Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Research Article: Dynamic Characteristics Research of A Steel/CFRP Drive Shaft

Caricato da

Matthew SmithTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Research Article: Dynamic Characteristics Research of A Steel/CFRP Drive Shaft

Caricato da

Matthew SmithCopyright:

Formati disponibili

Hindawi Publishing Corporation

Advances in Mechanical Engineering

Volume 2013, Article ID 609309, 9 pages

http://dx.doi.org/10.1155/2013/609309

Research Article

Dynamic Characteristics Research of a Steel/CFRP Drive Shaft

Jinguang Zhang,

1

Rui Yang,

1

Yefa Hu,

1

Guoping Ding,

1

Yan Xu,

2

and Jiaying Niu

1

1

School of Mechanical and Electronic Engineering, Wuhan University of Technology, Wuhan 430070, China

2

Lianyungang Yingyou Carbon Plastic Material Co., Ltd., Lianyungang 222000, China

Correspondence should be addressed to Jinguang Zhang; jgzhang@whut.edu.cn

Received 14 March 2013; Revised 11 July 2013; Accepted 17 July 2013

Academic Editor: Zhongwei Jiang

Copyright 2013 Jinguang Zhang et al. Tis is an open access article distributed under the Creative Commons Attribution License,

which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Te dynamic characteristics of a steel/CFRP (carbon fber reinforced plastic) drive shaf were studied. fnite element analysis (FEA)

and an experiment were carried out to investigate the natural frequencies and mode shapes. Te results of the experiment verifed

the efectiveness of the fnite element model. At the same time, the FEA was used to predict the dynamic characteristics of the

shaf for diferent stacking sequences, fber orientation angles, and layer thicknesses. Te results show that the natural frequency

increases with decreasing fber orientation angles. And the positive and negative stacking sequences are helpful to improve natural

frequency. Te layer thicknesses and stacking sequences will have a pronounced efect in a specifc size of the shaf.

1. Introduction

In recent years, CFRP has been used in many engineering

felds such as mechanical, automobile, aerospace and marine.

Tis is mainly due to its excellent mechanical properties, such

as high tensile strength-to-weight ratio, high temperature

resistance, and low coefcient of thermal expansion.

CFRP can improve the natural frequency and critical

speed and reduce the overall weight to achieve low noise,

low transmission energy loss when it is used for the shafs

manufacture. Diferent from the conventional metal shaf,

there are many parameters to be altered in the design of the

composite drive shaf, namely, the fber orientation angles,

stacking sequences, layer thicknesses, and number of layers.

Because of its anisotropy, CFRP can provide a large

number of possible designs, which could satisfy the diferent

dynamic performance requirements. So the dynamic perfor-

mance of a steel/CFRP shaf, whose external dimensions are

restricted, could be achieved by changing the parameters of

the CFRP laminates.

Tere are some studies with respect to the infuences of

lamination parameters on the dynamic performance.

Badie et al. [1] examined the efect of stacking sequence

on the natural frequency, buckling strength, and fatigue

life. Te results showed that the stacking sequence has

almost no efect on natural frequency but great infuence on

the buckling strength and fatigue life. In the dynamic study

of the composite material shaf, Singh and Gupta [2] learned

that the stacking sequence has no signifcant efect on the

natural frequency, while the natural frequency decreases

as the stacking angle increases.But the conclusion which

scholars have drawn is inconsistent. Shokrieh et al. [3]

investigated the efect of variable stacking sequences and

fber orientation angles on buckling torque and found that

the natural frequency decreases with the increasing torque.

Sekhar and Srinivas [4] analyzed the slotted composite drive

shafs vibration characteristics and learned that the natural

frequency rises from 316 Hz to 367 Hz for diferent stacking

sequences. Abu Talib et al. [5] came to the conclusion that in

changing carbon fbers winding angle from 0

to 90

, the loss

in the natural frequency of the shaf was 44.5%, while shifing

from the best to the worst stacking sequence, the drive shaf

caused a loss of 46.07% in its buckling strength.

Te efect of fber orientation angle for dynamic perfor-

mance has beendiscussedby many researchers. Badie et al. [1]

usedFEAto predict the bending natural frequency of a hybrid

shaf and drawn that the reducing fber orientation angle

increases the natural frequency and axial elastic modulus.

Gubran [6] developed a CFRP/metal hybrid shaf and carried

out an analysis of natural frequencies. Te conclusion drawn

was that the natural frequency depends on the ratio of the

elastic modulus and density while it decreases as the angle

2 Advances in Mechanical Engineering

0.81656742

0.80233873

0.78811003

0.77388133

0.75965264

0.74542394

0.73119525

0.71696655

0.70273786

0.68850916

0.67428046

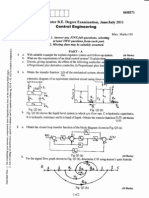

Figure 1: Te torsional strength analysis of carbon fber tube.

Table 1: Te mechanical properties of carbon fber-epoxy compos-

ites.

1

181 Gpa

13

7.17 Gpa

2

10.3 Gpa

1500 Mpa

3

10.3 Gpa

1500 Mpa

V

21

0.28

40 Mpa

V

32

0.3

246 Mpa

V

31

0.28 S 68 Mpa

12

7.17 Gpa

ply

0.3333 mm

23

3.78 Gpa

1

: longitudinal modulus,

2

,

3

: transverse modulus; V

21

: 21-direction Pois-

sons ratio, V

31

: 31-direction Poissons ratio, V

32

: 32-direction Poissons ratio;

12

,

13

: 12-direction, 13-direction shear modulus,

23

: 23-direction shear

modulus;

: longitudinal tensile strength,

: longitudinal compressive

strength;

: transverse tensile strength,

: transverse compressive strength;

S: inplane shear strength;

ply

: thickness of a lamina.

increases. However, there are some new conclusions which

are diferent from the above studies. Kim et al. [7] examined

the efect of material properties on metal/CFRP hybrid shafs

and drawn the conclusions that the frequency of the 0 case

is lower than those of some nonzero fber angle cases in

specifc /, but when shafs are very long (/ = 25), this

phenomenon disappears, and the lower fber angles give the

higher frequencies.

In addition, many researches have been carried out to

investigate the efect of thickness on the dynamic perfor-

mance. Wang and Zhou [8] found that, in certain cases, an

optimumthickness of steel could maximize the frequencies of

the metal/CFRP hybrid shafs. Gubran [6] found that varying

the layer thickness is helpful to improve the mechanical

properties, increase the natural frequency by about 12%17%,

and reduce stress. Wang and Zhou [8] used the FEA and

experimental analysis to study the efects of the number of

layers. Te natural frequency increases with the increasing

number. Te frst frequency increases by 8% when the

number rises from 1 to 3. Lee et al. [9] manufactured

a composite spindle and investigated the proper design for

dynamic performance. Tey learnedthat increasing thickness

will improve the vibration performance.

