Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Solar Panel Sizing

Caricato da

Mallela Sampath Kumar0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

224 visualizzazioni6 pagineSolar Panel Sizing

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoSolar Panel Sizing

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

224 visualizzazioni6 pagineSolar Panel Sizing

Caricato da

Mallela Sampath KumarSolar Panel Sizing

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 6

System sizing 1463Wc @24Vdc

Total Load Requirement [A1] 1,463.00 W Battery Type MODEL: 6x 12OPzV2000

System Voltage [A2] 24 V Float voltage [E1] 2.366 V

Array radiation @ 30 tilt [A3] 5.37 kWH/m2/day No cells in series [E2] 12 Based on Nominal of 2V per cell

Battery Temp Coeff [E3] -0.003 V/C/2V cell

Float Voltage @ 20C [E4] 28.39 V [E4] = [E1] * [E2]

Average Battery day time Temperature [E5] 23.8 C Day time average temp

Battery Float Voltage in December at above Temp [E6] 28.26 V [E6] = [E4] - ([E3] * [E2] * (20 - [E5])

Safety Factors to include (Spec) Load Equipment Voltage 24.00 V

Derating factors (ageing, dirt, dust and brid droppings) [A4] 20.0%

Above factors taken as per specifications. Type 195 W based on Tss4U / Gesolar GES-5M195

Required Array to Load Ratio in worst month as per specification [A5] 1.08 Rated Pmax [E7] 195 W

Isc [E8] 5.80 A @ 25C cell Temp 1000W/m2

Temp Coefficient of current [E9] 0.04 %/C

Temp Coefficient of voltage [E10] -0.32 %/C

NOCT [E11] 45.0 C @ 20C 800W/m2

Average Day Time Temp in Abu Dhabi (*1) [A6] 23.8 C Cell operating temp @ 23,8 C Ambient 48.8 C [E12] = [A6] + [E11] - 20

# Isc [E8] @48,8C cell temp 5.81 A [E13] = [E8] + (([E12] - 45) * [E9]*[E8]/100)

Cable Voltage drops (battery - array) [A7] 1.92 V # Normal Module Voltage during day time 30.655 V [E14] = [E6] + [A7] + [A8]

Charge controller Voltage drop [A8] 0.48 V %age Current reduction between Isc & I @ 30,6552 3.5% [E15] calculated from IV data Co-related

Module Current @ 031V 48,8C cell temp 5.606 A [E16] = [E13] * (1 - [E15]) @ 1000W/m2

Module rated current at peak Power voltage 5.420 A [E17] @ 25

o

C cell temperature Data Sheet

Continuous Load 1,463.00 W

Daily Load in AH on Battery [B1] 1463.00Ah

Required daily AH considering module derating factors (Daily Ah) 1755.60Ah [B2] = [B1]*(1 + [A4])

Module Current at operating V at 48,8oC cell temperature [B3] 5.606 A

Daily energy produced by each solar module 30.10 AH

No parallel modules required to support a 1755.6 AH Load 58.3

No parallel modules proposed [B6] 64

Daily energy produced by 64 parallel 195 modules [B7] 1,926.5 AH

Excess generation [B8] 9.7%

No of modules in series [B9] 1

Total No of modules proposed [B10] 64

Nominal Array Power [B11] 12,480 W

Achieved Array To Load Ratio (ALR) [B12] 1.097

Battery Autonomy Required (Days) [B13] 5

Capacity for autonomy period (LoadW/24V x 5 days x 24h) [B14] 7,315 AH

Battery Ageing Factor [B15] 0.80

TC=Battery Temperature Compensation Factor at 4.0

o

C [B16] 0.867

Adjusted Battery capacity for load (LxAFxTC) [B17] 10,547 AH

Minimum SOC (1-Maximum DoD) [B18] 20%

Final Capacity @C120 to 1.85V/cell [B19] 13183.75

Offered Battery Capacity @C120 to 1.85V/Cell [B20] 2629

No of parallel strings for 1x100% battery capacity [B21] 6

Total battery bank capacity [B22] 15774

Excess Available Capacity VS Calculated capacity [B23] 16.42%

Capacity to be recharged [B14] 7,315 Ah Consumed capacity during autonomy period

Excess Array output in worst month [B24] 170.90 Ah [B24] = [B7] - [B2] Difference between Array Output and Daily load

