Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

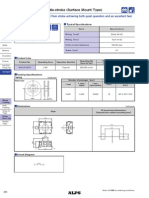

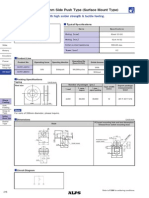

Water-Proof Type With Built-In Detector Switches

Caricato da

shyhuDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Water-Proof Type With Built-In Detector Switches

Caricato da

shyhuCopyright:

Formati disponibili

200

Detector

Rotary

Encoders

Power

Dual-in-line

Package Type

TACT Switch

TM

Push

Slide

Rotary

Type

Push

Type

Rocker

Type

Slide

Type

Japan Export

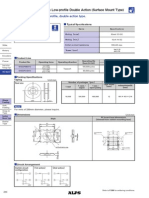

Circuit

arrangement

SPST

Travel

mm)

1.5

Operating force

2.5 1.5N

Mounting method

PC board

Minimum order unit pcs.)

150

Product No.

SDKRA10100

Product Line

1. This product is noI be used under waIer.lP67 dusI and waIer resisIance)

2. Depending on the loading conditions, Nitrogen OxideNOx)and moisture caused by opening / closing arc may

generate nitric acidHNO3). This can lead to corrosion of the metal inside causing functional failure. Please apply

contact protection circuitsarc suppressing circuits)or an OFF stage arc reducing circuit method.

Notes

1

1

a

b

1

1

a

b

Circuit Diagram

Viewed from Direction A)

Dimensions

Unit:mm

Style

PC board mounting

hole dimensions

Viewed from the Direction A)

0.5

PC board

mounting face

C

1

.

9

1

0

2.4

1

1.6

3

1

.

6

3

.

5

1

3

4.2

0.8

5.4

2.5

6 8

4

-R

2

1

5

15

1A125V~B

0.5 0.5

6

(

1

2

.

3

)

1

1

.

5

1

3

8

0.8 0.8

5VDC

10mA

0.5A250V~B

On stroke

Full stroke

Initial position

Momentary

DC switch terminal Nob

DC switch terminal Noa

AC switch terminal No

AC switch terminal No1

1

A

AC Switch DC Switch

6.7 2.9

86

4

-

1

.

2

h

o

le

s

1

.

6

h

o

le

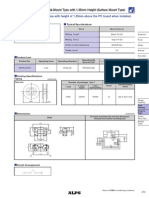

Bulk

Packing Specifications

3,000 750

Number of packagespcs.)

555 375 223

Export package

measurements

mm) 1 case / Japan 1 case / export packing

QRatings and Safety Standards

Items Specifications

AC Switch

1A 125V AC,0.5A 250V AC

Resistive load)

DC Switch 10mA 5V DCResistive load)

Ratings satisfying local electrical

appliance and material safety law

1A 125V AC

SDKR

Water-proof Typewith BuiIt-in Detector Switches)

For power resume in main power auto shut down, compact and

composite type suitab|e for AO and DO.

3,000

Refer to P.215 for soldering conditions.

Power Switches

196

Detector

Rotary

Encoders

Power

Dual-in-line

Package Type

TACT Switch

TM

Push

Slide

Rotary

Type

Push

Type

Rocker

Type

Slide

Type

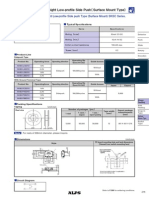

Slide

Push

Type Push Rocker

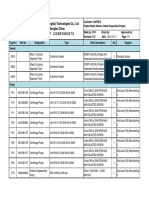

Series SDKN SDKR SDDH SDDJE

z1

z2

SDDJF

z1

z2

Photo

Rating

0.25A 250V AC

0.5A 125V AC

5mA 5V DC

0.5A 250V AC

1A 125V AC

10mA 5V DC

Ratingmax.):4.5A 12V DC

lamp load:27W`2)

Ratingmin.):10mA 12V DC

Resistive load)

10A 250V AC

6A / 96A 250V

16A 250V AC

166)/ 250

Operating life

5,200cycles 100,000cycles

100,000 cycles

10,000cycles

0.25A 250V AC 0.5A 250V AC 10A 250V AC 16A 250V AC

Travelmm)

9

9.7

1.5 3.7 3.4 5.2

Features

Water-proof type

With signal circuit

Water-proof

(IP68 rating)

Operating temperature

range

20T to 60T 10T to 85T 15T to80T 10T to 55T

Automotive use _ _

Life cycle (availability)

Electrical

performance

Contact

resistance

100mO max.