Generally, there are sufcient studies about the lamina-

tion parameters and their efects on the performance charac-

teristics, but the conclusions are inconsistent. Te study of the

mode shapes of a steel/CFRP shaf is inadequate and so is the

efect of layer thickness on the dynamic characteristics. Most

researchers used the control variable method to study the

efect of every single factor. However, at present, all the studies

did not consider the coupling efect of multiple factors.

Terefore, in this work, investigations were focused on

the efect of lamination parameters on the dynamic perfor-

mance. To assess the dynamic characteristics, a steel/CFRP

drive shafwas fabricated. Te FEAmethod and experimental

program on fabric test piece were used to investigate the

dynamic characteristics. Finally, a study of natural frequen-

cies and mode shapes was theoretically performed by FEA

under single variable and double variables in order to enable

the conclusion to be accurate and comprehensive.

2. Design of Test Piece

An entire carbon fber drive shaf is easy to be destroyed

in the place of holes or grooves when connected to other

components such as through key, stud, and fange. So the

steel/CFRP drive shaf was designed using both steel and

carbon fber-epoxy composites in which the major role

is to transmit the required torque. Taking into account

the requirement, the dimensions of the steel part and the

parameters of the composite were calculated.

2.1. Design of Steel Part. Te ultimate torque is 1500 Nm.

Te drive shaf must be designed to meet the requirement

of torque capacity according to the equation of metal shafs

torsional shear strength in mechanics of materials:

=

/

[].

Advances in Mechanical Engineering 3

Figure 2: Te test piece of CFRP/steel drive shaf.

In the formula,

=

3

/16, is the diameter of steel

part, and the safety coefcient is 1.5 corresponding to the

design torque.

Te calculated result = 50.316 mm. Te thickness of

the adhesive layer between the steel part and the CFRP part is

0.150.20 mm. In order to avoid the decimal of the dimension

for easy manufacture, the selected diameter is 50.7 mm.

2.2. Calculation on Carbon Fiber Part. Te fnite element

sofware SAMCEFwas usedto calculate andcheck the torsion

strength. Te results were shown in Figure 1.

According to the Tsai-Wu criterion, the failure index was

0.817 when the applied torque was 1500 Nm. So, the above

parameters of the carbon fber part can satisfy the torsional

strength.

Te composite shell is used for the type of element in

SAMCEF. While the CFRP tube was treated as orthotropic

material, so the material properties of three diferent direc-

tions should be defned according to Table 1.

Te stacking sequence was [45, 45, 90, 45, 45, 90, 45,

45, 45, 45, 45, 45, 90, 45, 45, 90, 45, 45].

Te number of stacking piles was 18, and the layer

thickness was 6 mm.

2.3. Calculation of Adhesive Layer. Te thickness of adhesive

layer has an efect on the bonding strength. Increasing layer

thickness can reduce stress concentration and improve the

bonding strength. However, too thick layers may cause bub-

bles and other defects, leading to the decreasing of bonding

strength. Practical experience shows that the appropriate

thickness was 0.10.15 mm; herein, the fnal selectedthickness

was 0.15 mm.

Te length of the adhesive layer was calculated according

to the empirical equation(fromthe Practical Guide to Rubber

Sealing Technology of Mechanical Products, 1995):

opt

=

0.025

0.2

(0.01

2

+ 1) [10]. In the equation, is the diameter

of the glued tube.

0.2

is the yield shear strength of the glued

material.

In this design, = 50.7 mm,

0.2

= 0.550.62

and

refers to 45 steel tensile yield limit; then, the calculated shear

yield limit is 177 Mpa. Te shear strength of the carbon fber

is relatively small, and

0.2

= 68 Mpa, so select

0.2

= 177 Mpa

for design.

Te calculated result

opt

=118.169 mm. Given the present

bonding technique, increasing adhesive length is helpful to

improve bonding strength, so, in this research, the fnal

Table 2: Te mechanical properties of 45 steel.

E 206 Gpa

7.85 kg/cm

3

0.28

E: longitudinal modulus, : density, : Poissons ratio.

1

4

0

1

1

0

640

500

150

6

6

3

4

1

5

.

5

Filling cements Filling cements

Figure 3: Te dimensional drawing of the test piece.

manufacturing length was lengthened to 150 mm. Te test

piece of CFRP/steel drive shaf was shown in Figure 2.

Figure 3 is the dimensional drawing of the test piece,

in which part 1 refers to steel part and part 2 refers to

the carbon fber part. Te carbon fber-epoxy prepreg is

T300/5208 manufactured by Lianyungang Yingyou Carbon

Plastic Material Co., Ltd. Tables 1 and 2 show the mechanical

properties of carbon fber-epoxy composites and the 45 steel.

3. Finite Element Analysis

Te sofware SAMCEF has a good performance in the fnite

element analysis of composite materials, so it is suitable for

the simulation of the steel/CFRP shaf. In the free mode of

the model, the selected element is the combinationof the shell

and the solid without setting any constraints.

Figure 4 showed the simplifed model of the steel/CFRP

shaf. In this model, two ends of the drive shaf were made

of steel and defned as solid elements. Because the holes in

fange would reduce the meshing quality, they were removed

to simplify the model. Te middle of the drive shaf was a

thin-walled tube made of CFRP and defned as composite

shell elements. In addition, the adhesive layer was ignored

and simplifed by GLUE command for difcult simulation.

3.1. Modeling, Loading, and Meshing. Te steel part was

considered as elastomeric material, while the CFRP tube was

treated as orthotropic material, whose material properties

were defnedaccording toTables 1 and2. Te order of stacking

sequence, thickness and angle was from inside to outside. In

order to make better for the continuity of the whole mesh,

the tetrahedral mesh was chosen by taking into account the

model transition region between the steel part and the CFRP

tube, and the whole CFRP tube is meshed by mapping mesh.

Te ply of CFRP tube and the typical meshing were shown in

Figures 5 and 6.

3.2. Finite Element Results. Te natural frequencies andmode

shapes of the steel/CFRP shaf were shown in Table 3 and

Figure 7.

4 Advances in Mechanical Engineering

Figure 4: Simplifed model of the steel/CFRP drive shaf.

Table 3: Te natural frequencies calculated by SAMCEF.

Frequency Nbr.1 193.21475

Frequency Nbr.2 193.223072

Frequency Nbr.3 513.584471

Frequency Nbr.4 672.061845

Frequency Nbr.5 672.144156

Frequency Nbr.6 1.070573e3

In Table 3, there were two same frequencies such as

193 Hz, 672 Hz, which resulted from the symmetrical direc-

tion of the bending mode shape shown as Figure 7. Terefore,

the top three natural frequencies of the test piece were 193 Hz,

513 Hz, 672 Hz, successively.

4. Experiment and Conclusion

At present, excitation method is usually applied to study

the structural dynamics in the feld of aerospace, automo-

tive, marine and construction engineering, and so forth.

Especially afer the invention of the FFT algorithm-based

digital signal analyzer, the advantages of this method are

more and more obvious. Te basic principle of excitation

method is that the excitation force is exerted on the stationary

drive shaf in the frequency range of the resonant point

to measure resonance frequency which is the excitation

frequency corresponding to vibration peaks.

