Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

35mm Size Ring Type: A Low-Profile Unit With 4.5mm Height and Good Operation Feel

Caricato da

shyhuTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

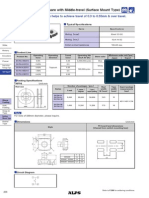

35mm Size Ring Type: A Low-Profile Unit With 4.5mm Height and Good Operation Feel

Caricato da

shyhuCopyright:

Formati disponibili

185

Metal

Shaft

Insulated

Shaft

Hollow

Shaft

Ring

Type

Detector

Slide

Push

Rotary

Encoders

Power

Dual-in-line

Package Type

TACT Switch

TM

Product Line

Product No.

Actuator length

mm

Number of detent

Number

of pulse

Detent torque

mNm

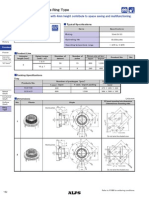

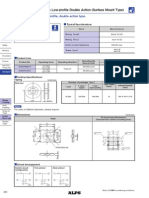

30 15 420 840 20 18 7 EC35A1520402

Minimum order unit pcs.

Japan Export

Dimensions Unit:mm

Style

2

8

.

8

3.5

3-1.5

4.5

3-8

3

.

3

3

.

5

1

7

.

5

3

5

20

36.5

14.5

2

9

.

4

29.4

36

2

-

3

6

.

4

2

-

2

8

.

6

4

-

4

.4

2

-

2

.

6

1.5

2

-

5

.

1

2

-

3

4

-

R

0

.

7

5

1

8

.

5

2-1.5

3

5

3

5

2-12

Y

Y

X X

2-11.5

1

8

.

7

2

3

.

6

2

5

3-1

90

90

A C

5

B

PC board mounting

hole dimensions

(Viewed from mounting side)

Packing Specications

Tray

840 420

Number of packagespcs.

360 540 380

Export package

measurements

mm 1 case / Japan 1 case / export packing

EC35A

35mm Size Ring Type

A low-profile unit with 4.5mm height and good operation feel.

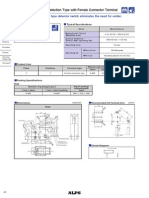

Typical Specifications

Items Specifications

Rating 10mA 5V DC

Operating life 50,000cycles

Operating temperature range 40 to 85

Output Wave Sliding Noise

V

1

=V

2

=2.5V max.

At R = 5k

Chattering : 5ms max. Bounce : 5ms max.

5V DC

R R

Terminal B Terminal A

Terminal C

Encoder

Test circuit

t t

V1

V2

5

V

ON ON OFF

Output waveform

Sliding direction

t : Masking time to avoid chattering Measurement conditionRotation speed 360/s

A signal

B signal ON

ON OFF

OFF

Detent stabillity position

CW direction

Refer to P.193 for soldering conditions.

Do not wire the shaded area

Encoders

158

Metal

Shaft

Insulated

Shaft

Hollow

Shaft

Ring

Type

Detector

Slide

Push

Rotary

Encoders

Power

Dual-in-line

Package Type

TACT Switch

TM

158

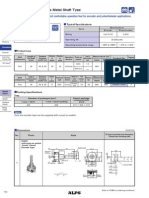

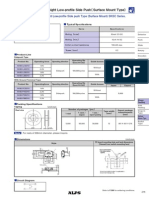

Type

Ring Type

21mm size 28mm size 35mm size

Series EC21A EC28A EC35A EC35AH EC35B

Photo

Output

Incremental

Two phase A and B

Incremental

Three phase A, B and C

Incremental

Two phase A and B /

Self-return switch

Shaft types Ring type

Number of pulse /

Number of detent

9 / 18

15 / 30

15 / 30

6ABC18

10ABC30

15 / 30

Dimensions

mm

W

21.6

28

35

35

D 29 37

H 4 4.5 12.1

Operating temperature range 40 to 85

Operating life 50,000 cycles 30,000 cycles

Automotive use

Life cycle (availability)

