Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Itinerario Del Trabajo - ENG (Reunión 28052014)

Caricato da

Mateo AndresDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Itinerario Del Trabajo - ENG (Reunión 28052014)

Caricato da

Mateo AndresCopyright:

Formati disponibili

Work Schedule Summary

1 Excavation

Define and identify manageable axis (it is advisable to begin with Urea Substation).

Begin the excavation on identified axis following the higher work easiness criterion; perform

a strategic movement of excavation equipment and subsequent tasks.

Stop at 50 cm from the bottom and supply a substitution layer.

Outline until reaching the maximum excavation depth and compact the subgrade zone by

manual means, set filling material.

Manage water by using drains and provisional sumps in order to place suction points for

motor pumps.

Start the foundation construction sequence.

Pick another core and continue with the above sequence.

Note. - According to the conditions of superficial or phreatic water, it shall be analyzed if 2 immersion

pits are set.

Figure 1. Excavation Sequence.

2 Foundations

Waterproof polyethylene setting.

Lean concrete setting.

Reinforcement Steel setting + formwork shore setting + casting to lintel level.

Continue with the next axis (following the above sequence).

Remove formworks and set up both backfilling and compacting.

Start backfilling and compacting tasks in the first group of built foundations and so on,

always taking into consideration:

Handling of 20-cm layer and compacting with equipment of less than 10 Tons.

Execution of requested tests and correspondent approval .

Note. - According to either superficial or phreatic water conditions, it shall be analyzed if immersion

pits are removed (so only motor pumps are left, thus pumping works may start in the following

enclosure to be excavated).

3 Bracing beams, framing beams, and others.

Beginning on intervened sections to lintel level (reinforcement steel + formwork shore

setting + casting).

Start bracing beams and continue above sequence (reinforcement steel + formwork shore

setting + casting).

Begin beam construction (reinforcement steel + formwork shore setting + casting).

Finish backfilling and compacting activities as per finishing sequence.

Begin floor tile construction preparations (reinforcement steel + formwork shore setting +

casting).

Begin scaffold and temporary structures setting in order to begin masonry works.

As previous tasks are concluded, masonry works shall be begun with.

Note. - Continue with superficial water management with motor pumps.

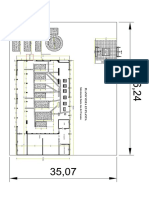

Figure 2. Ammonia Substation Infrastructure

Figure 3. Ammonia Substation Bracing Beams.

Figure 4. Urea Substation Infrastructure.

Figure 5. Urea Substation Bracing Beams.

Potrebbero piacerti anche

- Intake Well Methodology-Package 3C-GWSP - JWILDocumento25 pagineIntake Well Methodology-Package 3C-GWSP - JWILrvsingh17gmailcom100% (1)

- Method Statement For Bridge Deck PoursDocumento6 pagineMethod Statement For Bridge Deck Poursabdulrehman73183% (6)

- Method Statement BorepileDocumento47 pagineMethod Statement BorepileIera Jamil100% (1)

- TechNote Manhole Inverts March13Documento5 pagineTechNote Manhole Inverts March13Aruna JayasundaraNessuna valutazione finora

- Scope of Work-BAMDocumento21 pagineScope of Work-BAMShabeer Shaarim Abdul Jabbar100% (1)

- Method Statement Box Culvert Construction Procedure PDFDocumento7 pagineMethod Statement Box Culvert Construction Procedure PDFTAMILNessuna valutazione finora

- Bored Pile - Method StatementDocumento13 pagineBored Pile - Method Statementbtcong93100% (2)

- Building ConstructionDocumento88 pagineBuilding Constructionmurad_ce100% (5)

- Plinth Beam Work ProcedureDocumento3 paginePlinth Beam Work ProcedureMohd Muksin100% (2)

- LTA Civil Design CriteriaDocumento351 pagineLTA Civil Design CriteriaGeorge V0% (2)

- Creating A Retaining Wall Using Civil 3D Feature Lines and Grading ObjectsDocumento6 pagineCreating A Retaining Wall Using Civil 3D Feature Lines and Grading ObjectsMateo AndresNessuna valutazione finora

- BS en 10202-2001 (2003)Documento48 pagineBS en 10202-2001 (2003)Federico De MartiniNessuna valutazione finora

- Zon KerjaDocumento11 pagineZon KerjaigamamruNessuna valutazione finora

- Methoed Statetment RevisedDocumento71 pagineMethoed Statetment Revised'Tharindu Harshitha'Nessuna valutazione finora

- Bored Cast-In Situ PilesDocumento7 pagineBored Cast-In Situ PilesPathankot MandiNessuna valutazione finora

