Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

D151343 E - en

Caricato da

NayiveLizethBohorquezOjeda0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

566 visualizzazioni8 pagineThis document is to be considered as a whole, the parts of which must not be separated. It is intended to make a visual comparison, in a light chamber, between the colours of a coloured material and those of a colour standard under defined conditions. This method is applicable to coloured materials, in particular: - all finish paints, whether standard or with special effects, applied to bodyworks, - trim materials (textiles, etc.), - plastic parts, with ingrained colouring or

Descrizione originale:

Titolo originale

D151343--E_en

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document is to be considered as a whole, the parts of which must not be separated. It is intended to make a visual comparison, in a light chamber, between the colours of a coloured material and those of a colour standard under defined conditions. This method is applicable to coloured materials, in particular: - all finish paints, whether standard or with special effects, applied to bodyworks, - trim materials (textiles, etc.), - plastic parts, with ingrained colouring or

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

566 visualizzazioni8 pagineD151343 E - en

Caricato da

NayiveLizethBohorquezOjedaThis document is to be considered as a whole, the parts of which must not be separated. It is intended to make a visual comparison, in a light chamber, between the colours of a coloured material and those of a colour standard under defined conditions. This method is applicable to coloured materials, in particular: - all finish paints, whether standard or with special effects, applied to bodyworks, - trim materials (textiles, etc.), - plastic parts, with ingrained colouring or

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 8

TEST METHOD

6 Normalisation Renault Automobiles

DMC / Service 65810

COLOURED MATERIALS

VISUAL COMPARISON OF COLOURS

IN LIGHT CHAMBER

D15 1343 / - - E

RENAULT D15 1343 / - - E

This document is to be considered as a whole, the parts of which must not be separated.

RENAULT 2006.

No duplication permitted without the consent of the issuing department.

No circulation permitted without the consent of RENAULT.

DATE OF ISSUE

January 1981 - - -

REVISIONS

June 1983 - - B

June 1989 - - C

June 1997

- - D Complete revision.

Numbering change : prefix D15 added to the previous number.

Foreword deleted.

This issue originates from draft NC 96460 / - - C.

March 2006 - - E Confirmation of the validity.

REFERENCED DOCUMENTS

Standard : 00-10-409.

RENAULT V.I. Standard : 03-30-4002.

AFNOR Standards : NF EN 20105-A02 (12/94, classification index G07-010-2); NF T 30-061

(04/81) ; X 08-000 (12/75 ).

RENAULT 2006 Page 1/7

RENAULT D15 1343 / - - E

VALID FOR RENAULT V.I.

1. SCOPE AND FIELD OF APPLICATION

The purpose of this test method is to make a visual comparison, in a light chamber, between the

colours of a coloured material and those of a colour standard under defined conditions.

This method is applicable to coloured materials, in particular:

- all finish paints, whether standard or with special effects, applied to bodyworks,

- trim materials (textiles, etc.),

- plastic parts, with ingrained colouring or coated with paint.

It is used :

- for checking conformity of a coloured part with respect to the colour of the corresponding

standard,

- for determining whether a coloured item has changed colour during ageing, e.g. as a result of

exposure to light or a bleeding test.

2. PRINCIPLE

The coloured or painted part is placed next to a standard of the same colour and exposed to a

luminous lighting source.

The induced coloured impressions are visually compared.

The same comparison is made using artificial light under an incandescent lamp to detect metamerism.

If necessary, make a comparison in ultraviolet light (or black light) to show up fluorescence.

3. APPARATUS

3.1. INSPECTION CHAMBER

Room insulated from outside light (e.g. by black curtains), the inside surfaces of which (floor, walls,

ceiling) are coated with a neutral grey matt finish. The light coming from the various sources shall be

filtered through a diffusing screen which does not alter their spectral characteristics.

3.2. LIGHT SOURCES

For DESIGN approval tests, use the MACBETH apparatus, type D65-6 500 k.

For other tests on all other materials corresponding to the technical clauses defined below, the

following can be used:

- "MAC BETH" type light chamber,

- "GAMAIN" type light chamber

RENAULT 2006 Page 2/7

RENAULT D15 1343 / - - E

3.2.1. Daylight

Also called 'white light", this is illuminant D 65 defined by the International Lighting Commission. Its

rays constitute a close reproduction of average daylight rays, including those near to ultraviolet. Its

colour temperature is 6 500 K (see experimental French standard X 08-000).

