Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

EM - 63 Oil Spill Management

Caricato da

Raja Ramachandran0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

46 visualizzazioni7 pagineOIL SPILL

Titolo originale

EM - 63 Oil Spill Management.doc

Copyright

© © All Rights Reserved

Formati disponibili

DOC, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoOIL SPILL

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

46 visualizzazioni7 pagineEM - 63 Oil Spill Management

Caricato da

Raja RamachandranOIL SPILL

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOC, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 7

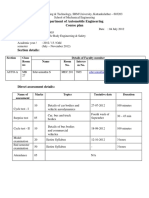

ORISSA POWER GENERATION CORPORATION LTD.

IB THERMAL POWER STATION, BANHARPALI

STANDARD OPERATING PROCEDURE

OIL SPILL MANAGEMENT PROCEDURE

Document No: EM 4/63

Filed At: All Departments

1. OBJECTIVES

The purpose of the SOP Oil Spill Management Procedure is to train the operating

personnel to enable OPGC to implement measures to reduce the potential for a spill

event to occur and enable staff to respond promptly to contain, and counteract the

discharge in a safe, practical, and systematic manner so that the adverse impact on

environment due to oil handling can be minimised.

2. RESPONSIBILITY

ll Team !eaders are responsible for implementation of this SOP in their respective

areas.

3. CLASSIFICATION OF OIL SPILL / LEAK

Oil lea"s and spills can be#

i$ %ithin the storage areas or associated secondary containment structures

ii$ %ithin the operational areas in &hich people &or".

Potential onsite spillages have been classified as

'$ Ma(or

)$ !ocali*ed

+$ Contained

,$ Minor

3.1 Ma!" S#$%%a&'( )E*'"&'+,- S$./a.$!+0

D'1$+$.$!+

Spills capable of causing significant offsite impacts on land or on the -ira"ud

.eservoir

SOP Oil Spill Management Procedure 1

S!/",'

!/O storage tan" 0)1112!$ and -S/ storage tan" 0MG.$

Turbine lube oil line lea"age outside bund area

Seal oil lea"age

Ca/('(

34treme hostile &hether conditions li"e cyclone, earth5ua"e, and heavy rain &ould

result in e4tensive damage to the Primary Storage Tan" and Secondary Containment

Structures. Turbine lube oil and generator seal oil lea"age shall occur doe to material

or gas"et failure.

3.2 L!,a%$2'3 S#$%%a&'(

D'1$+$.$!+

localised spill of )116'111 litres of oil spill escaping beyond the secondary

containment to a distance of '16)1 m

S!/",'(

!/O7-S/ tan"ers unloading bay

Oil storage sheds7containers

Turbine lube oil, generator seal oil lea"ages.

Coal pulveri*er gear bo4 oil lea"ages

Stac"er reclaimer hydraulic oil lea"ages

Ca/('(

May occur as a result of improper handling or storage practices, as &ell as

inade5uate secondary containment.

3.3 C!+.a$+'3 S#$%%a&'(

D'1$+$.$!+

The spilled oil escapes from the primary containment, either by lea"ing through the

body of the primary container or spillage from the primary container but is prevented

from escaping beyond the storage area8s secondary containment.

S!/",'

!/O Storage Tan" 0)1112!$ and -S/ Storage Tan" 0MG.$

Main Oil tan", /irty Oil tan", Po&er Transformers

ll Oil Storage Sheds 9 Containers

Ca/('(

May occur due to poor maintenance of storage vessels.

3.4 M$+!" S#$%%a&'(

D'1$+$.$!+

SOP Oil Spill Management Procedure 2

!ea"ages and small spillages that are generally#

!ess than )1 litres &here they have escaped outside the secondary containment

!ess than )11 litres &here the spilled material has been contained &ithin the

secondary containment.

S!/",'

ny of the oil storage areas.

Operating areas

4. PREVENTIVE MEASURES FOR MINIMISING OIL SPILL / LEAK

Concerned Operation and Maintenance 0O9M$ Team !eaders shall ensure follo&ing

preventive measures#

Minimise oil storage &here it is possible.

Provide good Primary Containers for storing oil.

3nsure provision of secondary containment for the primary oil container

0containing :); liter oil$ and primary oil containers are stored in a manner that

ma4imises spill prevention of oil to outside, incase of any oil lea" through primary

container.