4.1. Experimental Equipment. Figure 8 shows the modal

testing machine which is supplied by the Danish BK Ltd.

Te machine consists of a power sensor, an acceleration

sensor, a vibration exciter, an impulse hammer, a PULSE

analyzer platform, and so on. And the modal analysis sof-

ware MEscopeVES can analyze and calculate the dynamic

characteristics of the mechanical structure and, in addition,

display the mode shapes and other industrial data on the

three-dimensional model of the testing structure.

4.2. Equipment Confguration. With two fexible strings at

both ends, the test piece is suspended. It is in a free state and

has a maximum degree of freedom. Te free-free mode can

only be obtained when the test is performed for a free-free

boundary condition.

In the experiment, the exciter cannot reach the experi-

mental requirements due to the narrowband. So the hammer

is used to give excitation force, and the excited points were in

the middle of the test pieces upper surface.

Table 4: Comparison of fnite element analysis and experimental

result.

Natural frequency Finite element analysis Experimental

First 193 Hz 234 Hz

Second 513 Hz 596 Hz

Tree acceleration sensors are arranged equidistantly on

the upper surface of the test piece to convert the measured

signal into electrical signals.

4.3. Experiment Principle. Experiment modal analysis tech-

nique is the curve ftting according to measured transfer

function curves to calculate the modal frequency, modal

stifness, and modal mass. Te transfer function refects the

relationship between the system output and the input, that is,

the complex ratio of the output and the input frequency,

()

()

, (1)

where,

is the transfer function,

() is the Fourier

transformtransfer function of input (excitation), and

() is

the Fourier transform transfer function of output (response).

Te above transfer function is not associated with the initial

conditions of excitation system, and it only refects the

systems inherent dynamic properties. So the complicated

vibration system characteristics analysis can be transformed

into a relatively simple analysis of the input and output

signals, namely, the so-called system recognition, which

provides the basis for the vibration characteristics analysis,

the vibration fault analysis and diagnosis forecasting, and the

optimal design for structural dynamic characteristics of the

magnetic suspension rotor system.

4.4. Testing Procedure

(1) Create the structure graphics of the test piece, and

select hammer incentive mode as well as acceleration

response measurement point.

(2) Set excitation signal range, the trigger level, and time-

domain window, in order to identify the appropriate

frequency band.

(3) Set exciting nodes, achieve 3 times valid inputs, and

fnally read the experiment data.

4.5. Experimental Data. Figure 9 shows the frequency

response function graph of test shaf. Te frst natural

frequency of the test drive shaf is about 234 Hz, and the

second natural frequency is about 596 Hz.

4.6. Comparison and Discussion. Te comparison was shown

in Table 4. Tere was a diferent degree of deviation among

the above three methods. Te predicted frst natural fre-

quency agreed with experimental result with a deviation of

17.5%, while the second deviation was 13.9%. In the test,

Advances in Mechanical Engineering 5

No Name Material Tickness (mm) Angle (deg)

18 Elastic#2 0.3333

17 Elastic#2 0.3333 45

16 Elastic#2 0.3333 90

15 Elastic#2 0.3333

14 Elastic#2 0.3333 45

13 Elastic#2 0.3333 90

12 Elastic#2 0.3333

11 Elastic#2 0.3333 45

10 Elastic#2 0.3333

9 Elastic#2 0.3333 45

8 Elastic#2 0.3333

7 Elastic#2 0.3333 45

6 Elastic#2 0.3333 90

5 Elastic#2 0.3333

4 Elastic#2 0.3333 45

3 Elastic#2 0.3333 90

2 Elastic#2 0.3333

1 Elastic#2 0.3333 45

PLY 2

PLY 1

PLY 3

PLY 2

PLY 1

PLY 3

PLY 2

PLY 1

PLY 2

PLY 1

PLY 2

PLY 1

PLY 3

PLY 2

PLY 1

PLY 3

PLY 2

PLY 1

45

45

45

45

45

45

45

Figure 5: Te stacking of CFRP tube.

Table 5: Natural frequency of a composite shaf under diferent angles.

Laying angle (

) 90 75 75 60 45 30 15 10 5 0

First natural frequency (Hz) 109 112 112 120 140 181 271 281 255 244

Second natural frequency (Hz) 251 335 335 376 390 368 312 319 370 397

Figure 6: Te meshing of the steel/CFRP drive shaf.

Table 6: Natural frequency of a composite shaf under diferent

monolayer thicknesses.

Monolayer thickness (mm) 0.11 0.22 0.33 0.66 0.99 0.39

First natural frequency (Hz) 173 173 173 173 172 172

Second natural frequency (Hz) 560 560 559 559 548 560

the higher the order of the natural frequency ranked, the

lower the accuracy of the test results was.

Te reasons for the deviation were summed up as follows.

(1) Tere was a diference between the parameters of

the test shaf and that of the ones in fnite element

analysis.

(2) Te rigid connection between the carbon fber tube

and metal was idealized to neglect the adhesive layer.

In fnite element analysis, the adhesive layer was

replaced by GLUE command, and the hole of the

fange was eliminated.

(3) Te arrangement of sensors was imprecise, and the

intensity of each hammer excitation may not be

homogeneous.

In short, the error was within the allowable range. It

was proved that the fnite element analysis could be used to

predict the infuence of various stacking parameters on the

dynamic characteristics of the steel/CFRP shafs.

5. Effect of Ply Stacking

Finite element models were developed to study the efects of

ply stacking on the critical mechanical characteristics of the

CFRP shaf.

5.1. Fiber Orientation Angles. Te FEA is used in this type of

problems, and there is no need to apply a load because the

natural frequency is the only function of mass and stifness.

Te ends of the drive shaf are both simply supported. Te

fber orientation angle is taken as one variation of the test

piece. Some specifc angles were in the test, such as 0

, 15

,

30

, 45

, 60

, 75

, 75

, and 90

.

Te results are as follows in Table 5.

6 Advances in Mechanical Engineering

Te frst mode Te second mode

Te third mode Te fourth mode

Figure 7: Te mode shapes of the steel/CFRP shaf.

Table 7: Some classical stacking sequences.

Te frst case [45, 45, 90, 45, 45, 90, 45, 45, 45, 45, 45, 45, 90, 45, 45, 90, 45, 45]

Te second case [90, 45, 45, 90, 45, 45, 90, 45, 45, 90, 45, 45, 45, 45, 45, 45, 45, 45]

Te third case [0, 15, 15, 45, 45, 60, 60, 75, 75, 90, 75, 75, 60, 60, 45, 45, 15, 15]

Te fourth case [45, 45, 0, 15, 15, 75, 75, 75, 75, 60, 60, 90, 15, 15, 60, 60, 45, 45]

Te ffh case [75, 0, 45, 90, 45, 15, 90, 60, 75, 15, 0, 45, 0, 60, 90, 75, 15, 60]

Te sixth case [90, 90, 90, 15, 15, 15, 75, 75, 75, 60, 60, 60, 45, 45, 45, 0, 0, 0]

Figure 8: Modal testing machine with a test piece mounted on it.