Battery Inefficiency Factor [B25] 1.10 For recharge calculation only

Recharge Time with load connected in worst month [B26] 47 Day [B26] = [B14] * [B25] / [B24]

Recharge Time without load [B27] 4.18 Day

Daily Ah hours consumption from battery [B28] 853 Ah [B28] = [A1] / [A2] * 14Hr 14 hours daily period when battery alone feeding the load

Daily Cycling [B29] 5.41% [B29] = [B28] / [B22] Note-2

Notes:

1] The Average temperature is from Dubai Met Office. Contact for details dubaimet@emirates.net.ae

2] 14 Hours of night time is considered as average.

[B22] = [B20] * [B21]

[B23] = 1 - [B19]/[B22]

[B27] = [B14] * [B25] / [B7] Due to NO load connected all array output will be used to recharge the battery

Battery recharge time calculation

[B7] = [B6] * [B4] ENERGY PRODUCED

[B8] = ([B7] - [B2]) / [B2]

[B10] = [B9] * [B6]

[B11] = [B10] * [E7]

[B12] = [B7] / [B2]... ALR = energy produced / daily Ah

5 days autonomy selected.

[B14] = [A1] / [A2] * [B13] * 24H

[B17] = [B14] / ([B15] / [B16]) For autonomy Period.

[B19] = [B17] / (1 - [B18])

MODEL: 6x 12OPzV2000

Additional Design Assumptions

System Design Calculation

Daily load (W) * 24 (Hrs) / Nominal System Voltage

Tss4U

SOLAR POWER SYSTEMS

SOLAR SYSTEM SIZING FOR 1463Wc

Given Design Requirements (from Spec) Battery Performance Data

[B3] = [E16]

[B4] = [B3] * [A3] Module Current x array radiation of 5.37Kwh/m

2

[B5] = [B2] / [B4] Required daily load / one module output

Module Performance Data

System sizing 1287 Wc @24Vdc

Total Load Requirement [A1] 1,287.00 W Battery Type MODEL: 6x 12OPzV1500

System Voltage [A2] 24 V Float voltage [E1] 2.366 V

Array radiation @ 30 tilt [A3] 5.37 kWH/m2/day No cells in series [E2] 12 Based on Nominal of 2V per cell

Battery Temp Coeff [E3] -0.003 V/C/2V cell

Float Voltage @ 20C [E4] 28.39 V [E4] = [E1] * [E2]

Average Battery day time Temperature [E5] 23.8 C Day time average temp

Battery Float Voltage in December at above Temp [E6] 28.26 V [E6] = [E4] - ([E3] * [E2] * (20 - [E5])

Safety Factors to include (Spec) Load Equipment Voltage 24.00 V

Derating factors (ageing, dirt, dust and brid droppings) [A4] 20.0%

Above factors taken as per specifications. Type 195 W based on Tss4U / Gesolar GES-5M195

Required Array to Load Ratio in worst month as per specification [A5] 1.08 Rated Pmax [E7] 195 W

Isc [E8] 5.80 A @ 25C cell Temp 1000W/m2

Temp Coefficient of current [E9] 0.04 %/C

Temp Coefficient of voltage [E10] -0.32 %/C

NOCT [E11] 45.0 C @ 20C 800W/m2

Average Day Time Temp in Abu Dhabi (*1) [A6] 23.8 C Cell operating temp @ 23,8 C Ambient 48.8 C [E12] = [A6] + [E11] - 20

# Isc [E8] @48,8C cell temp 5.81 A [E13] = [E8] + (([E12] - 45) * [E9]*[E8]/100)

Cable Voltage drops (battery - array) [A7] 1.92 V # Normal Module Voltage during day time 30.655 V [E14] = [E6] + [A7] + [A8]

Charge controller Voltage drop [A8] 0.48 V %age Current reduction between Isc & I @ 30,6552 3.5% [E15] calculated from IV data Co-related

Module Current @ 031V 48,8C cell temp 5.606 A [E16] = [E13] * (1 - [E15]) @ 1000W/m2

Module rated current at peak Power voltage 5.420 A [E17] @ 25

o

C cell temperature Data Sheet

Continuous Load 1,287.00 W

Daily Load in AH on Battery [B1] 1287.00Ah

Required daily AH considering module derating factors (Daily Ah) 1544.40Ah [B2] = [B1]*(1 + [A4])