Secondary containment should be provided &ith ade5uate si*e, impervious

flooring and dy"e &all, floor slope and sump pit to prevent spillage outside

secondary containment incase of emergency lea"age7spillage from Primary

Containment.

<ncase of oil storage in barrels, a shed should be provided.

<ncase of oil storage in tan"s, no shed is re5uired.

Oil barrels should never be placed on pervious floor, &ithout ade5uate secondary

containment, lid 0cap$ and shed.

Suitable secondary containments are to be provided during transportation of oil

barrels.

/uring filling of oil ade5uate secondary containment is to be provided and use

hand pumps for filling.

Maintain the Primary Containers and secondary containment periodically to

prevent oil lea" through the body of the container.

Maintain pipes, valves, (oints etc periodically to prevent oil lea".

3nsure that concerned O9M personnel 0OPGC and Contractor$ of respective

Team are trained to operate and maintain e5uipments, and are a&are of the

response procedures to address oil lea"s and spillages.

SOP Oil Spill Management Procedure 3

3nsure that this standard procedure is follo&ed in respective Team for effective

spill prevention and mitigation.

3nsure daily inspections of all e5uipment7containers containing oils and

document such inspections and ensure that they are properly maintained.

Provide guidance and re5uired resources to the concerned contractors for

effective implementation of oil spill management procedure at the site.

N!.' 5 3nsure that Material Safety /ata Sheet 0MS/S$ of oil is available &ith each

Team handling oil and also it is displayed at the oil storage area.

P"'6'+.$6' M'a(/"'( $+ E*'"&'+,- S$./a.$!+

.eceiving advanced e4treme &eather condition &arnings, plant shut do&n

procedures are to be initiated, including emptying the ma(or Oil Storage Tan"s before

occurrence of such e4treme &eather conditions.

7. HANDLING OF MAJOR OIL SPILL/ LEAK )EMERGENCY SITUATION0

The follo&ing course of action should be underta"en &here a ma(or spill to occur

3vacuate the facility of all personnel not directly involved in controlling and

counteracting the spillage.

Stop the source of the spill if possible.

=se gravel filled bags to contain the spillage.

Coat the spilled material &ith foam to reduce the potential of the diesel oil

catching fire.

Collect the spilled material using a pump fitted &ith a strainer or suction valve.

Store the spilled material in )11 litre drums or other oil containers and send them

to the oil storage shed for subse5uent disposal to authorised recyclers.

8. HANDLING OF OTHER OIL SPILL/ LEAK

0!ocali*ed Spillage, Contained Spillage and Minor Spillage$

8.1 INCIDENT REPORTING9

<f any employee of OPGC and Contractor notices any oil spill7lea", shall

immediately inform the incident to concerned 3ngineer6in6charge7Team

!eader7T.!. 3nvironment. -o&ever, concerned O9M personnel are primarily

responsible for reporting all incidents of oil lea"s and spills &ithin their &or"ing

areas to their respective 3ngineer6<n6Charge7Team !eader on the same day of

incident.

ll incidents of oil spill shall be declared by concerned team in the daily morning

meeting.

SOP Oil Spill Management Procedure 4

<f the oil spill7lea" from primary container is continuous in nature 0either

continuous discharge or intermittent discharge in shape of drops$, it is to be

reported by concerned Team !eader to Team !eader 03nvironment$ as

3nvironmental <ncidence, in 3nvironmental <ncident .eporting >ormat 3.. ;7)?6

>'.

<f the oil spill7lea" from primary container is instantaneous and does not persist as

incase of spill during handling of oil drums7containers and oil topping etc., and the

5uantity of oil spill is : 7.; %$.'", 3nvironmental <ncident .eport is to be sent on

the same day by concerned T.! to T.!. 3nvironment in 3nvironmental <ncident

.eporting >ormat 3.. ;7)?6>'.

8.2 MITIGATION MEASURES

Concerned Operation and Maintenance 0O9M$ Team !eaders shall ensure follo&ing

mitigation measures in case of oil spill7lea"#

<n case of lea"age from body of the storage tan", pipeline, valve etc, lea"age

points shall be sealed immediately.

<ncase of lea"age from oil barrels, the barrel shall be immediately placed

hori*ontally and the lea"age point shall be "ept on the topside to minimi*e

lea"age.

3ntire 5uantity of oil shall be transferred to a good barrel to control the lea"age

completely.

