Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Method Statement Supercast SW30

Caricato da

Gry ArdiansyahTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Method Statement Supercast SW30

Caricato da

Gry ArdiansyahCopyright:

Formati disponibili

constructive solutions

PT.FOSROC

Indonesia

Jl.Akasia II Blok A8 No.1

Delta Silicon Industrial Park

Lippo Cikarang

Bekasi 17550

Indonesia

www.fosroc.com

telephone: fax: email:

+62 21 897 2103 +62 21 897 2107 indonesia@fosroc.co.id

+62 22 520 1308 +62 22 522 2713

+62 31 502 9142 +62 31 502 2711

SUPERCAST SW30

Method Statement

constructive solutions constructive solutions

SUPERCAST SW30 SERIES

HYDROPHILIC WATERSTOP

1 General

1.1 At all times during transport, storage and installation, before Supercast SW30

waterstop is fully encased in concrete on all sides, protect from contact with

water (particularly rain).

1.2 Supercast SW30 waterstops shall be located in the construction joint at the point

of 300 mm from concrete basement slab level.

1.3 Under no circumstances shall swellable waterstop be placed where it will have

less than 70 mm concrete cover in all directions after concrete is placed.

2 Concrete Surface Preparation

2.1 Ensure the joint faces to receive the waterstop are smooth, sound and free of

grease, dust, dirt, laitance or other loose material.

2.2 The standard of joint cleanliness is not as high as for sealant joints, but is

required to ensure the waterstop is able to be held on the joint surface by the

adhesive (Nitobond EC) without dislodgement during concrete placement.

3 Adhesives bedding compound

3.1 Mark out the line of the Supercast SW30 as shown in the drawings.

3.2 Apply a bead of adhesive of Nitobond EC to the joint face where Supercast

SW30 will be placed. The bead size shall be sufficient to ensure all roughness or

irregularities in the joint surface are filled and the full width of the Supercast SW

30 strip is in contact with the adhesive.

constructive solutions constructive solutions

4 Waterstop Placement

4.1 Press Supercast SW30 strip firmly into the adhesive to ensure full width contact

between strip and adhesive and between adhesive and joint face. Nail the strip,

if needed.

4.2 Where Supercast SW30 strips are joined to each other (end to end or end to

face), the joining faces shall have the adhesive applied between them,

completely covering all faces. At each such junction, the strip shall have a

mechanical fixing within 30 mm of the ends of back strip.

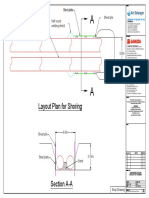

Detail Joint

4.1 Slab and slab

10-20cm

constructive solutions constructive solutions

4.2 Slab and wall

10-20cm

constructive solutions constructive solutions

4.1 Wall and Wall

4.1 Pipe and etc

Potrebbero piacerti anche

- Carpet Floorring-Method StatementDocumento6 pagineCarpet Floorring-Method StatementAli Bouchakor0% (1)

- Method Statement ConbextraGPDocumento7 pagineMethod Statement ConbextraGPsinambeladavidNessuna valutazione finora

- Method Statement Anti Termite r2 MRTDocumento10 pagineMethod Statement Anti Termite r2 MRTKeristiyantoNessuna valutazione finora

- Method Statement GeneralDocumento21 pagineMethod Statement GeneralSaibal Saha67% (3)

- GROUND Eng LowDocumento16 pagineGROUND Eng LowJohanNessuna valutazione finora

- Method StatementDocumento4 pagineMethod StatementDebraj RoyNessuna valutazione finora

- Internship CompanyDocumento19 pagineInternship CompanySourNessuna valutazione finora

- SGM - Struct SpecDocumento112 pagineSGM - Struct SpecabdouNessuna valutazione finora

- IR Sub Grade ConstructionDocumento2 pagineIR Sub Grade ConstructionWr Ar100% (2)

- Construction Method Statement For ApplicDocumento5 pagineConstruction Method Statement For ApplicKhasan MustofaNessuna valutazione finora

- Method Statement IFIDocumento17 pagineMethod Statement IFIHaitham M A Bechara0% (1)