Electrical

performance

Rating 10mA 5V DC

Max./min. operating current

Resistive load

10mA / 1mA

Insulation resistance 100Mmin. 250V DC

Voltage proof 300V AC for 1minute or 360V AC for 2s

300V AC for 1minute or

360V AC for 1s

Mechanical

performance

Detent torque

75mNm

167mNm

75mNm

127mNm

2010mNm

187mNm

125mNm

187mNm

3015mNm

2010mNm

Push-pull

strength

Push 100N

Pull 100N

Shaft configuration Ring type

Terminal type Insertion

Switch

Specications

Switch type - - - - Self-return switch

Contact

arrangement

- - - -

Single pole and

double throw

Travel mm - - - - 2.8 0.5

Operating

force N

- - - - 3.8 1.5

Switch ON

position

- - - - 15 5

Ratational

torgue

- - - - 40 25mNm

Rating - - - - 10mA 5V DC

Contact

resistance

- - - - 200m max.

Operating life - - - - 15,000cycles

Page 182 184 185 186 188

Encoders Soldering Conditions 193

Encoders Cautions 194

Note

indicates applicability to all products in the series.

List of Varieties

193

Metal

Shaft

Insulated

Shaft

Hollow

Shaft

Ring

Type

Detector

Slide

Push

Rotary

Encoders

Power

Dual-in-line

Package Type

TACT Switch

TM

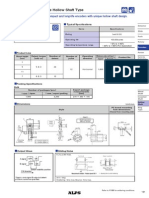

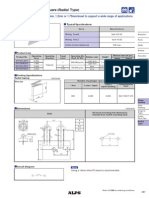

Encoders Soldering Conditions

Soldering surfacetemperature Soldering temperature Heating time Soldering time

No. of solders

3 s EC11J

EC10E, EC12D, EC12E

EC45A, EC60A

EC40A

EM20B

EC05E, EC09E, EC10E, EC111, EC11B,

EC11E, EC11G, EC11K, EC12D, EC12E,

EC18A, EC20A, EC21A, EC28A, EC35A,

EC35AH, EC35B, EC40A, EC45A, EC50A,

EC60A, EM20B

EC09E, EC11B, EC111, EC11E, EC11G,

EC11K, EC18A, EC20A, EC21A, EC28A,

EC35A, EC35AH, EC35B, EC50A

Series

Series

350 max. 3s max. 1 time

100 max. 2605 2 min. max. 51s 2 time max.

35010 2 time

100 max.

100 max.

110 max.

80 max.

2605

260 max.

260 max.

260 max.

1 min. max.

2 min. max.

1 min. max.

1 min. max.

31s

5s max.

10s max.

3s max.

2 time max.

2 time max.

1 time

2 time max.

Tip temperature Soldering time No. of solders

Preheating Dip soldering

Reference for Dip Soldering

Condition for Refow

Reference for Hand Soldering

EC05E

EC11J

Series

260 230 180 150 2 min.max. 3s 40s 4 min. max 2 time max.

250 min. 230 min. 180 150 60s to 120s 30s to 40s 2 time max.

A B C D E F G H No. of reows

Temperature profle

1

0

1.When using an infrared reow oven, solder may sometimes not be applied. Be sure to use a hot air reow oven or a

type that uses infrared rays in combination with hot air.

2.The temperatures given above are the maximum temperatures at the terminals of the potentiometer when

employing a hot air reow method. The temperature of the PC board and the surface temperature of the

potentiometer may vary greatly depending on the PC board material, its size and thickness. Ensure that the surface

temperature of the potentiometer does not rise to 250C or greater.

3.Conditions vary to some extent depending on the type of reow bath used. Be sure to give due consideration to this

prior to use.

Notes

300

200

100

A

B

C

Time (s)

G max.

F max.

H max.

E max.

Room

temperature

T

e

m

p

e

r

a

t

u

r

e

(

C

)

Pre-heating

D

Potrebbero piacerti anche

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Prometric Questions-1 AnswersDocumento45 paginePrometric Questions-1 AnswersNina Grace Joy Marayag-Alvarez100% (1)

- Storage-Tanks Titik Berat PDFDocumento72 pagineStorage-Tanks Titik Berat PDF'viki Art100% (1)

- High Speed Power TransferDocumento33 pagineHigh Speed Power TransferJAYKUMAR SINGHNessuna valutazione finora

- Iso Iec 25030 2007 eDocumento44 pagineIso Iec 25030 2007 eAngélica100% (1)

