Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Continuously Reinforced Concrete Pavement

Caricato da

ulhas_nakasheCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Continuously Reinforced Concrete Pavement

Caricato da

ulhas_nakasheCopyright:

Formati disponibili

engineeringcivil.com http://www.engineeringcivil.com/continuously-reinforced-concrete-pavement.

html

Continuously Reinforced Concrete Pavement

By

Prof. B. E. Gite, Mr. Yogesh S. Nagare

Amrutvahini College of Engineering, Sangamner

Abstract

Continuously reinforced concrete pavement as the title suggests this type of pavement is reinforced throughout

in longitudinal direction. This type of pavement has no transverse joints unless and until there is end of pavement

or the pavement comes in contact with some other pavement or bridge. A longitudinal joint exists only if the road is

wider than 14 feet. Due to reduction of joints smooth and continuous riding is possible resulting in fuel saving. Also

CRCP roads are maintenance free if properly constructed and care is taken while placement of steel. Once CRCP

roads are constructed they need not to be taken care of for the next 50-60 years. The principal behind this roads is

that Let the road crack, exactly opposite as in case of other type of roads where we avoid crack formation at any

cost. CRCP is allowed to crack due to which stresses in the pavement are released. The cracks formed are held

tightly by the reinforcement, due to which widening and deepening of cracks is restricted. Hence we can conclude

that in CRCP controlled cracking is permitted. The initial cost of CRCP is high, but as it is maintenance free, and

lasts for decades, overall cost of CRCP is less as compared to other type of reinforced concrete pavements.

Study and observations have shown that this type of roads are alarmingly successful, hence CRCP is widely used

in USA, GERMANY, BRITAN, and several other developed and developing nations. Use of CRCP will enhance the

cement, and steel industries; it will reduce the fuel consumption by vehicles, and will save lots of money required

for frequent construction and repairs of other type of pavements.

1. INTRODUCTION

Transport is a vital infrastructure for rapid economic growth of the country. Speedy transportation of natural

resources (such as raw materials), finished goods and perishable materials to all parts of the country including the

points of export outlets are basic inputs to economic growth. Recently there has been a major shift in

transportation mode from Railways towards the Road sector. Now a days about 60% of freight and 80% of

passenger transport is met by Road transport in India, which demonstrates the need for development of a good

road network.

In India flexible pavement (bitumen) is most common for both national and state highways. Majority of roads are

also built with conventional bitumen pavements considering its lower initial cost, though the life cycle cost of these

pavements are very high compared to rigid pavements due to frequent repairs and also need for complete

resurfacing at interval of 4-5 years. Further fuel consumption of vehicles is much higher on this type of pavement

than that on rigid pavement. In advanced countries rigid pavement is increasingly being used due to large number

of benefits it offers. Considering durability of concrete pavements some portion of Delhi Mathura and Mumbai

Pune expressway was built with jointed concrete pavement. Continuously reinforced concrete pavement, (CRCP)

eliminates the need for transverse joints (other than at bridges and other structures) and keep cracks tight,

resulting in a continuous, smooth-riding surface that is virtually maintenance free.

1.1 What is CRCP?

In concrete pavement the longitudinal reinforcing steel is continuous throughout the pavement length. It is a joint

less concrete pavement sufficiently reinforced to control cracking, without the aid of weakened transverse joints

such as are used in ordinary or conventional type of jointed concrete pavement. Reinforced bars in the concrete

are lapped to form continuous reinforcement holding the pavement together in all kinds of weather and preventing

formation of large cracks that would otherwise reduce the service life of the pavement. CRCP has all the good

features of concrete pavements such as durability, high structural strength, nonskid surface and good visibility at

night, wet or dryfeatures which make concrete, and especially continuously reinforced concrete, a permanent

road surfacing material.

In CRCP reinforcement steel is an important element and it offers the following functions:

1. Holds crack tight

2. Facilitates load transfer across cracks

3. Provides stiffness by restraining end movement

1.2. Definitions and Characteristics of CRCP

Continuously reinforced concrete pavement (CRCP) is concrete pavement reinforced with continuous steel bars

throughout its length. Its design eliminates the need for transverse joints (other than at bridges and other

structures) and keep cracks tight, resulting in a continuous, smooth-riding surface that is virtually maintenance-

free. The whole idea of CRCP is based essentially on the so-let-it-crack philosophy rather than the difficult

concept of avoiding cracks at any price. The principle in CRCP is to confine random cracking to acceptable

spacing and crack widths so that the slab performs the same as if no crack exists, i.e. equal deflection at cracks

and the mid span of the slab. In an unreinforced slab, cracks which occur will normally widen and get progressively

worse under the effects of traffic and climatic conditions. During the contraction of the concrete fine dirt enters the

wide cracks , leading to faulting , spalling and cracking and blow-ups develop , requiring extensive repairs and

early surfacing to restore the smooth surface. The amount of reinforcement required to control the cracking is

relatively smaller for shorter spans. As length of the slab increases amount of steel needed also increases.