100mO max. ACswitch)

500mO max. DCswitch)

500mO max. 100mO max.

Insulation

resistance

100MO min. 500V

DC

500MO min. 500V DC

ACswitch)

100MO min. 100V DC

DCswitch)

10MO min. 500V DC 500MO min. 500V DC

Voltage

proof

600V AC for 1minute

1000V AC for 1minute

ACswitch)

100V AC for 1minute

DCswitch)

500V AC for1minute 2,000V AC for 1minute

Mechanical

performance

Terminal

strength

50N for 1minute 5N for 1minute

Slider pull-out strength:

100N MIN

50N for for 1minute

lead terminal

5N for 1minute

(right-angle terminal)

60N for 1minut

lead terminal

10N for 1minute

(right-angle terminal)

Actuator

strength

Operating

direction

20N 100N 25N

Perpendicular

direction

30N 20N 25N

Environmental

performance

Cold 302T for 192h 202T for 240h 152T for 96h 202T for 96h

Dry heat 702T for 192h 852T for 240h 802T for 96h 852T for 96h

Damp heat

402T,

90to95%RH for 192h

602T,

90to95%RH for 1000h

402T, 90to95%RH for 96h

Page 198 200 201 202 206

Power Switches So|dering Oonditions 215

Power Switches Oautions 215

Power Switches Safety Standard 215

Notes

1. z1. Dip soldering can be used on SDDJE for PC board terminal and SDDJF right angle terminal types only.

2. z2. The operating temperature range for automotive applications can be raised upon request. Please contact us

for details.

8. indicates applicability to all products in the series, while _ indicates applicability to some products in the series.

Q List of Varieties

215

Detector

Rotary

Encoders

Power

Dual-in-line

Package Type

TACT Switch

TM

Slide

Push

Rotary

Type

Push

Type

Rocker

Type

Slide

Type

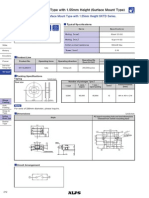

Power Switches Soldering Conditions

SDDJE, SDDJF, SDKP,

SDDJF1A , SDKZ, SDDE

SDKT

SDKR

35010

35010

30010

31 / 0s

30.5s

30.5s

Series

Soldering

temperature

Soldering time

Reference for Hand Soldering Reference for Dip Soldering

(For PO board termina| types and SDDJF right-

ang|e termina| types)

SDKR, SDDJE, SDDJF,

SDKP, SDKT, SDKZ, SDDE

2605 101s

Series

Dip soldering

Soldering

temperature

Duration of

immersion

Power Switches Cautions

Power Switches Safety Standards

1. The primary power supply switching is subject to the safety regulations, and the provisions differ by

each destination. Consult with us for non-standard use cases.

2. An unstable contact may occur if the switch current is lower than 0.5A. For this case, consult with us.

3. These power switches were produced for alternating current. For direct current, consult with us.

4. Appling load to terminals during soldering under certain conditions may cause deformation and

electrical property degradation.

5. Avoid use of water-soluble soldering flux, since it may corrode the switches.

6. When soldering twice, wait until the first soldered portion cools to normal temperature. Continuous

heating will deform the external portions, loosen or dislodge terminals, or may deteriorate their

electrical characteristics.

7. Before soldering switches with locking mechanism, release the locks. If they are soldered without

releasing the locks, the soldering heat may deform the locking mechanism.

8. Be sure to release the locks before removing the knobs. Otherwise, the locking mechanism may be

broken.