Module Current at operating V at 48,8oC cell temperature [B3] 5.606 A

Daily energy produced by each solar module 30.10 AH

No parallel modules required to support a 1544.4 AH Load 51.3

No parallel modules proposed [B6] 56

Daily energy produced by 56 parallel 195 modules [B7] 1,685.7 AH

Excess generation [B8] 9.1%

No of modules in series [B9] 1

Total No of modules proposed [B10] 56

Nominal Array Power [B11] 10,920 W

Achieved Array To Load Ratio (ALR) [B12] 1.091

Battery Autonomy Required (Days) [B13] 5

Capacity for autonomy period (LoadW/24V x 5 days x 24h) [B14] 6,435 AH

Battery Ageing Factor [B15] 0.80

TC=Battery Temperature Compensation Factor at 4.0

o

C [B16] 0.867

Adjusted Battery capacity for load (LxAFxTC) [B17] 9,278 AH

Minimum SOC (1-Maximum DoD) [B18] 20%

Final Capacity @C120 to 1.85V/cell [B19] 11597.5

Offered Battery Capacity @C120 to 1.85V/Cell [B20] 1967

No of parallel strings for 1x100% battery capacity [B21] 6

Total battery bank capacity [B22] 11802

Excess Available Capacity VS Calculated capacity [B23] 1.73%

Capacity to be recharged [B14] 6,435 Ah Consumed capacity during autonomy period

Excess Array output in worst month [B24] 141.29 Ah [B24] = [B7] - [B2] Difference between Array Output and Daily load

Battery Inefficiency Factor [B25] 1.10 For recharge calculation only

Recharge Time with load connected in worst month [B26] 50 Day [B26] = [B14] * [B25] / [B24]

Recharge Time without load [B27] 4.20 Day

Daily Ah hours consumption from battery [B28] 751 Ah [B28] = [A1] / [A2] * 14Hr 14 hours daily period when battery alone feeding the load

Daily Cycling [B29] 6.36% [B29] = [B28] / [B22] Note-2

Notes:

1] The Average temperature is from Dubai Met Office. Contact for details dubaimet@emirates.net.ae

2] 14 Hours of night time is considered as average.

[B3] = [E16]

[B4] = [B3] * [A3] Module Current x array radiation of 5.37Kwh/m

2

[B5] = [B2] / [B4] Required daily load / one module output

Module Performance Data

Additional Design Assumptions

System Design Calculation

Daily load (W) * 24 (Hrs) / Nominal System Voltage

Tss4U

SOLAR POWER SYSTEMS

SOLAR SYSTEM SIZING FOR 1287Wc

Given Design Requirements (from Spec) Battery Performance Data

[B7] = [B6] * [B4] ENERGY PRODUCED

[B8] = ([B7] - [B2]) / [B2]

[B10] = [B9] * [B6]

[B11] = [B10] * [E7]

[B12] = [B7] / [B2]... ALR = energy produced / daily Ah

5 days autonomy selected.

[B14] = [A1] / [A2] * [B13] * 24H

[B17] = [B14] / ([B15] / [B16]) For autonomy Period.

[B19] = [B17] / (1 - [B18])

MODEL: 6x 12OPzV1500

[B22] = [B20] * [B21]

[B23] = 1 - [B19]/[B22]

[B27] = [B14] * [B25] / [B7] Due to NO load connected all array output will be used to recharge the battery

Battery recharge time calculation

Scope of supply

The scope of supply comprises of the following hardware:

2 pcs. Solar Power System for 661 Wc @ 24Vdc

2 pcs. Solar Power System for 1463 Wc @ 24Vdc

2 pcs. Solar Power System for 1287 Wc @ 24Vdc

The Solar Power Systems are supplied in a tailor made kit for easy transportation and installation. All materials

required to assemble the complete system are included in the package.

Each solar system comprises of the following main components:

Solar array

Each solar array comprises:

Solar modules of 195 Wp / 24 V, each with reinforced anodized aluminium frame (IEC 61215 certified)

Installation materials to fix the solar modules on the support structures are included

Supporting structures in hot-dipped galvanised carbon steel + 140m powder coating to withstand wind

gusts up to 216 km/h at the 30 tilt angle. This support structure is of a unique design offering considerable

installation cost reductions. The support structure is provided with bird spikes for the top rows.