- Transmission Tower Installation ProcessDocumento50 pagineTransmission Tower Installation ProcessManoranjan Dash100% (8)

- New 170919 Method StatementDocumento2 pagineNew 170919 Method StatementZamaludin ZaimiNessuna valutazione finora

- MS007 Concrete Water TankDocumento5 pagineMS007 Concrete Water TankMhando IgnasNessuna valutazione finora

- Construction and Design of Multistorey BuildingDocumento38 pagineConstruction and Design of Multistorey BuildingRaj MohammadNessuna valutazione finora

- Execution Method For Spillway Hydraulic Surfaces of HKO Main DamDocumento20 pagineExecution Method For Spillway Hydraulic Surfaces of HKO Main DamJoseph NguyenNessuna valutazione finora

- Methodology For Replacing Existing Damaged Base: ProcedureDocumento1 paginaMethodology For Replacing Existing Damaged Base: ProcedureAli SafdarNessuna valutazione finora

- BK-HH-QAC-MS-0017 - Foundation of Central Control Room & Switch Gear BuildingDocumento12 pagineBK-HH-QAC-MS-0017 - Foundation of Central Control Room & Switch Gear BuildingSyed Abbas AliNessuna valutazione finora

- Method of Construction for Administration Building مسودةDocumento7 pagineMethod of Construction for Administration Building مسودةM.ZEKEBA50% (2)

- Bored PileDocumento15 pagineBored PileVănLêNessuna valutazione finora

- Drilling OperationsDocumento18 pagineDrilling OperationsGustavo TeixeiraNessuna valutazione finora

- Qualified Channel Bottom and Sand FillingDocumento4 pagineQualified Channel Bottom and Sand Fillinghello_lakho633Nessuna valutazione finora

- Method Statement For Construction of Box Culvert - Anil KumarDocumento3 pagineMethod Statement For Construction of Box Culvert - Anil KumarAsad AshfaqNessuna valutazione finora

- Methodology For Minor Bridges / Under Passes 1.0 Scope: Continental Engineering CorporationDocumento10 pagineMethodology For Minor Bridges / Under Passes 1.0 Scope: Continental Engineering Corporationvenkateswara rao PothinaNessuna valutazione finora

- MS DrainageDocumento5 pagineMS DrainageYin Mohd100% (4)

- Construction Procedures of Concrete Encasement, Anchor, and Thrust BlocksDocumento3 pagineConstruction Procedures of Concrete Encasement, Anchor, and Thrust BlocksJoe Mari CapaNessuna valutazione finora

- Bored PileDocumento7 pagineBored PileMichael Root100% (3)

- Construction Methodology For Test PIle NPBDocumento8 pagineConstruction Methodology For Test PIle NPBSheikh Nouman Mohsin RamziNessuna valutazione finora

- Construction PlanDocumento9 pagineConstruction PlanEngineeri TadiyosNessuna valutazione finora

- (O) - 1 Bored PileDocumento16 pagine(O) - 1 Bored Pileautienhai100% (4)

- SummeryDocumento13 pagineSummerySidAhmedNessuna valutazione finora

- Construction Methodlogy For Well Foundation: - 1 - VKLR, QmeDocumento4 pagineConstruction Methodlogy For Well Foundation: - 1 - VKLR, QmeBalaji ManneNessuna valutazione finora

- Method Statement: ApprovalDocumento21 pagineMethod Statement: ApprovalzhanghuiNessuna valutazione finora

- Manhole InvertsDocumento5 pagineManhole InvertsJovo BozovicNessuna valutazione finora

- Construction Methods and Equipment M1Documento75 pagineConstruction Methods and Equipment M1NITHIN A VNessuna valutazione finora

- SECTION 2.05 Trench ExcavationDocumento4 pagineSECTION 2.05 Trench ExcavationVipul RathiNessuna valutazione finora

- Section 334110 - Storm Drainage: TA1056 MBI Sampang Agung Brewery ExtensionDocumento3 pagineSection 334110 - Storm Drainage: TA1056 MBI Sampang Agung Brewery Extensionery achjariNessuna valutazione finora

- Access Road To The Intake & Manager's Quarters 1Documento16 pagineAccess Road To The Intake & Manager's Quarters 1NalinNessuna valutazione finora

- Slip FormsDocumento31 pagineSlip Formssabareesan09Nessuna valutazione finora

- Chapter 4 Sewer ConstructionDocumento27 pagineChapter 4 Sewer Constructionsahle mamoNessuna valutazione finora

- PQC - Road ConcreteDocumento10 paginePQC - Road Concretemangeshshinde124100% (1)

- Construction ProcedureDocumento2 pagineConstruction ProcedureVănLêNessuna valutazione finora

