base (KENR6081-15)Anderson Oliveira SilvaNessuna valutazione finora

- Electronic Control System ComponentsDocumento7 pagineElectronic Control System ComponentsTri WahyuningsihNessuna valutazione finora

- 6.4 TURBOCHARGER (Diesel) : Figure 6-9 TV45, TV51 Turbocharger AssemblyDocumento2 pagine6.4 TURBOCHARGER (Diesel) : Figure 6-9 TV45, TV51 Turbocharger AssemblyvictoverNessuna valutazione finora

- Water Pump 2 PDFDocumento2 pagineWater Pump 2 PDFvictoverNessuna valutazione finora

- Water Pump PDFDocumento2 pagineWater Pump PDFvictoverNessuna valutazione finora

- Two-Bolt Camshaft 2 PDFDocumento1 paginaTwo-Bolt Camshaft 2 PDFvictoverNessuna valutazione finora

- 8.2.3.2 Checking 12-Rib Poly-Vee Belt-Driven 50 DN Alternator Belt TensionDocumento2 pagine8.2.3.2 Checking 12-Rib Poly-Vee Belt-Driven 50 DN Alternator Belt TensionvictoverNessuna valutazione finora

- Series 60 Service Manual: From Bulletin 19-60-98 1-288cDocumento2 pagineSeries 60 Service Manual: From Bulletin 19-60-98 1-288cvictoverNessuna valutazione finora

- Steel Piston PDFDocumento14 pagineSteel Piston PDFvictoverNessuna valutazione finora

- Figure 2-382 Jake Brake and DDC Bolt Identification: Series 60 Service ManualDocumento2 pagineFigure 2-382 Jake Brake and DDC Bolt Identification: Series 60 Service Manualvictover100% (1)

- Two-Bolt Camshaft PDFDocumento7 pagineTwo-Bolt Camshaft PDFvictoverNessuna valutazione finora

- Service Manual PDFDocumento2 pagineService Manual PDFvictoverNessuna valutazione finora

- Steel Piston 2 PDFDocumento2 pagineSteel Piston 2 PDFvictoverNessuna valutazione finora

- 13.8.4.6 Stop Engine Light Did Not Illuminate: Series 60 Service ManualDocumento2 pagine13.8.4.6 Stop Engine Light Did Not Illuminate: Series 60 Service ManualvictoverNessuna valutazione finora

- Figure 12-9 Adjusting Leveling Screw: Series 60 Service ManualDocumento2 pagineFigure 12-9 Adjusting Leveling Screw: Series 60 Service ManualvictoverNessuna valutazione finora

- 13.8.4.1 Guidelines For Water Pump Replacement: Series 60 Service ManualDocumento2 pagine13.8.4.1 Guidelines For Water Pump Replacement: Series 60 Service ManualvictoverNessuna valutazione finora

- Tool Number Tool Name: Table 1-43 Engine-Cylinder BlockDocumento2 pagineTool Number Tool Name: Table 1-43 Engine-Cylinder BlockvictoverNessuna valutazione finora

- Jake Brake 1998 3 PDFDocumento2 pagineJake Brake 1998 3 PDFvictoverNessuna valutazione finora

- Figure 1-301 Gasket Eliminator Application: Series 60 Service ManualDocumento2 pagineFigure 1-301 Gasket Eliminator Application: Series 60 Service ManualvictoverNessuna valutazione finora

- Guidelines Water Pump 2 PDFDocumento2 pagineGuidelines Water Pump 2 PDFvictoverNessuna valutazione finora

- Guidelines Water Pump 3 PDFDocumento2 pagineGuidelines Water Pump 3 PDFvictoverNessuna valutazione finora

- 1.16.1 Repair or Replacement of Flywheel HousingDocumento2 pagine1.16.1 Repair or Replacement of Flywheel HousingvictoverNessuna valutazione finora

- Flywheel 2 PDFDocumento4 pagineFlywheel 2 PDFvictoverNessuna valutazione finora

- Figure 2-12 Electronic Unit Injector Terminal InstallationDocumento2 pagineFigure 2-12 Electronic Unit Injector Terminal InstallationvictoverNessuna valutazione finora

- Front Camshaft 2 PDFDocumento2 pagineFront Camshaft 2 PDFvictoverNessuna valutazione finora

- This Page Intentionally Left Blank.: Series 60 Service ManualDocumento2 pagineThis Page Intentionally Left Blank.: Series 60 Service ManualvictoverNessuna valutazione finora

- Forged Steel Piston PDFDocumento14 pagineForged Steel Piston PDFvictoverNessuna valutazione finora

- Engine Coolant PDFDocumento1 paginaEngine Coolant PDFvictoverNessuna valutazione finora

- Drain Water Pump PDFDocumento2 pagineDrain Water Pump PDFvictoverNessuna valutazione finora

- Nexus 7 Installation Service ManualDocumento2 pagineNexus 7 Installation Service ManualsolerviNessuna valutazione finora

- Define Clearance VolumeDocumento2 pagineDefine Clearance Volumeshalini deviNessuna valutazione finora

- Caja Fusibles Ford Explorer 2003Documento7 pagineCaja Fusibles Ford Explorer 2003Fabio HDNessuna valutazione finora

- Kubota Rc60 21b Mower Deck Wheel 850304062Documento7 pagineKubota Rc60 21b Mower Deck Wheel 850304062Roy MyersNessuna valutazione finora

- 2012 Jayco Jay Flight 28FT With BunkBeds!! - Rvs - by Owner - ..Documento3 pagine2012 Jayco Jay Flight 28FT With BunkBeds!! - Rvs - by Owner - ..James LongNessuna valutazione finora

- Lampiran C Spesifikasi AlatDocumento4 pagineLampiran C Spesifikasi AlatElva SyukriyatiNessuna valutazione finora

- UN R014r5eDocumento58 pagineUN R014r5e김동은Nessuna valutazione finora

- Gta Vicecity CheatsDocumento16 pagineGta Vicecity CheatsRoopeshraj Urs M P100% (1)

- b12 A7 HondaDocumento3 pagineb12 A7 Hondafrancisco AlbaNessuna valutazione finora

- A319 320 321 Autoflight PDFDocumento0 pagineA319 320 321 Autoflight PDFDipendra SenNessuna valutazione finora

- MS - 304 - Dated 09.02.2001Documento5 pagineMS - 304 - Dated 09.02.2001sujaraghupsNessuna valutazione finora

- 3fak 1998Documento47 pagine3fak 1998motorciNessuna valutazione finora

- Balancing A320Documento5 pagineBalancing A320Surya Agung S NNessuna valutazione finora

- KPI TAM BP Surabaya Kenjeran 12desemberDocumento15 pagineKPI TAM BP Surabaya Kenjeran 12desemberBP SuroboyoNessuna valutazione finora

- 2021 Truckers Guide.2Documento98 pagine2021 Truckers Guide.2david mckernanNessuna valutazione finora

- Charging Systems: in This Presentation You Will: Identify Different Types of Charging SystemsDocumento24 pagineCharging Systems: in This Presentation You Will: Identify Different Types of Charging SystemsEnoch MwesigwaNessuna valutazione finora

- Resume Template Auto MechanicDocumento1 paginaResume Template Auto MechanicNehal RaiNessuna valutazione finora

- Cat Comex Fuel InjectorDocumento12 pagineCat Comex Fuel InjectorGehovanny RíosNessuna valutazione finora

- NPS 75 - 45-155 CREW - ARK1233 - v02Documento4 pagineNPS 75 - 45-155 CREW - ARK1233 - v02GraingeNessuna valutazione finora