<n case of contained spill 0i.e. spilled oil contained &ithin secondary containment$,

spilled oil from sump shall be collected and stored in good barrels and shall be

sent to &aste oil storage shed for further disposal to registered recyclers and the

oily floor shall be cleaned immediately &ith Oil Spill Control 2it 0oil sorbent pad$

<n case of oil spillage beyond Secondary Containment, the spillage area shall be

barricaded immediately &ith Safety @arricading Tape.

Oil Spill Control 2it 0Oil Sorbent$ shall be used to contain the spilled oil spreading

on the floor and prevent disposal to drain7land.

<n cases of oil spill on the floor, the spilled oil shall be absorbed and recovered in

good barrel and thereafter the oily floor shall be cleaned &ith Oil Spill Control 2it

0oil sorbent pad$

<n case of minor oil lea"age from machines7 pipe line 7valves7(oints in operation

areas &here no permanent Secondary Containment is there, temporary

secondary containment li"e Tray7 Polythene &ith temporary dy"e7 Spill 2it

SOP Oil Spill Management Procedure 5

0Sorbent boom and pillo&$ shall be provided to contain the spilled oil and finally to

collect and dispose in closed barrels.

fter use oil contaminated spill "it 0Sorbent$ shall be stored in separate closed

barrel for reuse and final disposal to registered recyclers through %are -ouse 7 in

impervious closed pit.

Ao sand shall be used for cleaning oily floor incase of oil lea"7spill.

Ao oil6contaminated &aste shall be thro&n7disposed of here and there other than

the identified bins provided at &or" site.

8.3 ROOT CAUSE ANALYSIS OF INCIDENT

Concerned Operation and Maintenance 0O9M$ Team !eaders shall ta"e

appropriate corrective measures after doing root cause analysis of the incidents

0reported to T.!. 3nvironment$

8.4 CLOSURES AND DOCUMENTATION OF INCIDENT REPORT9

Concerned Team !eaders are primarily responsible for closing all oil spill7lea"

incidents 0reported to T.!. 3nvironment$ by doing root cause analysis ta"ing

corrective actions.

Concerned Team !eaders are primarily responsible for documenting all oil

spill7lea" incident reports of respective Team.

T.!. 3nvironment shall be responsible for documenting oil spill7lea" incident

reports received from different Teams and overall monitoring of oil spill7lea"

incident reports for final closure of the incidents.

8.7 TRAINING

Oil Spill .esponse Training shall be imparted to concerned employees of OPGC

and Contractors to prepare staff to respond actual spill incidents appropriately

and in a safe manner.

Spill prevention briefings shall be discussed &ith all personnel 0OPGC and

Contractors$ involved in the handling, storage and usage of oils.

These briefings shall highlight and describe actual oil spill incidents, implemented

corrections, corrective and preventive measures and some best practices.

S/,< ."a$+$+& (<!/%3

.emind the staff of the importance of environmental a&arenessB

3nable the staff to identify the unsafe conditions &ithin their respective

&or"places that could potentially result in an unplanned discharge.

3mpo&er staff to be able to identify oil lea"ages and spillages &ithin their

&or"place

SOP Oil Spill Management Procedure 6

Concerned Team !eaders are responsible for identifying the personnel 0OPGC

and Contractor$ associated &ith Oil Spill Management in respective Team and

recommending their name to Personnel /epartment for getting ade5uate training

on Oil Spill Management.

Personnel /epartment is responsible for arranging such training 0<n6

house734ternal$ periodically.

T.!. 3nvironment7S.O7>.O are responsible for imparting in6house training

periodically to concerned personnel of OPGC and Contractors, in addition to any

training imparted in6house7outside by e4ternal agencies.

Team level a&areness training shall be ensured regularly by concerned Team

!eaders through Monthly 3-S Meeting and other forum.

T.!. 3nvironment shall monitor the ade5uacy of such training.

8.8 SPILL RESPONSE PLAN = PREPAREDNESS9

ll Teams handling oil shall maintain ade5uate stoc" of Oil Spill Control 2it at the

handling site or near the handling area to handle oil spill incidents as 5uic" as

possible to minimi*e its adverse impact on environment.

3ach Teams handling oil, shall declare a combat group for handling oil spill

incidents.

Moc" drills on oil spill shall be conducted regularly by concerned Teams in

respective areas of operation.