- MS C 07 PaintingDocumento6 pagineMS C 07 PaintingYENDRU LALITHAKUMARINessuna valutazione finora

- Water Cascade MS - Pentens T-308+T-100Documento5 pagineWater Cascade MS - Pentens T-308+T-100Huzz EllieyzaNessuna valutazione finora

- Lumocons Company LimitedDocumento1 paginaLumocons Company LimitedDickson MatikuNessuna valutazione finora

- Lta-Sdre14-4-Gra 10Documento1 paginaLta-Sdre14-4-Gra 10Ong Wee KeongNessuna valutazione finora

- Potable Water Thrust Blocks Construction ChecklistDocumento1 paginaPotable Water Thrust Blocks Construction ChecklistJabinNessuna valutazione finora

- Ms For Indoor Ligthing InstallationDocumento6 pagineMs For Indoor Ligthing InstallationJoe_AverageNessuna valutazione finora

- Brushbond FlxiiiDocumento2 pagineBrushbond FlxiiiTori SmallNessuna valutazione finora

- Master List of Construction DrawingsDocumento94 pagineMaster List of Construction DrawingsSyerifaizal Hj. MustaphaNessuna valutazione finora

- EXW P006 0000 MQ SHC MS 00024 SubmittalDocumento47 pagineEXW P006 0000 MQ SHC MS 00024 SubmittalRaheelHashmiNessuna valutazione finora

- ShoringDocumento1 paginaShoringSyerifaizal Hj. MustaphaNessuna valutazione finora

- DTTN Dt1 PC Rfi ST 0100Documento1 paginaDTTN Dt1 PC Rfi ST 0100Tariq Ali SialNessuna valutazione finora

- 3B - Method Statement - StructuresDocumento123 pagine3B - Method Statement - Structuressreesailam100% (2)

- MS-Concourse Roof - Rev. DDocumento10 pagineMS-Concourse Roof - Rev. DJosephChongNessuna valutazione finora

- Section J: Structural Steel and Metal Works: @hakcipta JKR MalaysiaDocumento8 pagineSection J: Structural Steel and Metal Works: @hakcipta JKR MalaysiaZAHRUDIN ZAHIRUDDIN DAUD MoeNessuna valutazione finora

- TEC-031516 - MET-DoR-002 (Method Statement For Concrete Wall Construction Joint and Water Bar Repair)Documento8 pagineTEC-031516 - MET-DoR-002 (Method Statement For Concrete Wall Construction Joint and Water Bar Repair)Tomi Wiryandi SaputraNessuna valutazione finora

- Method Statement For Road Construction Over WetlandsDocumento4 pagineMethod Statement For Road Construction Over WetlandsYibeltal ChaneNessuna valutazione finora

- Azeeta Company ProfileDocumento36 pagineAzeeta Company ProfileNurul AkmaNessuna valutazione finora

- Method Statement For Road Surfacing in Existing IrrigigationDocumento14 pagineMethod Statement For Road Surfacing in Existing IrrigigationCamille TolentinoNessuna valutazione finora

- Section 034900 Glass Fiber Reinforced Concrete (EI 2017-04-02)Documento13 pagineSection 034900 Glass Fiber Reinforced Concrete (EI 2017-04-02)Nagarjuna MuthineniNessuna valutazione finora

- Celesta Prog Report No.22Documento74 pagineCelesta Prog Report No.22Ong George SammyNessuna valutazione finora

- Method of Statement For OPTIROC HGG 70SPDocumento1 paginaMethod of Statement For OPTIROC HGG 70SPDifa LiuNessuna valutazione finora

- Supercast PVC WaterstopDocumento4 pagineSupercast PVC WaterstopArun KumarNessuna valutazione finora

- Method Statement-EarthworkDocumento2 pagineMethod Statement-EarthworkChung May LynnNessuna valutazione finora

- Sika Top Seal 107 MSDocumento3 pagineSika Top Seal 107 MSTan TounNessuna valutazione finora

- O-n-M Manual - Flood Mitigation InfraDocumento42 pagineO-n-M Manual - Flood Mitigation InfraKuang Ngang ENessuna valutazione finora