Table 8: Natural frequencies of the steel/CFRP shaf with diferent

stacking sequence.

Cases 1 2 3 4 5 6

First natural frequency (Hz) 193 192 282 283 255 239

Second natural frequency (Hz) 513 550 441 495 371 356

Te results showed that the natural frequency increased

as the angle decreased in the same condition. Sometimes it

was not consistent, as the frst natural frequency of stacking

withthe angle of 10

was greater thanthat withangles of 5

and

0

. Te relationship of the fber orientation angle and natural

frequency is nonlinear because of the orthotropic material

properties of CFRP. So, in practical design, under the premise

of enough strength, it is useful to appropriately increase some

ply angles to improve the natural frequency and stay away

36

40

32

28

24

20

16

12

8

4

0

0 200 400 600 800

(Hz)

Frequency response H1 (response 2, force) (magnitude)

[

(

m

/

s

2

)

/

N

]

1k 1.2 k 1.4 k 1.6 k

Modal : input : input : modal FFT analyzer 1

Figure 9: Te frequency response function graph of the test piece.

from the resonant frequency to achieve high stability, longer

life.

5.2. Monolayer Tickness. Te monolayer thickness is taken

as the variable, and the other parameters are invariant. Te

selected monolayer thickness is 0.11 mm, 0.22 mm, 0.33 mm,

0.66 mm, 0.99 mm, and 0.39 mm.

Te results were shown in Table 6.

It can be found that monolayer thickness had little

infuence on the natural frequency. Compared with Table 6,

for the stacking with an angle of 45

, the top three natural

Advances in Mechanical Engineering 7

Table 9: Tree selected laminates with a variable thickness of the monolayer.

Layers

Cases 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

1

Tickness (mm) 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33

Angle (

) 45 45 45 45 45 45 45 45 45 45 45 45 45 45 45 45 45 45

2

Tickness (mm) 0.33 0.33 0.66 0.66 0.33 0.33 0.66 0.66 0.33 0.33 0.66 0.66

Angle(

) 45 45 45 45 45 45 45 45 45 45 45 45

3

Tickness (mm) 0.11 0.11 0.11 0.11 0.99 0.99 0.11 0.11 0.66 0.66 0.11 0.11 0.33 0.33 0.11 0.11 0.33 0.33 0.11 0.11

Angle (

) 45 45 45 45 45 45 45 45 45 45 45 45 45 45 45 45 45 45 45 45

Table 10: Tree selected laminates with a variable thickness of the monolayer.

Layers

Cases 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

1

Tickness (mm) 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33

Angle (

) 0 45 90 0 45 90 0 45 90 0 45 90 0 45 90 0 45 90

2

Tickness (mm) 0.33 0.33 0.33 0.11 0.11 0.11 0.33 0.33 0.33 0.22 0.22 0.22 0.33 0.33 0.33 0.66 0.66 0.66

Angle (

) 0 45 90 0 45 90 0 45 90 0 45 90 0 45 90 0 45 90

3

Tickness (mm) 0.22 0.11 0.66 0.33 0.22 0.33 0.33 0.33 0.33 0.11 0.33 0.33 0.66 0.33 0.22 0.33 0.66 0.11

Angle(

) 0 45 90 0 45 90 0 45 90 0 45 90 0 45 90 0 45 90

Table 11: Corresponding natural frequencies of steel/CFRP shafs

under the variable thickness of the monolayer.

Cases

Table 9 Table 10

1 2 3 1 2 3

First natural frequency (Hz) 193 192 282 283 255 239

Second natural frequency (Hz) 513 550 441 495 371 356

frequencies were 140 Hz, 390 Hz, and 521 Hz, whereas the

angle 45

was replaced by alternately 45

/45

; the top three

natural frequencies changed into 173 Hz, 559 Hz, and 655 Hz.

Te same phenomenon occurred in cases that positive and

negative angles were used alternatively. Terefore, maximiza-

tion of the positive and negative fber angles is to achieve

not only convenient processing but also improve dynamic

characteristics.

5.3. Stacking Sequence. As ananother variable of the stacking,

some classical sequences were arranged as Table 7.

As was shown in Table 8, the stacking sequence had little

efects on the frst natural frequency but had a certain degree

of impact on the second and third natural frequencies under

specifc conditions.

5.4. Variable Tickness of Monolayer. Under the premise of

the same fber angles and entire thickness, the monolayer

thickness was varied in the following cases as shown in Tables

9 and 10.

Te above variable confgurations had the same propor-

tion of each angle. It is unnecessary to consider the infuence

of diferent angles. Te comparison in Table 11 presented that

natural frequencies would change apparently when the layers

oriented at [0, 45, 90], and constant thickness of monolayer

contributed to greater natural frequencies. But due to the

limited size, the change of frst natural frequency was not

particularly remarkable. Te change would be more apparent

if the shaf size increased.

5.5. Multiple Factors. It is known that most scholars focused

on the efect of every single factor, leaving a blank for the

research of multiple factors. Te confgurations of the test

piece were taken as an example, and fve cases were discussed

in Table 12.

In Table 13, the top three confgurations showed that

the natural frequencies changed a lot because of varying

fber angles. Comparison between case 2 and case 4, as well

as case 3 and case 5, diferent thicknesses, and number of

layers contributed to the change of natural frequencies. In

conclusion, the natural frequency was mainly determined

by the selected angles, whereas the various thickness and

number of layers just had a little efect on it.

6. Conclusions

From the previously presented results, the conclusions are

drawn as follows.

(1) Te natural frequency of the steel/CFRP drive shaf

increases along with the decreasing of fber orienta-

tion angle.

(2) Te stacking sequence has a little efect on the natural

frequency.

(3) Varying layer thickness can change the natural fre-

quency of the steel/CFRP shaf, only if the shaf size

is big enough.

(4) Te predicted natural frequency agrees with the

analytical solution with a deviation of 7.8%.

8 Advances in Mechanical Engineering

Table 12: Corresponding natural frequencies of steel/CFRP shafs under the variable thickness of the monolayer.

Layers

Remarks

Cases 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

1

Tickness (mm) 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33

Angle (

) 45 45 90 45 45 90 45 45 45 45 45 45 90 45 45 90 45 45

2

Tickness (mm) 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33

Angle (

) 45 45 15 45 45 90 45 45 0 0 45 45 90 45 45 15 45 45

3

Tickness (mm) 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33 0.33

Angle (

) 45 45 15 45 45 90 45 45 0 45 45 15 45 45 90 45 45 0

4

Tickness (mm) 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.11

Case 4 has 36 layers

Angle (

) 45 45 15 45 45 90 45 45 0 0 45 45 90 45 45 15 45 45

Tickness (mm) 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22

Layers 1936

Angle (

) 45 45 15 45 45 90 45 45 0 0 45 45 90 45 45 15 45 45

5

Tickness (mm) 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.11 0.11

Case 5 has 36 layers

Angle (

) 45 45 15 45 45 90 45 45 0 45 45 15 45 45 90 45 45 0

Tickness (mm) 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22 0.22

Layers 1936

Angle (

) 45 45 15 45 45 90 45 45 0 45 45 15 45 45 90 45 45 0

Table 13: Te natural frequency of steel/CFRP shaf under multiple

factors.