.evision Ao

9 /ate

Prepared @y Cerified @y

Tech Cell

pproved @y

/irector 0Operation$

1?.').)11D

P.2.Mohapatra

T.!. 03nv$

SOP Oil Spill Management Procedure 7

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- 22 Immutable Laws of BrandingDocumento257 pagine22 Immutable Laws of BrandingMuhamad N. Ikhsan100% (3)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Safety Committee Meeting MinutesDocumento2 pagineSafety Committee Meeting MinutesSURJIT SINGH50% (2)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Safety Awareness Warehouse Safety Rules-Safety HandbookDocumento23 pagineSafety Awareness Warehouse Safety Rules-Safety HandbookMohammad Ali Zaman100% (1)

- START / Jump START Triage: ImmediateDocumento2 pagineSTART / Jump START Triage: ImmediateJerome DanielNessuna valutazione finora

- Construction Site PremisesDocumento78 pagineConstruction Site PremisesDrew B Mrtnz67% (6)

- Strategies To Prevent Fatalites and Severe Loss EventsDocumento35 pagineStrategies To Prevent Fatalites and Severe Loss EventsSreekumarNessuna valutazione finora

- Kenr8369 01 01 AllDocumento76 pagineKenr8369 01 01 AlllunikmirNessuna valutazione finora

- 10.1.1.476.5960-Fsa Cruise ShipsDocumento17 pagine10.1.1.476.5960-Fsa Cruise ShipsJay Jay0% (1)

- Practical Use of The MELDocumento3 paginePractical Use of The MELapi-3805097100% (9)

- Lifeboat Safety - Briefing BookletDocumento8 pagineLifeboat Safety - Briefing BookletRiyandiDwiPNessuna valutazione finora

- Baza v. BolinaoDocumento4 pagineBaza v. BolinaoReena MaNessuna valutazione finora

- Seacrest Drillship Sinking Investigation 1989Documento128 pagineSeacrest Drillship Sinking Investigation 1989Divers Association100% (2)

- Setra 413 DT FaceliftDocumento24 pagineSetra 413 DT FaceliftEdhem LjeljićNessuna valutazione finora

- Securing Roro CargoDocumento2 pagineSecuring Roro CargoIlter KocamanNessuna valutazione finora

- Thermodynamics - SunilDocumento5 pagineThermodynamics - SunilRaja RamachandranNessuna valutazione finora

- Non Traditional Machining TechniquesDocumento4 pagineNon Traditional Machining TechniquesRaja RamachandranNessuna valutazione finora

- Theory of Automotive EnginesDocumento7 pagineTheory of Automotive EnginesRaja RamachandranNessuna valutazione finora

- Vehicle Body EnggDocumento6 pagineVehicle Body EnggRaja RamachandranNessuna valutazione finora

- Department of Automobile Engineering Course PlanDocumento4 pagineDepartment of Automobile Engineering Course PlanRaja RamachandranNessuna valutazione finora

- Sources and Types of Municipal Solid WastesDocumento2 pagineSources and Types of Municipal Solid WastesRaja RamachandranNessuna valutazione finora

- Lesson Plan-CE1016 - Structural Design - Steel Academic Year 2015-16 (Semester Commencing in June 2015)Documento3 pagineLesson Plan-CE1016 - Structural Design - Steel Academic Year 2015-16 (Semester Commencing in June 2015)Raja RamachandranNessuna valutazione finora

- Video 8Documento2 pagineVideo 8Raja RamachandranNessuna valutazione finora

- CE1205 Lesson PlanDocumento2 pagineCE1205 Lesson PlanRaja RamachandranNessuna valutazione finora

- CE1008 Lesson PlanDocumento3 pagineCE1008 Lesson PlanRaja RamachandranNessuna valutazione finora

- CE1008 Lesson PlanDocumento3 pagineCE1008 Lesson PlanRaja RamachandranNessuna valutazione finora

- CE1006 Lesson PlanDocumento2 pagineCE1006 Lesson PlanRaja RamachandranNessuna valutazione finora

- Faculty Name: Sucheta Panda: Total Number of Hours 48Documento1 paginaFaculty Name: Sucheta Panda: Total Number of Hours 48Raja RamachandranNessuna valutazione finora

- Video 9Documento1 paginaVideo 9Raja RamachandranNessuna valutazione finora

- Veer Surendra Sai University of Technology, Burla Department of Metallurgy& Materials Engineering Lecture Plan-PT&HTDocumento4 pagineVeer Surendra Sai University of Technology, Burla Department of Metallurgy& Materials Engineering Lecture Plan-PT&HTRaja RamachandranNessuna valutazione finora

