Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Biomass Gasifiers For Sustainable Energy

Caricato da

rvnesariTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Biomass Gasifiers For Sustainable Energy

Caricato da

rvnesariCopyright:

Formati disponibili

1

Biomass-based Gasifier for Sustainable Rural Energy in India

Pierre Jaboyedoff

1

, Ulrik Birk Henriksen

2

, Jesper Ahrenfedt

3,

Sunil Dhingra

4

, Mohit Pushp

5

1

Sorane SA, Rationalisation Energtique, Ecublens, Switzerland

2

Technical University of Denmark (DTU), Risoe National Laboratory for Sustainable Energy, Denmark

3

Technical University of Denmark (DTU), Risoe National Laboratory for Sustainable Energy, Denmark

4

The Energy and Resource Institute, New Delhi, India

5

The Energy and Resource Institute, New Delhi, India

Presenting authors email address: pierre.jaboyedoff@sorane.ch

Abstract Record Number: 315

Presentation Theme (Theme 1, Theme 2, Theme 3): Theme 1

Key Words: rural energy, off-grid electricity generation, biomass, gasification, India

Brief biography of presenting author (80 words):

Pierre Jaboyedoff is a senior engineer specialising in energy efficient buildings and solar energy applications with

over 30 years experience in the field. While representing the Swiss Federal Office for Energy, he participated in

many major Research and Development projects lead by the International Energy Agency. He has developed the

energy concept for low-energy buildings such as the Rolex Learning Centre or the Swiss National Office for

Statistics. He has been working in India on energy efficiency since the early 80s.

Abstract (max 320 words):

Half of Indias rural households have no access to electricity. In 2005, more than 96,000 villages were still un-

electrified, and just over 40% of the 138 million households used electricity for lighting. Rural electrification is a

key concern for Indias social and economic development. Besides, rural electrification in remote areas poses

considerable challenges in terms of technological applications, investment costs and paying-off potential, as the

connection to the grid is found to be complex and costly, while the loads required are rather limited. For such

areas, small-decentralised biomass gasification based power plants emerge as an attractive option for rural

electrification provided biomass is managed locally in a sustainable manner.

During the last 3 decades, small-scale power gasifiers have been tested in many regions of the world. More recent

developments have demonstrated the feasibility of 100% gas systems, but the technology has not yet reached a

commercial level. Meanwhile, DTU has developed an innovative two-stage biomass gasification process, which is

characterised by having pyrolysis and gasification in separate reactors with an intermediate tar cracking zone. This

allows for a fine control of the process temperatures resulting in extremely low tar concentrations in the raw and

produced gas.

Based on a broad partnership involving the Swiss Agency for Development and Cooperation (SDC), the Energy

and Resources Institute (TERI) in India, the Indian NGO Gram Vikar, the National Thermal Power Corporation

(NTPC), Sorane SA and the Technical University of Denmark (DTU), an initiative was launched to apply the

technology to India for rural off-grid power production. Small-scale applications will range between 10 to 50 kWe.

The technology developed will allow remote communities to operate the system with minimal scheduled

maintenance, while making use of local material and human resources.

This project has the potential to facilitate the introduction of sustainable and reliable biomass based power

generation in villages, which will allow for increased social and economic benefits for the remote rural population

of India.

Paper

Introduction and purpose

With almost half of its rural households having no access to electricity, rural electrification is a key concern for

India. In 2005, more than 96,000 villages were still un-electrified, and just over 40% of the 138 million households

used electricity for lighting. The economics of remote rural electrification based on grid-extension are generally

unfavorable, mainly because of the high costs incurred by grid extension, the important grid losses in such remote

2

areas, as well as the small loads required and the low tariffs applicable. Out of these un-electrified villages, the

Government of India has identified 25,000 villages as remote and difficult to access. For these un-electrifiable

villages which stand out of the scope of grid-connected electrification, decentralized power generation systems are

better suited. Electricity needs of these villages are generally in the range of 5 to 25 kW depending upon their size.

It has been proposed that these villages should be electrified through renewable energy sources (e.g. biomass,

small hydro, solar PV etc.). Among various renewable energy sources solar PV is technically mature but the initial

costs are very high. Small hydro systems are comparatively cheaper, but these are site specific and the power

generating capacity fluctuates seasonally. In this scenario, small-decentralised biomass gasification based power

plants emerge as an attractive option for rural electrification provided biomass could be managed locally in a

sustainable manner.

The figure above presents the concepts of livelihood for remote biomass-based electrified villages. This concept

was developed by Joe Madiath, executive director of the renowned Indian NGO Gram Vikas, located in Orissa.