9. Be sure to use the switch with forced travel positioned as close to the total travel as possible.

10. Tighten the mounting screws by applying the specified torque. Tightening with a larger torque than

the specified will result in malfunction or breakage of screws.

11. Corrosive gas if generated by peripheral parts of a set, malfunction such as imperfect contact may

occur. Thorough investigation shall be required beforehand.

12. Storage

1 Store the products as delivered, at a normal temperature and humidity, without direct sunshine

and corrosive gas ambient. Use them at an earliest possible timing, not later than six months

upon receipt.

2 After breaking the seal, keep the products in a plastic bag to shut out ambient air, store them in the

same environment as above, and use them up as soon as possible.

3Do not stack too many switches.

1. Safety Standards Outline

Safety standards are established by a country or an organization representing it to protect general

users from electrical shock and fire hazards. It establishes standards for electrical devices and

components. For electrical equipment manufacturers, utilizing switches that have been safety-

approved ensures the safety of the switch. The use of a safety-approved switch also simplifies at

least one part of the process of obtaining certification by safety testing.

2. Major Safety Standards

1)Electrical Appliance and Material Safety Law

The conventional [Electrical Appliance and Material Control Law] has changed to [Electrical Appliance

and Material Safety Law] and has been enforced since April 1, 2001. Electrical appliances are

categorized into special electric appliances and partsformerly Class Aand Electrical appliances other

than the special electric appliances formerly Class B. Special electric appliances are required to

receive goodness of fit test at a certified test agency and to store the certificate. Also, penal provisions

have been reinforced.

2)ULUnderwriters Laboratories Inc.)

Underwriters Laboratories Inc. ULis the American safety approving organization. Its purpose is to

ensure consumer safety and protect them from fire hazards. State law requires that equipment to

be exported to the United States utilize UL approved power switches or power switches meeting UL

standards and capable of passing UL tests.

Potrebbero piacerti anche

- Electrical Codes, Standards, Recommended Practices and Regulations: An Examination of Relevant Safety ConsiderationsDa EverandElectrical Codes, Standards, Recommended Practices and Regulations: An Examination of Relevant Safety ConsiderationsValutazione: 5 su 5 stelle5/5 (5)

- Offshore Electrical Engineering ManualDa EverandOffshore Electrical Engineering ManualValutazione: 4 su 5 stelle4/5 (9)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDa Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsValutazione: 4 su 5 stelle4/5 (1)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionDa EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionValutazione: 4.5 su 5 stelle4.5/5 (3)

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionValutazione: 5 su 5 stelle5/5 (1)

- Auto Trans Diagnosis Mitsubishi MonteroDocumento25 pagineAuto Trans Diagnosis Mitsubishi Monteronicamarcos100% (3)

- ATC500 (BMW X5 2003-06) : Revision 07/2013Documento2 pagineATC500 (BMW X5 2003-06) : Revision 07/2013JanneLaukkanenNessuna valutazione finora

- Controls For Electric & Gas Forklifts, Golf CartsDocumento124 pagineControls For Electric & Gas Forklifts, Golf CartsFaizal Jamal60% (10)

- SDDJF: 16A 250V AC Qualified TypeDocumento4 pagineSDDJF: 16A 250V AC Qualified TypeshyhuNessuna valutazione finora

- Rotary Encoder and Power Switch GuideDocumento4 pagineRotary Encoder and Power Switch GuideshyhuNessuna valutazione finora

- Sddjf1A: Slim Type Single Pole Rocker Power SwitchDocumento3 pagineSddjf1A: Slim Type Single Pole Rocker Power SwitchshyhuNessuna valutazione finora

- Water-Proof Switch Compatible With 10ma To 4.5A: IP68 Water Resistant, Enabling Submerged OperationDocumento3 pagineWater-Proof Switch Compatible With 10ma To 4.5A: IP68 Water Resistant, Enabling Submerged OperationshyhuNessuna valutazione finora

- Sddje: 10A 250V AC Qualified TypeDocumento6 pagineSddje: 10A 250V AC Qualified TypeshyhuNessuna valutazione finora