3.2.2. Artificial light

This is illuminant A on the rays discharged by incandescent lamps with a colour temperature of 2 850

K (see experimental French standard X 08-000) and illuminant TL84 on the rays discharged by a

fluorescent lamp with a colour temperature of 4 200 K.

3.2.3. Black light

"Black" light is an ultraviolet light of wavelength 365 nanometres (nm).

3.2.4. Maintenance

The light sources shall be cleaned regularly, at least every three months. The operating times in

inspection chamber (3.1.) shall be in conformity with the limits indicated by the manufacturer. The

emission characteristics of the chamber shall be checked and adjusted by the manufacturer at least

once a year. The emission rate of the various light sources shall be checked once a month using a

"kelvinmeter" ( e.g. MINOLTA xy1 chronometer).

NOTE 1 :change the incandescent lamps when they are worn out (they seldom last more than

1000 hours),

NOTE 2 :change the fluorescent tubes every 3 500 hours for lighting divided into 500 switch-on

times; each switching is considered as 3 hours of ageing; after this period of 3 500 hours,

replace all the light sources and calibrate the lighting again.

NOTE 3 :always change the lamps in pairs (if one lamp is worn out, change the two).

NOTE 4 : if the paint on the inside of the chamber needs redoing, use only the paint specified by the

manufacturer (MUNSELL neutral grey N7).

3.3. COLOUR STANDARDS

Colour standards are :

- steel plates (or any other support) coated with paint,

- sheets of plastified polyvinyl chloride (PVCp), rigid plastic slabs, moulded parts painted or

not, sheets or carpets, composite materials, etc.

Colour standards shall be kept away from light in accordance with Standard 00-10-409 and other

specific standards such as Standard 03-30-4002 (RENAULT V.I.). Avoid contact between the right

side and other materials liable to damage the standards, such as cardboard or PVCp sheets. Also

avoid marking compressible materials such as velvets, carpets and felt by crushing.

Colour standards shall be handled with care without placing the fingers on the right side; take hold of

them by the edge, by the reverse side or by the support card on which they are clipped, if required.

4. VISUAL INSPECTION

Because of the significant differences in colour vision amongst the general population, it is necessary

to check the quality of colour vision of the observer an to ensure that he belongs to the normal

trichromate category. This examination is carried out by means of inspection methods such as the

"Farnsworth test" (see registered French Standard NF T 30-061).

The observer shall never wear tinted glasses when performing the examination.

RENAULT 2006 Page 3/7

RENAULT D15 1343 / - - E

5. PREPARING THE SPECIMENS

- The specimens under comparison shall be of identical dimensions or of dimensions as close as

possible.

- Clean them if necessary to remove all dirt. In the case of a material with a pile surface, brush in

order to equalise the sheen.

- If there is a difference in brilliance between the specimen and the standard, play with the

inclinations to neutralise the effect.

- If there is a significant difference in mattness (for example on an aged specimen, the surface

condition of which shows actual degradation), it is sometimes necessary to abandon the colour

inspection.

- If the materials have been subjected to heat treatment, the examination shall be performed

at 23 C 2 C (i.e. about 2 hours after curing).

- For paints, apply the paint on the support plate under the conditions specified in the normative

documents.

6. METHOD

The field of observation shall be cleared of any object liable to interfere with visual comparison

(standards or specimens of another colour; operator shall wear grey overalls).

6.1. DAYLIGHT

Switch on the "daylight" lighting (3.2.1.).

6.1.1.1. Non-metallic paints

Observe the colour of the test specimen n comparison with the corresponding colour standard by

placing them side by side on the front edge of the purpose-built test specimen support plate.

6.1.1.2. Metallic or pearled paints

Repeat the above operation while observing the specimens over the whole depth of the support plate

to detect any difference in colour due to goniometric phenomena.

6.1.1.3. Paints which have been subjected to ageing or chalking

Find an observation angle which best reduces the contrast due to the sheen, so that only the contrast

of the two colours are highlighted.

6.1.2. Other cases

Place side by side the test specimen to be examined and the colour standard on an observation plane

making an angle of approximately 30 above the horizontal plane (see diagram in annex 2).