2. DESIGN CONSIDERATIONS

2.1 Design Aspects:

The volume changes stresses in CRCP will be taken care by providing sufficient reinforcement to keep the cracks

tightly closed while maintaining adequate pavement thickness to counteract the stresses produced by wheel

loads. CRCP allows the concrete to develop very fine transverse cracks that seem to be uncontrolled and random.

The spacings of transverse cracks that occur in CRCP is an important variable that directly affect the behavior of

the pavement. Relatively large distances between cracks result in high steel stresses at the crack and in

excessive crack widths. A decrease in crack spacing reduces the steel stresses and crack widths.

2.1.1 Crack Spacing:

The limits on crack spacing are based on the possibility of spalling and punch outs. Based on experience, the

maximum spacing between consecutive cracks should be limited to 2.4m to minimize spalling. To minimize the

potential of punch outs, the minimum desirable crack spacing is about 1.1m.

2.1.2 Crack Width:

The limit on crack width is based on a consideration of spalling and water infiltration. The crack width should be

reduced as much as possible through the selection of higher steel percentage or smaller diameter reinforcing

bars. As per AASHTO stipulation the allowable crack width should not exceed 1.0mm.

2.2 Steel Stress:

The limiting stress of 75% of the ultimate tensile strength is recommended. AASHTO Design Nomographs and

Equation are available for determining the percentage of longitudinal reinforcement to satisfy the criteria of crack

spacing, crack width and steel stress respectively.The optimum amount of steel reinforcement is selected in CRCP

so that crack spacing lies between 1.1m to 2.4m, the crack width is less than 1.0mm and steel stress does not

exceed 75% of the ultimate tensile strength. CRCP allows the use of slightly smaller load transfer co-efficient

compared to JPCP. And hence the thickness requirement is less compared to JPCP. The maximum desirable

crack spacing is derived from a correlation between crack spacing and incidence of spalling. Maximum crack

spacing is derived from consideration of effect of slab length on the formation of punch-out.

2.2.1 Steel Reinforcement:

The amount and depth of longitudinal reinforcing steel are the most important aspects of steel reinforcement in

CRCP as it affects transverse crack spacing and the width of the cracks. The longitudinal reinforcement in CRCP

is used to control the fine transverse cracks that form due to volume changes in the concrete. The function of steel

is to hold the random cracks tightly closed, to provide structural continuity and to minimize the penetration of

potentially damaging surface water and incompressible.

2.2.2 Longitudinal Reinforcing Bars:

These are the main reinforcement in CRCP. The total area of longitudinal reinforcing bars required usually is

stated as a percentage of the cross-sectional area of the pavement. The amount of longitudinal reinforcing bars is

generally between 0.5% and 0.7% and it may be more where weather conditions are severe and also the

temperature differentials are more. Transverse reinforcements are useful to support the longitudinal steel when the

steel is preset prior to concrete placement. Transverse reinforcement may be lesser grade.

2.2.3 Transverse Reinforcing Bars:

The function of the bars is as follows:

1. To support the longitudinal bars and hold them at the specified spacing. When used for this purpose, the

longitudinal bars are tied or clipped to the transverse steel at specified locations.

2. To hold unplanned longitudinal cracks that may occur tightly closed.

2.3 Typical Design of CRCP:

The following parameters are considered for design:

1. Design Life -> (a) 20 years for Flexible pavement

(b) 30 years for Rigid pavements.

2. Traffic Density ->(a) 5000 Vehicles/day on 4-lane road

For Rigid Pavements:

1. Concrete grade: M40

2. Grade of steel: Fe 415

3. Maximum temperature differential between top and bottom of Slab = 21C (The maximum value for India as per

IRC 58)

4. Difference between mean temperatures of the slab at the time of construction and coldest period = 30C

(Assuming 35C at the time of construction and 5C at coldest period)

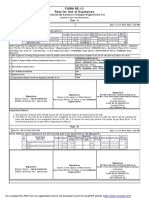

Table No. 2.1: Comparison of Different Types of Pavements for Highways

Item Flexible

Pavement

JPCP CRCP

Design Code IRC-37 IRC-58 British-HD 26/94,Part-

3,vol.7,section 2

AASHTO93

Total

pavement

thickness

(mm)

800 675 625 610

Grade of

concrete

- M40 M40 M40

Spacing of

contraction

joints

- 4.25 m - -

Steel

reinforcement

- Only at joints

occasionally thin

mesh in top surface

0.69% long 16mm @

140mm c/c Trans

12 mm@ 600 mm c/c

0.57% long 16 mm @

140mm c/c Trans 12 mm

@ 600mm c/c

Durability Poor (5-6

years)

Long (>30 years) Long (>30 years)

Saving in

Fuel

- 10-20% 10-20%

Maintenance High Less Very less

World

experience

Poor

performance

Good reports Very good reports. 4500 km in USA; all states have

started using CRCP

Construction Easy Special care is

needed

More special care needed

Expertise in

the country

Very large Yes Yes

Corrosion

problem

No R/F at joints needs

protection

No corrosion problem.