- 28mm Size Ring Type: A Low-Profile Unit With 4mm Height and Good Operation FeelDocumento3 pagine28mm Size Ring Type: A Low-Profile Unit With 4mm Height and Good Operation FeelshyhuNessuna valutazione finora

- 21mm Size Ring Type: Ring Encoder With 4mm Height Contribute To Space Saving and MultifunctioningDocumento4 pagine21mm Size Ring Type: Ring Encoder With 4mm Height Contribute To Space Saving and MultifunctioningshyhuNessuna valutazione finora

- EC35AH: 35mm Size ABC Switch TypeDocumento4 pagineEC35AH: 35mm Size ABC Switch TypeshyhuNessuna valutazione finora

- 40mm Size Ring Type: Less Shaft Wobble Achieves Good Operation FeelDocumento3 pagine40mm Size Ring Type: Less Shaft Wobble Achieves Good Operation FeelshyhuNessuna valutazione finora

- 45mm Size Ring Type: Large Ring, Heavy Torque Device Perfect For Large Ring Knob DesignDocumento3 pagine45mm Size Ring Type: Large Ring, Heavy Torque Device Perfect For Large Ring Knob DesignshyhuNessuna valutazione finora

- 60mm Size Ring Type: Large Ring Structure Contributes To MultifunctioningDocumento3 pagine60mm Size Ring Type: Large Ring Structure Contributes To MultifunctioningshyhuNessuna valutazione finora

- EC20A RK203: 20mm Size Metal Shaft TypeDocumento4 pagineEC20A RK203: 20mm Size Metal Shaft TypeshyhuNessuna valutazione finora

- 50mm Size Ring Type: Large Encoder With 31mm Inside Diameter Even Takes A Small LCDDocumento3 pagine50mm Size Ring Type: Large Encoder With 31mm Inside Diameter Even Takes A Small LCDshyhuNessuna valutazione finora

- 5mm Size Hollow Shaft Type: Compact Type Employing Alps' DRUMCODE™ TechnologyDocumento4 pagine5mm Size Hollow Shaft Type: Compact Type Employing Alps' DRUMCODE™ TechnologyshyhuNessuna valutazione finora

- 20mm Size Metal Shaft Magnetic TypeDocumento4 pagine20mm Size Metal Shaft Magnetic TypeshyhuNessuna valutazione finora

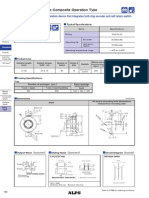

- 35mm Size Composite Operation Type: Composite Operation Device That Integrates Both Ring Encoder and Self Return SwitchDocumento3 pagine35mm Size Composite Operation Type: Composite Operation Device That Integrates Both Ring Encoder and Self Return SwitchshyhuNessuna valutazione finora

- 10mm Size Hollow Shaft Type: A Series of Compact and Long-Life Encoders With Unique Hollow Shaft DesignDocumento3 pagine10mm Size Hollow Shaft Type: A Series of Compact and Long-Life Encoders With Unique Hollow Shaft DesignshyhuNessuna valutazione finora

- 18mm Size Insulated Shaft Type: Absolute Type Achieving High Water Resistance and Heavy TorqueDocumento4 pagine18mm Size Insulated Shaft Type: Absolute Type Achieving High Water Resistance and Heavy TorqueshyhuNessuna valutazione finora

- 12mm Size Insulated Shaft TypeDocumento5 pagine12mm Size Insulated Shaft TypeshyhuNessuna valutazione finora

- 9mm Size Metal Shaft Type: A Compact 9.5mm Size and Round Shape Contribute To Save SpaceDocumento3 pagine9mm Size Metal Shaft Type: A Compact 9.5mm Size and Round Shape Contribute To Save SpaceshyhuNessuna valutazione finora

- High Operation Force, Low Contact Resistance Type (Surface Mount Type)Documento3 pagineHigh Operation Force, Low Contact Resistance Type (Surface Mount Type)shyhuNessuna valutazione finora

- 0.6mm Low-Profile, Double Action TypeDocumento3 pagine0.6mm Low-Profile, Double Action TypeshyhuNessuna valutazione finora