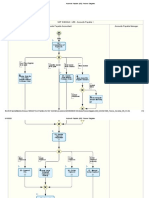

Central charge controller

The heart of the solar system is the charge control unit which carefully balances the energy generated by the solar

modules to the required load and the stored energy in the batteries. The charge controller is based upon the proven

concept of the Tss4U proprietary -Ahr series of controllers.

A charge control unit features all controls. For larger systems the charge control unit is expanded with extension units.

A unique feature of the -Ahr series controller is its three separate solar module inputs that results in a precise

charging regime for the battery and reduces the number of sub-array junction boxes.

The low PWM (Pulse-Width Modulation) rate guarantees no interference in telecommunication appliances.

The -Ahr series of controllers is suitable to assemble any tailor made charge controller system for single, dual or even

triple concept systems. It offers the following features:

Advanced temperature compensated boost- and float battery charge process

Charge controller and extension units for larger solar arrays

Built in overcharge and deep discharge protection batteries

Terminals for voltage / temperature sensor

Reverse polarity protection on solar array module inputs, on battery connection and volt/temp. sensor

Protection against reverse current during night

Low voltage and general alarm

Load output with SOC (State of Charge) dependent switch off limit (excessive discharge protection)

Load current compensated switch-off limit

Over-voltage protection for load due to system high voltage

Over-load protection for load output

Test switch for system diagnostic

Separated built in control signals for powering alarm switching relays

Alarm relays

Nanodac Metering unit / Datalogger

All assembled in a GRP enclosure

Typical block diagram -Ahr Charge Control Unit (with options)

Distribution board

The outputs of the Central Charge Controller is fed to the Distribution Board. The Distribution Board is incorporated in

the control box and comprises of:

1 pc. Dual diode

1 pc. Voltage limiter +/- 10%

1 pc. DC/DC converter 24V+/- 1%

6 pcs. / 7 pcs. Output MCB up to 32A

1 pc. Earth leakage monitor

Battery banks

The offered batteries are of the VRLA (Valve Regulated Lead Acid) type.

The temperature of the batteries is carefully monitored by the Tss4U -Ahr charge controller utilising a

volt/temperature sensor directly fixed on the battery terminals to optimize the charging process.

These batteries are of the make Enersys OPzV.

The offered batteries have an extremely low self-discharge and high charging efficiency.

These batteries in combination with the Tss4U -Ahr charge controller offer an economical price performance ratio in

terms of life time expectancy. Battery life time expectancy when used at 20 degrees C (float charge) is 20 years as

confirmed by the supplier.

This battery offers minimum 1200 cycles according IEC-60896-2

This battery is of a type designed for and proven in solar power applications.

Battery box

The battery box is made of epoxy coated SS316, IP43.

Battery MCCB

The battery MCCB is required to protect the batteries in case of short circuit and to provide a voltage free

environment for installation and maintenance of the solar system. The battery MCCB is located in the charge control

box.

Cables

A complete set of cables is provided for installation of the solar system. This set comprises of the following sub-sets:

From solar module to solar module (max. length 1 m)

From solar module to control box (max. length 12m)

From control box to distribution board (max. length 10m)

From charge controller to battery (power cables) (max. length 5 m)

From charge controller to battery (voltage to Temp. sensor, max. length 5 m)

All cables are suitable for outdoor installation UV protected / Rubber sheathed (H07RNF / Energyflex type)

Cable glands are of the polyamide type, IP66.

Please note that the cables from the distribution board to the load as well as earthing cables are excluded from the

scope of supply.

Services

Installation supervision, training for operators and commissioning services can be provided to make sure that the solar

system is handed over to the end-user in the most optimal way. These services are as follows:

1 Day explanation of solar system assembly and installation

1 Day in the field to verify that every component is properly installed

1 Day final commissioning (depending upon location and travel to the site and required system testing)

We require one week notice to plan the service activities.