- Method Statement Installation of Sheet PileDocumento9 pagineMethod Statement Installation of Sheet PileRonnie Jungco SarmientoNessuna valutazione finora

- T 305 CatalogueDocumento2 pagineT 305 CatalogueJohn KurongNessuna valutazione finora

- Ms Conc Block Masonry 01Documento3 pagineMs Conc Block Masonry 01Engr Muhammad SohailNessuna valutazione finora

- Weida Subsoil PipeDocumento4 pagineWeida Subsoil PipeOngNessuna valutazione finora

- Bca St11 Submission 28 JAN 2020 00: General Notes & Structure Drawing List (For Pontoon)Documento25 pagineBca St11 Submission 28 JAN 2020 00: General Notes & Structure Drawing List (For Pontoon)Gunawan IwanNessuna valutazione finora

- Midal Cables Method StatementDocumento13 pagineMidal Cables Method StatementRICHARD FUNUENessuna valutazione finora

- Method Statement Striking FormworkDocumento3 pagineMethod Statement Striking FormworkSurya HeriwijayaNessuna valutazione finora

- MS For Rectification Work of Concrete CrackDocumento18 pagineMS For Rectification Work of Concrete CrackFa Dyla100% (1)

- Method Statement Open TrenchDocumento4 pagineMethod Statement Open TrenchShafiq MustapaNessuna valutazione finora

- MS 1004 R0 Dewatering PDFDocumento6 pagineMS 1004 R0 Dewatering PDFDomie Neil Bucag SalasNessuna valutazione finora

- Mos PDFDocumento194 pagineMos PDFChoon Ewe LimNessuna valutazione finora

- Method Statement Log-CivilDocumento1 paginaMethod Statement Log-CivilDia AjjouriNessuna valutazione finora

- Method Statement For Laboratory Compressed Air and Vacuum SystemDocumento8 pagineMethod Statement For Laboratory Compressed Air and Vacuum SystemAhmed SherifNessuna valutazione finora

- CWYC Method Statement For Base & Sub-BaseDocumento9 pagineCWYC Method Statement For Base & Sub-Base施智捷100% (1)

- MS-01-Method Statement For Site EstablishmentDocumento26 pagineMS-01-Method Statement For Site EstablishmentAmila Priyadarshana DissanayakeNessuna valutazione finora

- Material Unit WeightDocumento2 pagineMaterial Unit WeightVishnu PriyaNessuna valutazione finora

- Precase Concrete Pipes (Mac, 16)Documento4 paginePrecase Concrete Pipes (Mac, 16)KpChuaNessuna valutazione finora

- TEC-036400 - MET-DoR-003a (Method Statement For Concrete Crack Repairing by Concresive 2200&concresive - 1Documento8 pagineTEC-036400 - MET-DoR-003a (Method Statement For Concrete Crack Repairing by Concresive 2200&concresive - 1Micheal B HaizenNessuna valutazione finora

- Sika WarrantyDocumento2 pagineSika WarrantyMatt CerosNessuna valutazione finora

- METHOD - STATEMENT - FOR D Wall and Guide WallDocumento6 pagineMETHOD - STATEMENT - FOR D Wall and Guide WalldhruvNessuna valutazione finora

- Check List For PVC Conduits Embedded in ConcreteDocumento2 pagineCheck List For PVC Conduits Embedded in ConcreteFiras DabboucyNessuna valutazione finora

- Conbextra EP300Documento3 pagineConbextra EP300Tori SmallNessuna valutazione finora

- Preliminary Method StatementDocumento36 paginePreliminary Method Statementalec63636100% (1)

- Fosroc Supercast SW30 TDSDocumento2 pagineFosroc Supercast SW30 TDSAnonymous dyoHdLP100% (1)

- Work Prog Wakiso PoultryDocumento1 paginaWork Prog Wakiso PoultryMwesigwa DaniNessuna valutazione finora

- Gillett SquareDocumento19 pagineGillett SquareAsha FarahNessuna valutazione finora

- SR Description Unit C1 C2 Total Remark Proj: RoomDocumento12 pagineSR Description Unit C1 C2 Total Remark Proj: RoomThi Ha SoeNessuna valutazione finora

