Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Quotation For 20-63mm PPR-AL-PPR Overlap Welding Pipe Machine-Sunshine KAIDE

Caricato da

Марал Эрдэнэ0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

125 visualizzazioni12 pagineTitolo originale

Quotation for 20-63mm PPR-AL-PPR Overlap Welding Pipe Machine-Sunshine KAIDE

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

125 visualizzazioni12 pagineQuotation For 20-63mm PPR-AL-PPR Overlap Welding Pipe Machine-Sunshine KAIDE

Caricato da

Марал ЭрдэнэCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 12

KAIDE

Address:Yinma indurstrial park,Changyi,city,Shangdong Province Post code 261317

Mobile:0086-13805363035 Tel 0086 536 85650536 Fax 0086 536 8650536

Email marketthree@kai-de.com Website www.kai-de.com

1

ISO9001:2008

Quotation for Ultrasonic Overlap Welding PPR-AL-PPR

Composite Pipe Set

20-63mm)

See Video on: http://www.kai-de.com/en/?About/Video/60.html

Client: Mr. Maral Erdene

From: Weifang Kaide Plastics Machinery Co. ,Ltd

Contact person: Sunshine Zheng

Mobile: +86 13805363035 Mail: marketthree@kai-de.com

Date: May 15, 2014

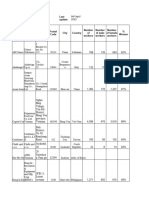

PART 1: QUOTATION LIST

Shipped from :Qingdao China

Shipped to:

Shipped by sea

Container Loader 1x40GP

Price Validity 30days

Delivery time 60 days

Warranty time One year

Payment Terms:

30%T/T down payment before production,70%

T/T balance before shipping.

Description of Goods Qty. FOB Qingdao Price

Overlap Welding PPR-AL-PPR Pipe

Line(20mm-63mm)

1set

$96,700USD

Material:

PPR, Adhesive, Aluminum

Producing

Speed:3-8m/min

Extruder:SJ -65/33 2, SJ -30/25X2

Remark: The Normal Electric power supply: Three phase four wire 380V,50HZ,If your power is different

with this, There will be extra 5% cost in basis of the current total price.

KAIDE

Address:Yinma indurstrial park,Changyi,city,Shangdong Province Post code 261317

Mobile:0086-13805363035 Tel 0086 536 85650536 Fax 0086 536 8650536

Email marketthree@kai-de.com Website www.kai-de.com

2

ISO9001:2008

PART 2 MACHINE SET COMPOSITION

NO. Machine Set Composition Qty.

1 Aluminum tape releaser device 1set

2 Aluminum tape storage device 1set

3 Ultrasonic Aluminum tape connecting welder 1set

4 Aluminum pipe forming device 1set

5 Ultrasonic Welder for Aluminum pipe forming 1set

6 SJ -65/33 PPR extruder with 37kw motor (Inner Pipe) 1set

7 SJ -65/33 PPR extruder with 45kw motor (Outer Pipe) 1set

8 SJ -30/25 Adhesive extruder with 4kw motor 2sets

9 XAL-300 Auto loader 4sets

10 XBD-75/XBD-25 Hot air dryer

2sets/2set

s

11

Inner pipe co-extrusion die head & molds( 20mm,25mm,32mm, 40mm,

50mm,63mm

1unit

12

Outer pipe co-extrusion die head & molds( 20mm,25mm,32mm,40mm,

50mm,63mm

1unit

13 SGL-63 Water cooling flume 2sets

14 PQ-500 Pipe Hauler 1set

15 WQ-63 Auto dustless type pipe cutter 1set

16 SGD-63 Auto pipe stacker(6000mm) 1set

17 Siemens PLC control System 1set

KAIDE

Address:Yinma indurstrial park,Changyi,city,Shangdong Province Post code 261317

Mobile:0086-13805363035 Tel 0086 536 85650536 Fax 0086 536 8650536

Email marketthree@kai-de.com Website www.kai-de.com

3

ISO9001:2008

PART 3 DETAILED INFORMATION of EACH PART

1. Aluminum tape releaser device

Configuration:

Type: Passive working mode

Feature: double working position, 360 of free rotation

2. Aluminum tape storage device

Configuration:

Dri ven motor: 0.37kw

Working mode: mechanical type

Storage capacity: 60meters

3. Ultrasonic Aluminum tape connecting welder

KAIDE

Address:Yinma indurstrial park,Changyi,city,Shangdong Province Post code 261317

Mobile:0086-13805363035 Tel 0086 536 85650536 Fax 0086 536 8650536

Email marketthree@kai-de.com Website www.kai-de.com

4

ISO9001:2008

Configuration:

Welding mode: Ultrasonic welding

Brand/Origin: Shanghai, China

4. Aluminum pipe forming device

Configuration:

Pipe forming mode: roller guide forming

Roller material: 40Cr with nitriding treatment

Forming mold quantity: 5 units

5. Ultrasonic welder for Aluminum pipe forming

KAIDE

Address:Yinma indurstrial park,Changyi,city,Shangdong Province Post code 261317

Mobile:0086-13805363035 Tel 0086 536 85650536 Fax 0086 536 8650536

Email marketthree@kai-de.com Website www.kai-de.com

5

ISO9001:2008

Configuration:

Welding mode: Ultrasonic welding

Brand/Origin: Shanghai, China

6. SJ -65/ 33 I nner pipe extruder

Configuration:

Motor: 37kw frequency converter motor

Frequency converter brand: ABB

Screw and Barrel:

Special designed screw and barrel for PPR, adopting high quality alloy steel 38CrMoAlA, and

treated by nitriding, polishing & honing, with nitriding thickness 0.5-0.7 mm.

KAIDE

Address:Yinma indurstrial park,Changyi,city,Shangdong Province Post code 261317

Mobile:0086-13805363035 Tel 0086 536 85650536 Fax 0086 536 8650536

Email marketthree@kai-de.com Website www.kai-de.com

6

ISO9001:2008

Heating mode:

heating by high efficient ceramic heater, and equipped with stainless steel safeguard

Temperature control:

PLC computer control temperature, with independent fans cooling in each heating zones,

Lower voltage electric element brand: Siemens or Schneider

Reducer: Specialized hard gear reducer,

Feeding seat: HT-200 material, with forced feeding function and cooled by circulating water, to

prevent the material blocking in the feed mouth

7. SJ -65/ 33 Outer pipe extruder

Configuration:

Motor: 45kw frequency converter motor

Frequency converter brand: ABB

Screw and Barrel:

Special designed screw and barrel for PPR, adopting high quality alloy steel 38CrMoAlA, and

treated by nitriding, polishing & honing, with nitriding thickness 0.5-0.7 mm.

Heating mode:

heating by high efficient ceramic heater, and equipped with stainless steel safeguard

Temperature control:

KAIDE

Address:Yinma indurstrial park,Changyi,city,Shangdong Province Post code 261317

Mobile:0086-13805363035 Tel 0086 536 85650536 Fax 0086 536 8650536

Email marketthree@kai-de.com Website www.kai-de.com

7

ISO9001:2008

PLC computer control temperature, with independent fans cooling in each heating zones,

Lower voltage electric element brand: Siemens or Schneider

Reducer: Specialized hard gear reducer,

Feeding seat: HT-200 material, with forced feeding function and cooled by circulating water, to

prevent the material blocking in the feed mouth

8. SJ -30/ 25 hot melt adhesive extruder

Configuration:

Motor: 4kw frequency converter motor

Frequency converter brand: ABB

Screw and Barrel:

Special designed screw and barrel for adhesive, adopting high quality alloy steel 38CrMoAlA, and

treated by nitriding, polishing & honing, with nitriding thickness 0.5-0.7 mm.

Heating mode:

heating by high efficient ceramic heater, and equipped with stainless steel safeguard

Temperature control:

PLC computer control temperature, with independent fans cooling in each heating zones,

Reducer: Specialized hard gear reducer,

9. XAL-300 Automatic Loader

Configuration:

Auto loading capacity: 300KG/H.