- Panasonic TC-22LR30 LCDDocumento62 paginePanasonic TC-22LR30 LCDngoclinhdtddNessuna valutazione finora

- LG L194WTDocumento29 pagineLG L194WTqxbgwhvuNessuna valutazione finora

- LG FLATRON Monitor W1752T Service ManualDocumento26 pagineLG FLATRON Monitor W1752T Service ManualNunu Bagja SetiaNessuna valutazione finora

- LG Flatron l227wtg-Pfs-A Chassis Lm72d SMDocumento29 pagineLG Flatron l227wtg-Pfs-A Chassis Lm72d SMxor_45Nessuna valutazione finora

- DMC TZ1Documento63 pagineDMC TZ1Brayan Stiven ArevaloNessuna valutazione finora

- 0201Documento80 pagine0201Ashenafi Gebremeskel MezgeboNessuna valutazione finora

- D U200 WDocumento14 pagineD U200 WbansalrNessuna valutazione finora

- SAMSUNG LCD Service Manual Internal) - ES15UDocumento81 pagineSAMSUNG LCD Service Manual Internal) - ES15Uqwerzwill905560Nessuna valutazione finora

- SAMSUNG LCD Service Manual (Internal) - ES15UDocumento81 pagineSAMSUNG LCD Service Manual (Internal) - ES15Umeng798651Nessuna valutazione finora

- JVC mx-gt80 gt90 SM No-Sch (ET)Documento48 pagineJVC mx-gt80 gt90 SM No-Sch (ET)Cliffton FilipinoPrd ShraderNessuna valutazione finora

- L196WTQ-S, BFQ eDocumento30 pagineL196WTQ-S, BFQ eadisistemsNessuna valutazione finora

- TFT-LCD Monitor Service ManualDocumento48 pagineTFT-LCD Monitor Service Manualsupriyo110Nessuna valutazione finora

- Panasonic Lumix DMC-FX30P Serice ManualDocumento52 paginePanasonic Lumix DMC-FX30P Serice ManualdasxaxNessuna valutazione finora

- Vd4 Vacuum Circuit-Breaker With Embedded PolesDocumento32 pagineVd4 Vacuum Circuit-Breaker With Embedded Polesjiajun8Nessuna valutazione finora

- Transistorized inverter instruction manualDocumento79 pagineTransistorized inverter instruction manualPuvan80Nessuna valutazione finora

- CT720g S774AAR5S2NCDocumento45 pagineCT720g S774AAR5S2NCAnonymous CJnGHNNessuna valutazione finora

- GRL100B 6F2S0835 2.7Documento392 pagineGRL100B 6F2S0835 2.7Nazi SweetNessuna valutazione finora

- 8516902-Panasonic Hdc-Sd5 Series Service Manual Repair GuideDocumento79 pagine8516902-Panasonic Hdc-Sd5 Series Service Manual Repair Guidekdm004Nessuna valutazione finora

- Samsung SyncMaster 913NDocumento56 pagineSamsung SyncMaster 913NddaaggNessuna valutazione finora

- AC Current Clamp: Instruction SheetDocumento6 pagineAC Current Clamp: Instruction SheetKhaled Aboul-ELaNessuna valutazione finora

- TFT-LCD Monitor Service ManualDocumento32 pagineTFT-LCD Monitor Service Manualtodd956Nessuna valutazione finora

- TFT-LCD MONITOR SERVICE MANUALDocumento52 pagineTFT-LCD MONITOR SERVICE MANUALdanishadvanceNessuna valutazione finora

- Kd-Sd80bte Sd80bten Sd80btey (Sm-Ma530 Rev.001)Documento51 pagineKd-Sd80bte Sd80bten Sd80btey (Sm-Ma530 Rev.001)Roberd MihailovNessuna valutazione finora

- Service Manual: Gr-Pd1Ek, Gr-Pd1Ex, Gr-Pd1Ey, Gr-Pd1EzDocumento24 pagineService Manual: Gr-Pd1Ek, Gr-Pd1Ex, Gr-Pd1Ey, Gr-Pd1EzchimcamNessuna valutazione finora