- SheraDocumento5 pagineSheraPrast AjjaNessuna valutazione finora

- Punch List Checklist - SafetyCultureDocumento6 paginePunch List Checklist - SafetyCultureMikael Marlthel BenedictoNessuna valutazione finora

- Belfast Interfaces - Security Barriers and Defensive Use of SpaceDocumento132 pagineBelfast Interfaces - Security Barriers and Defensive Use of SpaceInstitute for Conflict Research100% (1)

- Concrete Quantity Calculation: Project TitleDocumento2 pagineConcrete Quantity Calculation: Project TitleAlfie Angelo ReyesNessuna valutazione finora

- P.garcia CattleDocumento53 pagineP.garcia Cattlearkhie_abadNessuna valutazione finora

- Civil Engineering Building Project ReportDocumento203 pagineCivil Engineering Building Project ReportJessiSharma50% (6)

- 13 - INI Design Studio - Lotus VillaDocumento11 pagine13 - INI Design Studio - Lotus VillaSneha PatilNessuna valutazione finora

- Packing ListDocumento4 paginePacking ListMoath AlhajiriNessuna valutazione finora

- Loom Crafts Modular Homes & CottagesDocumento120 pagineLoom Crafts Modular Homes & Cottagespondy raajNessuna valutazione finora

- Oscar Niemeyer: History of Modern Architecture P.ShabithaDocumento34 pagineOscar Niemeyer: History of Modern Architecture P.ShabithaSergio DanushNessuna valutazione finora

- Figure X.y: Plan Layout of Conference Hall SlabDocumento6 pagineFigure X.y: Plan Layout of Conference Hall SlabephremNessuna valutazione finora

- Construction Contract To Monterey Peninsula Engineering 04-04-16Documento6 pagineConstruction Contract To Monterey Peninsula Engineering 04-04-16L. A. PatersonNessuna valutazione finora

- Technical Specification For Proposed OneDocumento5 pagineTechnical Specification For Proposed OneAngel JinHiroNessuna valutazione finora

- Korean Modern ArchitectureDocumento316 pagineKorean Modern ArchitectureValerie Ann OpinaNessuna valutazione finora

- Concrete Sleeper Retaining WallDocumento51 pagineConcrete Sleeper Retaining WallNazar BazaraaNessuna valutazione finora

- Architectural Services 17011aa059Documento10 pagineArchitectural Services 17011aa059harshinireddy mandadiNessuna valutazione finora

- Emmanuel O. Bobor CVDocumento4 pagineEmmanuel O. Bobor CVBobor Emmanuel OfovweNessuna valutazione finora

- Terminologies in Prestressed DesignDocumento4 pagineTerminologies in Prestressed DesignMegan FerrarinNessuna valutazione finora

- Final Draft - Ahtesham KhanDocumento40 pagineFinal Draft - Ahtesham KhanAhtesham KhanNessuna valutazione finora

- Quantity Take Off: Applied Science UniversityDocumento25 pagineQuantity Take Off: Applied Science UniversityMarlon Arvin Marmita83% (6)

- Tranquil E-BrochureDocumento21 pagineTranquil E-BrochureLAVANYA MURALINessuna valutazione finora

- 5.KE - 28th Street Apartments PDFDocumento1 pagina5.KE - 28th Street Apartments PDFMohammed WasimNessuna valutazione finora

- Case Study On London City Hall (By Sumaiya Hussien)Documento29 pagineCase Study On London City Hall (By Sumaiya Hussien)Sumaiya HussenNessuna valutazione finora

- HVAC Design and Drafting Per ASHRAE PDFDocumento8 pagineHVAC Design and Drafting Per ASHRAE PDFFrankNessuna valutazione finora

- Providence HouseDocumento19 pagineProvidence HouseChandra Irawan AlfiantoNessuna valutazione finora

- Kohinoor Square, Mumbai, IndiaDocumento21 pagineKohinoor Square, Mumbai, IndiaTahmina Sultana Brishty100% (1)

- Interior Oxford JournalDocumento18 pagineInterior Oxford Journalapi-3709098Nessuna valutazione finora