3. METHODOLOGY

CRCP is characterized by the presence of a continuous steel reinforcement set into the cement and by the

omission of transverse joints other than construction and terminal joints Instead of being concentrated in the

contraction joints as is the case with JPCP, volumetric changes (due to temperature and moisture) result in the

development of a large number of evenly distributed hairline cracks appearing at random. The amount of

longitudinal reinforcement is determined so as to control cracking and to ensure structural continuity of the

pavement. The aim sought is a great number of cracks fine enough to limit the penetration of de-icing salts and to

ensure proper aggregate interlock which leads to a higher load transfer efficiency. One of the main arguments for

the use of this type of slab is that it requires little or no maintenance. This represents savings in maintenance costs

but also direct savings for users. Initial costs are heftier due to the reinforcement but these costs are similar to

those for a conventional pavement after 10 to 15 years according to the World Road Association (PIARC), or after

15 to 18 years according to Belgian experts. Other favorable factors are a better long-term performance and

longevity of pavement smoothness. The use of CRCP is recommended for urban and rural-area highways,

especially where there is high-volume traffic and great number of trucks. Use of CRCP is widespread in the world,

especially in the United States and Europe.

The United States first used this concrete pavement in 1921. Several road tests were conducted during the

1940s and 1950s. Today, over 50 000 kilometers of highway lanes have been built in CRCP.

Belgium built its first CRCP section in 1950. This country has made extensive use of this type of concrete

pavement since 1970. Several projects were conducted since then to arrive at the current design. It is interesting

to note that this country uses CRCP not only on its highways but also on its country roads and national highways.

The participants of the 2001 Qubec Tour in Belgium had the opportunity to witness first-hand this countrys know

how in the area of concrete pavement.

France has used CRCP since 1983 and, to date, it has over 600 lane-kilometers, as well as, several

rehabilitation projects underway.

3.1. Construction of CRCP:

Construction of CRCP is similar to that of other concrete pavement types. Planning and execution are crucial since

errors made during these stages can be detrimental to the overall success of the project. It is important to pay

special attention to certain details such as the selection and installation of the reinforcement, the carrying out of

the construction joints, and so forth. As with any other type of pavement, the base must be finished to ensure a

uniform roadbed for the reinforcement supports and construction equipment, as well as, to provide a uniform slab

thickness. The base must ensure proper drainage to the slab base interface and be non-erodible to limit the

potential of punch-outs. A permeable base fully satisfies these criteria. First, the transverse reinforcement bars are

manually placed on metal supports by teams of steel fixers. A sufficient amount of supports will prevent any

collapsing under a 250-kg load. Their design must be in accordance with the concrete cover specifications.

Longitudinal reinforcement bars are placed on the transverse ones and then tied to the latter. Generally, it is

recommended that longitudinal reinforcement be placed on the upper third section of the slab to limit crack

openings. A sufficient amount of concrete cover above the reinforcement is necessary to prevent any corrosion. A

minimum spacing of 150 mm between the reinforcement bars is recommended to ensure adequate steel cover.

The longitudinal bars may be welded to one another or tied. If tied, the recommended overlap is 25 to 35 bar

diameters. The overlaps are usually offset from one lane to the next to ensure they are not all in the same cross

section. The free ends of CRCP are exposed to movements mainly caused by temperature differentials. Systems

are installed at each end to restrict the movements from the last 100 meters of the slab. Surveys conducted in

certain American states concluded that a wide-flange beam provides a cost-effective method for accommodating

end movements. In Belgium, anchors made of fixed beams embedded in the base are used. The use of bridge

expansion joints is also acceptable. Figure 3 shows the plan of work and a picture of an anchorage beam.

Concrete placement for the CRCP is similar to that of the conventional pavement. Desirable results are dependent

on the following factors: vibrator adjustment to avoid contact with the reinforcement bars and concrete workability

to ensure adequate steel cover. Figure 4 shows pavement placement achieved with a slip form paver. Tie-bars

should be placed in longitudinal construction joints to keep slab edges together on either side the joint. Special

attention must be paid when forming the transverse construction joints when concrete placement is completed at

the end of the day. The Belgians noted incidents of slab blow-ups (9) at construction joint mainly due to the poorer

quality of concrete resulting from a delayed or inadequate vibratory compaction on one or both sides of the joint.

The phases subsequent to the placement of CRCP (finishing, texturing, curing, saw cutting of the longitudinal

joints and sealing) resemble to that of other slab types.