Cases 1 2 3 4 5

First natural frequency (Hz) 193 255 258 255 244

Second natural frequency (Hz) 513 628 478 513 654

And there are some newconclusions that can be drawn to

guide future design.

(1) When positive and negative angles are used for

layers at the same time, the natural frequency of the

steel/CFRP drive shaf is higher than that of a shaf

with only positive or negative angles.

(2) When multiple factors work together, the trend of the

efect of every single factor on natural frequency is

hardly afectedby other factors. Te natural frequency

is mainly determined by the fber orientation angle

and slightly afected by the stacking sequence and

layer thickness.

7. Recommendations for Further Work

Tere are many defciencies and unresolved issues in this

study. Suggestions for further work are listed as follows.

(1) Te reason for the deviation between experiment

and fnite element analysis. Modeling defects and the

simulation of the adhesive layer need to be solved for

the better prediction in future designs.

(2) Te efects of stacking sequence, layer thickness, and

other factors on natural frequency in all cases.

(3) Optimal design of lamination parameters for the best

dynamic performance.

(4) Te damping characteristic and dynamic natural

frequency for further research.

Conflict of Interests

Te authors declare that they have no fnancial and personal

relationships with other people or organizations that can

inappropriately infuence their work, and there is no profes-

sional or other personal interest of any nature or kind in any

product, service, and/or company that could be construed as

infuencing the position presented in our paper.

References

[1] M. A. Badie, E. Mahdi, and A. M. S. Hamouda, Aninvestigation

into hybrid carbon/glass fber reinforced epoxy composite

automotive drive shaf, Materials and Design, vol. 32, no. 3, pp.

14851500, 2011.

[2] S. P. Singh and K. Gupta, Free damped fexural vibration

analysis of composite cylindrical tubes using beam and shell

theories, Journal of Sound and Vibration, vol. 172, no. 2, pp. 171

190, 1994.

[3] M. M. Shokrieh, A. Hasani, and L. B. Lessard, Shear buckling

of a composite drive shaf under torsion, Composite Structures,

vol. 64, no. 1, pp. 6369, 2004.

[4] A. S. Sekhar and B. N. Srinivas, Dynamics of cracked compos-

ite shafs, Journal of Reinforced Plastics and Composites, vol. 22,

no. 7, pp. 637653, 2003.

[5] A. R. Abu Talib, A. Ali, M. A. Badie, N. Azida Che Lah, and

A. F. Golestaneh, Developing a hybrid, carbon/glass fber-

reinforced, epoxy composite automotive drive shaf, Materials

and Design, vol. 31, no. 1, pp. 514521, 2010.

Advances in Mechanical Engineering 9

[6] H. B. H. Gubran, Dynamics of hybrid shafs, Mechanics

Research Communications, vol. 32, no. 4, pp. 368374, 2005.

[7] W. Kim, A. Argento, and P. S. Mohanty, Bending natural

frequencies of circular CFRP shafs with a metal core or casing,

Journal of Composite Materials, vol. 38, no. 6, pp. 475494, 2004.

[8] G. P. Wang and P. Zhou, Vibration characteristics research

of hybrid aluminum/CFRP composite drive shafs, Forum of

low-carbon economy, high-tech manufacturing industries and

intelligent manufacturing development, Wuhan, China, 2010.

[9] D. G. Lee, J. W. Kim, and H. Y. Hwang, Torsional fatigue

characteristics of aluminum-composite co-cured shafs with

axial compressive preload, Journal of Composite Materials, vol.

38, no. 9, pp. 737756, 2004.

[10] M. D. Wu, Practical Guide of Mechanical Products Adhesive

Bonding and Sealing Technology, Liaoning Science and Technol-

ogy Press, Liaoning, China, 1995.

Submit your manuscripts at

http://www.hindawi.com

VLSI Design

Hindawi Publishing Corporation

http://www.hindawi.com Volume 2014

International Journal of

Rotating

Machinery

Hindawi Publishing Corporation

http://www.hindawi.com Volume 2014

Hindawi Publishing Corporation

http://www.hindawi.com

Journal of

Engineering

Volume 2014

Hindawi Publishing Corporation

http://www.hindawi.com Volume 2014

Shock and Vibration

Hindawi Publishing Corporation

http://www.hindawi.com Volume 2014

Mechanical

Engineering

Advances in

Hindawi Publishing Corporation

http://www.hindawi.com Volume 2014

Civil Engineering

Advances in

Acoustics and Vibration

Advances in

Hindawi Publishing Corporation

http://www.hindawi.com Volume 2014

Hindawi Publishing Corporation

http://www.hindawi.com Volume 2014

Electrical and Computer

Engineering

Journal of

Hindawi Publishing Corporation

http://www.hindawi.com Volume 2014

Distributed

Sensor Networks

International Journal of

The Scientifc

World Journal

Hindawi Publishing Corporation

http://www.hindawi.com Volume 2014

Sensors

Journal of

Hindawi Publishing Corporation

http://www.hindawi.com Volume 2014

Modelling &

Simulation

in Engineering

Hindawi Publishing Corporation

http://www.hindawi.com Volume 2014

Hindawi Publishing Corporation

http://www.hindawi.com Volume 2014

Active and Passive

Electronic Components

Hindawi Publishing Corporation

http://www.hindawi.com Volume 2014

Chemical Engineering

International Journal of

Control Science

and Engineering

Journal of

Hindawi Publishing Corporation

http://www.hindawi.com Volume 2014

Antennas and

Propagation

International Journal of

Hindawi Publishing Corporation

http://www.hindawi.com Volume 2014

Hindawi Publishing Corporation

http://www.hindawi.com Volume 2014

Navigation and

Observation

International Journal of

Advances in

OptoElectronics

Hindawi Publishing Corporation

http://www.hindawi.com

Volume 2014

Robotics

Journal of

Hindawi Publishing Corporation

http://www.hindawi.com Volume 2014

Potrebbero piacerti anche

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesDa EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNessuna valutazione finora

- Stress Deformation & Stiffness Analysis of Two Materials (Steel and Glass / Epoxy) of Flexspline Using ANSYSDocumento6 pagineStress Deformation & Stiffness Analysis of Two Materials (Steel and Glass / Epoxy) of Flexspline Using ANSYSijsretNessuna valutazione finora

- Joining of Polymer-Metal Hybrid Structures: Principles and ApplicationsDa EverandJoining of Polymer-Metal Hybrid Structures: Principles and ApplicationsSergio T. Amancio FilhoNessuna valutazione finora

- A Comparative Study of Fatigue Behavior and Life Predictions of Forged Steel and PM Connecting RodsDocumento12 pagineA Comparative Study of Fatigue Behavior and Life Predictions of Forged Steel and PM Connecting RodsalexcpmNessuna valutazione finora