Compare them in this position and continue the comparison rotating the observation plane from + 30

to - 30 around the horizontal axis. Return to the original position.

Rotate the specimens by a quarter turn in their own plane. Repeat the comparison as shown

previously. Carry out the same comparison after a second, then a third quarter of a revolution carried

out in the same direction. Note the mean result of these comparisons.

In the case of a material presenting an anisotropic appearance (for example corduroy, close-cut

carpet, slab moulded in a given grain, metallic effect of paints), orientate the test specimen and the

colour standard in the same way. When the test specimen examined or the colour standard have their

surface condition modified in relation to the initial condition (for example velvet crushed by a cover in

RENAULT 2006 Page 4/7

RENAULT D15 1343 / - - E

the area exposed to light, etc.) find the angle of observation which best reduces the contrast in

brilliance, so as to remain sensitive to the contrast in colour only.

Switch of the "daylight" lighting.

6.2. ARTIFICIAL LIGHT

Switch on the incandescent lamps defined in paragraph 3.2.2. and carry out the same comparisons as

in paragraph 6.1. under this light. This second observation, in addition to the first, enables

metamerism to be revealed.

Switch of the "artificial lighting".

NOTE : two specimens are metamerised if they are identical under one light and different under an

other.

6.3. BLACK LIGHT

If the installation allows it, switch on the "black light" defined in paragraph 3.2.3. and carry out the

same comparisons under this light. This third observation reveals any fluorescence.

Switch off the "black light".

6.4. MULTIPLE EXAMINATIONS

It is permitted to examine successively materials of similar colours, for example a series in shades of

blue.

On the other hand, if a successive examination of different colours must be carried out, it is

necessary:

- to start with neutral, light then dark shades,

- to continue with brighter shades,

- to finish with red shades.

The observer must allow himself a visual rest when passing from one colour to another colour; a few

minutes are generally sufficient. He may also rest his sight by looking at neutral grey.

RENAULT 2006 Page 5/7

RENAULT D15 1343 / - - E

7. EXPRESSION OF RESULTS

Indicate whether the colour of the specimen examined is:

- in conformity, (Accepted),

- not in conformity, ("NC or Rejected),

NOTE : optional rating :

- acceptance limit, (exemption).

according to the differences observed between the specimen and the corresponding colour standard

(or the specimen and the sample of the original material).

In the case of an unacceptable colour, indicate how the colour is distinguished from that of the colour

standard (or that of the sample of the original material) :

- difference in intensity or luminance (lighter, darker),

- difference in tonality (redder or yellower),

- difference in saturation (brighter or less bright in the same tonality),

- contrast compared to the grey scale in accordance with French standard NF EN 20105-A02, or

contrast compared to that of other specimens subjected to the same ageing,

- presence of metamerism,

- presence of fluorescence (i.e. emission of visible radiation under the influence of invisible

radiation, for example ultraviolet).

Note also any difference in surface appearance (brilliance).

8. TEST REPORT

In addition to the results obtained, the test report shall include:

- the reference of this test method,

- the sources of light chosen,

- the operating details not specified in the method as well as any incidents which might have

affected the results.

RENAULT 2006 Page 6/7

RENAULT D15 1343 / - - E

RENAULT 2006 Page 7/7

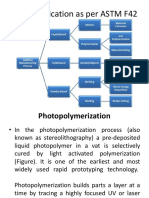

ANNEX

EXAMPLE OF LIGHT CHAMBER INSTALLATION

specimen

Eye of observer

Diffuser screen

Light

sources

Potrebbero piacerti anche

- Performance, Acoustical and Insulators, Interior Assemblies WSS-M99P32-E1 1. ScopeDocumento6 paginePerformance, Acoustical and Insulators, Interior Assemblies WSS-M99P32-E1 1. Scopeerik0007Nessuna valutazione finora

- Din en Iso 2039 1 2003 PDFDocumento10 pagineDin en Iso 2039 1 2003 PDFUsman HameedNessuna valutazione finora

- STJLR.50.5041 2009Documento9 pagineSTJLR.50.5041 2009Jason-chungNessuna valutazione finora