At the time when this concept was developed, the technology for 100% biomass-based power gasification was still

quite new. Most of the existing systems had very complex gas cleaning systems. Most of the technology

developers focused on end-of-the-pipe gas cleaning treatment.

Meanwhile, the Technical University of Denmark (DTU), has developed an innovative two-stage gasification

process, which allows for biomass-based small-scale power generation.

Based on a broad partnership involving the Swiss Agency for Development and Cooperation (SDC), the Energy

and Resources Institute (TERI) in India, the Indian NGO Gram Vikar, the National Thermal Power Corporation

(NTPC), Sorane SA and the Technical University of Denmark (DTU), an initiative was launched to apply the

technology to India for rural off-grid power production. The main objective of the project funded by SDC is to

adapt the DTU technology for a small-scale 100% woodgas power gasifier, suitable for remote rural electrification

in India. Small-scale applications will range between 10 to 50 kWe. The technology developed will allow remote

communities to operate the system with minimal scheduled maintenance, while making use of local material and

human resources.

Figure 1: LIBERA framework diagram

(The first framework was developed by Joe Madiath and Pierre Jaboyedoff)

3

Design and Methods

During the last 3 decades, small-scale power gasifiers have been tested in many regions of the world. More recent

developments have demonstrated the feasibility of 100% gas systems, but the technology has not yet reached a

commercial level. Conventional systems consist of a gasifier, a gas cooling and cleaning system and an internal

combustion engine. Most of the development has been focusing on the gas cleaning to avoid high tar

concentrations.

Figure 2: Typical gasifier and gas cleaning arrangement in the early 2000' (Kishore 2006)

When installed in villages, most of these systems had very serious operational problems. Starting the engine was

very difficult, and tar condensation at various places of the cleaning system occurred very frequently. The

development of the technology was advanced and its needs well framed, but its actual implementation was very

problematic due to its technical complexity and difficult operation.

Sorane SA is a consulting engineering company created in 1977 in Lausanne, specialised in energy efficiency in

buildings as well as renewable energy applications. Sorane has worked on energy efficiency and renewable energy

in India since the 80s.

The Technical University of Denmark (DTU), is ranked as one of the foremost technical universities in Europe. It

continues to set new records in the number of publications, in the development of new partnerships with industry

and in its public sector consultancy assignments. For almost two centuries DTU has been dedicated to developing

and creating value using scientific research to benefit society.

The Energy and Resource Institute (TERI), is a renowned research organisation established in 1974 in view of

supporting sustainable use of resources. TERI is a non-governmental organisation, that carries out research and

consultancy on renewable energies and energy efficiency with a view of contributing to poverty alleviation and

sustainable development. In 1998, TERI created its own university.

The NGO Gram Vikas was established by student volunteers, who came to Orissa, as part of the Young Students'

Movement for Development (YSMD), Chennai, in the early 70s to help the victims of the cyclone. Gram Vikas

currently serves over 350000 people in villages spread over 24 districts in Orissa.

NTPC, the National Thermal Power Corporation is the largest power generating major in India, with an installed

capacity of 36,014 MW. It has also diversified into hydro power, coal mining, power equipment manufacturing, oil

& gas exploration, power trading & distribution. With an increasing presence in the power value chain, NTPC is

well on its way to becoming an Integrated Power Major. NTPC is a key partner of the Government of India in

implementation of the National Strategy for Renewable Energy Development in the country.

4

The Swiss Agency for Development and Cooperation (SDC) is Switzerlands international cooperation agency

within the Federal Department of Foreign Affairs (FDFA). The Agency engages in direct operations, supports

programmes of multilateral organisations, and helps to finance programmes run by Swiss and international relief

organizations in four operational areas. SDC has been active in India since 1963 with development cooperation

programmes and humanitarian aid interventions designed to improve the living conditions of the poor and

marginalised segments of the population and to contribute to sustainable development. Since 1992, as part of its

global environmental programme, SDC India has contributed to Indias efforts in dealing with global

environmental problems anchored in national concerns by implementing projects to i) facilitate technology

transfer, ii) train workers to maintain new technologies, iii) develop, demonstrate and disseminate energy efficient

and environmentally friendly technologies in the energy intensive small scale industries. Considering the fast

growing importance of India as a key player on the regional and international scene, Switzerland has engaged in a

new type of collaboration in areas of common interest. Today, Swiss Cooperation programmes are focused on

climate mitigation and adaptation and are managed by the recently created Climate Change Division (CCD) in the

Embassy of Switzerland to India.