3.2. Performance of the CRCP:

A provincial long-term performance program was implemented at MTQ in 1992. Its main objectives are to improve

pavement life and performance as well as to optimize the use of the funds allocated to the construction and

maintenance of the road network. Our will to improve our practices and the various steps taken to meet the

abovementioned objectives are insufficient unless a genuine feedback process such as field visits for data

collection on pavement performance is implemented. It is at this stage that our methods must be validated. A

result may lead to the rejection, modification or standardization of a new technique. A pavement performance

study started in 2000 and 2003 on the first two CRCP projects carried out by MTQ. Two 150-m long sections per

project are being closely monitored. The survey includes:

Distress mapping on the 150-m sections and general survey of the entire CRCP projects

Measurements of crack openings and end joints

Measurements of longitudinal profile (smoothness)

Measurements of transversal profile (ruts)

Coring and sampling

Measurements of deflections on the slab and at joint edges

Measurements of skid resistance and macro texture

Measurements of salt penetration levels in the concrete (Highway only)

Measurements of steel corrosion potential (Highway only)

To date on Highway, at least two series of detailed measures have been carried out: in 2000, just before opening

to traffic after reconstruction and in 2002, within a grand tour of all the road test sections in the Greater Montreal

Area. On Highway, measurements have been conducted in November 2003, just before opening to traffic. Certain

monitored parameters such as smoothness and skid resistance were the object of extensive measures on the

entire section of the CRCP. This article will focus on the parameters specific to CRCP such as cracking (rate,

spacing and width) and smoothness. Levels of salt penetration in the concrete are measures that can be useful in

the evaluation of the efficiency of the concrete to protect reinforcement against corrosion.

4.2.1. CRACKING:

Cracking rates were obtained by compiling the crack lengths using mapping measure from test sections. The

results shown in figure 5 are expressed in m/m2. The cracking rates are presented per 150-m section and

represent the mean rate of the three lanes and the left shoulder for Highway and of the three lanes for Highway.

During the first winter season, that is four months after opening to traffic, the rate of cracking is similar for the four

test sections. Afterwards for Highway , the progression remains significant yet less markedly so. 30 months after

reconstruction, the cracking rates are 0.83 and 0.89 m/m2 respectively for sections 1 and 2 of Highway . These

mean cracking rates are similar to the minimum allowable crack width criteria used for the design of the

reinforcement of Highway (1.07 m or 3.5 feet). To verify this result in terms of the effective crack spacing on site,

calculations were made using the June 2002 mapping measurements. Approximately 9% of the spacings were in

the range of 0.2 to 0.6 m, 20% in the 0.5 to 0.8 m range, 60 % in the 0.8 to 3-m range and 8% were over 3 m. A

certain proportion of the crack spacing is inferior to design limit values, something that will have to be closely

monitored in the months to come. However, to date, the CRCP has not revealed any damage whatsoever. On

Highway , three crack-width measurements were made using a so-called comparative method. The crack widths

taken between spring (17.5

o

C) and winter (- 22.5

o

C) were 0.183, 0.057 and 0.055 mm for a mean of 0.098 mm.

Another measurement was taken in June 2003 at a temperature of 37

o

C. There was a 0.1-mm difference with the

winter opening measurement, which is far lower than the width specified in the design (1- mm). The 0.1-mm value

reported is very similar to that published by the Belgians for temperatures oscillating between -1

o

C and 19

o

C .

3.2.2 Smoothness:

A profile survey to evaluate the pavements smoothness, that is, the irregularity of the longitudinal profile in the

wheel paths compared to a perfectly smooth reference surface. The index used by MTQ to rate the smoothness is

the IRI (International Roughness Index). For a paved surface, the scale ranges from 0 to 12, 0 being a perfectly

smooth surface. Note that a surface rated 1.2 is the allowable limit indicated in the specifications, and anything

beyond that may bring about a penalty. On Highway , grinding was forbidden for values up to 1.8 so this was not

the case for Highway . Figure 6 shows the mean IRI values in the three lanes for the entire sector in CRCP for

Highway (2 km) and for a JPCP section (1.5 km) immediately adjacent to the CRCP section. The mean values for

the entire three lanes of Highway are also presented on the same figure. Immediately after reconstruction of

Highway, the IRI values of two of the three lanes with JPCP are higher than those of CRCP. Three years later,

there is little change in the smoothness of the CRCP whereas there is a 0.2 increase in the values of the JPCP.

For Highway, we observed a slight increase in the first winter.

4. CONCLUSION

1. Compared to flexible pavement, CRCP gives additional design life of at least 10 years. Further, it offers much

better riding quality, less dislocations to traffic movement and substantial saving in vehicle operating cost

comprising reduced consumption of fuel, lubricants etc.

2. Considering durability and maintenance free service of CRCP it is desirable to construct all these concrete

roads with CRCP.

3. Thermo mechanically treated, TMT, bars are desirable for CRCP pavement. Corrosion resistant TMT bars may

be used in corrosion prone areas.

4. The demerit of CRCP is its high initial cost & difficulty in repair works required to be done if not constructed

properly.

5. Joint less concrete pavement, CRCP offers excellent smooth Riding surface for the vehicles that maximizes the

comfort for the passengers.

6. It needs minimum cost of maintenance and rehabilitation. It minimizes the detrimental dynamic loads that are

applied to the vehicles and pavement. Air and noise environment improve along the thickly populated existing

corridor. Concentrations of CO and NOX are expected to reduce by around 70 % and 45% respectively. The noise

level would reduce substantially.