- Paper192046 2050 PDFDocumento5 paginePaper192046 2050 PDFPrateek KesarwaniNessuna valutazione finora

- Modal AnalysisDocumento4 pagineModal AnalysisJournalNX - a Multidisciplinary Peer Reviewed JournalNessuna valutazione finora

- Seismic Retrofit Techniques For Reinforced Concrete Bridge Columns ...Documento10 pagineSeismic Retrofit Techniques For Reinforced Concrete Bridge Columns ...오상진Nessuna valutazione finora

- Analysis of Cold-Formed Steel Built-Up Closed Sections Strengthened With GFRPDocumento14 pagineAnalysis of Cold-Formed Steel Built-Up Closed Sections Strengthened With GFRPخوێندن لە ئەوروپاNessuna valutazione finora

- Design, Manufacture and Analysis of Al/Sic Mmcs For Connecting RodDocumento8 pagineDesign, Manufacture and Analysis of Al/Sic Mmcs For Connecting RodBima SorayaNessuna valutazione finora

- CFRP Strengthening of Steel Beams With Web Openings: October 2017Documento13 pagineCFRP Strengthening of Steel Beams With Web Openings: October 2017Muhammad MalikNessuna valutazione finora

- Effect of Steel Reinforcement Ratio On Flexural Enhancement in Cfrp-Strengthened Concrete Curved BeamsDocumento13 pagineEffect of Steel Reinforcement Ratio On Flexural Enhancement in Cfrp-Strengthened Concrete Curved BeamsAbhishek PawarNessuna valutazione finora

- A Study On Strengthening of Hollow Steel Section by Using CFRP and AfrpDocumento10 pagineA Study On Strengthening of Hollow Steel Section by Using CFRP and AfrpAmuye AdugnawNessuna valutazione finora

- 2.design and Analysis of Connecting RodDocumento52 pagine2.design and Analysis of Connecting RodNaresh DamaNessuna valutazione finora

- Pin Design 2Documento18 paginePin Design 2palash roy choudhuryNessuna valutazione finora

- Aljanabi 2020 IOP Conf. Ser. Mater. Sci. Eng. 871 012004Documento11 pagineAljanabi 2020 IOP Conf. Ser. Mater. Sci. Eng. 871 012004alaa hassoonNessuna valutazione finora

- Experimental Study On Modal and Harmonic Analysis of Small Wind Turbine Blades Using NACA 63-415 Aerofoil Cross-SectionDocumento13 pagineExperimental Study On Modal and Harmonic Analysis of Small Wind Turbine Blades Using NACA 63-415 Aerofoil Cross-Sectioncad camNessuna valutazione finora

- Effect of Tool Rotational Speed On The MicrostructDocumento11 pagineEffect of Tool Rotational Speed On The MicrostructlarryNessuna valutazione finora

- Analysis of Post-Tensioned Precast Segmental Bridge Piers Reinforced With Steel and FRP Bars-Accepted VersionDocumento6 pagineAnalysis of Post-Tensioned Precast Segmental Bridge Piers Reinforced With Steel and FRP Bars-Accepted VersionEdward TsaiNessuna valutazione finora

- Study On Repair Method Using CFRP For Corroded Steel Girder EndsDocumento12 pagineStudy On Repair Method Using CFRP For Corroded Steel Girder EndsRandi G JoviNessuna valutazione finora

- Testing of A Laterally Stable Eccentrically Braced Frame For Steel Bridge PiersDocumento6 pagineTesting of A Laterally Stable Eccentrically Braced Frame For Steel Bridge PiersFlorian GranceaNessuna valutazione finora

- Multi Pass MseDocumento7 pagineMulti Pass MseAbdulRhman AL-OmariNessuna valutazione finora

- Development and Application of Final Permanent MagDocumento9 pagineDevelopment and Application of Final Permanent MagEvren ÇaprazNessuna valutazione finora

- Behavior of Fullscale Concrete Columns Internally Reinforced With Glass FRP Bars Under Pure PDFDocumento10 pagineBehavior of Fullscale Concrete Columns Internally Reinforced With Glass FRP Bars Under Pure PDFsrividyaNessuna valutazione finora

- Friction Stir Welding ENHANCEMENT SEMINAR Friction Stir WeldingDocumento66 pagineFriction Stir Welding ENHANCEMENT SEMINAR Friction Stir Weldingrobertalha100% (1)

- Effect of Cyclic Loading On Flexural Behaviour of FRP Strengthened RC Beams: A Stability Point ApproachDocumento18 pagineEffect of Cyclic Loading On Flexural Behaviour of FRP Strengthened RC Beams: A Stability Point ApproachTam LamNessuna valutazione finora

- E3sconf Icemee2018 03035Documento5 pagineE3sconf Icemee2018 03035jasimabdNessuna valutazione finora

- Discussion On Bonding Performance Between FRP Bars and ConcreteDocumento5 pagineDiscussion On Bonding Performance Between FRP Bars and ConcreteEng-Alma AhmadNessuna valutazione finora

- 10 18400-Tekderg 674889-1190133Documento26 pagine10 18400-Tekderg 674889-1190133natasha asnaNessuna valutazione finora

- Mukhtar 2019 IOP Conf. Ser. Mater. Sci. Eng. 670 012005Documento6 pagineMukhtar 2019 IOP Conf. Ser. Mater. Sci. Eng. 670 012005sanjusamsonNessuna valutazione finora

- Recent Development in Finite Element Analysis of Self-Piercing Riveted JointsDocumento7 pagineRecent Development in Finite Element Analysis of Self-Piercing Riveted JointsYahaira Ruiz OrtegaNessuna valutazione finora

- Connecting RodDocumento57 pagineConnecting RodNaveenprakashNessuna valutazione finora

- Effect of Drilling Parameters and Tool Geometry On Drilling Performance in Drilling Carbon Fiber-Reinforced Plastic/ Titanium Alloy StacksDocumento16 pagineEffect of Drilling Parameters and Tool Geometry On Drilling Performance in Drilling Carbon Fiber-Reinforced Plastic/ Titanium Alloy StacksFarah AzzNessuna valutazione finora

- Materials 15 09045Documento16 pagineMaterials 15 0904525Maulana Yusuf IbrahimNessuna valutazione finora

- Multi Leaf SpringDocumento7 pagineMulti Leaf Springsamiraayadi466Nessuna valutazione finora

- Effect of Surface Ultrasonic Rolling On Evolution of Surface Microstructure of EA4T Axle SteelDocumento10 pagineEffect of Surface Ultrasonic Rolling On Evolution of Surface Microstructure of EA4T Axle SteelMUIN ABDULLAH-ALNessuna valutazione finora

- 2.12 Modeling of Concrete Beams Prestressed With AFRP TendonsDocumento6 pagine2.12 Modeling of Concrete Beams Prestressed With AFRP TendonsCarlos SYNessuna valutazione finora

- Review On Design and Analysis of Two Wheeler Connecting RodDocumento5 pagineReview On Design and Analysis of Two Wheeler Connecting RodVIVEK UPADHYAYNessuna valutazione finora