- 1.2 (H) MM, Single-Side Recoil TypeDocumento4 pagine1.2 (H) MM, Single-Side Recoil TypeshyhuNessuna valutazione finora

- Sped2: 4.5mm-Travel Push-Push TypeDocumento3 pagineSped2: 4.5mm-Travel Push-Push TypeshyhuNessuna valutazione finora

- Recoil Type For Single-Side and Both SidesDocumento5 pagineRecoil Type For Single-Side and Both SidesshyhuNessuna valutazione finora

- 4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeDocumento3 pagine4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeshyhuNessuna valutazione finora

- 4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingDocumento3 pagine4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingshyhuNessuna valutazione finora

- 3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)Documento3 pagine3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)shyhuNessuna valutazione finora

- 1.25mm Height Low-Profile Side Push Surface Mount TypeDocumento3 pagine1.25mm Height Low-Profile Side Push Surface Mount TypeshyhuNessuna valutazione finora

- Side Push Surface Mount Type With 1.55mm Height SKTD SeriesDocumento3 pagineSide Push Surface Mount Type With 1.55mm Height SKTD SeriesshyhuNessuna valutazione finora

- SKEGDocumento4 pagineSKEGshyhuNessuna valutazione finora

- 7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsDocumento3 pagine7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsshyhuNessuna valutazione finora

- Low-Profile Tri-Directional Operation TypeDocumento3 pagineLow-Profile Tri-Directional Operation TypeshyhuNessuna valutazione finora

- 6.6mm Square (Snap-In Type) : Dust Proof With Sharp Operational Feel Suitable For General PurposeDocumento5 pagine6.6mm Square (Snap-In Type) : Dust Proof With Sharp Operational Feel Suitable For General PurposeshyhuNessuna valutazione finora

- Total Hight of 3.1mm. Surface Mount Package With Ground TerminalDocumento3 pagineTotal Hight of 3.1mm. Surface Mount Package With Ground TerminalshyhuNessuna valutazione finora

- Quiet Type With 0.9mm Stroke (Surface Mount Type)Documento3 pagineQuiet Type With 0.9mm Stroke (Surface Mount Type)shyhuNessuna valutazione finora

- Quiet Middle-Stroke (Surface Mount Type) : Switch With 0.7mm Stroke Achieving Both Quiet Operation and An Excellent FeelDocumento3 pagineQuiet Middle-Stroke (Surface Mount Type) : Switch With 0.7mm Stroke Achieving Both Quiet Operation and An Excellent FeelshyhuNessuna valutazione finora

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Documento3 pagineSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuNessuna valutazione finora

- 6mm Square Dust-Proof (Snap-In Type)Documento3 pagine6mm Square Dust-Proof (Snap-In Type)shyhuNessuna valutazione finora

- 6mm Square (Snap-In Type)Documento6 pagine6mm Square (Snap-In Type)shyhuNessuna valutazione finora

- Side Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)Documento3 pagineSide Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)shyhuNessuna valutazione finora

- 6×3.5mm Compact (Snap-In Type) : Switch Contributing To High-Density Mounting, Available With Top or Side Push OperationDocumento4 pagine6×3.5mm Compact (Snap-In Type) : Switch Contributing To High-Density Mounting, Available With Top or Side Push OperationshyhuNessuna valutazione finora

- 4.5mm Square Compact (Snap-In Type)Documento3 pagine4.5mm Square Compact (Snap-In Type)shyhuNessuna valutazione finora

- 5.2mm Square Low-Profile (Surface Mount Type)Documento4 pagine5.2mm Square Low-Profile (Surface Mount Type)shyhuNessuna valutazione finora

- Tall Height (4.3mm and 5.0mm) and Surface Mount TypeDocumento3 pagineTall Height (4.3mm and 5.0mm) and Surface Mount TypeshyhuNessuna valutazione finora

- SSC W FemaleDocumento3 pagineSSC W FemaleshyhuNessuna valutazione finora

- SSSS7Documento5 pagineSSSS7shyhuNessuna valutazione finora

- 10mm Square Water-Proof (Snap-In Type)Documento5 pagine10mm Square Water-Proof (Snap-In Type)shyhuNessuna valutazione finora