7. Concrete can withstand even the heaviest traffic loads. Theres no need to worry about ruts, shoving effects

common with asphalt pavement.

8. Concretes hard surface makes it easier for rolling wheels. Studies have even shown that this can increase

truck fuel efficiency. Savings in fuel to the extent of 20%, may be considered ultimately reducing the vehicle

operating cost.

9. Concrete roads facilitate increased speed and thereby savings in time and money. Almost maintenance free

service reduces traffic disturbances and thus reduces man-hour loss to the road users.

10. Use of CRCP drastically can reduce import of bitumen there by leading to saving of foreign currency.

REFERENCES

1. Seongcheol Choi a, Soojun Ha b, Moon C. Wonc Horizontal cracking of continuously reinforced concrete

pavement Sunder environmental loadings.

2. By seong-min kim effect of bond stesses & slip model for continuously reinforce concrete pavements.

3.Amrut Nashikkar,Nirav Shah Siddharth, Nautiyal Vinayraj, A.K.Vivek Sahay In Partial Fulfilment of the

requirements of the course Infrastructure Development and Financing.

4.E J Yoder Concrete Roads Alternate Construction Methods, Brajendra Singh, Principles of Pavement Design,

National Seminar on Concrete Roads & pavements.

We at engineeringcivil.com are thankful to Prof. B. E. Gite and Mr. Yogesh S. Nagare for submitting their

research paper on Continuously Reinforced Concrete Pavement to us. We are sure this will be very helpful

to the ones looking for information on Continuously Reinforced Concrete Pavements.

Potrebbero piacerti anche

- Continuosly Reinforced Concrete Pavement Design For AirportDocumento27 pagineContinuosly Reinforced Concrete Pavement Design For AirportDIPAK VINAYAK SHIRBHATE100% (1)

- Road Pavement: Requirements of A PavementDocumento12 pagineRoad Pavement: Requirements of A PavementPrashant PalNessuna valutazione finora

- AoR-2020 (MGNREGA), Vol-IDocumento135 pagineAoR-2020 (MGNREGA), Vol-ISaroj ChakmaNessuna valutazione finora

- Box Culvert Design VVIMPDocumento11 pagineBox Culvert Design VVIMPAshishNessuna valutazione finora

- Design of Flexible Design - AASHTODocumento9 pagineDesign of Flexible Design - AASHTOdineshNessuna valutazione finora

- Engineering Science and Technology, An International JournalDocumento7 pagineEngineering Science and Technology, An International JournalPoun KumarNessuna valutazione finora

- Slab Culvert Irc 21 Irc 112Documento5 pagineSlab Culvert Irc 21 Irc 112Rupendra palNessuna valutazione finora

- Complete WorkDocumento51 pagineComplete WorkOdell Arome Darian100% (3)

- Stabilization of Black Cotton Soil by Admixtures PDFDocumento19 pagineStabilization of Black Cotton Soil by Admixtures PDFSantosh NaikNessuna valutazione finora

- Experimental Observations and Parametric Study of Piled Raft Foundation Using PlaxisDocumento7 pagineExperimental Observations and Parametric Study of Piled Raft Foundation Using PlaxisAngelinSavioNessuna valutazione finora

- Liquefaction Potential of Cohesionless SoilsDocumento80 pagineLiquefaction Potential of Cohesionless SoilsBrice DurandNessuna valutazione finora

- Flexible Pavement Design IRC37 2001 1Documento5 pagineFlexible Pavement Design IRC37 2001 1Chatnoir NoirNessuna valutazione finora

- White Topping Concrete RoadsDocumento20 pagineWhite Topping Concrete RoadsSohan MeharwadeNessuna valutazione finora

- Structural Design ReportDocumento208 pagineStructural Design Reportmohan sundarNessuna valutazione finora

- Duct Drain Section RCC DesignDocumento1 paginaDuct Drain Section RCC Designhammad jagirdarNessuna valutazione finora

- Plate Girder Design and ComponentsDocumento36 paginePlate Girder Design and ComponentssomumallidiNessuna valutazione finora

- Earth Pressure TheoryDocumento20 pagineEarth Pressure TheoryMohan ManickamNessuna valutazione finora

- Computer Aided Design of Foot Over BridgeDocumento6 pagineComputer Aided Design of Foot Over Bridgepp3986Nessuna valutazione finora

- Field Density Test (SRM)Documento2 pagineField Density Test (SRM)manish upadhyay0% (1)

- Analysis On The Causes of Cracks in BridgesDocumento14 pagineAnalysis On The Causes of Cracks in BridgesNguyễn Văn MinhNessuna valutazione finora

- Deck Slab DesignDocumento27 pagineDeck Slab Designquithanqui100% (1)

- Bridge Design Aashto ReferDocumento7 pagineBridge Design Aashto ReferKangho WonNessuna valutazione finora