Seaworthy packing (bulk packed)

As an option the solar power system material can be seaworthy packed. According the Tss4U standards the major

material will be packed as follows:

Solar modules packed in carton boxes and placed on pallets with plastic shrinking

Battery cells are placed on pallets with plastic shrinking

Cabling on drums

Support structures, battery boxes and control boxes in wooden crates

Exclusions from the scope

The following are excluded from our scope of supply:

Cables and cable glands to the load

Cable markers and ty-raps for outside cabling

Anchor bolts for the support structures

Civil work (concrete foundations)

Earthing cable from earth bolts to ground bed

Examples of central charge control

Example of a Central Charge Controller in a sheet steel enclosure

Example of a Central Charge Controller in a GRP enclosure

Potrebbero piacerti anche

- Earthing Grid Calculations For Khondbond R3 For ApprovalDocumento27 pagineEarthing Grid Calculations For Khondbond R3 For ApprovalDipankar ChatterjeeNessuna valutazione finora

- Short Circuit CalculationDocumento18 pagineShort Circuit Calculationurkirannanda0% (1)

- 1.5KW SystemDocumento5 pagine1.5KW SystemAmna JamshaidNessuna valutazione finora

- Electrical Installation DesignDocumento27 pagineElectrical Installation DesignLasantha AbeykoonNessuna valutazione finora

- Peter Manning Electronic Music and CompuDocumento570 paginePeter Manning Electronic Music and CompuEmptyRoom Alejandro Bello100% (1)

- Solar SizingDocumento4 pagineSolar SizingKishoreNessuna valutazione finora

- Project Job Ref. Part of Structure Date of Issue Sheet No. Rev. No. 0Documento3 pagineProject Job Ref. Part of Structure Date of Issue Sheet No. Rev. No. 0meeng2014Nessuna valutazione finora

- 25+ Tricky SAP BODS Interview Questions 3Documento1 pagina25+ Tricky SAP BODS Interview Questions 3pattabhikvNessuna valutazione finora

- Load Schedule Calculation SheetDocumento6 pagineLoad Schedule Calculation SheetlakshminarayananNessuna valutazione finora

- Solar PV SizingDocumento18 pagineSolar PV SizingMuhammad Jawad AfzalNessuna valutazione finora

- AA-036322-001 Anchor Bolt Details PDFDocumento1 paginaAA-036322-001 Anchor Bolt Details PDFMallela Sampath Kumar100% (1)

- IEC 60439-1 What About Type Tested AssembliesDocumento29 pagineIEC 60439-1 What About Type Tested AssembliesHaldirLeaoNessuna valutazione finora

- Accounts Payable (J60) - Process DiagramsDocumento16 pagineAccounts Payable (J60) - Process Diagramsgobasha100% (1)

- DC System DesignDocumento6 pagineDC System DesignTukaram Pawar100% (1)

- Solar PV System SizingDocumento11 pagineSolar PV System SizingSachin V Tiwade100% (2)

- Industrial Process Plant Construction Estimating and Man-Hour AnalysisDa EverandIndustrial Process Plant Construction Estimating and Man-Hour AnalysisValutazione: 5 su 5 stelle5/5 (1)

- Solar Panel Design Calculations SampleDocumento2 pagineSolar Panel Design Calculations SampleVincent RuizNessuna valutazione finora

- Earth MatDocumento6 pagineEarth MatSmitha PatelNessuna valutazione finora

- 33 Short Circuit Current at Various Point of Distribution System 1.9.15Documento8 pagine33 Short Circuit Current at Various Point of Distribution System 1.9.15Rajendra Prasad ShuklaNessuna valutazione finora

- Earthing CalculationsDocumento8 pagineEarthing CalculationsBalamurugan ArumugamNessuna valutazione finora

- Cable SizingDocumento339 pagineCable SizingSalmanu AbduNessuna valutazione finora

- Solar Panel Design 22-8-12Documento9 pagineSolar Panel Design 22-8-12544057Nessuna valutazione finora

- Solar System SizingDocumento10 pagineSolar System SizingDoly DamanikNessuna valutazione finora

- Module - 4 Elecritical SafetyDocumento35 pagineModule - 4 Elecritical Safetyaaron loboNessuna valutazione finora

- G + 5 (Calculation Details)Documento104 pagineG + 5 (Calculation Details)shashikantcivil025Nessuna valutazione finora

- The Pillar of Computation TheoryDocumento343 pagineThe Pillar of Computation TheoryAngelo MerlettiNessuna valutazione finora