- Low-Profile, 1.2mm Height, Long Travel TypeDocumento3 pagineLow-Profile, 1.2mm Height, Long Travel TypeshyhuNessuna valutazione finora

- 6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelDocumento3 pagine6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelshyhuNessuna valutazione finora

- 3.7mm Square Low-Profile (Surface Mount Type)Documento3 pagine3.7mm Square Low-Profile (Surface Mount Type)Hung KeeNessuna valutazione finora

- 12mm Square (Snap-In Type) : Joint Stem & Flat Stem With Stable Operation FeelingDocumento4 pagine12mm Square (Snap-In Type) : Joint Stem & Flat Stem With Stable Operation FeelingshyhuNessuna valutazione finora

- Spvqa: Water-Proof TypeDocumento4 pagineSpvqa: Water-Proof Typeshyhu100% (1)

- Spvq5: Micro Switch Type With Female Connector TerminalDocumento3 pagineSpvq5: Micro Switch Type With Female Connector TerminalshyhuNessuna valutazione finora

- 12mm Square Long-Life (Snap-In Type) : Long-Life Type With Unique Dust-Proof Structure and Highly Reliable Metal ContactsDocumento4 pagine12mm Square Long-Life (Snap-In Type) : Long-Life Type With Unique Dust-Proof Structure and Highly Reliable Metal ContactsshyhuNessuna valutazione finora

- List of Varieties: Detector Slide Push RotaryDocumento5 pagineList of Varieties: Detector Slide Push RotaryshyhuNessuna valutazione finora

- 6.1 × 3.7mm Compact High-Speed Mounting (Surface Mount Type)Documento3 pagine6.1 × 3.7mm Compact High-Speed Mounting (Surface Mount Type)shyhuNessuna valutazione finora

- 12mm Size Insulated Shaft TypeDocumento4 pagine12mm Size Insulated Shaft TypeZoltán Halász100% (2)

- Linear Type: The High Accuracy Space Saving Design Contributes To Reduced Weight and Size of SetsDocumento5 pagineLinear Type: The High Accuracy Space Saving Design Contributes To Reduced Weight and Size of SetsshyhuNessuna valutazione finora

- Tyco Rele EC V23078-c1002-A303 DatasheetDocumento5 pagineTyco Rele EC V23078-c1002-A303 DatasheetLuis Gustavo Coqueiro LeiteNessuna valutazione finora

- Resolver Smart SynDocumento12 pagineResolver Smart SynLeon de RuijterNessuna valutazione finora

- Hollow-Shaft Type That Enables Output Covering The Whole 360-Degree Angle Due To Adoption of 2-Phase OutputDocumento4 pagineHollow-Shaft Type That Enables Output Covering The Whole 360-Degree Angle Due To Adoption of 2-Phase OutputshyhuNessuna valutazione finora

- 6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeDocumento4 pagine6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeshyhuNessuna valutazione finora

- Linear Type Exclusively Used To Detect The Angle of Vehicle Head LightsDocumento5 pagineLinear Type Exclusively Used To Detect The Angle of Vehicle Head LightsshyhuNessuna valutazione finora

- RD6R1A: Rotary Type CustomDocumento4 pagineRD6R1A: Rotary Type CustomshyhuNessuna valutazione finora

- Optimist 21 HQDocumento64 pagineOptimist 21 HQshyhuNessuna valutazione finora

- RDC40 RDC50 RDC90: Rotary TypeDocumento6 pagineRDC40 RDC50 RDC90: Rotary TypeshyhuNessuna valutazione finora

- List of Varieties: Resistive Position SensorsDocumento1 paginaList of Varieties: Resistive Position SensorsshyhuNessuna valutazione finora

- Hollow-Shaft Type That Enables Output Covering The Whole 360-Degree Angle Due To Adoption of 2-Phase OutputDocumento4 pagineHollow-Shaft Type That Enables Output Covering The Whole 360-Degree Angle Due To Adoption of 2-Phase OutputshyhuNessuna valutazione finora

- WM 00013Documento127 pagineWM 00013shyhuNessuna valutazione finora

- 4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeDocumento3 pagine4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeshyhuNessuna valutazione finora

- List of Varieties: Detector Slide Push RotaryDocumento5 pagineList of Varieties: Detector Slide Push RotaryshyhuNessuna valutazione finora