- 012-OKK-Final Culvert Design Report (Bhawanipatna - Khariar)Documento40 pagine012-OKK-Final Culvert Design Report (Bhawanipatna - Khariar)Jimmy Villca Sainz100% (1)

- Drawing Title: Employer Project Design Consultant: HouseDocumento5 pagineDrawing Title: Employer Project Design Consultant: HouseRoshan KejariwalNessuna valutazione finora

- Pipe CulvertDocumento8 paginePipe CulvertKrishna DixitNessuna valutazione finora

- IS-2911-part-1sec-1-2010-design-and Construction-Of-Pile-Foundation PDFDocumento22 pagineIS-2911-part-1sec-1-2010-design-and Construction-Of-Pile-Foundation PDFRajan VANessuna valutazione finora

- Footings - Rectangular Spread Footing AnalysisDocumento9 pagineFootings - Rectangular Spread Footing AnalysisWilbert Tapia BallesterosNessuna valutazione finora

- Design of Mechanically Stabilzed Earth Walls (Msew)Documento22 pagineDesign of Mechanically Stabilzed Earth Walls (Msew)SUNDARAVELNessuna valutazione finora

- RCC Developers LTD.: Design of Retaining Walls @bridge Approach KM 368+385Documento13 pagineRCC Developers LTD.: Design of Retaining Walls @bridge Approach KM 368+385Shivendra KumarNessuna valutazione finora

- Approximate Design Method For Piled Raft FoundationsDocumento10 pagineApproximate Design Method For Piled Raft FoundationsAnirudh SharmaNessuna valutazione finora

- KRIDL Quality Control Instructions for Concrete WorksDocumento36 pagineKRIDL Quality Control Instructions for Concrete WorksvivekNessuna valutazione finora

- M25 DesignDocumento4 pagineM25 DesignAmit KumarNessuna valutazione finora

- Slope Movement Processes and CharacteristicsDocumento39 pagineSlope Movement Processes and CharacteristicsAzealdeen AlJawadiNessuna valutazione finora

- Development Design Specification D4Documento10 pagineDevelopment Design Specification D4Timothy KimemiaNessuna valutazione finora

- VivaDocumento76 pagineVivaRam NepaliNessuna valutazione finora

- A Review Paper Study On Skew Slab Bridge Using ETAB Software by Finite Element MethodDocumento4 pagineA Review Paper Study On Skew Slab Bridge Using ETAB Software by Finite Element MethodEditor IJTSRDNessuna valutazione finora

- Hydraulic Analysis of Major BridgeDocumento10 pagineHydraulic Analysis of Major BridgeUmar KarimiNessuna valutazione finora

- Journal of The IRC April-June-2017 78 Part-1 Pages 1-56 + CoverDocumento60 pagineJournal of The IRC April-June-2017 78 Part-1 Pages 1-56 + CovermunisamyprabakaranNessuna valutazione finora

- What Is A Culvert - Types of Culverts, Its Materials and LocationDocumento4 pagineWhat Is A Culvert - Types of Culverts, Its Materials and LocationJustin MusopoleNessuna valutazione finora

- Rebound Hammer PresentationDocumento18 pagineRebound Hammer PresentationMohmed RiazNessuna valutazione finora

- Basic Function of Retaining WallDocumento9 pagineBasic Function of Retaining Wallillya amyra100% (1)

- STAAD ProDocumento1 paginaSTAAD ProkamalnitrrNessuna valutazione finora

- Name of Work:-Construction of Major Bridge Across River Vattigedda at KM 492/2-4 of Raipur - Visakhapatnam Section of NH-43 in Andhra PradeshDocumento4 pagineName of Work:-Construction of Major Bridge Across River Vattigedda at KM 492/2-4 of Raipur - Visakhapatnam Section of NH-43 in Andhra PradeshUpadhyayula Subba RaoNessuna valutazione finora

- 2 Design of Causeways in Developing CountriesDocumento8 pagine2 Design of Causeways in Developing CountriesMichael100% (1)

- KDS 11 70 20 Rockfall and Debris Prevention Facility Design StandardsDocumento15 pagineKDS 11 70 20 Rockfall and Debris Prevention Facility Design StandardsSH Big ShimNessuna valutazione finora

- Traffic Final Report Group 7Documento86 pagineTraffic Final Report Group 7erlyn alagonNessuna valutazione finora

- Samer Fawzi CV 2Documento6 pagineSamer Fawzi CV 2Samer SulimanNessuna valutazione finora

- Ch-3 Introduction To Prestressed ConcreteDocumento29 pagineCh-3 Introduction To Prestressed ConcreteGolisa RobaNessuna valutazione finora

- CRCPDocumento15 pagineCRCPaskarahNessuna valutazione finora

- 1.retaining Walls (1-2Documento43 pagine1.retaining Walls (1-2Anonymous MDDp1Ryi100% (1)