- Adtya SynopsisDocumento27 pagineAdtya SynopsisCH 09 Dileep KumarNessuna valutazione finora

- Elastic-Plastic Behaviour of A Nuclear Pipe Elbow With Axial Through Wall Crack at Crown Under In-Plane BendingDocumento9 pagineElastic-Plastic Behaviour of A Nuclear Pipe Elbow With Axial Through Wall Crack at Crown Under In-Plane BendingPeto FoteNessuna valutazione finora

- CD Shaft GhatageDocumento11 pagineCD Shaft GhatageMatthew SmithNessuna valutazione finora

- 1 s2.0 S2214785316303856 Main - 3Documento7 pagine1 s2.0 S2214785316303856 Main - 3mesfin DemiseNessuna valutazione finora

- Paper 5Documento7 paginePaper 5Shakuntal KhamarNessuna valutazione finora

- SPL02090341Documento7 pagineSPL02090341Narasimha DvlNessuna valutazione finora

- 10 1016@j Compstruct 2018 03 094Documento44 pagine10 1016@j Compstruct 2018 03 094AbdelkaderBenyoucefNessuna valutazione finora

- Journal of Building Engineering: Yong Xu, Hongyuan Tang, Junlong Chen, Yigang Jia, Ruizhong LiuDocumento16 pagineJournal of Building Engineering: Yong Xu, Hongyuan Tang, Junlong Chen, Yigang Jia, Ruizhong LiuDoua AbdouNessuna valutazione finora

- Predicting The de Ection of RC Beams Strengthened With FRP LaminatesDocumento9 paginePredicting The de Ection of RC Beams Strengthened With FRP LaminatesRikson TandelilinNessuna valutazione finora

- 6 478ryeryeryeDocumento9 pagine6 478ryeryeryeankitsarvaiyaNessuna valutazione finora

- Seminar Report On FEA Analysis of Shear Test Punching, TE ProjectDocumento16 pagineSeminar Report On FEA Analysis of Shear Test Punching, TE Projectnishantgaurav48Nessuna valutazione finora

- Design of ShellDocumento11 pagineDesign of ShellsachinNessuna valutazione finora

- Blanking and Piercing Theory Applications and Rece PDFDocumento11 pagineBlanking and Piercing Theory Applications and Rece PDFAbdulqahar M.SabirNessuna valutazione finora

- Bellow Using FemDocumento9 pagineBellow Using FemSonam Behl KambojNessuna valutazione finora

- Project Report (6461)Documento22 pagineProject Report (6461)Bhagvad JaideepNessuna valutazione finora

- Design and Simulation of Connecting Rods With Several Test Cases Using Al Alloys and High Tensile SteelDocumento8 pagineDesign and Simulation of Connecting Rods With Several Test Cases Using Al Alloys and High Tensile SteelTJPRC PublicationsNessuna valutazione finora

- Process Parameters Optimization For Friction Stir Welding of RDE-40 Aluminium Alloy Using Taguchi TechniqueDocumento7 pagineProcess Parameters Optimization For Friction Stir Welding of RDE-40 Aluminium Alloy Using Taguchi TechniquePunEit SinghNessuna valutazione finora

- LBW OptimizationDocumento11 pagineLBW Optimizationfathi.alfazaniNessuna valutazione finora

- Optimum Design On Structural Parameters of Reciprocating Refrigeration Compressor CrankshaftDocumento6 pagineOptimum Design On Structural Parameters of Reciprocating Refrigeration Compressor CrankshaftSaeedAkbarzadehNessuna valutazione finora

- Effect of Spot Continual Induction Hardening On The Tribological Performance of Grey Cast Iron With Curved SurfaceDocumento10 pagineEffect of Spot Continual Induction Hardening On The Tribological Performance of Grey Cast Iron With Curved SurfaceSreekumar RajendrababuNessuna valutazione finora

- Journal Pre-Proofs: Infrared Physics & TechnologyDocumento21 pagineJournal Pre-Proofs: Infrared Physics & TechnologyVishwa ChethanNessuna valutazione finora

- 10.1016@j.engstruct.2020.110828 - Plantilla 1Documento20 pagine10.1016@j.engstruct.2020.110828 - Plantilla 1emil bautista mezaNessuna valutazione finora

- Abu Talib CDSDocumento8 pagineAbu Talib CDSMatthew SmithNessuna valutazione finora

- C 20 MTT 1 2 SemDocumento165 pagineC 20 MTT 1 2 SemMatthew SmithNessuna valutazione finora

- Material Science - CompressedDocumento82 pagineMaterial Science - CompressedMatthew SmithNessuna valutazione finora

- Combustion PDFDocumento24 pagineCombustion PDFserkalemtNessuna valutazione finora

- Maths 3 CompressedDocumento208 pagineMaths 3 CompressedMatthew SmithNessuna valutazione finora

- Combustion in Si EnginesDocumento36 pagineCombustion in Si Enginesrgopi_83Nessuna valutazione finora

- C 20 MY 3 4 SemDocumento80 pagineC 20 MY 3 4 SemMatthew SmithNessuna valutazione finora

- Time Management Conference 2019Documento28 pagineTime Management Conference 2019Matthew SmithNessuna valutazione finora

- 10 1 1 558 3354Documento12 pagine10 1 1 558 3354Matthew SmithNessuna valutazione finora

- 6Rph6Wxglhv RQ 0hfkdqlfdo 3urshuwlhv Ri (SR (/&7%1&od/ %Dvhg3Ro/Phu 1Dqrfrpsrvlwhv 31&Documento8 pagine6Rph6Wxglhv RQ 0hfkdqlfdo 3urshuwlhv Ri (SR (/&7%1&od/ %Dvhg3Ro/Phu 1Dqrfrpsrvlwhv 31&Matthew SmithNessuna valutazione finora

- Abst PHD EnotiadisDocumento2 pagineAbst PHD EnotiadisMatthew SmithNessuna valutazione finora

- 1 s2.0 S0263822315005164 MainDocumento22 pagine1 s2.0 S0263822315005164 MainMatthew SmithNessuna valutazione finora

- 1 s2.0 S2211812814005872 MainDocumento7 pagine1 s2.0 S2211812814005872 MainMatthew SmithNessuna valutazione finora

- Influence of Interface On Epoxy/clay Nanocomposites: 1. Morphology StructureDocumento6 pagineInfluence of Interface On Epoxy/clay Nanocomposites: 1. Morphology StructureMatthew SmithNessuna valutazione finora

- 813201113306Documento10 pagine813201113306Matthew SmithNessuna valutazione finora

- Front-Wheel-Drive (Transaxle and CV Joint) Fundamentals: © 2012 Delmar, Cengage LearningDocumento25 pagineFront-Wheel-Drive (Transaxle and CV Joint) Fundamentals: © 2012 Delmar, Cengage LearningMatthew SmithNessuna valutazione finora