- Linear Type: The High Accuracy Space Saving Design Contributes To Reduced Weight and Size of SetsDocumento5 pagineLinear Type: The High Accuracy Space Saving Design Contributes To Reduced Weight and Size of SetsshyhuNessuna valutazione finora

- 0.6mm Low-Profile, Double Action TypeDocumento3 pagine0.6mm Low-Profile, Double Action TypeshyhuNessuna valutazione finora

- List of Varieties: Detector Slide Push RotaryDocumento5 pagineList of Varieties: Detector Slide Push RotaryshyhuNessuna valutazione finora

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Documento3 pagineSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuNessuna valutazione finora

- Linear Type Exclusively Used To Detect The Angle of Vehicle Head LightsDocumento5 pagineLinear Type Exclusively Used To Detect The Angle of Vehicle Head LightsshyhuNessuna valutazione finora

- 3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)Documento3 pagine3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)shyhuNessuna valutazione finora

- 6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeDocumento4 pagine6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeshyhuNessuna valutazione finora

- Tall Height (4.3mm and 5.0mm) and Surface Mount TypeDocumento3 pagineTall Height (4.3mm and 5.0mm) and Surface Mount TypeshyhuNessuna valutazione finora

- 5.2mm Square Low-Profile (Surface Mount Type)Documento4 pagine5.2mm Square Low-Profile (Surface Mount Type)shyhuNessuna valutazione finora

- 6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelDocumento3 pagine6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelshyhuNessuna valutazione finora

- Quiet Type With 0.9mm Stroke (Surface Mount Type)Documento3 pagineQuiet Type With 0.9mm Stroke (Surface Mount Type)shyhuNessuna valutazione finora

- Quiet Middle-Stroke (Surface Mount Type) : Switch With 0.7mm Stroke Achieving Both Quiet Operation and An Excellent FeelDocumento3 pagineQuiet Middle-Stroke (Surface Mount Type) : Switch With 0.7mm Stroke Achieving Both Quiet Operation and An Excellent FeelshyhuNessuna valutazione finora

- 6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeDocumento4 pagine6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeshyhuNessuna valutazione finora

- Side Push Surface Mount Type With 1.55mm Height SKTD SeriesDocumento3 pagineSide Push Surface Mount Type With 1.55mm Height SKTD SeriesshyhuNessuna valutazione finora

- Side Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)Documento3 pagineSide Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)shyhuNessuna valutazione finora

- 6.1 × 3.7mm Compact High-Speed Mounting (Surface Mount Type)Documento3 pagine6.1 × 3.7mm Compact High-Speed Mounting (Surface Mount Type)shyhuNessuna valutazione finora

- Total Hight of 3.1mm. Surface Mount Package With Ground TerminalDocumento3 pagineTotal Hight of 3.1mm. Surface Mount Package With Ground TerminalshyhuNessuna valutazione finora

- 1.25mm Height Low-Profile Side Push Surface Mount TypeDocumento3 pagine1.25mm Height Low-Profile Side Push Surface Mount TypeshyhuNessuna valutazione finora

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Documento3 pagineSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuNessuna valutazione finora

- Measurement and Test Methods: 〔Rotational Torque(Operating Force)〕Documento1 paginaMeasurement and Test Methods: 〔Rotational Torque(Operating Force)〕shyhuNessuna valutazione finora

- 4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingDocumento3 pagine4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingshyhuNessuna valutazione finora

- List of Varieties: Top Push Side PushDocumento5 pagineList of Varieties: Top Push Side PushshyhuNessuna valutazione finora

- Construction Drawing: Legend Notes For Sanitary Piping Installation General Notes NotesDocumento1 paginaConstruction Drawing: Legend Notes For Sanitary Piping Installation General Notes NotesrajavelNessuna valutazione finora

- Evan Lagueux - H Argument EssayDocumento7 pagineEvan Lagueux - H Argument Essayapi-692561087Nessuna valutazione finora

- DatuinMA (Activity #5 - NSTP 10)Documento2 pagineDatuinMA (Activity #5 - NSTP 10)Marc Alen Porlaje DatuinNessuna valutazione finora