- Bearing Capacity of Closed and Open Ended Piles Installed in Loose Sand PDFDocumento22 pagineBearing Capacity of Closed and Open Ended Piles Installed in Loose Sand PDFAnonymous 8KOUFYqNessuna valutazione finora

- Is 7784 1 1993 PDFDocumento18 pagineIs 7784 1 1993 PDFZankar R ParikhNessuna valutazione finora

- Enhancing the Climate Resilience of Africa's Infrastructure: The Power and Water SectorsDa EverandEnhancing the Climate Resilience of Africa's Infrastructure: The Power and Water SectorsNessuna valutazione finora

- Continuously Reinforced Concrete PavementDocumento2 pagineContinuously Reinforced Concrete PavementArnold TunduliNessuna valutazione finora

- Continuously Reinforced Concrete PavementDocumento21 pagineContinuously Reinforced Concrete PavementAnastasios Karahalios100% (1)

- Continuously Reinforced Concrete PavementDocumento21 pagineContinuously Reinforced Concrete PavementAHMED SOHEL100% (2)

- CRCP Design Main NoteDocumento20 pagineCRCP Design Main NoteSunil BoseNessuna valutazione finora

- Pt. Vilas Thuse: - Gruha Pravesh - Kalash Poojan Samagri (Material) ListDocumento4 paginePt. Vilas Thuse: - Gruha Pravesh - Kalash Poojan Samagri (Material) Listulhas_nakasheNessuna valutazione finora

- GrahapraveshaDocumento8 pagineGrahapraveshaSuresh PoonkavanamNessuna valutazione finora

- UAE Labour LawDocumento44 pagineUAE Labour LawShankar RaoNessuna valutazione finora

- Diaphragm Wall Method StatementDocumento67 pagineDiaphragm Wall Method Statementulhas_nakashe100% (3)

- Diet Plan in DetailedDocumento6 pagineDiet Plan in Detailedulhas_nakasheNessuna valutazione finora

- User Owner Ford EcosportDocumento193 pagineUser Owner Ford EcosportRene BermudezNessuna valutazione finora

- Eos Rebelsl2 200d Im en PDFDocumento458 pagineEos Rebelsl2 200d Im en PDFAlejandro García IglesiasNessuna valutazione finora

- VASTU POOJA RITUALSDocumento3 pagineVASTU POOJA RITUALStandon_rakesh100% (1)

- Getting Started With The EOS 200DDocumento21 pagineGetting Started With The EOS 200Dulhas_nakasheNessuna valutazione finora

- Unprotect Excel SheetDocumento2 pagineUnprotect Excel Sheetulhas_nakasheNessuna valutazione finora

- BS 5950 Part 1 Structural Use of Steelwork in Building1 PDFDocumento224 pagineBS 5950 Part 1 Structural Use of Steelwork in Building1 PDFHlineNessuna valutazione finora

- What Are The Main Responsibilities of Managers - TelegraphDocumento5 pagineWhat Are The Main Responsibilities of Managers - Telegraphulhas_nakasheNessuna valutazione finora

- Name of The Applicant, Home Address in Parent CountryDocumento2 pagineName of The Applicant, Home Address in Parent Countryulhas_nakasheNessuna valutazione finora

- Immunization GuidelineDocumento79 pagineImmunization Guidelinesi13nzNessuna valutazione finora

- FORM 15G DECLARATIONDocumento3 pagineFORM 15G DECLARATIONulhas_nakasheNessuna valutazione finora

- FIDIC Conditions of ContractDocumento13 pagineFIDIC Conditions of Contractulhas_nakashe100% (2)

- My Life ListDocumento13 pagineMy Life Listulhas_nakasheNessuna valutazione finora

- Rheomac 707Documento3 pagineRheomac 707ulhas_nakashe100% (1)

- My Life ListDocumento13 pagineMy Life Listulhas_nakasheNessuna valutazione finora

- Secant Piles: What Are Secant Pile Walls?Documento3 pagineSecant Piles: What Are Secant Pile Walls?ulhas_nakashe100% (2)

- Final Manual For Specification StandardsDocumento192 pagineFinal Manual For Specification Standardsbhargavraparti100% (1)

- Abu Dhabi Street Design Manual FINALDocumento172 pagineAbu Dhabi Street Design Manual FINALJacob VanSickle100% (1)

- Sand Qnty SpreadsheetDocumento1 paginaSand Qnty Spreadsheetulhas_nakasheNessuna valutazione finora

- Sheet Pile Design HandbookDocumento368 pagineSheet Pile Design HandbookLandon Mitchell92% (12)

- Varanasi Pilgrimage GuideDocumento27 pagineVaranasi Pilgrimage Guideulhas_nakasheNessuna valutazione finora

- Mix DesignDocumento22 pagineMix Designemirm84Nessuna valutazione finora

- Indian Rolled Sections 756Documento1 paginaIndian Rolled Sections 756Naman GirdharNessuna valutazione finora