- Application of Taguchi Method For Optimization of Process Parameters in Improving The Surface Roughness of Lathe Facing OperationDocumento7 pagineApplication of Taguchi Method For Optimization of Process Parameters in Improving The Surface Roughness of Lathe Facing Operationwww.irjes.comNessuna valutazione finora

- Basic Thermo 3Documento65 pagineBasic Thermo 3Matthew SmithNessuna valutazione finora

- Automatic Transmission SystemDocumento21 pagineAutomatic Transmission SystemMamesh Mathankar100% (1)

- Automatic Transmission ApplicationsDocumento26 pagineAutomatic Transmission ApplicationsMatthew SmithNessuna valutazione finora

- Study of Friction and Wear of ABS/Zno Polymer Composite Using Taguchi TechniqueDocumento10 pagineStudy of Friction and Wear of ABS/Zno Polymer Composite Using Taguchi TechniqueMatthew SmithNessuna valutazione finora

- CE June 2011Documento2 pagineCE June 2011sohan2902Nessuna valutazione finora

- Fluid Mechanics Question Paper December 2014 January 2015Documento2 pagineFluid Mechanics Question Paper December 2014 January 2015Matthew SmithNessuna valutazione finora

- FM II AssaignmentDocumento2 pagineFM II AssaignmentMatthew SmithNessuna valutazione finora

- BTD - QBDocumento25 pagineBTD - QBMatthew SmithNessuna valutazione finora

- 1 PBDocumento8 pagine1 PBMatthew SmithNessuna valutazione finora

- 1 PBDocumento8 pagine1 PBMatthew SmithNessuna valutazione finora

- Automatic Transmission SystemDocumento21 pagineAutomatic Transmission SystemMamesh Mathankar100% (1)

- Automobile EnginesDocumento86 pagineAutomobile EnginesMatthew SmithNessuna valutazione finora

- Describe The Construction and Operation of Manual and Semi-Automatic Transmissions Used On Light VehiclesDocumento3 pagineDescribe The Construction and Operation of Manual and Semi-Automatic Transmissions Used On Light VehiclesMatthew SmithNessuna valutazione finora

- Types of Chassis LayoutDocumento8 pagineTypes of Chassis LayoutMatthew SmithNessuna valutazione finora

- Material Testing of M12 BoltsDocumento72 pagineMaterial Testing of M12 BoltsdhaktodesatyajitNessuna valutazione finora

- Finite Element by Tarun KantDocumento7 pagineFinite Element by Tarun KantVijayraj11Nessuna valutazione finora

- 1.15 The Slider-Crank Chain: Mechanisms and MachinesDocumento8 pagine1.15 The Slider-Crank Chain: Mechanisms and MachinesNAGU2009Nessuna valutazione finora

- Turbin99 IIDocumento12 pagineTurbin99 IIKristijan HorvatNessuna valutazione finora

- Steel - 02-Prof. Zahid SiddiqiDocumento31 pagineSteel - 02-Prof. Zahid SiddiqiMuhammad AhmedNessuna valutazione finora

- SD 2013 IYPT Reference Kit PDFDocumento81 pagineSD 2013 IYPT Reference Kit PDFMateus Corato ZanarellaNessuna valutazione finora

- Modified Cam Clay Modell (MCCM)Documento15 pagineModified Cam Clay Modell (MCCM)Jorge Hernan LopezNessuna valutazione finora

- Centre of Mass Frame of ReferenceDocumento21 pagineCentre of Mass Frame of ReferencesNessuna valutazione finora

- 1.6 Surface Tension and Capillarity - CE 309-CE22S2 - Fluid MechanicsDocumento4 pagine1.6 Surface Tension and Capillarity - CE 309-CE22S2 - Fluid MechanicsRusselNessuna valutazione finora

- HW 5Documento8 pagineHW 5Anonymous AjrDxGNessuna valutazione finora

- I.I.T Foundation Programme: Class: VIII Sound PhysicsDocumento10 pagineI.I.T Foundation Programme: Class: VIII Sound PhysicsSesha Sai KumarNessuna valutazione finora

- Energy Forms and Changes TESTDocumento9 pagineEnergy Forms and Changes TESTAndrei100% (2)

- JETIR2206426Documento5 pagineJETIR2206426Saksham jaiswalNessuna valutazione finora

- Benchtop Learning Model: Robotized Manual Gearbox: User's Guide For MT-BVRDocumento74 pagineBenchtop Learning Model: Robotized Manual Gearbox: User's Guide For MT-BVRKristiqn KolevNessuna valutazione finora

- Lab: Fre in e T In: Read The Entire InvestigationDocumento5 pagineLab: Fre in e T In: Read The Entire InvestigationRoshan Jawad ZafirNessuna valutazione finora

- Pre-Test in MOTIONFinalDocumento5 paginePre-Test in MOTIONFinalElyzza Wye AlbaoNessuna valutazione finora

- 4.0 Thermal PhysicsDocumento38 pagine4.0 Thermal Physicsmuhd hafizzudinNessuna valutazione finora

- Worksheet Week 5Documento4 pagineWorksheet Week 5Jaybie TejadaNessuna valutazione finora

- Chapter 5 - The Gas Phase List ALL Basic QuestionsDocumento45 pagineChapter 5 - The Gas Phase List ALL Basic QuestionsSara Al SaeedNessuna valutazione finora

- Hubbert and Willis, 1972 Mechanics of Hydr FracDocumento19 pagineHubbert and Willis, 1972 Mechanics of Hydr Fracnic7522Nessuna valutazione finora

- Moment Distribution MethodDocumento13 pagineMoment Distribution MethodMD. SHUVO RAHMANNessuna valutazione finora

- Fluid MechanicsDocumento11 pagineFluid Mechanicsjhc1123Nessuna valutazione finora

- Properties of Liquid SimpleDocumento3 pagineProperties of Liquid SimpleOsadreuasa100% (3)

- Mathcad - Analysis - Singly Reinforced Beam Section (Tension Yielding Steel)Documento8 pagineMathcad - Analysis - Singly Reinforced Beam Section (Tension Yielding Steel)nikita saleNessuna valutazione finora

- Leg Calculation 02Documento15 pagineLeg Calculation 02rudi 01Nessuna valutazione finora

- Lab Report TENSILEDocumento13 pagineLab Report TENSILEshareen tanNessuna valutazione finora

- FrictionDocumento3 pagineFrictionRESPECT MomentNessuna valutazione finora

- Ramana Prasad Intro ImpDocumento10 pagineRamana Prasad Intro ImpVijayalakshmi R.Nessuna valutazione finora

- PinoyBix Engineering MechanicsDocumento59 paginePinoyBix Engineering MechanicsChris Balmaceda100% (1)

- Transverse Vibrations of A Rotating Uniform Cantilever Beam With Tip Mass As Predicted by Using Beam Characteristic Orthogonal Polynomials in The Rayleigh-Ritz MethodDocumento12 pagineTransverse Vibrations of A Rotating Uniform Cantilever Beam With Tip Mass As Predicted by Using Beam Characteristic Orthogonal Polynomials in The Rayleigh-Ritz MethodHassanImranNessuna valutazione finora