- DPDT Basic Switch For Two Independent Circuit ControlDocumento5 pagineDPDT Basic Switch For Two Independent Circuit ControlShubham GuptaNessuna valutazione finora

- Color Monitor: Service ManualDocumento35 pagineColor Monitor: Service Manualmoshu_85Nessuna valutazione finora

- OnkyoC701A JP SMDocumento21 pagineOnkyoC701A JP SMHelder MartinsNessuna valutazione finora

- HDCSD9Documento68 pagineHDCSD9gabir980% (1)

- JVC HX-Z9 Manual de ServicioDocumento66 pagineJVC HX-Z9 Manual de ServicioJosé BenavidesNessuna valutazione finora

- RAS-14EH1/RAC-14EH1 Service ManualDocumento93 pagineRAS-14EH1/RAC-14EH1 Service Manualpeterdodov100% (1)

- Samsung LCD Ltm295wxDocumento89 pagineSamsung LCD Ltm295wxparis68Nessuna valutazione finora

- VDR-D50 Service ManualDocumento56 pagineVDR-D50 Service ManualgondifNessuna valutazione finora

- Insulation - Test (UENR1283-06)Documento3 pagineInsulation - Test (UENR1283-06)ale gamingNessuna valutazione finora

- Reed Switch Specification GuideDocumento5 pagineReed Switch Specification GuideIrfan Fachrudin PriyantaNessuna valutazione finora

- AC/DC CLAMP ADAPTOR INSTRUCTION MANUALDocumento16 pagineAC/DC CLAMP ADAPTOR INSTRUCTION MANUALchockanan suwanprasertNessuna valutazione finora

- SMD ManualDocumento8 pagineSMD ManualJose K ManadanNessuna valutazione finora

- Color Monitor: Service ManualDocumento24 pagineColor Monitor: Service Manualmoshu_85Nessuna valutazione finora

- JVC LT-23X475 PDFDocumento90 pagineJVC LT-23X475 PDFcogelon1Nessuna valutazione finora

- LG lrm-519 (ET)Documento158 pagineLG lrm-519 (ET)joeblow44Nessuna valutazione finora

- Samsung Gh19bsDocumento42 pagineSamsung Gh19bsalgjocNessuna valutazione finora

- Eps Mma Tig en PDFDocumento18 pagineEps Mma Tig en PDFAdrian EftimieNessuna valutazione finora

- Gold Capacitors: Electric Double Layer CapacitorsDocumento28 pagineGold Capacitors: Electric Double Layer Capacitorsgiapy0000Nessuna valutazione finora

- The IEE Wiring Regulations Explained and IllustratedDa EverandThe IEE Wiring Regulations Explained and IllustratedValutazione: 4 su 5 stelle4/5 (14)

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionNessuna valutazione finora

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsDa EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNessuna valutazione finora

- Linear Type Exclusively Used To Detect The Angle of Vehicle Head LightsDocumento5 pagineLinear Type Exclusively Used To Detect The Angle of Vehicle Head LightsshyhuNessuna valutazione finora

- WM 00013Documento127 pagineWM 00013shyhuNessuna valutazione finora

- List of Varieties: Resistive Position SensorsDocumento1 paginaList of Varieties: Resistive Position SensorsshyhuNessuna valutazione finora

- Medijski linč Gorana JevtićaDocumento64 pagineMedijski linč Gorana JevtićashyhuNessuna valutazione finora

- RDC40 RDC50 RDC90: Rotary TypeDocumento6 pagineRDC40 RDC50 RDC90: Rotary TypeshyhuNessuna valutazione finora

- List of Varieties: Detector Slide Push RotaryDocumento5 pagineList of Varieties: Detector Slide Push RotaryshyhuNessuna valutazione finora

- Resistive Position Sensors Linear Type Specifications and VarietiesDocumento5 pagineResistive Position Sensors Linear Type Specifications and VarietiesshyhuNessuna valutazione finora