Facing the challenge of developing an adapted technology for off-grid biomass-based rural electrification, Sorane

assisted TERI in identifying technological partners able to bring in technologies of gasification practically without

tar. After a comprehensive review of the sectors developments, Sorane SA established a contact with DTU. A

first mission was then organised to launch a collaboration between DTU, TERI with Sorane being the consultant

for system integration.

After analysing and recognising the problems of tar in the existing gasifiers in India, it was decided to have a first

field test with a charcoal-based gasifier. Charcoal as a fuel presents the advantage of containing very little tar, as it

is removed by pyrolysis during the process of charcoal preparation. A first cooperation agreement was established

between SDC, TERI and DTU. DTU assisted in the design of this charcoal system, following which the gasifier

was installed in a village near the head office of the NGO Gram Vikas in Orissa.

Figure 1: the 10 kWe charcoal gasifier installed at Kanheiput, Orissa (Kishore, 2006)

5

Figure 2: View of the filter before the engine after 200 hours of operation

The system was operated daily for more than 3000 hours with minimal level of maintenance. The technological

application and field experience demonstrated that it was possible to run small-scale power gasifiers, provided the

tar level in the gas remains very low.

Over the last 15 years, DTU has developed an innovative two-stage biomass gasification process, which has been

demonstrated on a pilot plant with fully automatic operation for more than 3000 hours. The two-stage process is

characterised by having pyrolysis and gasification in separate reactors with an intermediate tar cracking zone. This

allows for a fine control of the process temperatures resulting in extremely low tar concentrations in the raw and

produced gas. Measured performance levels are 20% to 30%, from biomass to electricity. The main aim of the

research lead by DTU was to develop a fully automatic and unmanned operation plant.

The main advantage of this technology is that the biomass is first heated up to about 600C, which provokes

pyrolysis reactions. After that, the pyrolysis gases and the biomass enter the reactor. This technology allows to

produce gas practically without any tar.

Figure 3: Schematic principle of the Viking Gasifier

6

Figure 4: A view of the Viking gasifier developed and tested by DTU

The Viking two-stage gasifier developed by the biomass gasification group of the Technical University of

Denmark (DTU), has been tested in automatic operation for over 3000 hours. The reliability and performance were

excellent. The gasifier efficiency was over 90%, the overall electrical efficiency at 25%, the tar level below 1

mg/Nm3.

The main advantage of this technology is the simplicity of the gas cleaning.

Applications for remote rural use in India would not require such sophisticated automatic control mechanisms,

because local employment generation is a priority in areas where poverty alleviation is a primary concern.

Sorane SA assisted TERI and DTU to get funding to make the technology transfer and its adaptation to Indian

conditions possible. After unsuccessful attempts with the World Bank, SDC eventually accepted to fund the TERI-

DTU partnership.

Within the current project framework, the conceptual design of the wood-based gasifiers and the system

configuration will be developed, following which a prototype will be created and then tested for optimisation. The

partnership with the National Thermal Power Corporation will help to formulate a long term strategy for

technology up-gradation and implementation of Renewable Energy and Distributed Generation.

Results

The prototype has been successfully developed and is now adapted for application in the framework of rural

electrification in India. The results achieved through this testing are summarized below:

The two stage biomass gasifier system, along with the cleaning and cooling system, has been

tested with engine on a 10 kWe load.

Cumulative operation: 195 h including 95 h of engine operation

High quality gas: Tar <25 mg/m3; CV > 4 MJ/kg with H

2

and CO content in the range of 22-

24% and 15-18 % respectively

Low specific fuel consumption: around 1 kg/kWh

Elimination of the LPG for preheating which is being carried out by thermal gasifiers for both

reactor and pyrolysis unit

Simple dry time cooling cleaning system developed

No waste water generation in cleaning and cooling system

Optimization of parasitic load to reduce them and improve the net output from the system

7

Experimentation on the existing system for further improvement with use of the waste heat

streams and trial of different feed stocks

Following the success of this first phase, the detailed design of the second generation (20 kWe) has been finalized

and the fabrication is now under progress. After testing and validation at TERI, it will be packaged and transferred

to NTPC for system fabrication and installation at their premise. NTCP will then test it under variable load

conditions, and produce and install 4 pilot units in villages.

After this phase, the system will be reengineered for a power of 40 kWe and will be disseminated in unlectrified

villages where biomass supply is secured and managed in a sustainable way. This technology will be part of Indian

NTPCs renewable energy generation strategy.

This project has the potential to facilitate the introduction of sustainable and reliable biomass based power

generation in villages. The two stage process developed by DTU and TERI jointly brings a much simpler and more

reliable technology with better performances than the conventional end-of-the-pipe treatment systems used

traditionally.