Loading mode: Vacuum suction loading

Quantity: 4 nos

10. XBD-75 /XBD-25 Hot Air Typed Dryer

KAIDE

Address:Yinma indurstrial park,Changyi,city,Shangdong Province Post code 261317

Mobile:0086-13805363035 Tel 0086 536 85650536 Fax 0086 536 8650536

Email marketthree@kai-de.com Website www.kai-de.com

8

ISO9001:2008

Effective volume: 75L/25L

Quantity: 2sets/2sets

11. I nner pipe co-extrusion die head and mold

12. Outer pipe co-extrusion die head and mold

Configuration:

Made by high quality mould steel 40Cr; special designed co-extrusion runner, to make sure the

even thickness of each layer. Each layer thickness can be adjusted freely and simply.

Die mold size:20mm, 25mm,32mm, 40mm,50mm,63mm.

13. SGL-63 Cooling flume

KAIDE

Address:Yinma indurstrial park,Changyi,city,Shangdong Province Post code 261317

Mobile:0086-13805363035 Tel 0086 536 85650536 Fax 0086 536 8650536

Email marketthree@kai-de.com Website www.kai-de.com

9

ISO9001:2008

Configuration:

Casing material: Stainless Steel

Cooling method: water immersion

Length: 6000 mm

Quantity: 2nos

Features: Equipped with auto water supply and drainage system and auto water temperature

control system.

14. PQ-500 Pipe hauler

Configuration:

KAIDE

Address:Yinma indurstrial park,Changyi,city,Shangdong Province Post code 261317

Mobile:0086-13805363035 Tel 0086 536 85650536 Fax 0086 536 8650536

Email marketthree@kai-de.com Website www.kai-de.com

1

ISO9001:2008

Dri ven motor type: 4 KW frequency converter motor

Frequency Inverter: ABB

Equipped with:

wear-resisting rubber belt, multi-group rollers pneumatic clamping, with high hauling speed and

good stability.

15. WQ-63 Auto dustless type pipe cutter

Configuration:

Dri ven motor type: 1.1kw motor driven

Pipe clamping mode: high precision linear guide rail control clamping

Control system: Siemens PLC control, with Parameter setting function

Features:

Accurate and reasonable design structure, no accessory parts required, cutting pipe end surface is

smooth, and no fur.

16. SGD-63 Pipe Auto Stacker

KAIDE

Address:Yinma indurstrial park,Changyi,city,Shangdong Province Post code 261317

Mobile:0086-13805363035 Tel 0086 536 85650536 Fax 0086 536 8650536

Email marketthree@kai-de.com Website www.kai-de.com

11

ISO9001:2008

Stacking mode: pneumatic stacking

Stacking length: 6000mm

17. Siemens PLC programmable computer control system

The most professional plastics machinery control system-Germany SIEMENS brand computer

industrial controlling system, entered into by order setting, inside built in the precision sync control

function module for the whole line, the main and auxiliary machine are controlled at the same step,

not only inching but linkage all the line. Intelligence distributed control, the newest scheme of

Germany SIEMENS, diaphragm type man-machine interface, can program every class alarm and

protect function.

PART 4: USE CONDITIONS

1 Place indoors

KAIDE

Address:Yinma indurstrial park,Changyi,city,Shangdong Province Post code 261317

Mobile:0086-13805363035 Tel 0086 536 85650536 Fax 0086 536 8650536

Email marketthree@kai-de.com Website www.kai-de.com

12

ISO9001:2008

2 Temperature 0-45

3 Humidity level 85% without condensation

4 Power line 3 phase 4 wire; 380V 50Hz

5 Production line : (L X W XH) 42m x 3.5 m x 2.5m

6 Container quantity : 1 set of 40" container

7 Rated installation power 161kw/h

8 The actual power consumption: 88-95KW/h

PART 5: INSTALLATION & TRAINING STAFF

1. ONE engineer would be sent to your factory to do installation & training service; taking about

10-15 days. The round trip and travel charges, board & lodging cost of the service people and

Chinese interpreter are undertaken by the buyers according to the international practices;

USD$100/day for each sellers technician.