- Hollow-Shaft Type That Enables Output Covering The Whole 360-Degree Angle Due To Adoption of 2-Phase OutputDocumento4 pagineHollow-Shaft Type That Enables Output Covering The Whole 360-Degree Angle Due To Adoption of 2-Phase OutputshyhuNessuna valutazione finora

- Resistive Position Sensors Specifications and Testing MethodsDocumento4 pagineResistive Position Sensors Specifications and Testing MethodsshyhuNessuna valutazione finora

- Quiet Surface Mount Switch SpecificationsDocumento3 pagineQuiet Surface Mount Switch SpecificationsshyhuNessuna valutazione finora

- List of Varieties: Detector Slide Push RotaryDocumento5 pagineList of Varieties: Detector Slide Push RotaryshyhuNessuna valutazione finora

- TACT Switch GuideDocumento3 pagineTACT Switch GuideshyhuNessuna valutazione finora

- 3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)Documento3 pagine3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)shyhuNessuna valutazione finora

- 4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeDocumento3 pagine4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeshyhuNessuna valutazione finora

- SKQM 6 × 3.5mm Compact (Surface Mount TypeDocumento3 pagineSKQM 6 × 3.5mm Compact (Surface Mount TypeshyhuNessuna valutazione finora

- 5.2mm Square Low-Profile (Surface Mount Type)Documento4 pagine5.2mm Square Low-Profile (Surface Mount Type)shyhuNessuna valutazione finora

- 265 6.1×3.7mm Compact Switch SpecsDocumento3 pagine265 6.1×3.7mm Compact Switch SpecsshyhuNessuna valutazione finora

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Documento3 pagineSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuNessuna valutazione finora

- Quiet Type With 0.9mm Stroke (Surface Mount Type)Documento3 pagineQuiet Type With 0.9mm Stroke (Surface Mount Type)shyhuNessuna valutazione finora

- 6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeDocumento4 pagine6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeshyhuNessuna valutazione finora

- Total Hight of 3.1mm. Surface Mount Package With Ground TerminalDocumento3 pagineTotal Hight of 3.1mm. Surface Mount Package With Ground TerminalshyhuNessuna valutazione finora

- 6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelDocumento3 pagine6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelshyhuNessuna valutazione finora

- Side Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)Documento3 pagineSide Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)shyhuNessuna valutazione finora

- 6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeDocumento4 pagine6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeshyhuNessuna valutazione finora

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Documento3 pagineSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuNessuna valutazione finora

- 1.25mm Height Low-Profile Side Push Surface Mount TypeDocumento3 pagine1.25mm Height Low-Profile Side Push Surface Mount TypeshyhuNessuna valutazione finora

- Side Push Surface Mount Type With 1.55mm Height SKTD SeriesDocumento3 pagineSide Push Surface Mount Type With 1.55mm Height SKTD SeriesshyhuNessuna valutazione finora

- 4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingDocumento3 pagine4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingshyhuNessuna valutazione finora

- Measuring Torque, Wobble, Voltage Withstand and Insulation of Rotating ShaftsDocumento1 paginaMeasuring Torque, Wobble, Voltage Withstand and Insulation of Rotating ShaftsshyhuNessuna valutazione finora

- List of Varieties: Top Push Side PushDocumento5 pagineList of Varieties: Top Push Side PushshyhuNessuna valutazione finora

- Field Wireable Connectors: Features and Selection GuidesDocumento7 pagineField Wireable Connectors: Features and Selection GuidesCarloss Ruiz RNessuna valutazione finora

- Form 2: Residential Loads Feeder 1: Use: 100 KVADocumento38 pagineForm 2: Residential Loads Feeder 1: Use: 100 KVAZaul tatingNessuna valutazione finora

- TRI-MODE HEAT DETECTOR BUILT-IN SHORT-CIRCUIT PROTECTIONDocumento2 pagineTRI-MODE HEAT DETECTOR BUILT-IN SHORT-CIRCUIT PROTECTIONjelson paulNessuna valutazione finora