- TUV Siemens Solar Exchange 05 19Documento39 pagineTUV Siemens Solar Exchange 05 19Thilina Rajapaksha100% (1)

- 2022 Steps of Calculation For Solar Power StationDocumento4 pagine2022 Steps of Calculation For Solar Power StationAhmed waleedNessuna valutazione finora

- NGR Technical InformationDocumento6 pagineNGR Technical InformationPrabakar PNessuna valutazione finora

- Bus Switching Configurations in Air Insulated Substations AISDocumento5 pagineBus Switching Configurations in Air Insulated Substations AISArnel Pascual LaquindanumNessuna valutazione finora

- Estimation For Roof Top 1Kw Solar Plant InstallationDocumento3 pagineEstimation For Roof Top 1Kw Solar Plant InstallationBADRI VENKATESHNessuna valutazione finora

- Solar Panel Sizing - How To Calculate Home Solar System SizeDocumento12 pagineSolar Panel Sizing - How To Calculate Home Solar System SizealiNessuna valutazione finora

- CsoundDocumento238 pagineCsoundorchestration100% (1)

- A684 Cable Sizing Calculations PDFDocumento1 paginaA684 Cable Sizing Calculations PDFamrit100% (1)

- Solar Generations Impact On Fault CurrentDocumento32 pagineSolar Generations Impact On Fault CurrentchintanpNessuna valutazione finora

- Swe-Spp-001-P-Dc-061 - DC String Cable Sizing - R3Documento9 pagineSwe-Spp-001-P-Dc-061 - DC String Cable Sizing - R3Vishnu Kumar VyasNessuna valutazione finora

- Transformer Sizing HandoutDocumento25 pagineTransformer Sizing HandoutShahina Parvin ShaikNessuna valutazione finora

- Oi Lgas Engineering TrainingDocumento236 pagineOi Lgas Engineering TrainingMallela Sampath Kumar100% (2)

- Design of Solar Panel / Battery Bank / InvertorDocumento9 pagineDesign of Solar Panel / Battery Bank / Invertornaveen_86Nessuna valutazione finora

- 50 MWTechnicalProposal-final2Documento31 pagine50 MWTechnicalProposal-final2Rahul SrivastavaNessuna valutazione finora

- Free License Keys of Kaspersky Internet Security 2017 Activation Code PDFDocumento20 pagineFree License Keys of Kaspersky Internet Security 2017 Activation Code PDFCaesar Catalin Caratasu0% (1)

- EF4e Int EndtestB AnswersheetDocumento2 pagineEF4e Int EndtestB AnswersheetB Mc0% (1)

- Short Circuit Force Calculation For 132 KV Substation at Noida-Sector 62Documento7 pagineShort Circuit Force Calculation For 132 KV Substation at Noida-Sector 62raghvendraNessuna valutazione finora

- Calculate Number of Plate / Pipe EarthingDocumento36 pagineCalculate Number of Plate / Pipe EarthingPhanhai KakaNessuna valutazione finora

- Solar DC Cable Calculation 4Sq MM DC Cable: Imax Isc No. of Parallel String 1.25, Where 1.25 Is Design MargineDocumento7 pagineSolar DC Cable Calculation 4Sq MM DC Cable: Imax Isc No. of Parallel String 1.25, Where 1.25 Is Design MargineRiasad AminNessuna valutazione finora

- Sample Short Circuit CalculationDocumento5 pagineSample Short Circuit CalculationSunil SinghNessuna valutazione finora

- 1B30 07Documento542 pagine1B30 07saNessuna valutazione finora

- NGR SizingDocumento14 pagineNGR SizingSibolis Naburju0% (1)

- Managing Liquid Transients and Vibration Within Pump Facilities (ASCE 2015)Documento8 pagineManaging Liquid Transients and Vibration Within Pump Facilities (ASCE 2015)Mallela Sampath KumarNessuna valutazione finora

- Checklist For Power Factor Correction EnglDocumento2 pagineChecklist For Power Factor Correction EnglBishoy MekhaelNessuna valutazione finora

- DPR 5MW Sahil Energy Kadiri 1Documento58 pagineDPR 5MW Sahil Energy Kadiri 1Vamsi Krishna SivadiNessuna valutazione finora