- D45 1195 - C - EN - Thickness & CompressibilityDocumento4 pagineD45 1195 - C - EN - Thickness & CompressibilityTeoTyJayNessuna valutazione finora

- Attach # 2. Routine Test Reports (Internal) - ReviewedDocumento3 pagineAttach # 2. Routine Test Reports (Internal) - ReviewedAvinash PatilNessuna valutazione finora

- Scope: Formerly Um 817 Provisional Method - 1995 © 1995 TAPPIDocumento5 pagineScope: Formerly Um 817 Provisional Method - 1995 © 1995 TAPPIguruprasadcvNessuna valutazione finora

- D251413 B - enDocumento9 pagineD251413 B - enNayiveLizethBohorquezOjedaNessuna valutazione finora

- D271389 F' PDFDocumento13 pagineD271389 F' PDFReza AbdolahiNessuna valutazione finora

- GDT Dfa 2 PDFDocumento7 pagineGDT Dfa 2 PDFRui AguiarNessuna valutazione finora

- 00 124A What Is HumidityDocumento4 pagine00 124A What Is Humiditypaulprem1725Nessuna valutazione finora

- Quadrant Design Machining GuideDocumento43 pagineQuadrant Design Machining GuideCahaya AnNurNessuna valutazione finora

- 02 Datums51Documento51 pagine02 Datums51maddy_scribdNessuna valutazione finora

- D51 3022 - B - EN - Peeling 90 - Interior Trim MaterialsDocumento10 pagineD51 3022 - B - EN - Peeling 90 - Interior Trim MaterialsTeoTyJayNessuna valutazione finora

- GT&DDocumento17 pagineGT&DMicha VardyNessuna valutazione finora

- TL 211 enDocumento19 pagineTL 211 enCarlos AraujoNessuna valutazione finora

- Measuring The Force-Displacement of A Membrane Switch: Standard Test Method ForDocumento5 pagineMeasuring The Force-Displacement of A Membrane Switch: Standard Test Method Formasoud132Nessuna valutazione finora

- 00-10-001 - F - Nov.2000Documento0 pagine00-10-001 - F - Nov.2000Levi MurdokNessuna valutazione finora

- IMM Online TRGDocumento35 pagineIMM Online TRGpsp710Nessuna valutazione finora

- AstmDocumento5 pagineAstmAndrei PopescuNessuna valutazione finora

- 535 CatDocumento1 pagina535 CatHubertNessuna valutazione finora

- Agco - Cfsen04018 (2011 Yılı)Documento6 pagineAgco - Cfsen04018 (2011 Yılı)CEMRE YAŞLINessuna valutazione finora

- Test of Ozone Resistance and Plastic Deformation: Group StandardDocumento4 pagineTest of Ozone Resistance and Plastic Deformation: Group Standardali soydaşNessuna valutazione finora

- D 1415 - 88 R99 - Rde0mtu - PDFDocumento5 pagineD 1415 - 88 R99 - Rde0mtu - PDFGyna SHNessuna valutazione finora

- 01 DFMA OverviewDocumento75 pagine01 DFMA Overviewanwar anwaryNessuna valutazione finora

- TMS6900Documento14 pagineTMS6900Josue Garcia QuiniNessuna valutazione finora

- Blow Molding PDFDocumento63 pagineBlow Molding PDFaleskytronNessuna valutazione finora

- Tolerancing GuidelinesDocumento14 pagineTolerancing GuidelinesDhatchina Moorthy100% (1)

- Din En12020-2001Documento15 pagineDin En12020-2001Ricardo VitorianoNessuna valutazione finora

- A32 4140 (Rev. A 2007.06) EN - UNSPECIFIED TOLERANCES PLASTIC PARTSDocumento8 pagineA32 4140 (Rev. A 2007.06) EN - UNSPECIFIED TOLERANCES PLASTIC PARTSDiego CamargoNessuna valutazione finora

- D 5628 - 96 R01 - Rdu2mjg - PDFDocumento10 pagineD 5628 - 96 R01 - Rdu2mjg - PDFJuan Pablo ApazaNessuna valutazione finora

- Cie DS 014-4.3Documento12 pagineCie DS 014-4.3Domenico AzzolliniNessuna valutazione finora

- Agco - Cfsen04019 (2011 Yılı)Documento7 pagineAgco - Cfsen04019 (2011 Yılı)CEMRE YAŞLINessuna valutazione finora