- User Manual: 3.6KW/5.6KW Solar Inverter / ChargerDocumento82 pagineUser Manual: 3.6KW/5.6KW Solar Inverter / ChargerStLisNessuna valutazione finora

- Steca PV Off Grid Catalogue 2014-2015 enDocumento39 pagineSteca PV Off Grid Catalogue 2014-2015 entunznathNessuna valutazione finora

- Honda IDSI SM - 5 PDFDocumento14 pagineHonda IDSI SM - 5 PDFauto projectNessuna valutazione finora

- 2022.03.03 - Toda - Murata (OP1 - SLD3 Glass) - Xoa FixDocumento14 pagine2022.03.03 - Toda - Murata (OP1 - SLD3 Glass) - Xoa FixHiếu NguyễnNessuna valutazione finora

- Highrise Review PrelimDocumento48 pagineHighrise Review PrelimZYJA DLANE MALITNessuna valutazione finora

- Component List V01 PDFDocumento9 pagineComponent List V01 PDFshenNessuna valutazione finora

- Repair KeretaDocumento17 pagineRepair KeretaIefa Shafie100% (3)

- 4 To 20 Ma Remote Indicator: Instructions, Operation Maintenance ManualDocumento24 pagine4 To 20 Ma Remote Indicator: Instructions, Operation Maintenance ManualsancakemreNessuna valutazione finora

- Beam Master Gleeson ReelDocumento2 pagineBeam Master Gleeson ReelhecsaorNessuna valutazione finora

- Instrumentation valves and accessoriesDocumento20 pagineInstrumentation valves and accessorieshisaj4uNessuna valutazione finora

- 2 Basic Working Principle, ConfigurationDocumento17 pagine2 Basic Working Principle, Configurationrichardcaroncstj100% (1)

- Candy Ctl128 12Documento16 pagineCandy Ctl128 12Luis Alberto SchunkNessuna valutazione finora

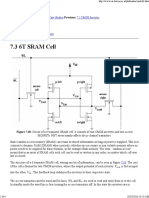

- 7.3 6T SRAM Cell: 7.4 Ring Oscillator 7. Case Studies 7.2 CMOS InverterDocumento4 pagine7.3 6T SRAM Cell: 7.4 Ring Oscillator 7. Case Studies 7.2 CMOS InverterGowtham SpNessuna valutazione finora

- 2017 BMW R Ninet Scrambler 71662Documento163 pagine2017 BMW R Ninet Scrambler 71662Anas KhanNessuna valutazione finora

- Shunt Regulator 18Documento2 pagineShunt Regulator 18Tania AndronicNessuna valutazione finora

- Last Herb 204 SLDocumento3 pagineLast Herb 204 SLlastbikesNessuna valutazione finora

- Generator Automatic Voltage Regulator Operation ManualDocumento6 pagineGenerator Automatic Voltage Regulator Operation ManualJuan MoraNessuna valutazione finora

- EMI Filter Design For An Isolated DC-DC Boost ConverterDocumento25 pagineEMI Filter Design For An Isolated DC-DC Boost ConvertershrikrisNessuna valutazione finora

- Engström Carestation - Service ManualDocumento225 pagineEngström Carestation - Service Manualcoleveio100% (1)

- Canon PIXMA MP830 Parts CatalogDocumento8 pagineCanon PIXMA MP830 Parts Catalogaperez999Nessuna valutazione finora

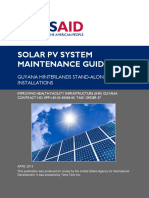

- Maintain stand-alone solar PV systemsDocumento14 pagineMaintain stand-alone solar PV systemsEdmund YoongNessuna valutazione finora

- MC56F8013Documento126 pagineMC56F8013Asad AhmedNessuna valutazione finora

- Tecumseh Model Lav35 40327k Parts ListDocumento8 pagineTecumseh Model Lav35 40327k Parts ListTorney BenedictNessuna valutazione finora