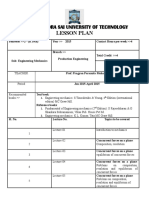

- Lesson Plan Subject Name-Robotics and Flexible Manufacturing Systems Branch-Production Engineering Subject Code-BPE 2802 Semester - 8Documento2 pagineLesson Plan Subject Name-Robotics and Flexible Manufacturing Systems Branch-Production Engineering Subject Code-BPE 2802 Semester - 8Raja RamachandranNessuna valutazione finora

- Veer Surendra Sai University of Technology, Burla Department of Metallurgy& Materials Engineering Lecture Plan-Transport PhenomenaDocumento3 pagineVeer Surendra Sai University of Technology, Burla Department of Metallurgy& Materials Engineering Lecture Plan-Transport PhenomenaRaja RamachandranNessuna valutazione finora

- Lesson Plan: Veer Surendra Sai University of TechnologyDocumento4 pagineLesson Plan: Veer Surendra Sai University of TechnologyRaja RamachandranNessuna valutazione finora

- Lesson Plan Subject Name-Automation & Numerical Control Machines Branch-Production Engineering Subject Code - BPE 2701 Semester - 7Documento2 pagineLesson Plan Subject Name-Automation & Numerical Control Machines Branch-Production Engineering Subject Code - BPE 2701 Semester - 7Raja RamachandranNessuna valutazione finora

- Video PDFDocumento2 pagineVideo PDFRaja RamachandranNessuna valutazione finora

- Lesson Plan Subject Name-Theory of Metal Forming Branch - Production Engineering Subject Code - BPE 2603 Semester - 6Documento2 pagineLesson Plan Subject Name-Theory of Metal Forming Branch - Production Engineering Subject Code - BPE 2603 Semester - 6Raja RamachandranNessuna valutazione finora

- Lesson Plan Subject Name-Advanced Casting and Welding Branch - Production Engineering Subject Code - BPE 2605 Semester - 8Documento2 pagineLesson Plan Subject Name-Advanced Casting and Welding Branch - Production Engineering Subject Code - BPE 2605 Semester - 8Raja RamachandranNessuna valutazione finora

- Golf-October-2002 PDFDocumento44 pagineGolf-October-2002 PDFCaroline PuckettNessuna valutazione finora

- Me Machine Shop Guide v2Documento18 pagineMe Machine Shop Guide v2Ibrahim SameirNessuna valutazione finora

- Safety PrecautionsDocumento14 pagineSafety Precautionspavanramana100% (2)

- Oegc Adv Teachersnotes 04Documento5 pagineOegc Adv Teachersnotes 04Karina Garcia VênusNessuna valutazione finora

- Group 2 RAILWAY SIGNALLING SYSTEMDocumento8 pagineGroup 2 RAILWAY SIGNALLING SYSTEMZulfikar FikriNessuna valutazione finora

- HBR11 - How To Avoid CatastropheDocumento18 pagineHBR11 - How To Avoid CatastropheMrTransistorNessuna valutazione finora

- Major Accidents Involving ContractorsDocumento6 pagineMajor Accidents Involving ContractorsSt_LairNessuna valutazione finora

- AP Workbook 5-E-1Documento3 pagineAP Workbook 5-E-1Steve PeraltaNessuna valutazione finora

- Taylor Lawsuit SMTX NEWSDocumento44 pagineTaylor Lawsuit SMTX NEWSRussell WildeNessuna valutazione finora

- Time ArsenalDocumento29 pagineTime Arsenalapi-194369927Nessuna valutazione finora

- Army Aviation Digest - Jul 1978Documento52 pagineArmy Aviation Digest - Jul 1978Aviation/Space History LibraryNessuna valutazione finora

- The Hound of BaskervillesDocumento149 pagineThe Hound of BaskervillesManojna NimmagaddaNessuna valutazione finora

- Fitness Anywhere PRDocumento3 pagineFitness Anywhere PRelsucioNessuna valutazione finora

- Workbook 4Documento9 pagineWorkbook 4Isabela BmNessuna valutazione finora

- Present Perfect, Past and Past PerfectDocumento4 paginePresent Perfect, Past and Past PerfectBlanka MazuchNessuna valutazione finora

- STALL STD QB English PDFDocumento27 pagineSTALL STD QB English PDFPabitra Kumar Patra100% (1)