- Tender 10 KW Rooftop SolarDocumento14 pagineTender 10 KW Rooftop Solarsrirajt4uNessuna valutazione finora

- Relay Setting Calculation NPC Yas152 Rev 1Documento18 pagineRelay Setting Calculation NPC Yas152 Rev 1মোঃ মহসিনNessuna valutazione finora

- Short Circuit Current Calculation (Base KVA Method)Documento4 pagineShort Circuit Current Calculation (Base KVA Method)Pramod B.WankhadeNessuna valutazione finora

- Ts131 Large Solar PV Above 200kw or Rotating Generating SystemsDocumento52 pagineTs131 Large Solar PV Above 200kw or Rotating Generating SystemsphilipnartNessuna valutazione finora

- Grounding & Lightning Protection SystemDocumento16 pagineGrounding & Lightning Protection Systemshahramkarimi76100% (2)

- Photovoltaic System DesignDocumento21 paginePhotovoltaic System DesignMuhammad Amusa100% (1)

- VAmp 265 PDFDocumento226 pagineVAmp 265 PDFdhinakaranNessuna valutazione finora

- 100 KWDocumento16 pagine100 KWRajaNessuna valutazione finora

- Backlog Including Delta Requirements and Gaps: PurposeDocumento30 pagineBacklog Including Delta Requirements and Gaps: PurposeCleberton AntunesNessuna valutazione finora

- Design of 12MW Power System Interconnecting Negros Siquijor and CebuDocumento26 pagineDesign of 12MW Power System Interconnecting Negros Siquijor and CebuRonn AlbertNessuna valutazione finora

- Building Lighting Protection CalculationDocumento5 pagineBuilding Lighting Protection CalculationsupermannonNessuna valutazione finora

- Surge Protective Devices-Rev01Documento15 pagineSurge Protective Devices-Rev01Mohamed HamedNessuna valutazione finora

- CodesDocumento3 pagineCodesSandra Moses100% (2)

- Voltage Dip Calculation For DG SizingDocumento1 paginaVoltage Dip Calculation For DG SizingshivaramNessuna valutazione finora

- Standalone PV Sizing GuideDocumento13 pagineStandalone PV Sizing Guideأمير معروفNessuna valutazione finora

- Geng5506 Am 2Documento2 pagineGeng5506 Am 2Law AnsonNessuna valutazione finora

- A Project On Solar Home System: Submitted By: Md. Masudur RahmanDocumento13 pagineA Project On Solar Home System: Submitted By: Md. Masudur RahmanGS ShawonNessuna valutazione finora

- Load List: Ultimate Average Dry Weather Flow (ADWF)Documento1 paginaLoad List: Ultimate Average Dry Weather Flow (ADWF)Rohit BaliNessuna valutazione finora

- Report - 2022 12 20Documento24 pagineReport - 2022 12 20imadsedkaNessuna valutazione finora

- Designing A Temperature Based Heating SystemDocumento9 pagineDesigning A Temperature Based Heating SystemAmarnath M DamodaranNessuna valutazione finora

- Jntuportal inDocumento8 pagineJntuportal insaikiran1074Nessuna valutazione finora

- Material List - Fabrication: - / - A1ZA-1 2 PMDocumento2 pagineMaterial List - Fabrication: - / - A1ZA-1 2 PMMallela Sampath KumarNessuna valutazione finora

- Autopipe: Connect V11.1Documento29 pagineAutopipe: Connect V11.1Mallela Sampath KumarNessuna valutazione finora

- Structural Engineering ScopeDocumento5 pagineStructural Engineering ScopeMallela Sampath KumarNessuna valutazione finora

- ANNA W01 M00 GC 0600 12 General ArrangementDocumento1 paginaANNA W01 M00 GC 0600 12 General ArrangementMallela Sampath KumarNessuna valutazione finora

- Sys 07Documento1 paginaSys 07Mallela Sampath KumarNessuna valutazione finora

- Asme b31.3 InterpretationsDocumento18 pagineAsme b31.3 InterpretationsMallela Sampath KumarNessuna valutazione finora

- Ceasar2pipingsoftwaretutorialpdf PDFDocumento3 pagineCeasar2pipingsoftwaretutorialpdf PDFMallela Sampath KumarNessuna valutazione finora