Thanks to the adaptation of this innovative technology, rural electrification of some of Indias villages will be

achieved in a sustainable way.

Conclusion

The SDC-funded biomass gasifier project is an example of technological applications that take into account social

and economic needs as well as environmental concerns. The technological development is directly geared at

providing energy, comfort and a better working environment to Indias remote rural population. As shown by the

LIBERA Diagram, the two stage biomass based gasification technology for rural electrification has the potential to

provide means for irrigation, enhancing food security, enabling domestic access to water and lighting as well as

opportunities for additional monetary resources.

Reference List

Henriksen, U and alt. (2006) The design, construction and operation of a 75 kW two-stage gasifier, Energy,

Volume 31, Issues 1011, August 2006, Pages 15421553

Kishore, VVN (2006) Biomass and gasification success stories and lessons learned, IEA Bioenergy Agreement,

Task 33, Fall 2006 meeting at GTI

Jaboyedoff, Pierre (2010) 100% Woodgas based 100% Woodgas based small scale power gasifier for added

income generation in biomass-rich non grid connected areas, Summary of activities in India between SDC,

TERI and DTU (internal report for SDC Head Offices, Bern)

Dhingra, Sunil (2012) Biomass gasification project at TERI, DSDS 2012 (Delhi Sustainable Development

Summit), Special event on Moving towards alternative energy for addressing rural energy needs

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Design Guidelines For Safety in Piping NetworkDocumento15 pagineDesign Guidelines For Safety in Piping NetworkrvnesariNessuna valutazione finora

- Role of Education in Energy ConservationDocumento4 pagineRole of Education in Energy ConservationrvnesariNessuna valutazione finora

- Role of Education in Energy ConservationDocumento4 pagineRole of Education in Energy ConservationrvnesariNessuna valutazione finora

- DO 178 B Brief NotesDocumento18 pagineDO 178 B Brief NotesMani Shankar PrasadNessuna valutazione finora

- Hand Book IlluminationDocumento151 pagineHand Book IlluminationrvnesariNessuna valutazione finora

- Engineering Design Guideline - HX Rev2Documento24 pagineEngineering Design Guideline - HX Rev2Ashfaq AnwerNessuna valutazione finora

- Mastering Microcontrollers Helped by ArduinoDocumento23 pagineMastering Microcontrollers Helped by ArduinoMeri Terihaj100% (2)

- CPS 800 12 900 10 Parts List 2012 02 ENG 2205 6006 51 PDFDocumento51 pagineCPS 800 12 900 10 Parts List 2012 02 ENG 2205 6006 51 PDFMar SolNessuna valutazione finora

- Biomass Energy Data BookDocumento254 pagineBiomass Energy Data BookrvnesariNessuna valutazione finora

- Tailless AircraftDocumento17 pagineTailless AircraftVikasVickyNessuna valutazione finora

- Best Practices Manual PIPINGDocumento40 pagineBest Practices Manual PIPINGrvnesariNessuna valutazione finora

- Glass GuideDocumento121 pagineGlass Guidervnesari100% (1)

- Ammonia Technology TodayDocumento22 pagineAmmonia Technology Todayrvnesari100% (3)

- Boiler Design and Operation PDFDocumento8 pagineBoiler Design and Operation PDFChungNguyenNessuna valutazione finora

- CHE 322 - Gaseous Fuel ProblemsDocumento26 pagineCHE 322 - Gaseous Fuel ProblemsDanice LunaNessuna valutazione finora

- 1 RCF Ammo V RevampDocumento7 pagine1 RCF Ammo V RevamprvnesariNessuna valutazione finora

- Revamping of Ammonia Plant - OptionsDocumento11 pagineRevamping of Ammonia Plant - OptionsrvnesariNessuna valutazione finora

- CDM Methodology Booklet - Nov. 12Documento264 pagineCDM Methodology Booklet - Nov. 12rvnesariNessuna valutazione finora

- Waste Heat Recovery Considering Environmental FactorsDocumento7 pagineWaste Heat Recovery Considering Environmental FactorsrvnesariNessuna valutazione finora

- Hazop Model RequirementsDocumento30 pagineHazop Model RequirementsrvnesariNessuna valutazione finora

- PAT Scheme in IndiaDocumento44 paginePAT Scheme in IndiarvnesariNessuna valutazione finora

- Name: Ramchandra V NesariDocumento10 pagineName: Ramchandra V NesarirvnesariNessuna valutazione finora