2. The warranty period is valid for 12 months from the date of delivery. The freight fee of

subsequent fitting is charged by buyer. The seller can supply technology guide and consultation

by telephone or Email.

3. Before our technician coming, please let your worker to learn the machine manual first, and

also get water, electric, compressed air source, related tools and machine layout ready according

to our layout drawings or photos.

4. The acceptance of machine will be carried out at the sellers factory.

BLANK BELOW

Potrebbero piacerti anche

- Horizontal Cladding SystemDocumento6 pagineHorizontal Cladding SystemAndres PeruchaNessuna valutazione finora

- CY Special Offer of Mini Plasma Sputtering CoaterDocumento5 pagineCY Special Offer of Mini Plasma Sputtering Coaterşenol KayaNessuna valutazione finora

- Technical DataDocumento16 pagineTechnical DataAdrian DumitruNessuna valutazione finora

- SY100 High Speed Paper Cup Making MachineDocumento10 pagineSY100 High Speed Paper Cup Making MachineReda MashalNessuna valutazione finora

- King Rabbit KIII Cutting Plotter QuotationDocumento1 paginaKing Rabbit KIII Cutting Plotter QuotationManuel CaberoNessuna valutazione finora

- STING-Pillow Packing Machine (With Auto Feeding System)Documento8 pagineSTING-Pillow Packing Machine (With Auto Feeding System)Rajendra ChaudharyNessuna valutazione finora

- Semi ABL& PBL Lami Tube Production LineDocumento9 pagineSemi ABL& PBL Lami Tube Production Lineannabi.anissaNessuna valutazione finora

- Plastic ProductionDocumento5 paginePlastic ProductionJoseph KfouryNessuna valutazione finora

- 50-250PVC Pipe ExtruderDocumento4 pagine50-250PVC Pipe ExtruderzakariaNessuna valutazione finora

- HG32High-Frequency Welded Pipe Mill Line - Pakistan 210224Documento14 pagineHG32High-Frequency Welded Pipe Mill Line - Pakistan 210224Arslan AbbasNessuna valutazione finora

- Bundy Tube Uncoiling & Cutting Machine 20211015Documento3 pagineBundy Tube Uncoiling & Cutting Machine 20211015spactraNessuna valutazione finora

- Little PlasmaDocumento29 pagineLittle PlasmaMETALEX SNNessuna valutazione finora

- Catalog of TLANMP Mechanical Seals 2018 PDFDocumento60 pagineCatalog of TLANMP Mechanical Seals 2018 PDFCong SonNessuna valutazione finora

- Iraq Tariq Camellie 50mm PVC Pipe Extrusion Line 20191206Documento7 pagineIraq Tariq Camellie 50mm PVC Pipe Extrusion Line 20191206tariq82aliNessuna valutazione finora

- 200-250kv Directional ModelsDocumento2 pagine200-250kv Directional Modelsmohamed hassaninNessuna valutazione finora

- Shandong Lu Young Machinery Co.,Ltd: Quotation & SpecificationDocumento10 pagineShandong Lu Young Machinery Co.,Ltd: Quotation & SpecificationLuciano Lopez CastroNessuna valutazione finora

- 2016CompositeList Web 59Documento1 pagina2016CompositeList Web 59AnuranjanNessuna valutazione finora

- Quotation: JY-40B Fast Lab Shaker: USD600EXWDocumento4 pagineQuotation: JY-40B Fast Lab Shaker: USD600EXWsunartoNessuna valutazione finora

- PI Rewinding Machine MinnieDocumento6 paginePI Rewinding Machine MinnieSALEELNessuna valutazione finora

- FS1325A-R CNC RouterDocumento6 pagineFS1325A-R CNC RouterBengkel WojojoyoNessuna valutazione finora

- Prima Turret Punch LaserDocumento8 paginePrima Turret Punch LaserRobson CamachoNessuna valutazione finora