- Approach 2: Considered Both Positive and Negative Impulse LoadsDocumento2 pagineApproach 2: Considered Both Positive and Negative Impulse LoadsMallela Sampath KumarNessuna valutazione finora

- Elbow Center of GravityDocumento2 pagineElbow Center of GravityMallela Sampath KumarNessuna valutazione finora

- Ceasar2pipingsoftwaretutorialpdf PDFDocumento3 pagineCeasar2pipingsoftwaretutorialpdf PDFMallela Sampath KumarNessuna valutazione finora

- Preliminary G.A DrawingDocumento2 paginePreliminary G.A DrawingMallela Sampath KumarNessuna valutazione finora

- 29 TAC ExamplesDocumento8 pagine29 TAC ExamplessathiyanitNessuna valutazione finora

- Electromach EX Poster2016 PDFDocumento1 paginaElectromach EX Poster2016 PDFphilippe69Nessuna valutazione finora

- Numerical Solution For Nonlinear MHD Jeffery-Hamel Blood Flow Problem Through Neural Networks Optimized TechniquesDocumento11 pagineNumerical Solution For Nonlinear MHD Jeffery-Hamel Blood Flow Problem Through Neural Networks Optimized TechniquesMuhammad Imran KhanNessuna valutazione finora

- Tommy Molina ResumeDocumento2 pagineTommy Molina Resumeapi-266666163Nessuna valutazione finora

- International Molecular Pathology Catalog 2020Documento222 pagineInternational Molecular Pathology Catalog 2020nam7124119Nessuna valutazione finora

- Coupling and CohesionDocumento2 pagineCoupling and CohesionDebadatta GadanayakNessuna valutazione finora

- CaFSET (Antigua) Office Workbook - Sixth Edition - Programming Concepts Sample PagesDocumento4 pagineCaFSET (Antigua) Office Workbook - Sixth Edition - Programming Concepts Sample PagescafsetNessuna valutazione finora

- R-PLS Path Modeling ExampleDocumento8 pagineR-PLS Path Modeling ExamplemagargieNessuna valutazione finora

- Ultra-Low Standby Power SRAM With Adaptive Data-Retention-Voltage-Regulating SchemeDocumento4 pagineUltra-Low Standby Power SRAM With Adaptive Data-Retention-Voltage-Regulating SchemeTasmiyaNessuna valutazione finora

- bc817, bc818 FairchildDocumento6 paginebc817, bc818 FairchildCarlos EspinozaNessuna valutazione finora

- Vandana New ResumeDocumento1 paginaVandana New ResumeVandu KNessuna valutazione finora

- Chapter 4 - Introduction To WindowsDocumento8 pagineChapter 4 - Introduction To WindowsKelvin mwaiNessuna valutazione finora

- Axioms Activity (Games) PDFDocumento3 pagineAxioms Activity (Games) PDFKristopher TreyNessuna valutazione finora

- Mygps: A Diy Project - Portable and Astronomy Gps Based On Arduino NanoDocumento9 pagineMygps: A Diy Project - Portable and Astronomy Gps Based On Arduino NanoadiasmesquitaNessuna valutazione finora

- LM78S40 Switching Voltage Regulator Applications: National Semiconductor Application Note 711 March 2000Documento17 pagineLM78S40 Switching Voltage Regulator Applications: National Semiconductor Application Note 711 March 2000Pravin MevadaNessuna valutazione finora

- Harshitha C P ResumeDocumento3 pagineHarshitha C P ResumeHarshitha C PNessuna valutazione finora

- Scrum: Question & AnswersDocumento7 pagineScrum: Question & AnswersSuraj ShresthaNessuna valutazione finora

- Strategic Renewal of OrganizationsDocumento13 pagineStrategic Renewal of Organizationsv_rohatgiNessuna valutazione finora

- Samsung Monte CodesDocumento2 pagineSamsung Monte CodesideaamulNessuna valutazione finora

- 174872-Report On Voice Enabled Enterprise ChatbotDocumento61 pagine174872-Report On Voice Enabled Enterprise ChatbotBalaji GrandhiNessuna valutazione finora

- A Business Case For SAP GIS IntegrationDocumento7 pagineA Business Case For SAP GIS IntegrationCharles AshmanNessuna valutazione finora