- Slip Formwork: Guided by Prof. VRK Murthy Submitted by Vikas B. More (73036) Aniruddha S. Namojwar (73038)Documento27 pagineSlip Formwork: Guided by Prof. VRK Murthy Submitted by Vikas B. More (73036) Aniruddha S. Namojwar (73038)simple_ani100% (1)

- Methodology of ConstructionDocumento19 pagineMethodology of Constructionsumit249100% (1)

- Homework Exercise-Ii: Submitted By: GairikDocumento5 pagineHomework Exercise-Ii: Submitted By: GairikGairik ChakrabortyNessuna valutazione finora

- Constructive Instruction For Crawl SpaceDocumento16 pagineConstructive Instruction For Crawl SpaceIonescu StefanNessuna valutazione finora

- Tender Notice 07-10-14 BOQ Pile DesignDocumento158 pagineTender Notice 07-10-14 BOQ Pile DesignJibonGhoshPritomNessuna valutazione finora

- Tunnel Form ConstructionDocumento11 pagineTunnel Form Constructionmohammed alzanganaNessuna valutazione finora

- Precast Concrete Manufacturing Techniques and InstallationDocumento21 paginePrecast Concrete Manufacturing Techniques and InstallationVIgneshNessuna valutazione finora

- Methodology For PQC (00) Toll Plaza L&TDocumento4 pagineMethodology For PQC (00) Toll Plaza L&TDeven PatleNessuna valutazione finora

- Diaphargm Wall Construction DetailsDocumento48 pagineDiaphargm Wall Construction DetailsAkshay Joshi100% (1)

- UnderpinningDocumento58 pagineUnderpinningZoeyHakim100% (1)

- METHOD STATEMENT FOR EARLY WORKS PACKAGE Rev-3 - Emaar The ViewsDocumento6 pagineMETHOD STATEMENT FOR EARLY WORKS PACKAGE Rev-3 - Emaar The Viewsaliengineer953Nessuna valutazione finora

- OUTLINE of Static Load Test: Indochina Plaza HanoiDocumento8 pagineOUTLINE of Static Load Test: Indochina Plaza HanoiTran HungNessuna valutazione finora

- Building Construction ItemsDocumento39 pagineBuilding Construction ItemsMetre SNessuna valutazione finora

- Quantity Schedule For Both Entry Exit GatesDocumento10 pagineQuantity Schedule For Both Entry Exit GatesMATRIX ENGINEERSNessuna valutazione finora

- Diaphragm WallsDocumento15 pagineDiaphragm WallsWan Eira100% (1)

- Work ProgramDocumento21 pagineWork ProgramEngineeri TadiyosNessuna valutazione finora

- Transactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173Da EverandTransactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173Nessuna valutazione finora

- Favor SumarDocumento8 pagineFavor SumarMateo AndresNessuna valutazione finora

- Layout PGLDocumento1 paginaLayout PGLMateo AndresNessuna valutazione finora

- Favor SumarDocumento8 pagineFavor SumarMateo AndresNessuna valutazione finora

- Placing Drawings ETN C 4 15Documento5 paginePlacing Drawings ETN C 4 15Mateo AndresNessuna valutazione finora

- Usace Report Gl-92-3 On DCPDocumento52 pagineUsace Report Gl-92-3 On DCPMateo AndresNessuna valutazione finora

- OS1500 - II Model - 1Documento1 paginaOS1500 - II Model - 1Mateo AndresNessuna valutazione finora

- Item3c QAQC STRUCTURALCONCRETEDocumento6 pagineItem3c QAQC STRUCTURALCONCRETEMateo AndresNessuna valutazione finora

- WBSDocumento6 pagineWBSLuthfi HanafiNessuna valutazione finora

- Cat® Skid Steer LoaderDocumento20 pagineCat® Skid Steer LoaderMateo AndresNessuna valutazione finora

- Microsoft Project Scheduling ManualDocumento66 pagineMicrosoft Project Scheduling ManualMateo Andres100% (1)

- 0309 SVPDocumento1 pagina0309 SVPMateo AndresNessuna valutazione finora

- Plastering and Rendering MortarsDocumento3 paginePlastering and Rendering MortarsMateo AndresNessuna valutazione finora

- Roof Drain Selector Guide WattsDocumento8 pagineRoof Drain Selector Guide WattsMateo AndresNessuna valutazione finora

- Resource LevelingDocumento16 pagineResource LevelingMateo AndresNessuna valutazione finora

- Roof DrainDocumento1 paginaRoof DrainMateo AndresNessuna valutazione finora

- Plano General de La Planta /: Work Scope QC DepartmentDocumento1 paginaPlano General de La Planta /: Work Scope QC DepartmentMateo AndresNessuna valutazione finora