- GH 2KW Greef Wind Turbine CatalgoueDocumento8 pagineGH 2KW Greef Wind Turbine CatalgoueSanjayan MaratNessuna valutazione finora

- 2016CompositeList Web 130Documento1 pagina2016CompositeList Web 130AnuranjanNessuna valutazione finora

- INVOICE Coilmat Mould 180728Documento2 pagineINVOICE Coilmat Mould 180728Anonymous 20vuAObSPzNessuna valutazione finora

- Hoton Quotation For Cd6250b-1000mmDocumento8 pagineHoton Quotation For Cd6250b-1000mmChitko KoNessuna valutazione finora

- Vcta FL 302dDocumento2 pagineVcta FL 302dqeeNessuna valutazione finora

- Project Book For Thermal Paper Production LineDocumento12 pagineProject Book For Thermal Paper Production LineMohamed IbrahemNessuna valutazione finora

- Blank Mask Making Machine (SE-GW2015) : WWW - Ultrasonicwelding.inDocumento6 pagineBlank Mask Making Machine (SE-GW2015) : WWW - Ultrasonicwelding.inploglNessuna valutazione finora

- HQA20221122Documento11 pagineHQA20221122mosab aliNessuna valutazione finora

- Sabm SX (500-205) ElectricalDocumento10 pagineSabm SX (500-205) ElectricalRafik Mohamed AlhajiNessuna valutazione finora

- Professional Cable Wire Machinery Manufacturer Since 1990: Jiangsu Jiacheng Technology Co., LTDDocumento10 pagineProfessional Cable Wire Machinery Manufacturer Since 1990: Jiangsu Jiacheng Technology Co., LTDTú PhanNessuna valutazione finora

- FVQZD-2600C Gluer and Stitching All-In-One MachineDocumento8 pagineFVQZD-2600C Gluer and Stitching All-In-One MachineJunaid MazharNessuna valutazione finora

- 15T 1000x1000mm RUBBER VULCANIZING PRESS PROFORMA INVOICE - Steady Machinery-Bob)Documento10 pagine15T 1000x1000mm RUBBER VULCANIZING PRESS PROFORMA INVOICE - Steady Machinery-Bob)Angelo Faccilongo GutierrezNessuna valutazione finora

- Press Brake WC67Y 250 3200 PDFDocumento9 paginePress Brake WC67Y 250 3200 PDFJet Tools TanzaniaNessuna valutazione finora

- The Supreme Industries LTD.: EX-FACTORY PRICE LIST W.E.F. 01/09/2017Documento1 paginaThe Supreme Industries LTD.: EX-FACTORY PRICE LIST W.E.F. 01/09/2017Prasanth Pawar NNessuna valutazione finora

- Quotation of Vacuum Lifter GL-LD Series - QingdaoSinofirst 1801204Documento6 pagineQuotation of Vacuum Lifter GL-LD Series - QingdaoSinofirst 1801204leo limpiasNessuna valutazione finora

- Ceramic SG6 Three Roll Mill QuotationDocumento3 pagineCeramic SG6 Three Roll Mill QuotationLe DuNessuna valutazione finora

- Technical Specification: LGS63 Light Gauge Steel Framing MachineDocumento6 pagineTechnical Specification: LGS63 Light Gauge Steel Framing MachineKalai Sham06Nessuna valutazione finora

- Oilfield Instruments CatalogueDocumento38 pagineOilfield Instruments CatalogueNot GeniusNessuna valutazione finora

- Mars Quotation of Chicken Cage Welding Machine DP-AW-1200HDocumento10 pagineMars Quotation of Chicken Cage Welding Machine DP-AW-1200HRobert AdrianNessuna valutazione finora

- SC - 431 - Single Head Manual Cutting Saw Dia 400 MMDocumento2 pagineSC - 431 - Single Head Manual Cutting Saw Dia 400 MMNikhil PatilNessuna valutazione finora

- Quotation of Chicken Slaughtering Line From HelenDocumento14 pagineQuotation of Chicken Slaughtering Line From HelendmagnetoNessuna valutazione finora