- Mix DesignDocumento22 pagineMix Designemirm84Nessuna valutazione finora

- Dream Is Not What U See in Sleep, It's The Thing Which Does Not Let U SL EepDocumento1 paginaDream Is Not What U See in Sleep, It's The Thing Which Does Not Let U SL Eepulhas_nakasheNessuna valutazione finora

- Postgraduate Notes in OrthodonticsDocumento257 paginePostgraduate Notes in OrthodonticsSabrina Nitulescu100% (4)

- IDocumento2 pagineIsometoiajeNessuna valutazione finora

- Biology Mapping GuideDocumento28 pagineBiology Mapping GuideGazar100% (1)

- Surgery Lecture - 01 Asepsis, Antisepsis & OperationDocumento60 pagineSurgery Lecture - 01 Asepsis, Antisepsis & OperationChris QueiklinNessuna valutazione finora

- KPMG Inpection ReportDocumento11 pagineKPMG Inpection ReportMacharia NgunjiriNessuna valutazione finora

- Level 3 Repair PBA Parts LayoutDocumento32 pagineLevel 3 Repair PBA Parts LayoutabivecueNessuna valutazione finora

- Maj. Terry McBurney IndictedDocumento8 pagineMaj. Terry McBurney IndictedUSA TODAY NetworkNessuna valutazione finora

- تاااتتاااDocumento14 pagineتاااتتاااMegdam Sameeh TarawnehNessuna valutazione finora

- Zelev 1Documento2 pagineZelev 1evansparrowNessuna valutazione finora

- Ujian Madrasah Kelas VIDocumento6 pagineUjian Madrasah Kelas VIrahniez faurizkaNessuna valutazione finora

- Lifespan Development Canadian 6th Edition Boyd Test BankDocumento57 pagineLifespan Development Canadian 6th Edition Boyd Test Bankshamekascoles2528zNessuna valutazione finora

- Propiedades Grado 50 A572Documento2 paginePropiedades Grado 50 A572daniel moreno jassoNessuna valutazione finora

- Chennai Metro Rail BoQ for Tunnel WorksDocumento6 pagineChennai Metro Rail BoQ for Tunnel WorksDEBASIS BARMANNessuna valutazione finora

- Petty Cash Vouchers:: Accountability Accounted ForDocumento3 paginePetty Cash Vouchers:: Accountability Accounted ForCrizhae OconNessuna valutazione finora

- Interpretation of Arterial Blood Gases (ABGs)Documento6 pagineInterpretation of Arterial Blood Gases (ABGs)afalfitraNessuna valutazione finora

- Leaked David Fry II Conversation Regarding Loopholes and Embezzlement at AFK Gamer LoungeDocumento6 pagineLeaked David Fry II Conversation Regarding Loopholes and Embezzlement at AFK Gamer LoungeAnonymous iTNFz0a0Nessuna valutazione finora

- AgentScope: A Flexible Yet Robust Multi-Agent PlatformDocumento24 pagineAgentScope: A Flexible Yet Robust Multi-Agent PlatformRijalNessuna valutazione finora

- PROF ED 10-ACTIVITY #1 (Chapter 1)Documento4 paginePROF ED 10-ACTIVITY #1 (Chapter 1)Nizelle Arevalo100% (1)

- Portfolio Artifact Entry Form - Ostp Standard 3Documento1 paginaPortfolio Artifact Entry Form - Ostp Standard 3api-253007574Nessuna valutazione finora

- Nama: Yetri Muliza Nim: 180101152 Bahasa Inggris V Reading Comprehension A. Read The Text Carefully and Answer The Questions! (40 Points)Documento3 pagineNama: Yetri Muliza Nim: 180101152 Bahasa Inggris V Reading Comprehension A. Read The Text Carefully and Answer The Questions! (40 Points)Yetri MulizaNessuna valutazione finora

- Exercises2 SolutionsDocumento7 pagineExercises2 Solutionspedroagv08Nessuna valutazione finora

- India Today 11-02-2019 PDFDocumento85 pagineIndia Today 11-02-2019 PDFGNessuna valutazione finora

- DLP in Health 4Documento15 pagineDLP in Health 4Nina Claire Bustamante100% (1)

- всё необходимое для изучения английского языкаDocumento9 pagineвсё необходимое для изучения английского языкаNikita Chernyak100% (1)

- Survey Course OverviewDocumento3 pagineSurvey Course OverviewAnil MarsaniNessuna valutazione finora

- Android software download guideDocumento60 pagineAndroid software download guideRizky PradaniNessuna valutazione finora

- 20 Ua412s en 2.0 V1.16 EagDocumento122 pagine20 Ua412s en 2.0 V1.16 Eagxie samNessuna valutazione finora

- Briana SmithDocumento3 pagineBriana SmithAbdul Rafay Ali KhanNessuna valutazione finora

- En dx300lc 5 Brochure PDFDocumento24 pagineEn dx300lc 5 Brochure PDFsaroniNessuna valutazione finora

- PESO Online Explosives-Returns SystemDocumento1 paginaPESO Online Explosives-Returns Systemgirinandini0% (1)