- TL 52682 enDocumento8 pagineTL 52682 enRenato AlbinoNessuna valutazione finora

- NPTF / PTF Threads: Total Solution For Thread GaugingDocumento3 pagineNPTF / PTF Threads: Total Solution For Thread GaugingFatih YükselNessuna valutazione finora

- Sae - J576-1991 Astm D4364Documento5 pagineSae - J576-1991 Astm D4364Thanh TruongNessuna valutazione finora

- 30 Automotive Applications of Plastics: Past, Present, and FutureDocumento23 pagine30 Automotive Applications of Plastics: Past, Present, and FuturePatito Lisbhet Romero BuenoNessuna valutazione finora

- TL 52622 en 07-2012Documento12 pagineTL 52622 en 07-2012Juan Carlos Jaramillo LariosNessuna valutazione finora

- Geometric Dimensioning and Tolerancing Visual GlossaryDocumento23 pagineGeometric Dimensioning and Tolerancing Visual GlossarypdmnbraoNessuna valutazione finora

- D41 1029 - D - EN - Tensile Strength - Textile & LeatherDocumento6 pagineD41 1029 - D - EN - Tensile Strength - Textile & LeatherTeoTyJayNessuna valutazione finora

- AM Classification As Per ASTM F42Documento19 pagineAM Classification As Per ASTM F42RajijackNessuna valutazione finora

- M&I 04-Dimensional Chains Stack Up2017 V02uncovDocumento20 pagineM&I 04-Dimensional Chains Stack Up2017 V02uncovMritunjay SharmaNessuna valutazione finora

- Auto Noise Vibration Harshness Analysis Full VehicleDocumento5 pagineAuto Noise Vibration Harshness Analysis Full VehicleManeesh M KaimalNessuna valutazione finora

- Metrology: ME3190 Machine Tools and MetrologyDocumento64 pagineMetrology: ME3190 Machine Tools and MetrologySujit MuleNessuna valutazione finora

- GD&T CylindricityDocumento15 pagineGD&T CylindricityjaithilagarajNessuna valutazione finora

- VW 01055 enDocumento47 pagineVW 01055 enIsabel SierraNessuna valutazione finora

- Mold WorksDocumento2 pagineMold WorksMax Elizondo OrtizNessuna valutazione finora

- ISO-187-2022 Papel y Carton - AcondicionamientoDocumento10 pagineISO-187-2022 Papel y Carton - AcondicionamientoDaniela Serna PulgarinNessuna valutazione finora

- Casting ToleranceDocumento1 paginaCasting ToleranceTrushant NakumNessuna valutazione finora

- GD&TDocumento5 pagineGD&TkbhattacNessuna valutazione finora

- Mvss206 Door LockDocumento51 pagineMvss206 Door LockPratik_rush2905Nessuna valutazione finora

- Design Du PontDocumento37 pagineDesign Du PontandreafarronatoNessuna valutazione finora

- Mold Cost Estimation PDFDocumento5 pagineMold Cost Estimation PDFDanistergladwinNessuna valutazione finora

- Linear Vibration Welding Design GuideDocumento2 pagineLinear Vibration Welding Design GuideguptaashishNessuna valutazione finora

- Volkswagen SpecsDocumento1 paginaVolkswagen SpecsYash KanherkarNessuna valutazione finora

- Iso 2285Documento13 pagineIso 2285Selçuk Tosun100% (1)

- Datum NsDocumento24 pagineDatum NsnaveenNessuna valutazione finora

- GD & TDocumento63 pagineGD & THemanth KumarNessuna valutazione finora

- Is 101 - 4 - 2Documento6 pagineIs 101 - 4 - 2GopalMahantaNessuna valutazione finora

- ColourtoleranceRev1 4EN (Final)Documento8 pagineColourtoleranceRev1 4EN (Final)Bravooo8344Nessuna valutazione finora

- Fuji Reala Data SheetDocumento4 pagineFuji Reala Data SheetNate CochraneNessuna valutazione finora

- 2017-Thermal Compression Bonding Understanding Heat Transfer by in Situ Measurements and ModelingDocumento7 pagine2017-Thermal Compression Bonding Understanding Heat Transfer by in Situ Measurements and ModelingDanNessuna valutazione finora