- Technical Specifications of MOTI-30-3NC Busbar MachineDocumento26 pagineTechnical Specifications of MOTI-30-3NC Busbar MachineycemalNessuna valutazione finora

- Catalogo Taian Taizhuo CNC Turning Center TCK550Documento6 pagineCatalogo Taian Taizhuo CNC Turning Center TCK550DiegoNessuna valutazione finora

- Single Drive Portable CNC Plasma Cutting Machine JX-1840Documento11 pagineSingle Drive Portable CNC Plasma Cutting Machine JX-1840Elajmi RostomNessuna valutazione finora

- 3015H Quotation PDFDocumento11 pagine3015H Quotation PDFMurat ErdemNessuna valutazione finora

- QGQ750 Automatic Painting Filling LineDocumento13 pagineQGQ750 Automatic Painting Filling LineCamilo GuardadoNessuna valutazione finora

- Strip Cutter For Urine Strips and Glucose StripsDocumento3 pagineStrip Cutter For Urine Strips and Glucose Stripsfandi dwi setyokoNessuna valutazione finora

- LG-8X3200-Hydraulic Brake Shearing MachineDocumento8 pagineLG-8X3200-Hydraulic Brake Shearing MachineFahadNessuna valutazione finora

- ZJZJP Roots Vauum PumpDocumento8 pagineZJZJP Roots Vauum PumpAnonymous Tj3ApePIrNessuna valutazione finora

- CATALOGO PP China HAIDE K53Documento3 pagineCATALOGO PP China HAIDE K53Avoti PlacasNessuna valutazione finora

- MWL315 C, CE, CEP, CL, CEL, CA, CEA Etc. CNC Wood Lathe Price List From Jinan MastecDocumento11 pagineMWL315 C, CE, CEP, CL, CEL, CA, CEA Etc. CNC Wood Lathe Price List From Jinan MastecJuan Martín Montes NeriNessuna valutazione finora

- Reatech-Rebar Tools AmarrarDocumento7 pagineReatech-Rebar Tools AmarrarCristian Gonzalo Fiorilo BravoNessuna valutazione finora

- MazambiqueDocumento18 pagineMazambiqueDaniel KalyoowaNessuna valutazione finora

- Quotation For Motocycle Wheel Rim Whole Line - 2022Documento7 pagineQuotation For Motocycle Wheel Rim Whole Line - 2022HamzaNessuna valutazione finora

- SIL CO2 EngraverDocumento4 pagineSIL CO2 Engravertapanvnahar musicNessuna valutazione finora

- Quotation: Jiangyin Baoli Machinery Manufacturing Co., LTDDocumento9 pagineQuotation: Jiangyin Baoli Machinery Manufacturing Co., LTDGalo Abad Huayta FernándezNessuna valutazione finora

- 2X1200 Slitter - Docxpakistan 21224Documento8 pagine2X1200 Slitter - Docxpakistan 21224Arslan AbbasNessuna valutazione finora

- Hoton Quotation For Jyp300vfDocumento11 pagineHoton Quotation For Jyp300vfmarcostNessuna valutazione finora

- Weld Like a Pro: Beginning to Advanced TechniquesDa EverandWeld Like a Pro: Beginning to Advanced TechniquesValutazione: 4.5 su 5 stelle4.5/5 (6)

- New ScriptDocumento2 pagineNew ScriptDeveloper 4Nessuna valutazione finora

- Completation Inteligent RevistaDocumento9 pagineCompletation Inteligent RevistaGabriel Castellon HinojosaNessuna valutazione finora

- An Ecient Uniform-Cost Normalized Edit Distance AlgorithmDocumento12 pagineAn Ecient Uniform-Cost Normalized Edit Distance Algorithmanon-75650Nessuna valutazione finora

- AIR IOS ReadmeDocumento2 pagineAIR IOS ReadmeHeir TatamiNessuna valutazione finora

- Recent Developments On The Interpretation of Dissolved Gas Analysis in TransformersDocumento33 pagineRecent Developments On The Interpretation of Dissolved Gas Analysis in TransformersputrasejahtraNessuna valutazione finora