- Adolescents' Gender and Their Social Adjustment The Role of The Counsellor in NigeriaDocumento20 pagineAdolescents' Gender and Their Social Adjustment The Role of The Counsellor in NigeriaEfosaNessuna valutazione finora

- DADTCO Presentation PDFDocumento34 pagineDADTCO Presentation PDFIngeniería Industrias Alimentarias Itsm100% (1)

- Pull Cord Switch JayashreeDocumento1 paginaPull Cord Switch JayashreeNCNessuna valutazione finora

- GNSS COrs SystemDocumento20 pagineGNSS COrs SystemKostPutriMalangNessuna valutazione finora

- Paper 1 Computer Science ASDocumento194 paginePaper 1 Computer Science ASLailaEl-BeheiryNessuna valutazione finora

- Pizza Restaurant PowerPoint TemplatesDocumento49 paginePizza Restaurant PowerPoint TemplatesAindrila BeraNessuna valutazione finora

- FS 1 Episode 2Documento6 pagineFS 1 Episode 2Jayson Garcillan UmipigNessuna valutazione finora

- Pot-Roasted Beef BrisketDocumento4 paginePot-Roasted Beef Brisketmarcelo nubileNessuna valutazione finora

- The Determinants of Corporate Dividend PolicyDocumento16 pagineThe Determinants of Corporate Dividend PolicyRutvikNessuna valutazione finora

- Ferrero A.M. Et Al. (2015) - Experimental Tests For The Application of An Analytical Model For Flexible Debris Flow Barrier Design PDFDocumento10 pagineFerrero A.M. Et Al. (2015) - Experimental Tests For The Application of An Analytical Model For Flexible Debris Flow Barrier Design PDFEnrico MassaNessuna valutazione finora

- Immobilization of Rhodococcus Rhodochrous BX2 (An AcetonitriledegradingDocumento7 pagineImmobilization of Rhodococcus Rhodochrous BX2 (An AcetonitriledegradingSahar IrankhahNessuna valutazione finora

- PID Marcado Operación Del Paquete Del Compresor de Hidrogeno PHP-K-002 PDFDocumento7 paginePID Marcado Operación Del Paquete Del Compresor de Hidrogeno PHP-K-002 PDFDenisNessuna valutazione finora

- WoundVite®, The #1 Most Comprehensive Wound, Scar and Post-Surgical Repair Formula Receives Amazon's Choice High RatingsDocumento3 pagineWoundVite®, The #1 Most Comprehensive Wound, Scar and Post-Surgical Repair Formula Receives Amazon's Choice High RatingsPR.comNessuna valutazione finora

- Antenatal Care (ANC)Documento77 pagineAntenatal Care (ANC)tareNessuna valutazione finora

- ProjectDocumento32 pagineProjectroshan jaiswalNessuna valutazione finora

- Batron: 29 5 MM Character Height LCD Modules 29Documento1 paginaBatron: 29 5 MM Character Height LCD Modules 29Diego OliveiraNessuna valutazione finora

- UpdateJul2007 3julDocumento10 pagineUpdateJul2007 3julAnshul SinghNessuna valutazione finora

- GR 9 Eng CodebDocumento6 pagineGR 9 Eng CodebSharmista WalterNessuna valutazione finora

- Citrus Information Kit-Update: Reprint - Information Current in 1998Documento53 pagineCitrus Information Kit-Update: Reprint - Information Current in 1998hamsa sewakNessuna valutazione finora

- (Schottel) Aspects of The Design Procedure For Propellers Providing Max Bollard PullDocumento10 pagine(Schottel) Aspects of The Design Procedure For Propellers Providing Max Bollard Pulldevu2chodankarNessuna valutazione finora

- Materials Management - 1 - Dr. VP - 2017-18Documento33 pagineMaterials Management - 1 - Dr. VP - 2017-18Vrushabh ShelkarNessuna valutazione finora

- 2396510-14-8EN - r1 - Service Information and Procedures Class MDocumento2.072 pagine2396510-14-8EN - r1 - Service Information and Procedures Class MJuan Bautista PradoNessuna valutazione finora

- MC4 CoCU 6 - Welding Records and Report DocumentationDocumento8 pagineMC4 CoCU 6 - Welding Records and Report Documentationnizam1372100% (1)