- PhysicsBowl 2017Documento11 paginePhysicsBowl 2017Ajay NegiNessuna valutazione finora

- Reforming Electrolytic CapacitorsDocumento3 pagineReforming Electrolytic Capacitorsbadit991Nessuna valutazione finora

- General Series Overhead Crane: User ManualDocumento30 pagineGeneral Series Overhead Crane: User ManualjokoNessuna valutazione finora

- Black Holes in General Relativity and STDocumento17 pagineBlack Holes in General Relativity and STDiogo MesquitaNessuna valutazione finora

- A Mini Project ON Dark Sensor Using Ic555 TimerDocumento31 pagineA Mini Project ON Dark Sensor Using Ic555 TimerGajula Suresh0% (1)

- Instruction, Use and Maintenance Manual: Translation of The Original Instructions in ITALIAN TI215G0010Documento56 pagineInstruction, Use and Maintenance Manual: Translation of The Original Instructions in ITALIAN TI215G0010tgffcgfgNessuna valutazione finora

- Lec4 PDFDocumento91 pagineLec4 PDFArun ShalNessuna valutazione finora

- Homemade Laser Module - 5 Steps (With Pictures) - InstructablesDocumento1 paginaHomemade Laser Module - 5 Steps (With Pictures) - InstructablesStefan CorneaNessuna valutazione finora

- Non-Closed Lie Subgroups of Lie GroupsDocumento6 pagineNon-Closed Lie Subgroups of Lie Groupslaura lopezNessuna valutazione finora

- Introduction To Electrical Engineering: Chapter 6: Parallel CircuitDocumento19 pagineIntroduction To Electrical Engineering: Chapter 6: Parallel Circuitahnaf arnobNessuna valutazione finora

- Chem1777 1815Documento4 pagineChem1777 1815Maki DonatoNessuna valutazione finora

- Calero Caes Model Power SystemDocumento13 pagineCalero Caes Model Power Systemzain ul AbideenNessuna valutazione finora

- TFX02 Torque ChartDocumento1 paginaTFX02 Torque ChartArnulfo SánchezNessuna valutazione finora

- (Maa 3.9) More Trigonometric FunctionsDocumento18 pagine(Maa 3.9) More Trigonometric FunctionsAli GorganiNessuna valutazione finora

- Solar Divicon Pump Station Installation InstructionsDocumento8 pagineSolar Divicon Pump Station Installation Instructionse-ComfortUSANessuna valutazione finora

- 999 enDocumento131 pagine999 enM RefaiNessuna valutazione finora

- FM Certificado Bomba 250 GPMDocumento2 pagineFM Certificado Bomba 250 GPMCarlos Andres Neira AgudeloNessuna valutazione finora

- Liners For Shaped Charges by Manfred Held (2001) PDFDocumento1 paginaLiners For Shaped Charges by Manfred Held (2001) PDFMalikHodzicNessuna valutazione finora

- Copl-136 841 01Documento52 pagineCopl-136 841 01Lucila Figueroa GalloNessuna valutazione finora

- Mechanics of Bolted ConnectionsDocumento12 pagineMechanics of Bolted ConnectionsJunaid AliNessuna valutazione finora

- Astm E309-01Documento5 pagineAstm E309-01Carlos Raul Caballero LeonNessuna valutazione finora

- Chapter One 1.0 1.1 Background of StudyDocumento19 pagineChapter One 1.0 1.1 Background of Studyblock boyNessuna valutazione finora

- Lab 5-2 Elevator PracticumDocumento9 pagineLab 5-2 Elevator Practicumapi-636322199Nessuna valutazione finora

- Som Assignments PDFDocumento12 pagineSom Assignments PDFLaxmi HattiholiNessuna valutazione finora

- MID 082 - CID 0885 - FMI 05: TroubleshootingDocumento4 pagineMID 082 - CID 0885 - FMI 05: TroubleshootingCory PurbaNessuna valutazione finora

- Sintering Performance of Magnetite-Hematite-GoethiDocumento19 pagineSintering Performance of Magnetite-Hematite-GoethiDeidaNessuna valutazione finora

- Gear Selection ThesisDocumento13 pagineGear Selection ThesismastermechNessuna valutazione finora