- Transportation ProblemDocumento3 pagineTransportation ProblemSalilNessuna valutazione finora

- Long Quiz Direct VariationDocumento2 pagineLong Quiz Direct VariationHermann Dejero LozanoNessuna valutazione finora

- Ball BearingsDocumento31 pagineBall Bearingsnike_y2kNessuna valutazione finora

- 3.032 Problem Set 2 Solutions: Due: Start of Lecture, 09.21.07Documento16 pagine3.032 Problem Set 2 Solutions: Due: Start of Lecture, 09.21.07Pkay TandohNessuna valutazione finora

- Project Report On Modulation (Class 12)Documento14 pagineProject Report On Modulation (Class 12)Shivam Tripathi100% (9)

- Firetroll User Interface Manual Ns550f-01-Instruction-manualDocumento16 pagineFiretroll User Interface Manual Ns550f-01-Instruction-manualMike CerreroNessuna valutazione finora

- Gree Dehumidifier Service ManualDocumento58 pagineGree Dehumidifier Service Manualjdv1234Nessuna valutazione finora

- Shape and Volume: A Presentation On AcousticsDocumento35 pagineShape and Volume: A Presentation On AcousticsSiddharth BhandariNessuna valutazione finora

- Asset Failure Detention Codes (ICMS - PAM - ZN - SECR 312)Documento5 pagineAsset Failure Detention Codes (ICMS - PAM - ZN - SECR 312)mukesh lachhwani100% (1)

- Case StudyDocumento6 pagineCase Studyzaid bin shafiNessuna valutazione finora

- Article On Online ShoppingDocumento23 pagineArticle On Online ShoppingsaravmbaNessuna valutazione finora

- Report OmarDocumento14 pagineReport OmarYasir KhursheedNessuna valutazione finora

- Quantum Computing: Exercise Sheet 1: Steven Herbert and Anuj DawarDocumento2 pagineQuantum Computing: Exercise Sheet 1: Steven Herbert and Anuj DawarJuan DiegoNessuna valutazione finora

- Pump Station System Curves Session 1Documento29 paginePump Station System Curves Session 1Toan LeNessuna valutazione finora

- Fixed Frequency, 99% Duty Cycle Peak Current Mode Notebook System Power ControllerDocumento44 pagineFixed Frequency, 99% Duty Cycle Peak Current Mode Notebook System Power ControllerAualasNessuna valutazione finora

- 1575 Tania SultanaDocumento10 pagine1575 Tania SultanaTania SultanaNessuna valutazione finora

- BM2 24H+Installation+InstructionsDocumento7 pagineBM2 24H+Installation+InstructionsremediospereiraNessuna valutazione finora

- Atomic Structure ActivityDocumento4 pagineAtomic Structure ActivityClarisse BonaobraNessuna valutazione finora

- Mozart Symphony 6 TimpaniDocumento2 pagineMozart Symphony 6 Timpaniגיל עברוןNessuna valutazione finora

- T60 Transformer Management Relay: UR Series Instruction ManualDocumento404 pagineT60 Transformer Management Relay: UR Series Instruction Manualeng amadaNessuna valutazione finora

- Construction Cost EstimatesDocumento25 pagineConstruction Cost EstimatesAnonymous zwnFXURJNessuna valutazione finora

- The My Letter To All.1Documento33 pagineThe My Letter To All.1Victor Corpus AntonioNessuna valutazione finora

- Connecting Piping Design in AutoCAD Plant 3D To Piping Fabrication Through Spoolgen-Ian Matthew-AU2018Documento12 pagineConnecting Piping Design in AutoCAD Plant 3D To Piping Fabrication Through Spoolgen-Ian Matthew-AU2018Gabriel DezoutterNessuna valutazione finora

- ASM Lab Record BookDocumento36 pagineASM Lab Record BookNandan HegdeNessuna valutazione finora

- IB Lite 1 11 0 New FeaturesDocumento11 pagineIB Lite 1 11 0 New Featuresm.n.malasNessuna valutazione finora