- RE Study ReportDocumento207 pagineRE Study ReportrvnesariNessuna valutazione finora

- R V Nesari (A)Documento12 pagineR V Nesari (A)rvnesariNessuna valutazione finora

- Energy in Rural IndiaDocumento36 pagineEnergy in Rural IndiarvnesariNessuna valutazione finora

- The Importance of Subscale Jet Engine TestingDocumento8 pagineThe Importance of Subscale Jet Engine TestingKKayNessuna valutazione finora

- Electrical SubstationsDocumento16 pagineElectrical SubstationsEngr Syed Numan ShahNessuna valutazione finora

- Ex Delta Ex Delta - Dia: OVAL CorporationDocumento8 pagineEx Delta Ex Delta - Dia: OVAL CorporationDaniela GuajardoNessuna valutazione finora

- Activation and Deactivation of CatalystsDocumento16 pagineActivation and Deactivation of Catalystsshan0214Nessuna valutazione finora

- Unit 16 AssignmentDocumento15 pagineUnit 16 AssignmentRavi Gajenthran100% (1)

- Quidway 20S5300 20series 20ethernet 20switches 20hardware 20Documento98 pagineQuidway 20S5300 20series 20ethernet 20switches 20hardware 20Hamza_yakan967Nessuna valutazione finora

- Desmophen 1200 - en - 00134597 17947398 20766463Documento3 pagineDesmophen 1200 - en - 00134597 17947398 20766463Sabri AeroChemNessuna valutazione finora

- Meitrack Gprs Protocol v1.6Documento45 pagineMeitrack Gprs Protocol v1.6monillo123Nessuna valutazione finora

- Synthetic Rubber Proofed/Coated Fuel Pump Diaphragm Fabric-Specification (Documento9 pagineSynthetic Rubber Proofed/Coated Fuel Pump Diaphragm Fabric-Specification (Ved PrakashNessuna valutazione finora

- Conjoint SpssDocumento28 pagineConjoint SpssstatsoumyaNessuna valutazione finora

- BMW X4 (2019-2022) Vs Audi Q5 Vs Land Rover Discovery Sport Vs Mercedes-Benz GLE - CarWaleDocumento1 paginaBMW X4 (2019-2022) Vs Audi Q5 Vs Land Rover Discovery Sport Vs Mercedes-Benz GLE - CarWaleSahil GoyalNessuna valutazione finora

- APP157 CoP For Site Supervision 2009 202109Documento92 pagineAPP157 CoP For Site Supervision 2009 202109Alex LeungNessuna valutazione finora

- Problem 1-4Documento6 pagineProblem 1-4Anonymous xIzzEifjPNessuna valutazione finora

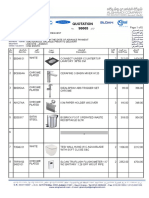

- Quotation 98665Documento5 pagineQuotation 98665Reda IsmailNessuna valutazione finora

- Health Safety StatementDocumento22 pagineHealth Safety StatementShafiqul IslamNessuna valutazione finora

- Raft TheoryDocumento37 pagineRaft Theorymuktha mukuNessuna valutazione finora

- Wrights Mushroom ColumnDocumento33 pagineWrights Mushroom ColumnKeithy GandhiNessuna valutazione finora

- Seismic Design & Installation Guide: Suspended Ceiling SystemDocumento28 pagineSeismic Design & Installation Guide: Suspended Ceiling SystemhersonNessuna valutazione finora

- NanoDocumento10 pagineNanoRavi TejaNessuna valutazione finora

- SunstarDocumento189 pagineSunstarSarvesh Chandra SaxenaNessuna valutazione finora

- Research Papers in Mechanical Engineering Free Download PDFDocumento4 pagineResearch Papers in Mechanical Engineering Free Download PDFtitamyg1p1j2Nessuna valutazione finora

- Review of C++ Programming: Sheng-Fang HuangDocumento49 pagineReview of C++ Programming: Sheng-Fang HuangIfat NixNessuna valutazione finora

- 1SDA066479R1 Rhe xt1 xt3 F P Stand ReturnedDocumento3 pagine1SDA066479R1 Rhe xt1 xt3 F P Stand ReturnedAndrés Muñoz PeraltaNessuna valutazione finora

- Metric DIN 434 Square Taper Washers: Visit Our For Product AvailabilityDocumento4 pagineMetric DIN 434 Square Taper Washers: Visit Our For Product AvailabilityRodrigoNessuna valutazione finora

- AVR Interrupt Programming in Assembly and CDocumento38 pagineAVR Interrupt Programming in Assembly and CK142526 AlishanNessuna valutazione finora