- Pocket Guide To Brick ConstructionsDocumento130 paginePocket Guide To Brick ConstructionsLeontin Leon100% (3)

- ManualThermoplasticValvesBooklet MTV5-08Documento64 pagineManualThermoplasticValvesBooklet MTV5-08Mateo AndresNessuna valutazione finora

- Earthing - Useful PowerpointDocumento50 pagineEarthing - Useful PowerpointdifxNessuna valutazione finora

- SP1246 Part-5 PDFDocumento23 pagineSP1246 Part-5 PDFMohammad Aamir Perwaiz100% (1)

- CamberDocumento4 pagineCamberdorao80Nessuna valutazione finora

- Is 15774 2007 PDFDocumento19 pagineIs 15774 2007 PDFchandramohanNessuna valutazione finora

- USQC WQRDocumento2 pagineUSQC WQRMuhammad fahmyNessuna valutazione finora

- ManifoldCatalogJune02pt1 PGIDocumento37 pagineManifoldCatalogJune02pt1 PGIManuel GerardoNessuna valutazione finora

- Reciprocating Pumps BrochureDocumento8 pagineReciprocating Pumps BrochureJaikumar ChandranNessuna valutazione finora

- Structural ExampleDocumento32 pagineStructural ExampleHarry Ccayascca FloresNessuna valutazione finora

- ME3251 RevisionDocumento9 pagineME3251 RevisionJordan NgNessuna valutazione finora

- Water Jet Unit: Advanced High Efficient Marine Propulsion SystemDocumento4 pagineWater Jet Unit: Advanced High Efficient Marine Propulsion SystemPoentech CA100% (1)

- NAAMM EMMA 557-20 Standards For Expanded MetalDocumento18 pagineNAAMM EMMA 557-20 Standards For Expanded MetalScott NorrisNessuna valutazione finora

- Fig-4970-4970G-NEW DESIGNDocumento1 paginaFig-4970-4970G-NEW DESIGNAsmaaNessuna valutazione finora

- 10 March 2018 - 15 March 2018Documento4 pagine10 March 2018 - 15 March 2018Abdul Ahad LoneNessuna valutazione finora

- Astm A 767 - A 767MDocumento4 pagineAstm A 767 - A 767Meddyew100% (1)

- Posco: A New Steel Plant in IndiaDocumento2 paginePosco: A New Steel Plant in Indiashadi22Nessuna valutazione finora

- Meena International Training & Certification DivisionDocumento2 pagineMeena International Training & Certification DivisionShanmuga NavaneethanNessuna valutazione finora

- ASTM A36 Steel, PlateDocumento1 paginaASTM A36 Steel, PlateI-SignNessuna valutazione finora

- Msds Stainless SteelDocumento11 pagineMsds Stainless Steelrakesh marwahNessuna valutazione finora

- Welding Specification ChartDocumento189 pagineWelding Specification ChartVivek SatapathyNessuna valutazione finora

- The Reactivity Series of MetalsDocumento27 pagineThe Reactivity Series of Metals118latelyNessuna valutazione finora

- 699752.construction Materials Roadmap For Research and DevelopmentDocumento22 pagine699752.construction Materials Roadmap For Research and DevelopmentFarjallah Al-AssãadNessuna valutazione finora

- GJ Profile (11-Jan-2015)Documento15 pagineGJ Profile (11-Jan-2015)nirdoshkumarNessuna valutazione finora

- Iso 17637-2016Documento14 pagineIso 17637-2016Upul Eranda Abeyrathna83% (6)

- Astm A263 2009Documento6 pagineAstm A263 2009DenilsonRomãoNessuna valutazione finora

- Process Industry Practices Structural: PIP STE05121 Anchor Bolt Design GuideDocumento55 pagineProcess Industry Practices Structural: PIP STE05121 Anchor Bolt Design GuidemithileshNessuna valutazione finora

- Crimson Star Series Transformer PumpersDocumento8 pagineCrimson Star Series Transformer PumpersPaoloFregonaraNessuna valutazione finora

- Flange Fixed Joint BDocumento5 pagineFlange Fixed Joint BRefandi WidodoNessuna valutazione finora

- High Conductive High Galvanized Round Steel WireDocumento2 pagineHigh Conductive High Galvanized Round Steel WireAMARENDRA SINessuna valutazione finora

- Assignment b3 MetfisDocumento3 pagineAssignment b3 MetfisDewi Lestari Natalia MarpaungNessuna valutazione finora

- The Most Economical Solution For Drilling!: Indexable DrillDocumento20 pagineThe Most Economical Solution For Drilling!: Indexable DrillapulavartyNessuna valutazione finora